Device and method for reducing urea crystals of SCR system

A technology of SCR system and urea, which is applied to the electric control of exhaust device, muffler device, exhaust treatment device, etc., and can solve the problems such as the abnormal operation of the after-treatment system, the reduction of NOx conversion efficiency, and the increase of back pressure of the SCR system. , to reduce the probability of forming a liquid film, improve the conversion efficiency, and increase the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

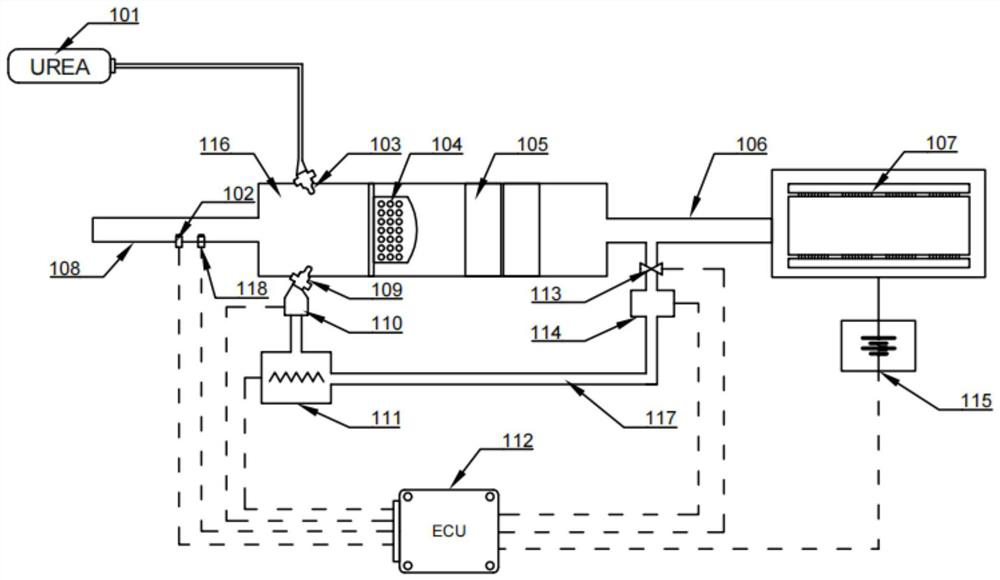

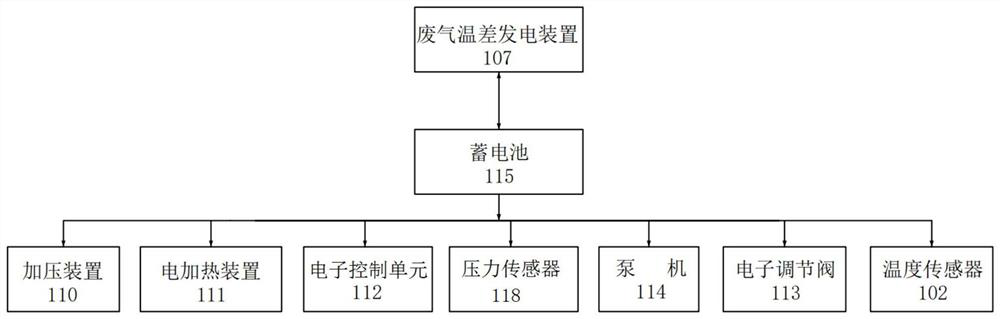

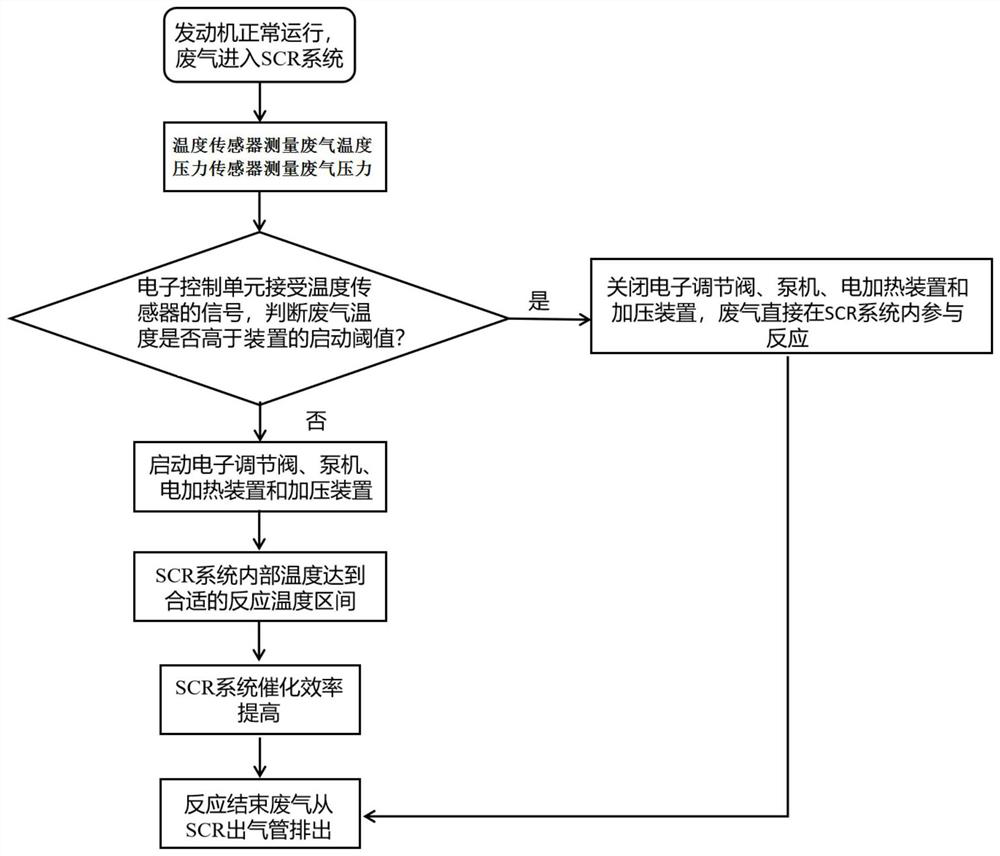

[0026] The present invention provides a device for reducing urea crystallization in an SCR system (device for short). The SCR system includes a urea tank 101, a urea nozzle 103, a mixer 104, a catalytic converter 105, an air outlet pipe 106, an air inlet pipe 108, and an air mixing chamber 116; between the air inlet pipe 108 and the air outlet pipe 106, a gas mixing chamber 116, a mixer 104 and a catalytic converter 105 are arranged in sequence according to the gas flow direction; the beginning of the air inlet pipe 108 is connected to the DPF system, and the exhaust gas processed by the DPF system enters the SCR system; the urea tank 101 is connected to the urea nozzle 103 through a pipeline; the end of the urea nozzle 103 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com