Diffuser assembly for non-turbulent air flow

a diffuser and air flow technology, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of smoke, heat and fumes migrating, and the exhaust hood cannot capture all the elements,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

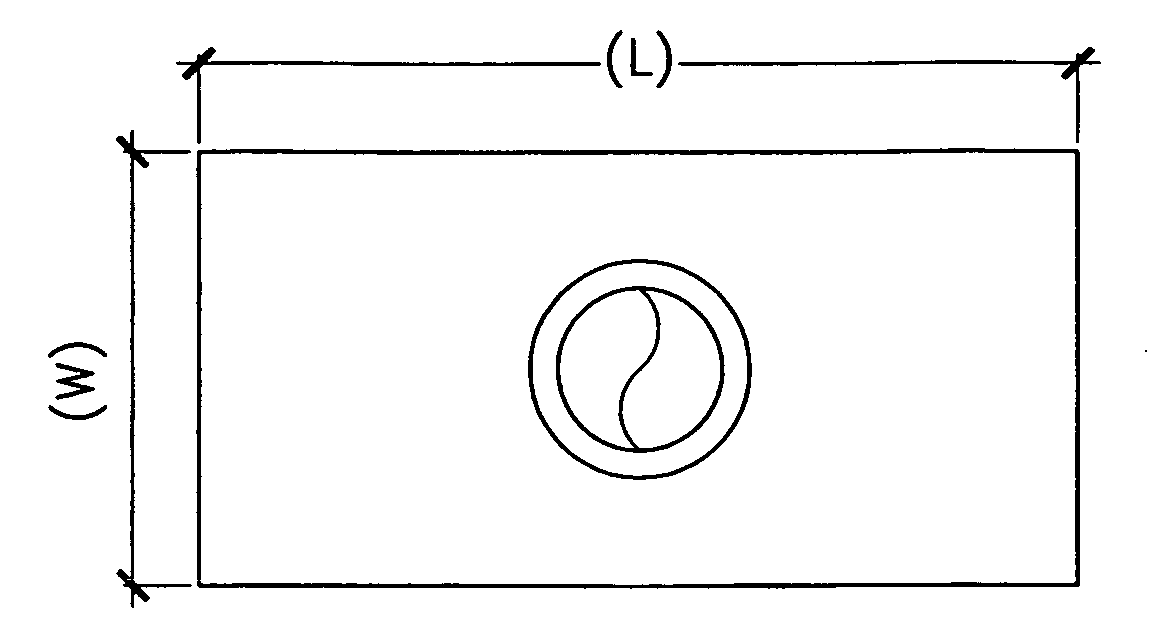

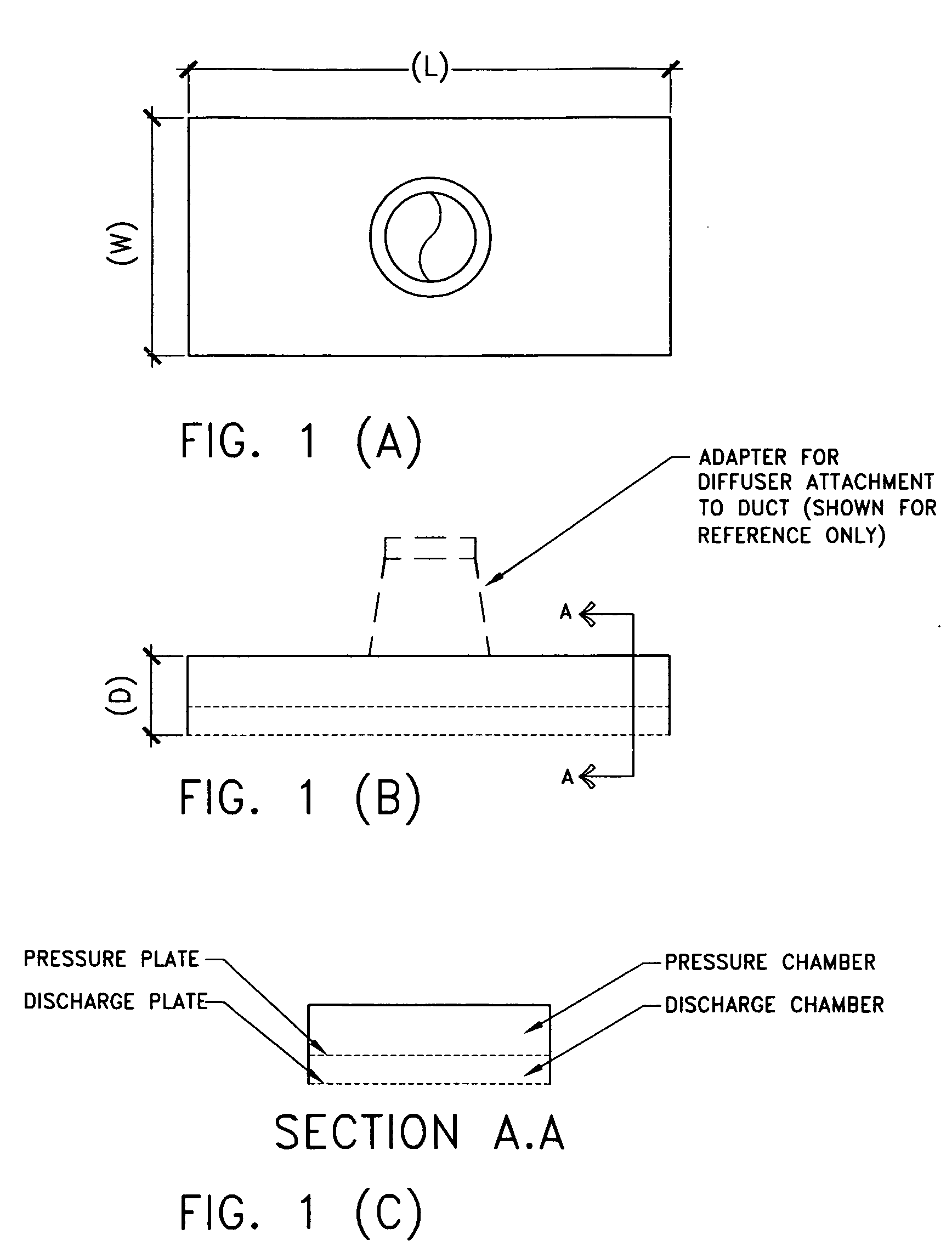

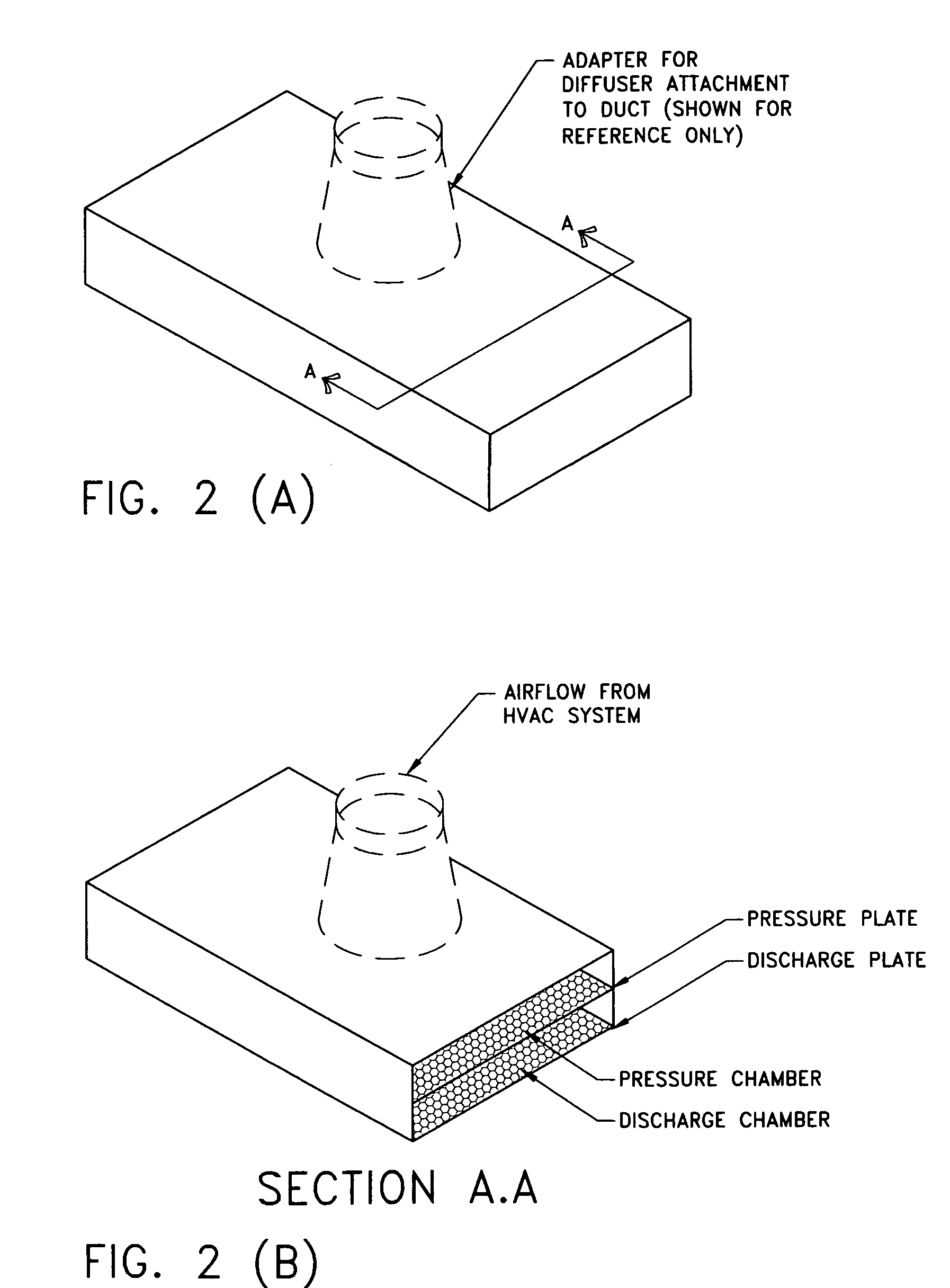

[0020]The diffuser assembly for non-turbulent air flow replaces currently used diffusers in applications where turbulence and uncontrolled dispersion of the air from a ventilation or A / C unit do not meet the requirements of the system. Representative examples include: the use of ventilation or A / C as make-up air for grease exhaust hoods for cooking over open flame or heated grill surfaces; ventilation or A / C make-up air for exhaust hoods in laboratories where the hoods are used to exhaust toxic or noxious fumes; for the ventilation or A / C provided make-up air for spray booths where the over-spray is filtered and exhausted outside the facility; and in meeting rooms, restaurants and auditoriums where less turbulence reduces unwanted drafts and air currents. With the make-up air being provided with current diffusers that employ louvers or deflector plates to direct air flow there is still turbulence that causes unwanted fumes from the heated grill or open flame cooking surfaces, or lab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com