Aviation-used fuel cell system radiator and aviation-used fuel cell system

A fuel cell system and radiator technology, applied in fuel cells, secondary batteries, electrochemical generators, etc., can solve the problems of wasting metal materials, small ambient temperature difference, increasing the amount of heat sinks, etc., and increase air turbulence. , the effect of saving volume and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

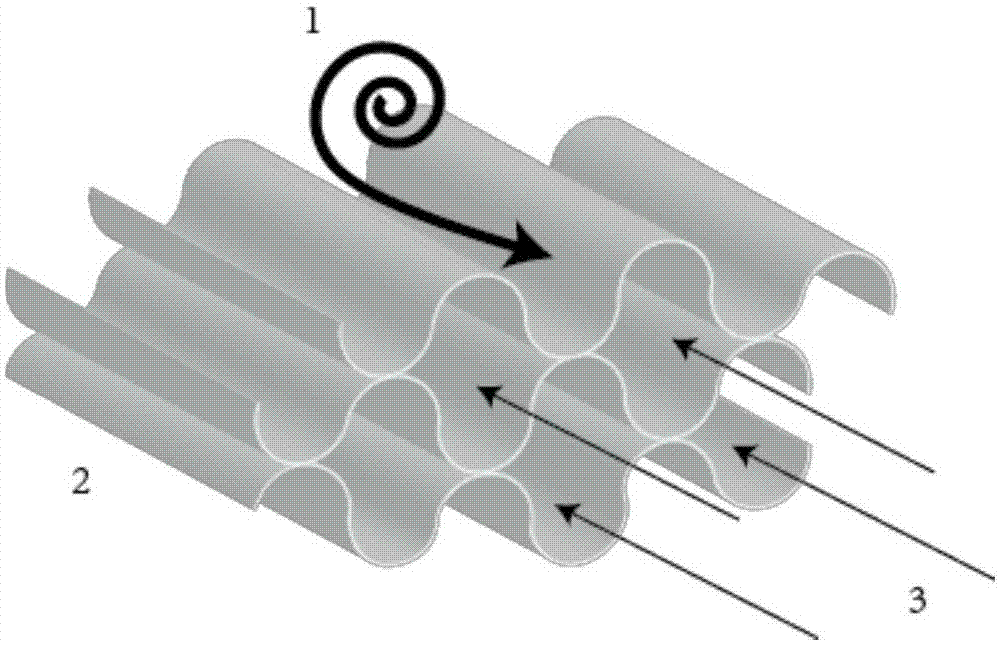

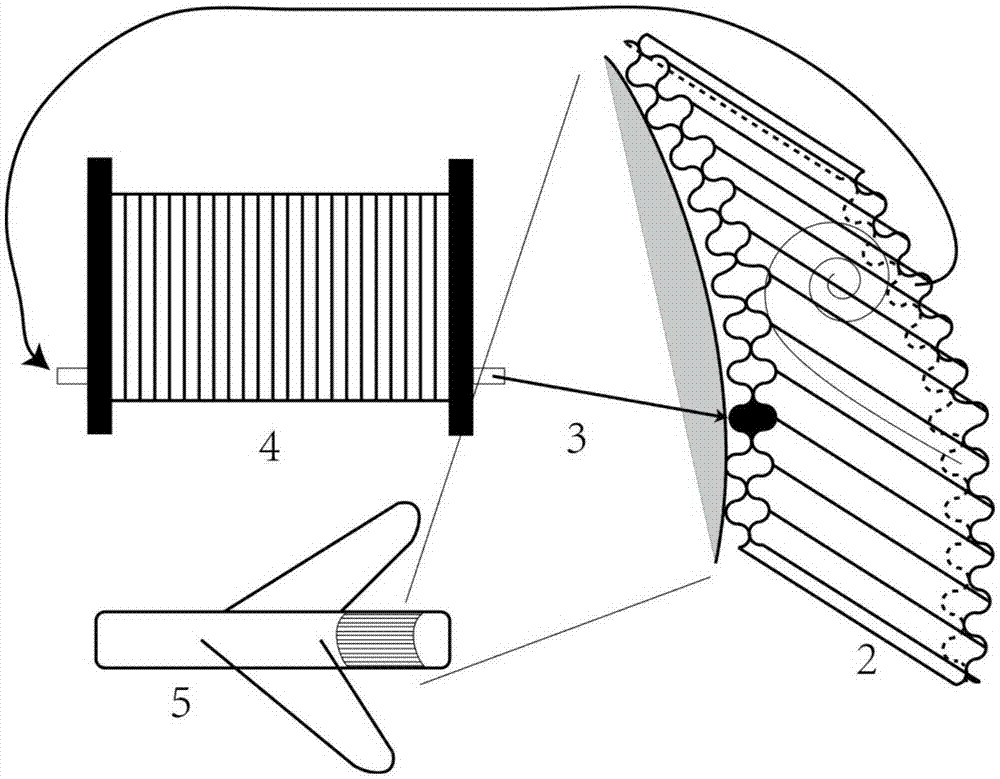

[0018] Such as figure 2 As shown, a radiator for a direct methanol fuel cell system for an aircraft includes a 3-layer laminated corrugated sheet and sealing heads arranged at both ends of the 3-layer laminated corrugated sheet; inlet and a cooling working medium outlet. The radiator head is made of stainless steel. The corrugated sheet is stamped from a stainless steel sheet with a thickness of 0.1 mm. The corrugated protrusions of the corrugated sheet are arc-shaped, and the diameter of the arc is 5 mm. The high-temperature saturated air from the cathode outlet of the direct methanol fuel cell stack passes through the inside of the corrugated radiator, and the excess heat of the fuel cell system is transferred to the outer wall of the corrugated radiator through phase change heat transfer and convective heat transfer on the inner wall of the corrugated radiator . The high-temperature fluid from the fuel cell flows back into the gas-liquid separator of the fuel cell syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com