PERC solar cell light-injection induced regeneration process and equipment

A technology of solar cells and regeneration equipment, applied in the field of solar cells, can solve the problems of low cell efficiency, minority carrier attenuation, slow rate of H passivation, etc., and achieve the effect of reducing maintenance times, reducing labor, and reducing recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

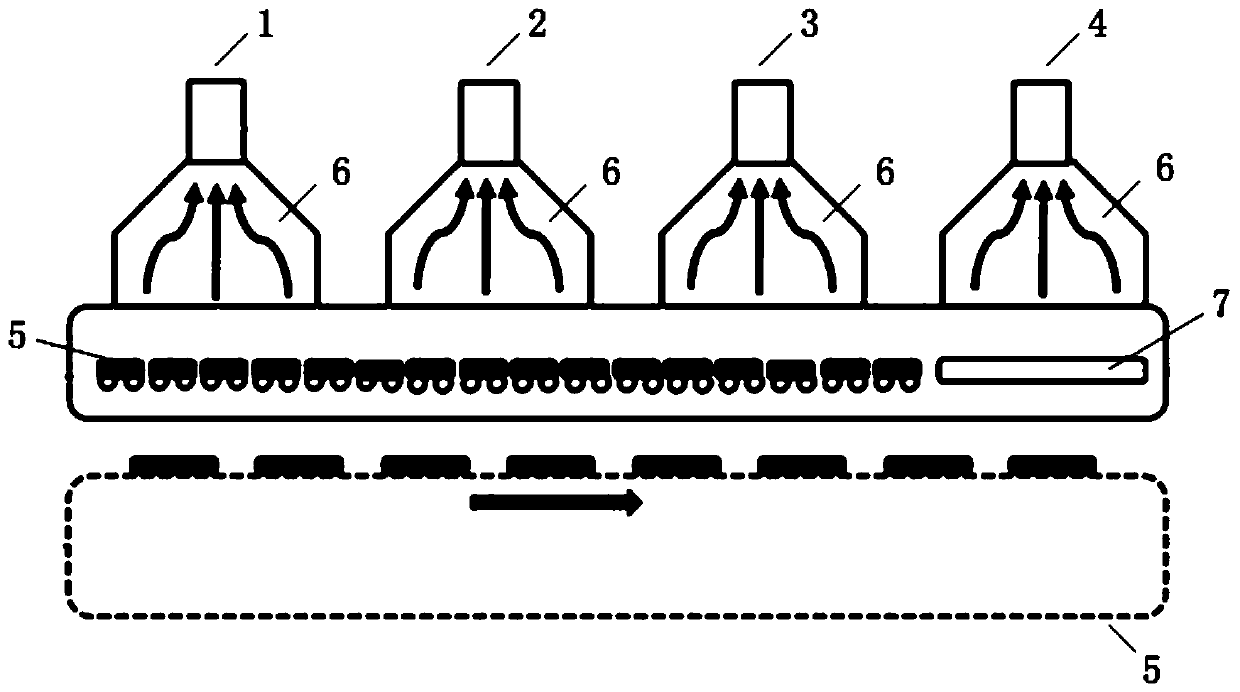

Method used

Image

Examples

Embodiment 1

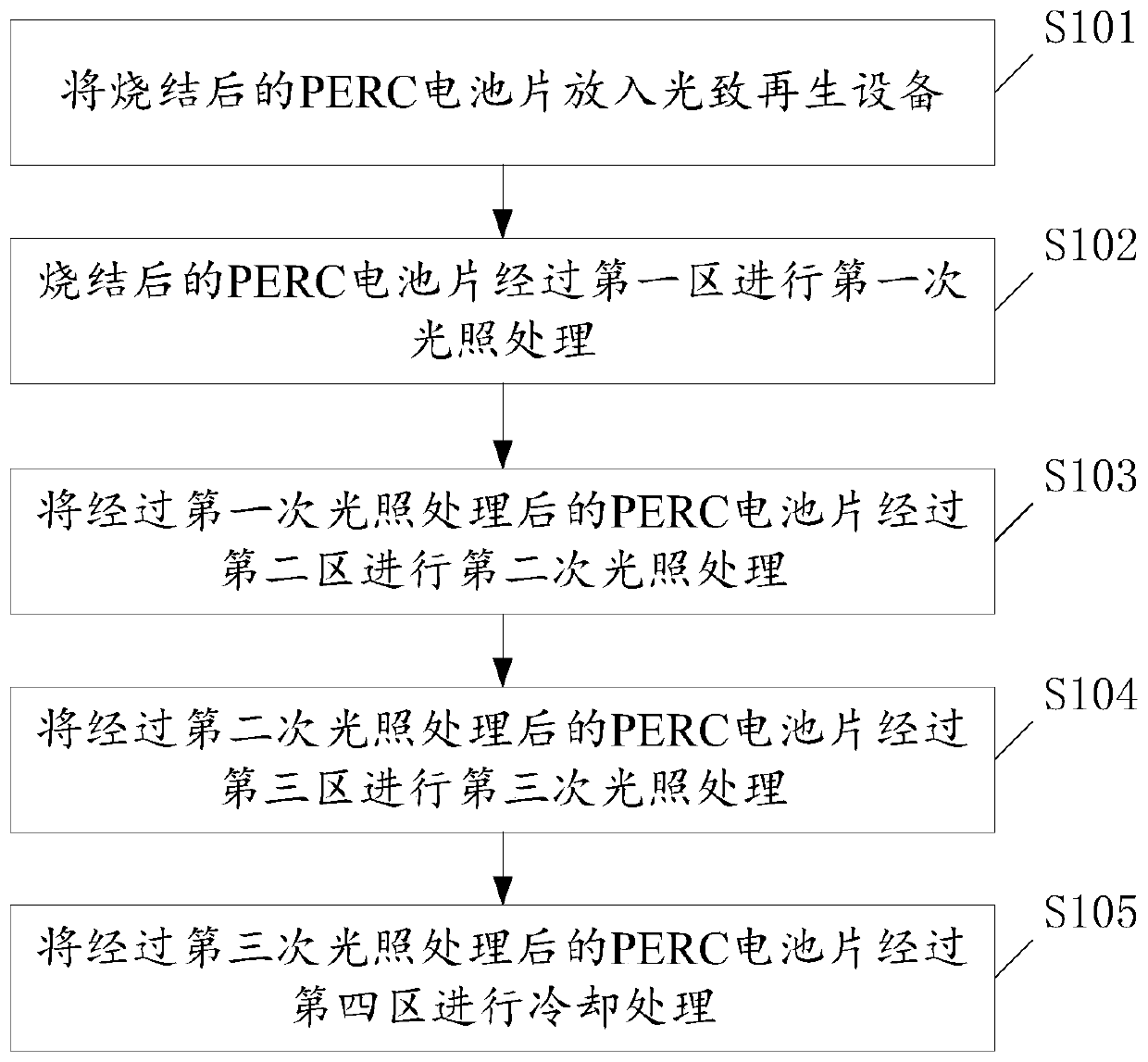

[0071] (1) Put the sintered PERC cell into the photoregeneration equipment, and move it through the conveyor belt at a speed of 6m / min;

[0072] (2) After the sintered PERC cell is subjected to the first light treatment in the first area, the power of the LED light group in the first area is 87%, the minimum light intensity of the LED light group is 100% power is not less than 18suns, and the temperature is controlled at 295 ℃;

[0073] (3) After the first light treatment, the PERC cells are subjected to the second light treatment in the second area. The power of the LED light group in the second area is 95%, and the minimum light intensity of the LED light group at 100% power is not less than 18suns, the temperature is controlled at 235°C;

[0074] (4) After the second light treatment, the PERC cells are subjected to the third light treatment in the third area. The power of the LED light group in the third area is 95%, and the minimum light intensity of the LED light group a...

Embodiment 2

[0078] (1) Put the sintered PERC cells into the photoregeneration equipment, and move at a speed of 5.8m / min through the conveyor belt;

[0079] (2) After the sintered PERC cells are subjected to the first light treatment in the first area, the power of the LED light group in the first area is 83%, the minimum light intensity of the LED light group is 100% power is not less than 18suns, and the temperature is controlled at 295 ℃;

[0080] (3) After the first light treatment, the PERC cells are subjected to the second light treatment in the second area. The power of the LED lamp group in the second area is 87%, and the minimum light intensity of the LED light group at 100% power is not less than 18suns, the temperature is controlled at 235°C;

[0081] (4) After the second light treatment, the PERC cells are subjected to the third light treatment in the third area. The power of the LED light group in the third area is 90%, and the minimum light intensity of the LED light group ...

Embodiment 3

[0085] (1) Put the sintered PERC cell into the photoregeneration equipment, and move it through the conveyor belt at a speed of 5.7m / min;

[0086] (2) After the sintered PERC cells are subjected to the first light treatment in the first area, the power of the LED light group in the first area is 85%, the minimum light intensity of the LED light group is 100% power is not less than 22suns, and the temperature is controlled at 290 ℃;

[0087] (3) After the first light treatment, the PERC cells are subjected to the second light treatment in the second area. The power of the LED light group in the second area is 90%, and the minimum light intensity of the LED light group is 100% power is not less than 22suns, the temperature is controlled at 238°C;

[0088] (4) After the second light treatment, the PERC cells are subjected to the third light treatment in the third area. The power of the LED lamp group in the third area is 91%, and the minimum light intensity of the LED light grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com