Heat exchange fin, heat exchanger and air conditioner

A technology of heat exchange fins and heat exchangers, which is applied in the fields of heat exchange fins, heat exchangers and air conditioners, can solve the problems of low heat exchange efficiency of heat exchange fins, improve the heat exchange effect and improve the whole year. Coefficient of performance, the effect of avoiding the accumulation of water bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

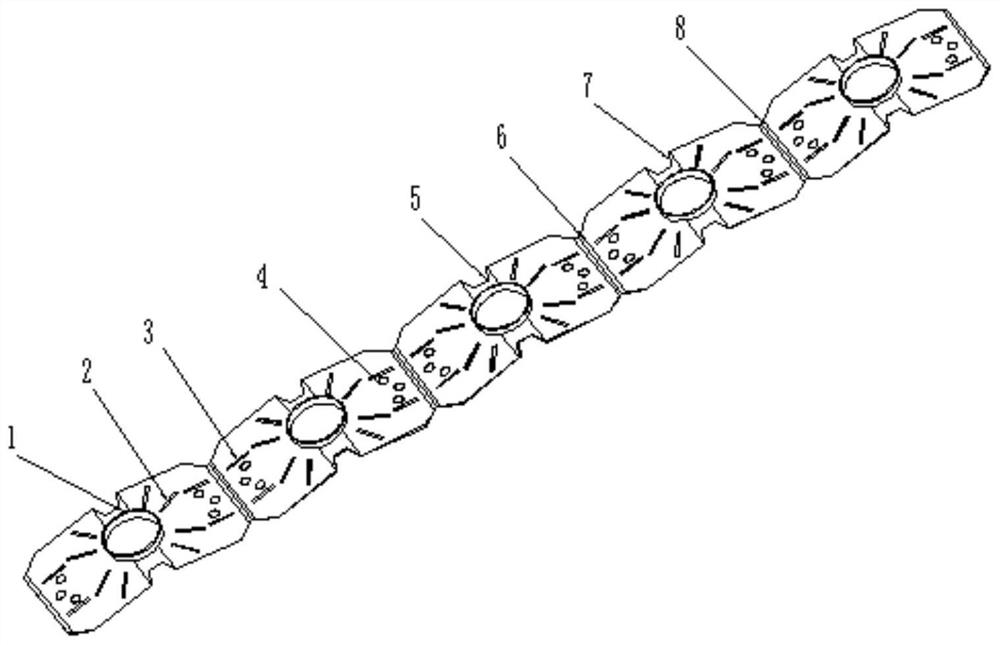

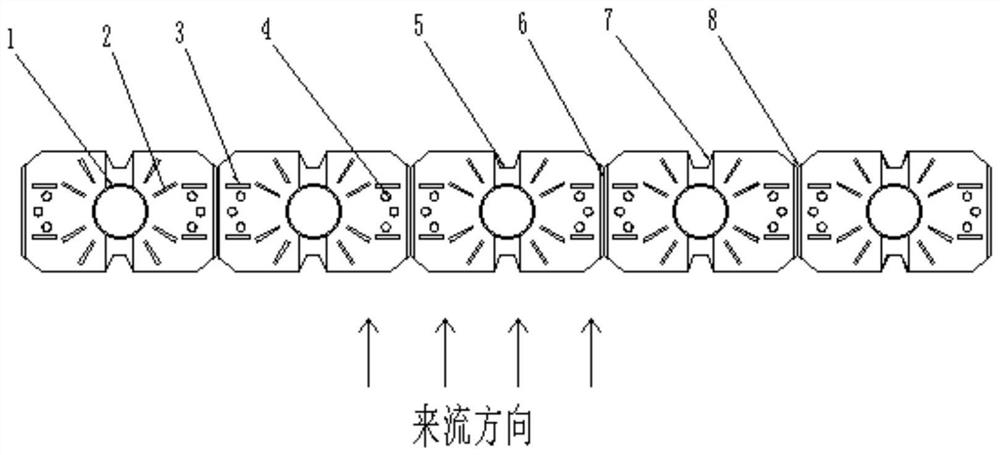

[0040] In this embodiment, a heat exchange fin is provided, and the heat exchange fin includes: at least one fin unit,

[0041] The fin unit has a plate-shaped main body, and the plate-shaped main body is a curved plate;

[0042] The plate-shaped main body is provided with a tube hole 1 on its protruding top and forms a flanging around the tube hole 1, and the protruding direction of the flanging is the same as that of the curved plate;

[0043] The plate-shaped main body is formed around the tube hole with a first hollow structure 2 divergently extending from the tube hole 1 to the outer periphery;

[0044] The plate-shaped main body is formed with a first diversion groove 5 on one or both sides of the pipe hole along the radial direction of the pipe hole 1. One end of the first diversion groove 5 extends to the edge of the plate-shaped main body, and the other end extends to the flange ;

[0045] Wherein the first hollow structure 2 is distributed on both sides of the firs...

Embodiment 2

[0066] Based on the heat exchanging fins in Embodiment 1, a heat exchanger is provided in this embodiment, and the heat exchanger includes any one of the above heat exchanging fins. The heat exchanging fins are stacked and the copper tubes are passed through the tube holes 1 . The heat exchanger can be used for heat exchange in an air conditioner.

[0067] Furthermore, this embodiment further describes the heat exchanger in combination with the specific structure of the heat exchange fins in Embodiment 1.

[0068] As shown in 1, the heat exchange fins are formed with tube holes 1, a first hollow structure 2, a second hollow structure 3, protrusions or grooves 4, a first guide groove 5 and a first guide gap 7, a second The diversion groove 6 and the second diversion notch 8 .

[0069] Since the main body of the heat exchange fin used in the heat exchanger is a plate-shaped structure, the first guide groove 5 protrudes toward the direction of the flange of the tube hole ( im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com