Efficient turn-back type SDS (sodium dodecyl sulfate) desulfurizing tower device

A desulfurization tower, turn-back type technology, applied in the field of high-efficiency turn-back SDS desulfurization tower device, SDS sodium-based dry desulfurization system, can solve the problem of difficult matching of dust removal system connection mode, insufficient mixing of desulfurizer and flue gas, desulfurization tower system Difficult to deal with problems such as dust accumulation, to achieve the effect of prolonging the desulfurization reaction time, improving the desulfurization reaction efficiency, and achieving independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

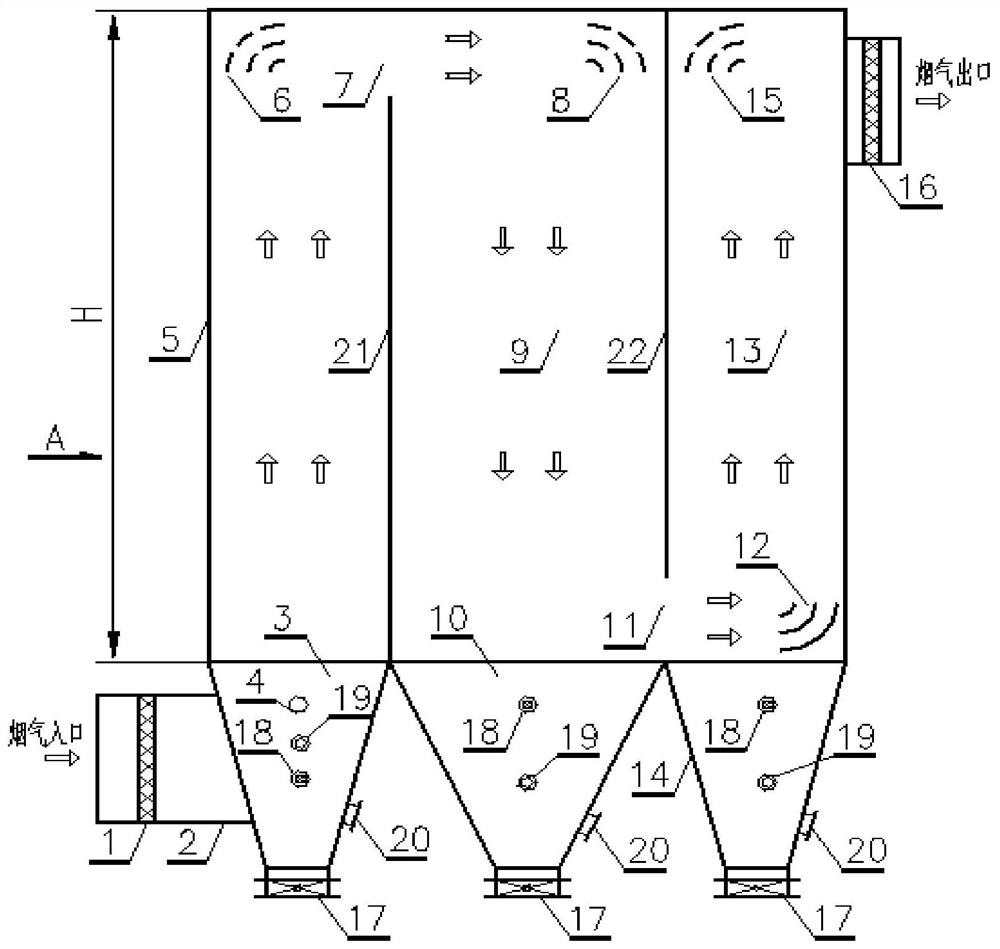

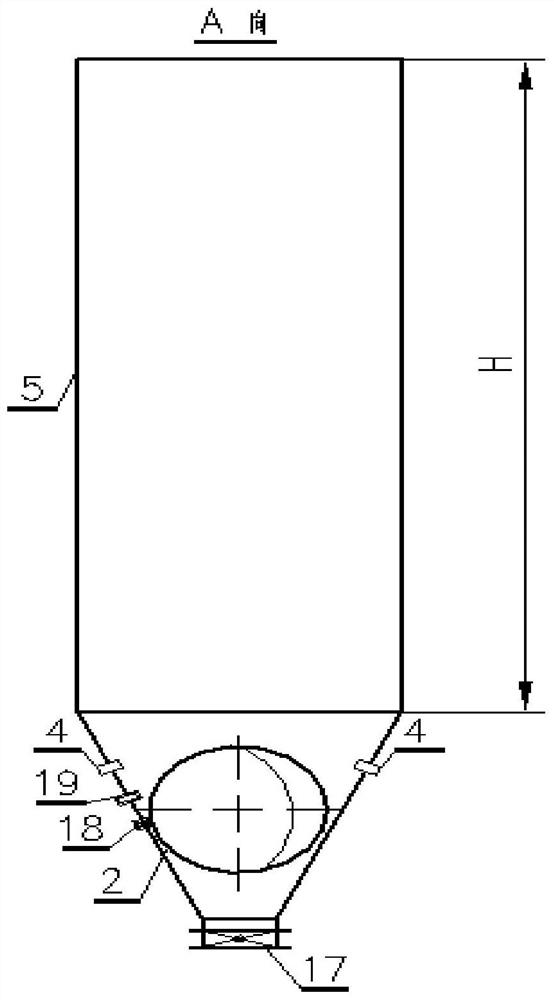

[0034] The present invention includes inlet compensator 1, inlet flue 2, first ascending bin ash hopper 3, injection hole 4, first ascending bin 5, deflector 6, Unicom opening 7, deflector 8, descending bin 9 , ash hopper 10 for lowering bin, Unicom opening 11, deflector 12, second ascending bin 13, second ascending bin ash hopper 14, deflector 15, outlet compensator 16, ash unloading valve 17, level gauge 18, Rapper 19, inspection hole 20, first partition 21, second partition 22;

[0035] The inlet compensator 1, the inlet flue 2, the ash bucket 3 of the ascending chamber are connected with the ascending chamber 5;

[0036] The injection hole 4 is installed on the side wall of the ash hopper 3 of the first ascending bin; the deflector 6 is installed inside the first ascending bin 5; the first ascending bin 5 and the descending bin 9 communicate internally through the communication opening 7, and the deflector 8 is installed inside the descending chamber 9, and the descending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com