Patents

Literature

104results about How to "Promote turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

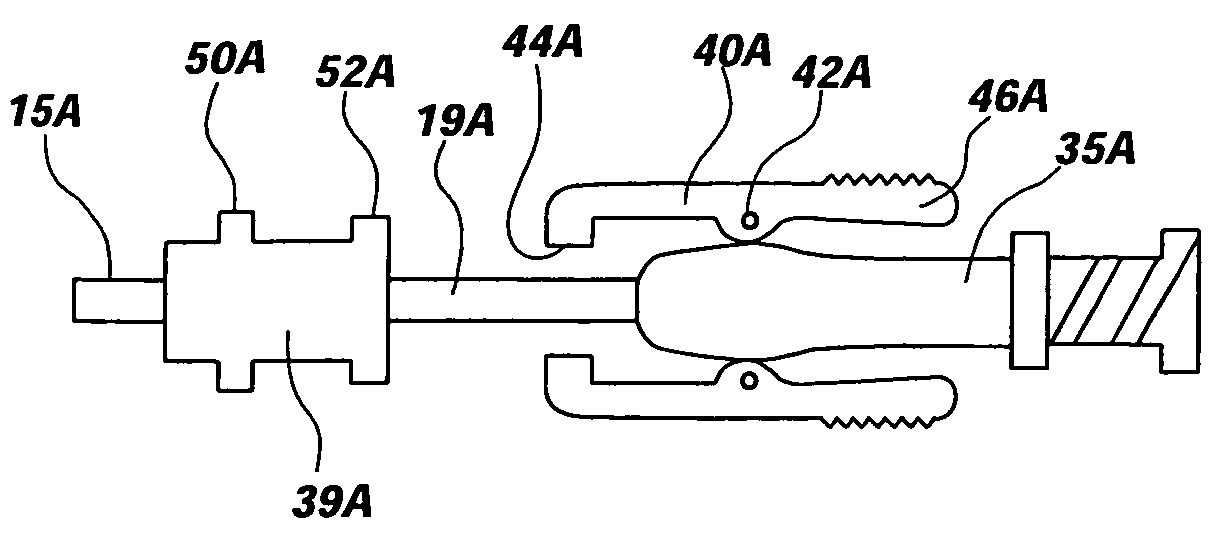

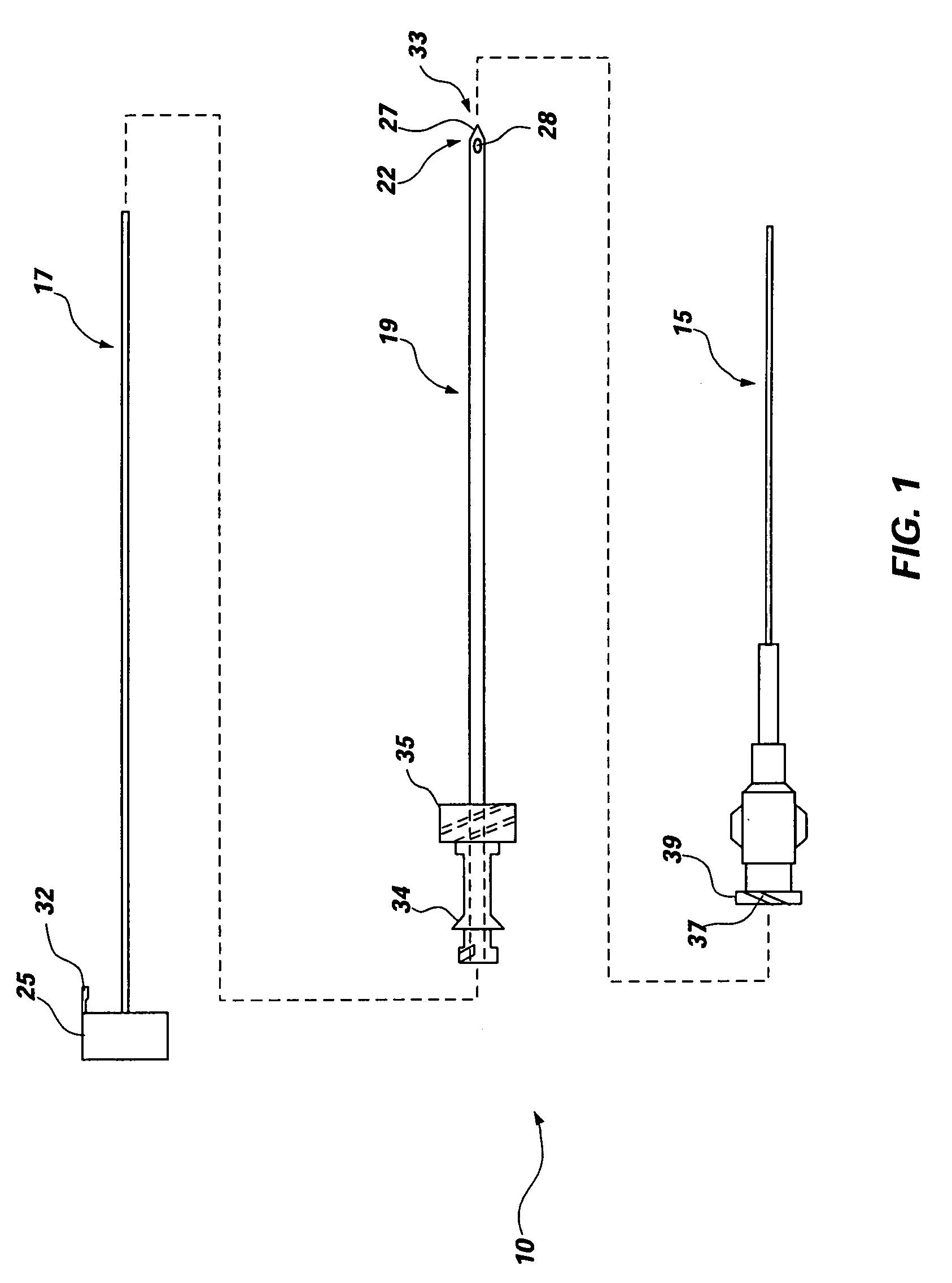

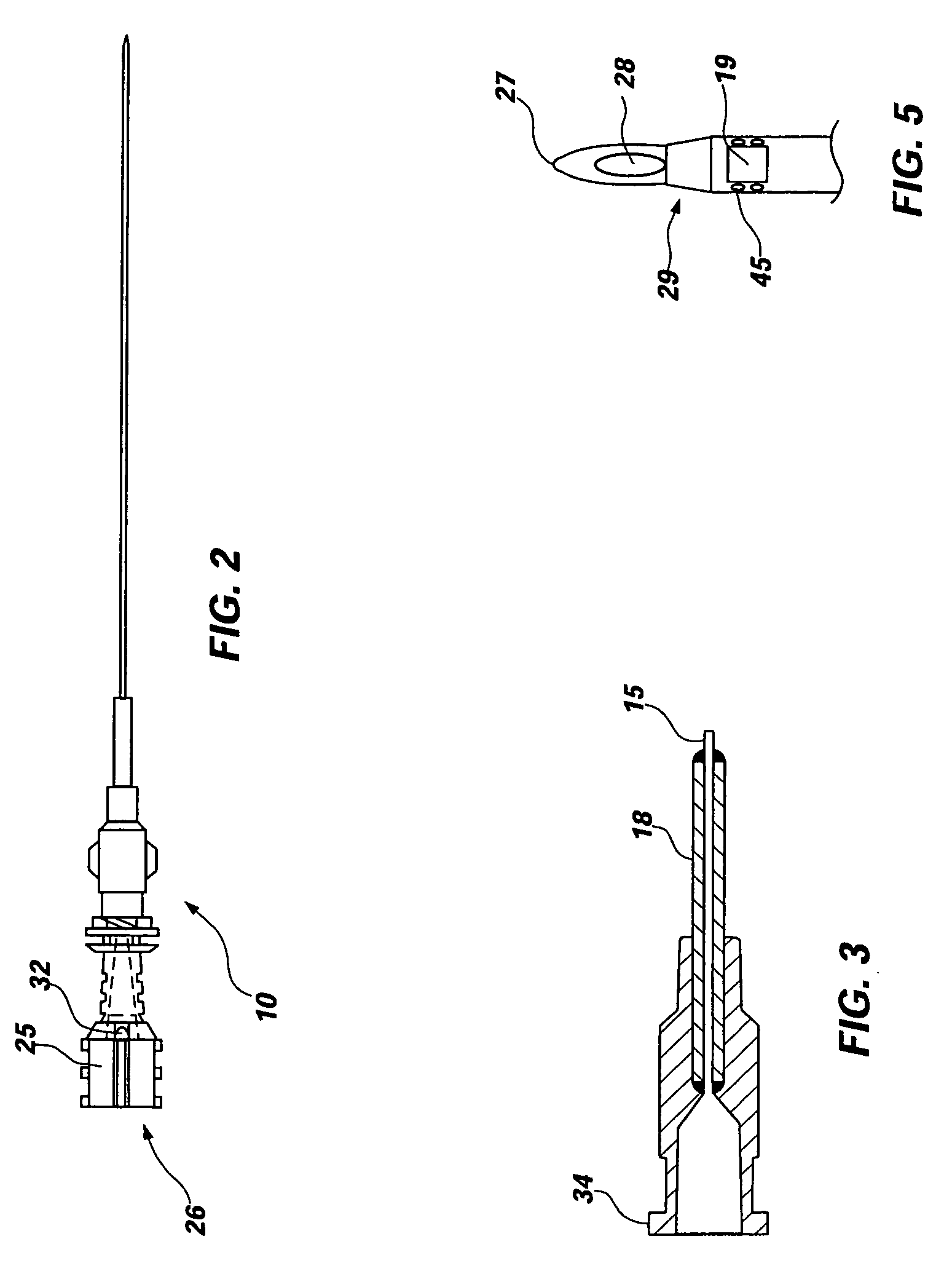

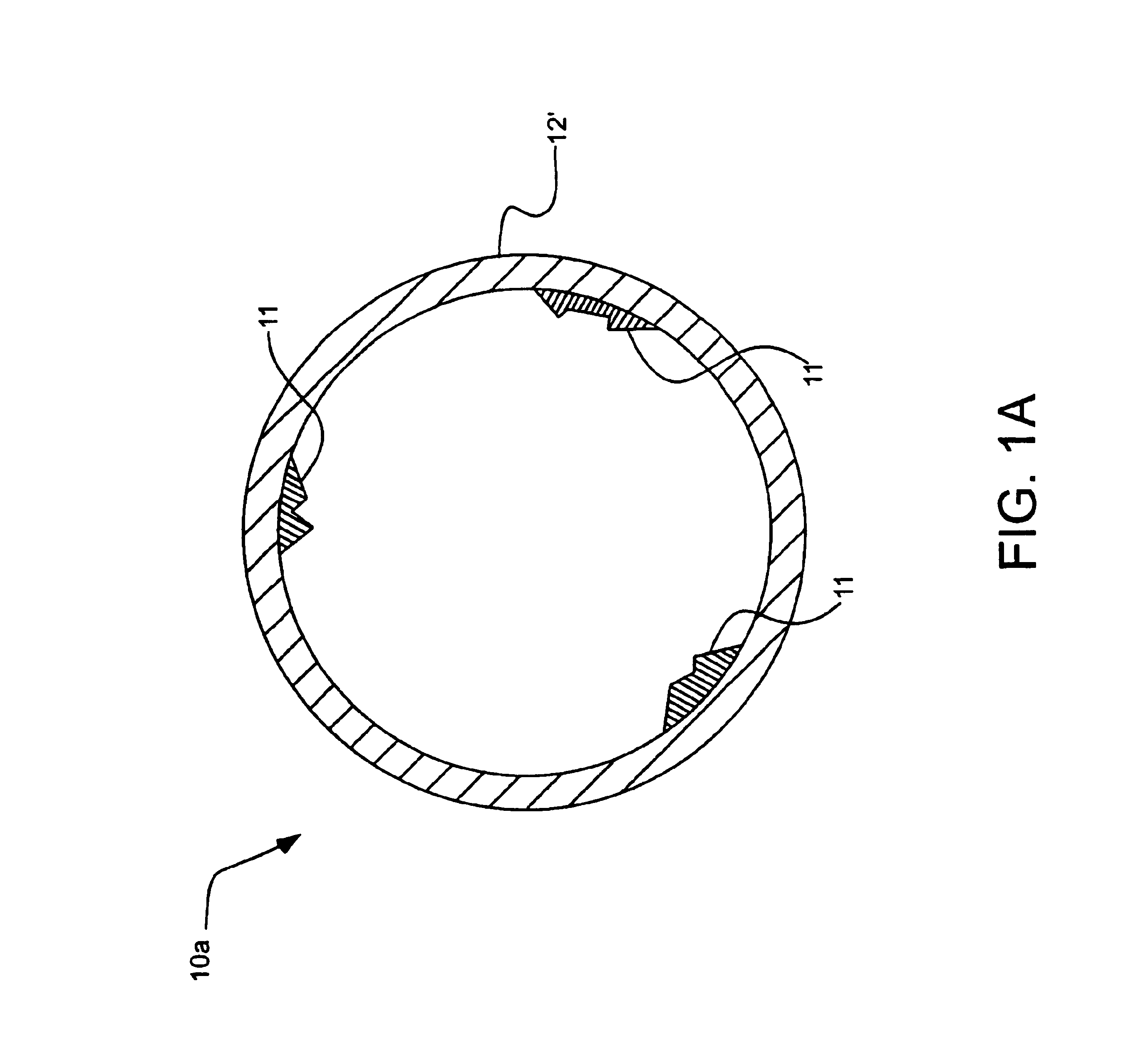

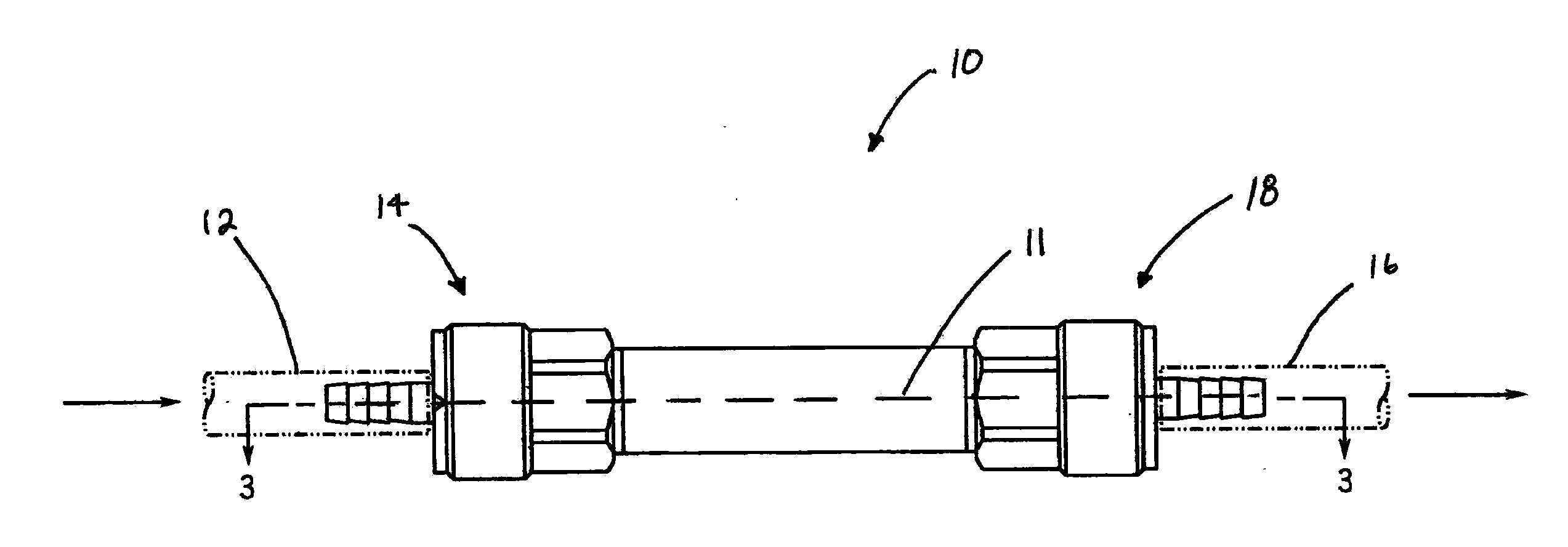

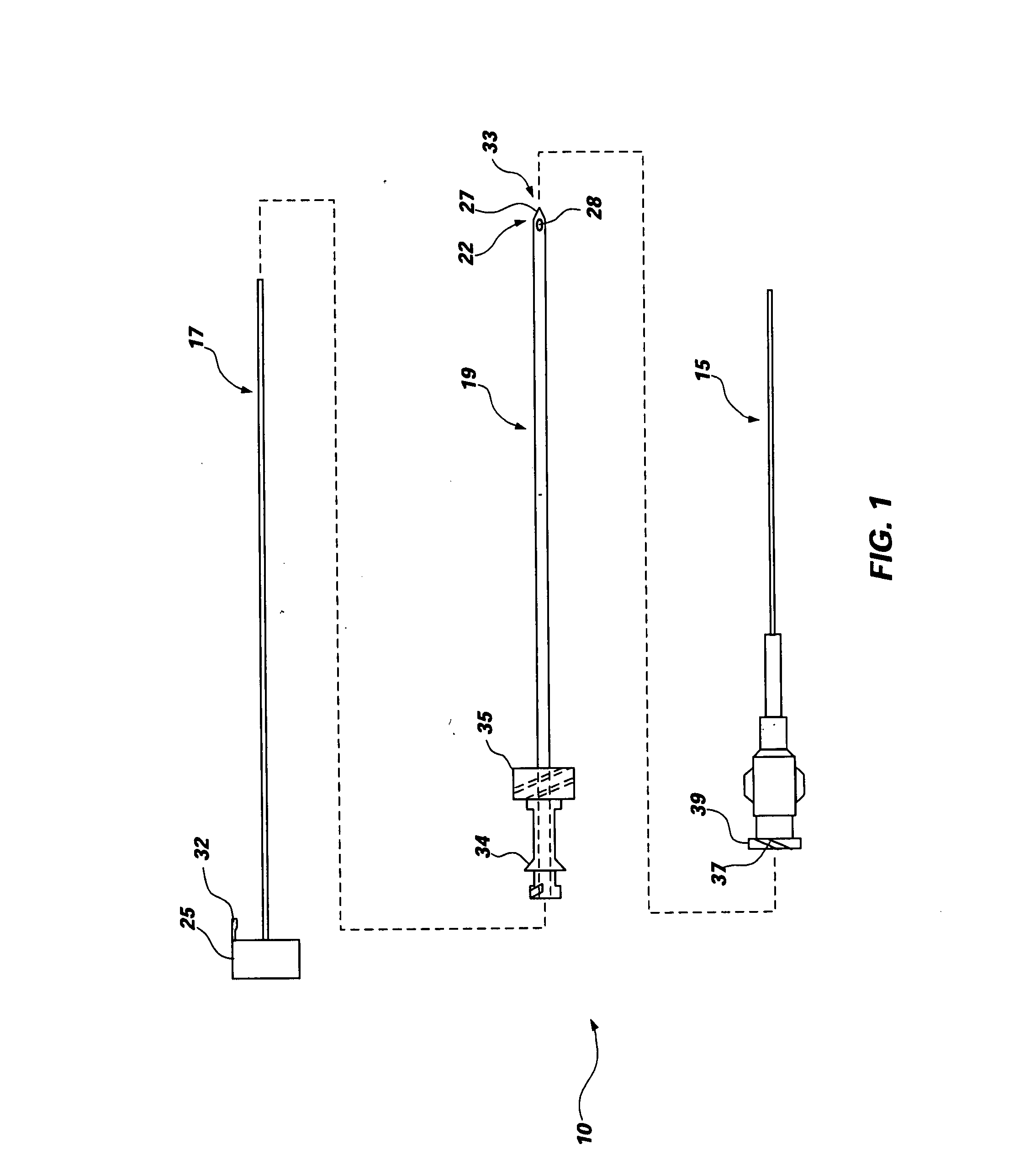

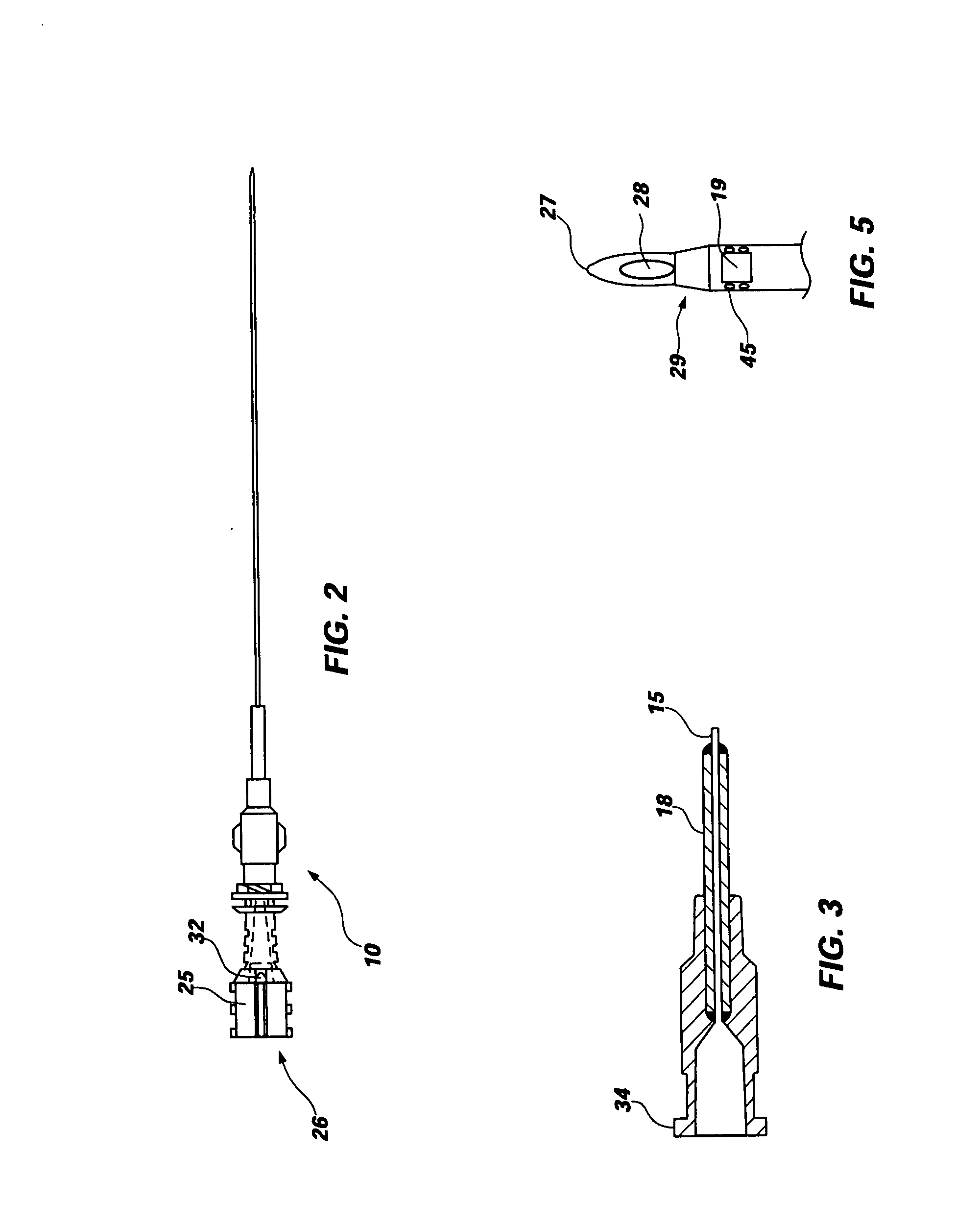

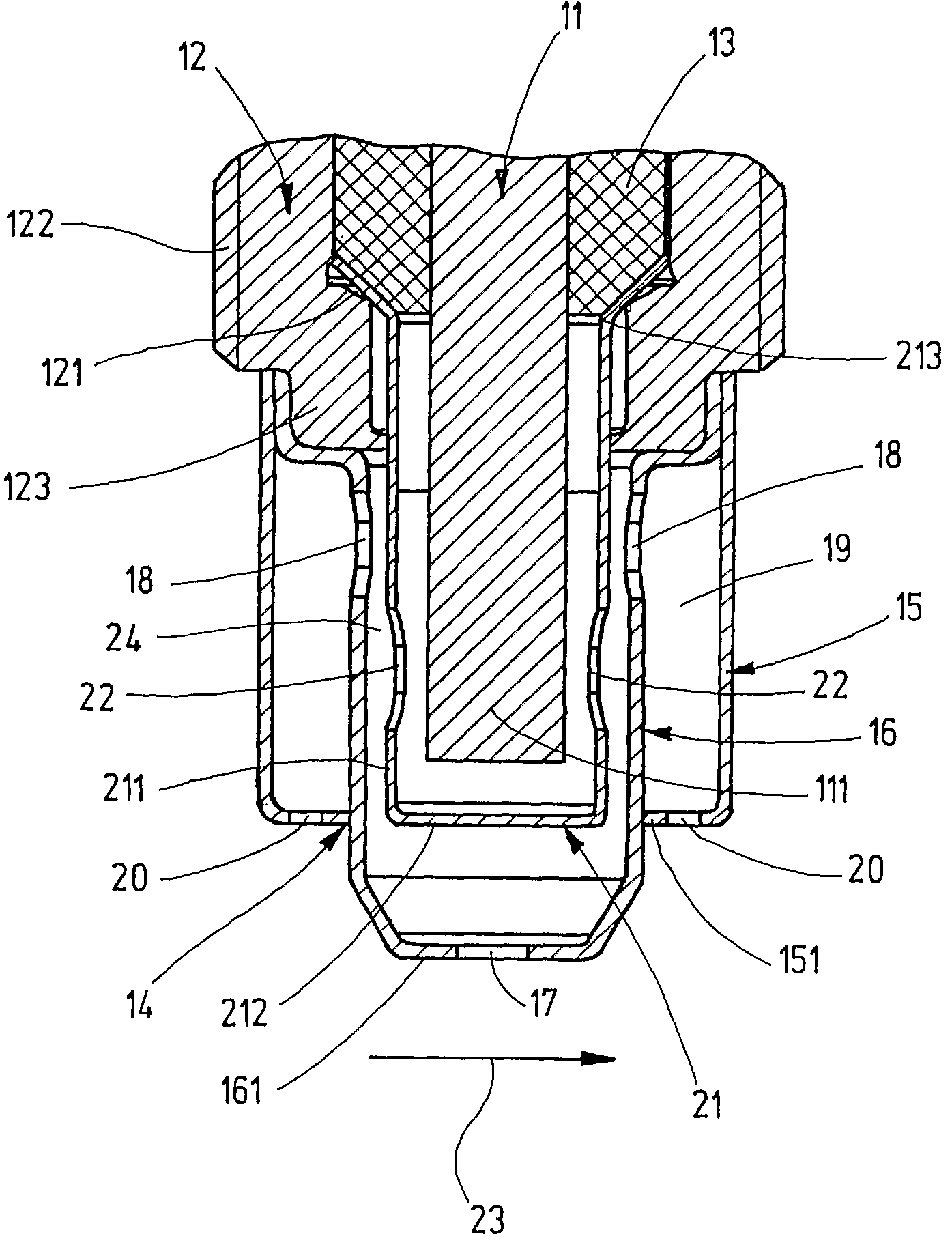

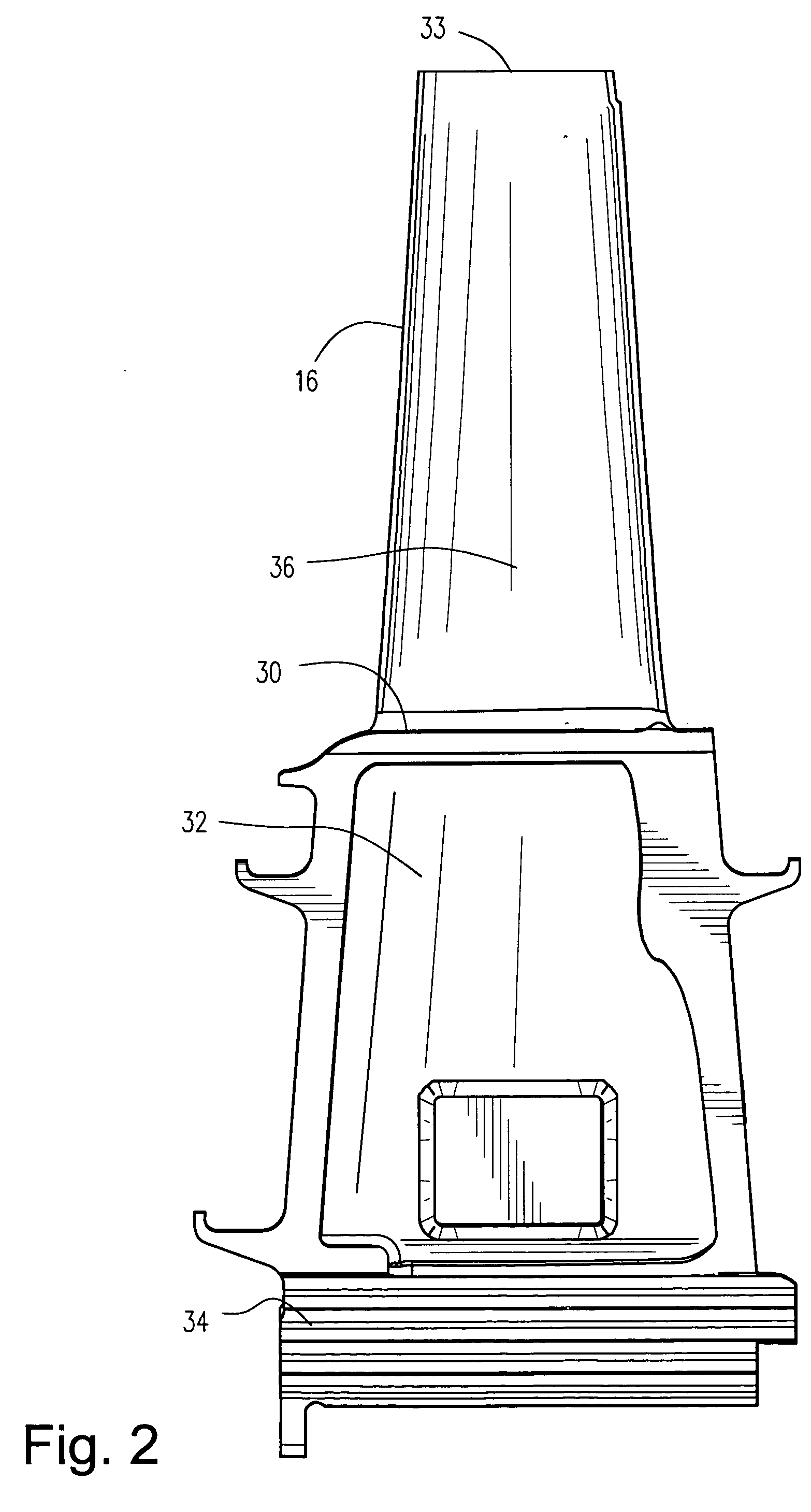

Safety spinal catheter

InactiveUS20050090801A1Simple and straightforward catheter insertionEasy and faster flowGuide needlesInfusion syringesSpinal columnCatheter Gauge

An apparatus and method to insert a spinal catheter and minimize incidence of post dural puncture headache. The apparatus typically includes a support needle with a non-cutting piercing tip and an exteriorly mounted catheter. The catheter gauge is reduced, while ease of use is increased by the exterior mounting. The catheter may include a kink sleeve that protects against kinking when bent during use. A central stylet maybe included to prevent entry of matter into the support needle opening during insertion. Methods using a single stick insertion procedure allow for catheter placement to be determined and adjusted based on physical feedback obtained during the single stick insertion.

Owner:CUSTOM MEDICAL APPL

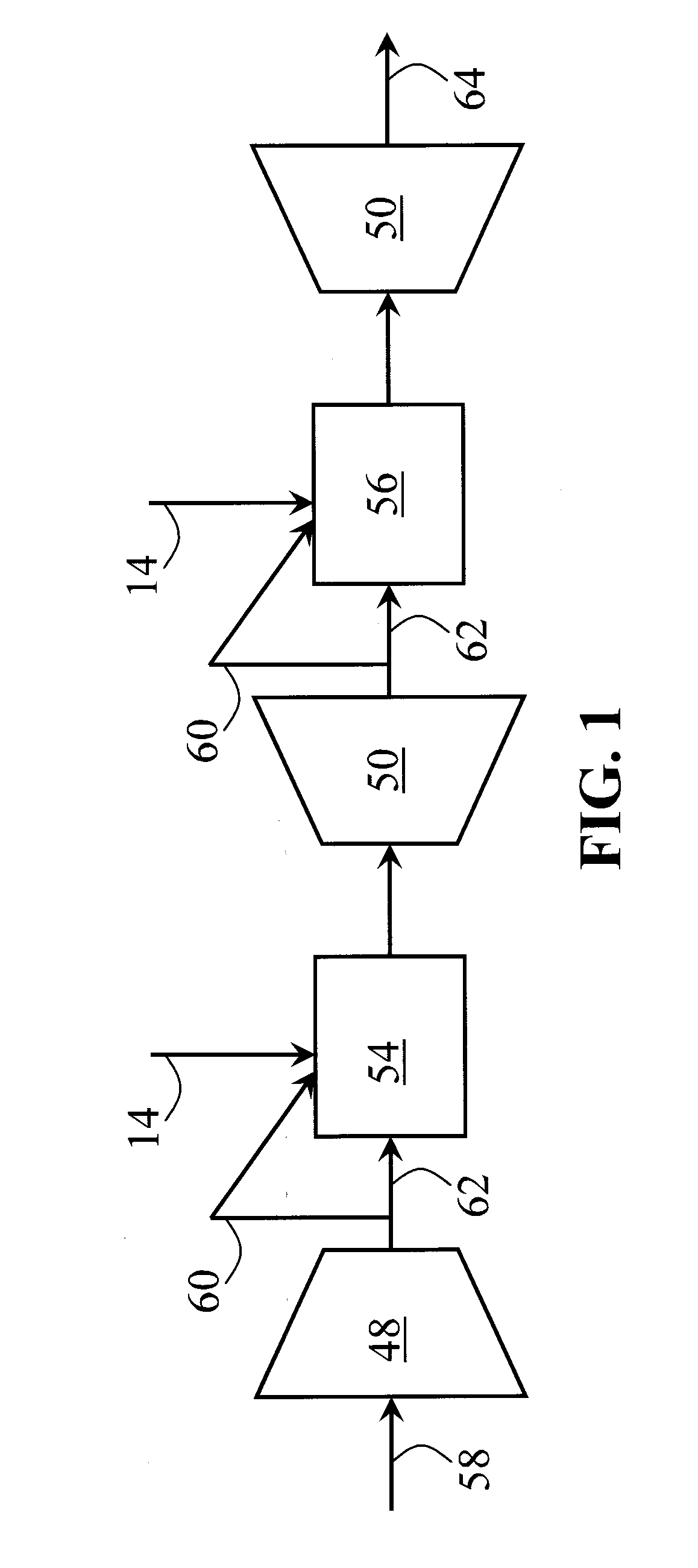

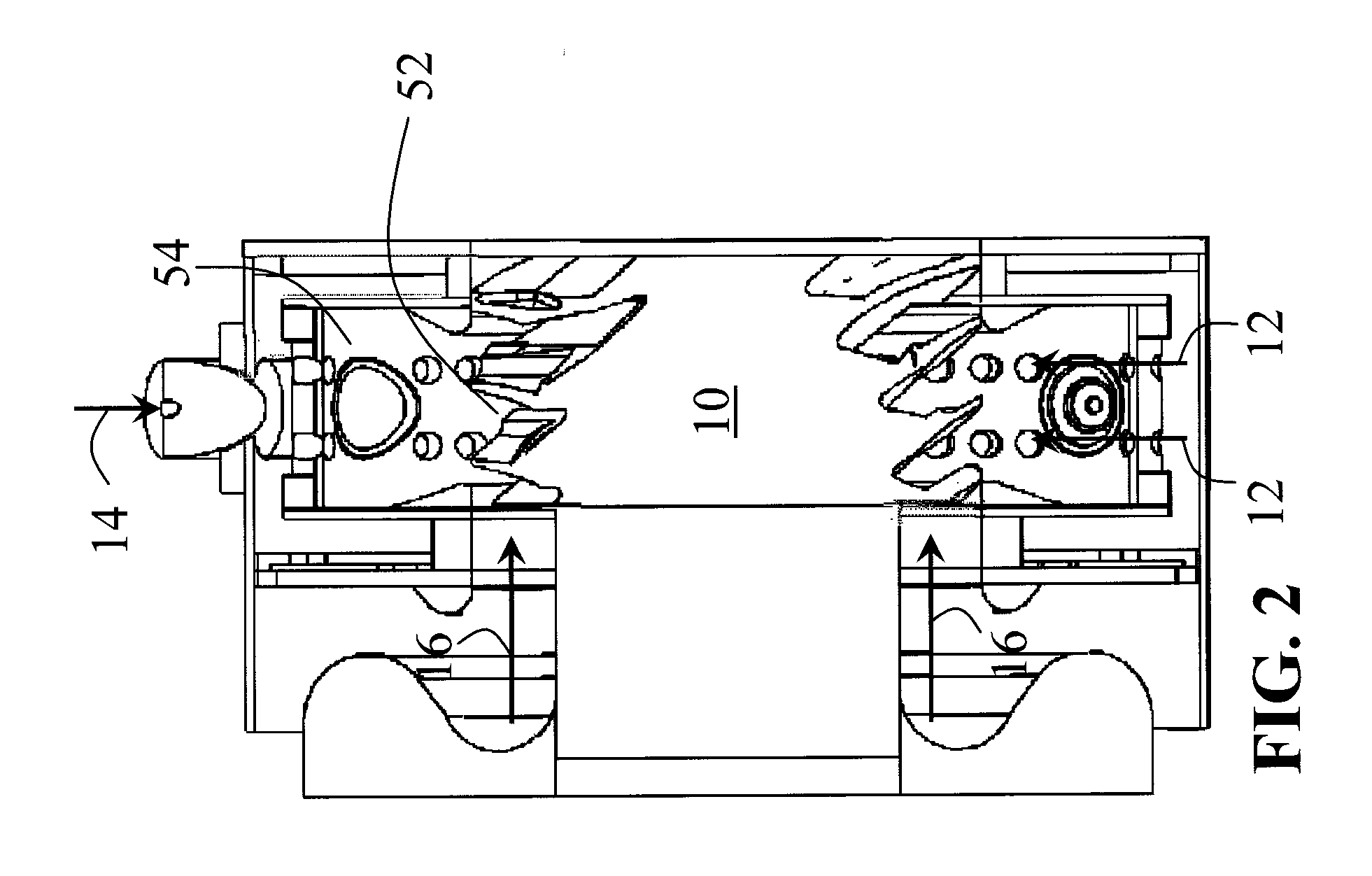

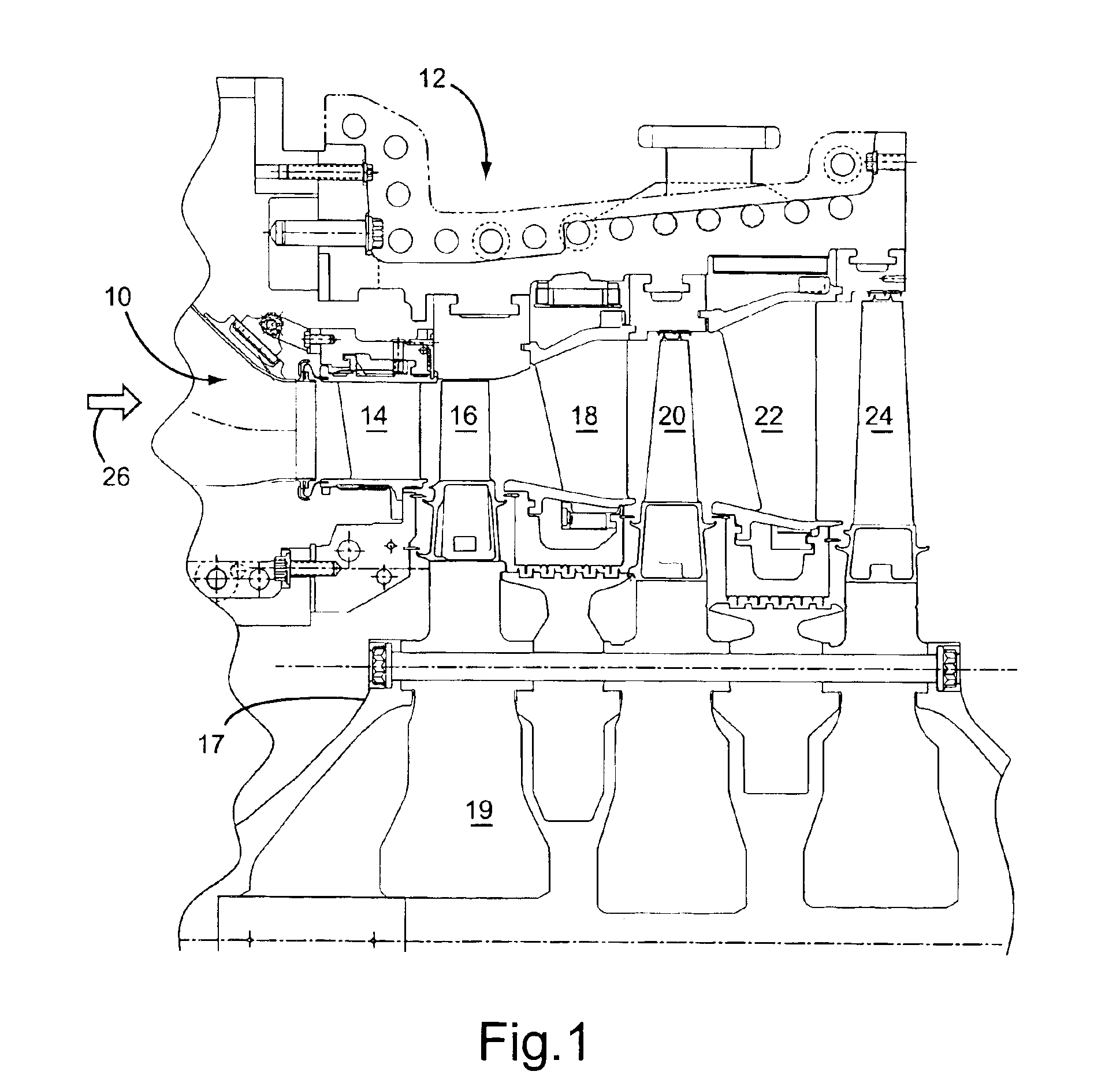

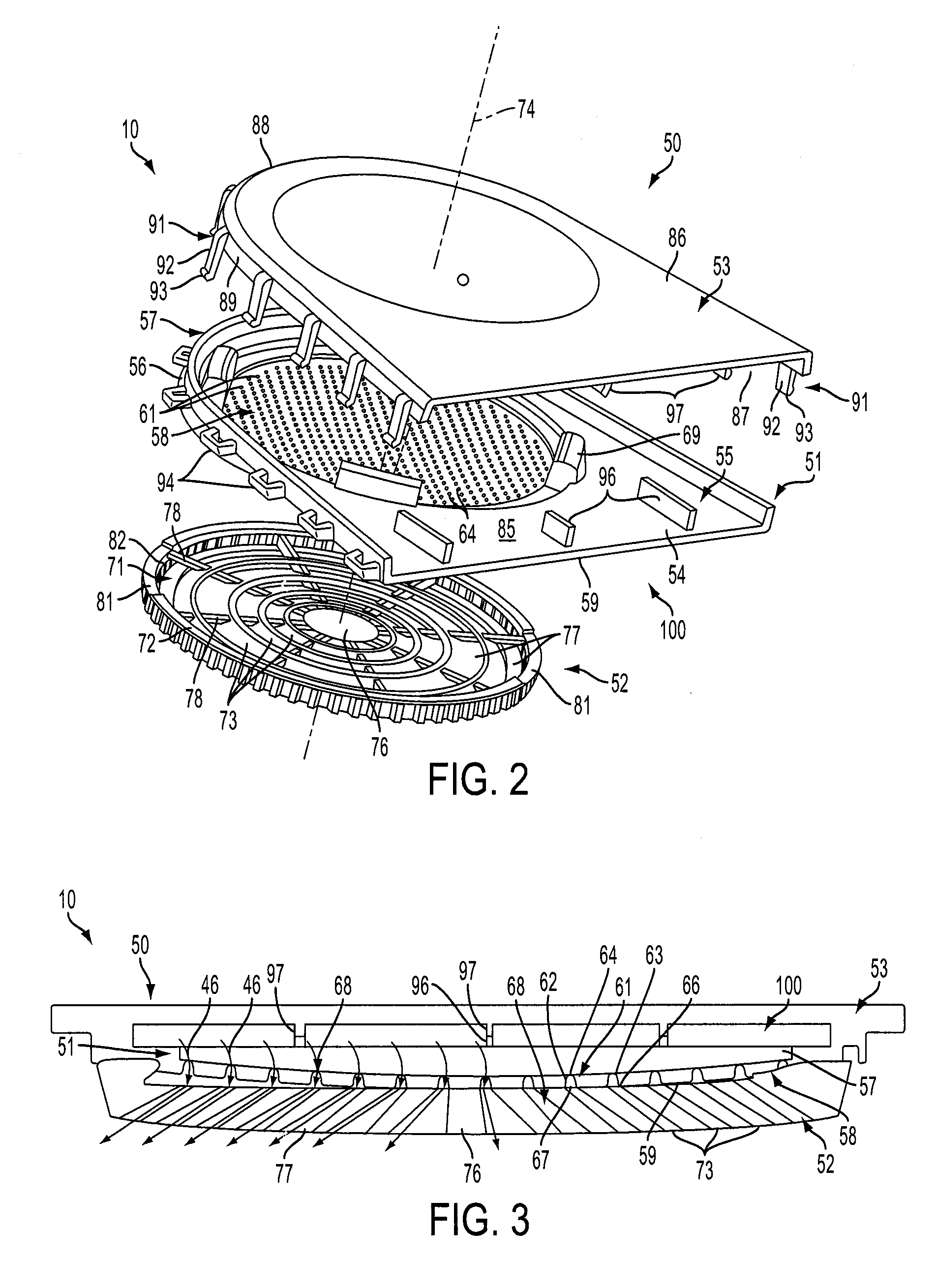

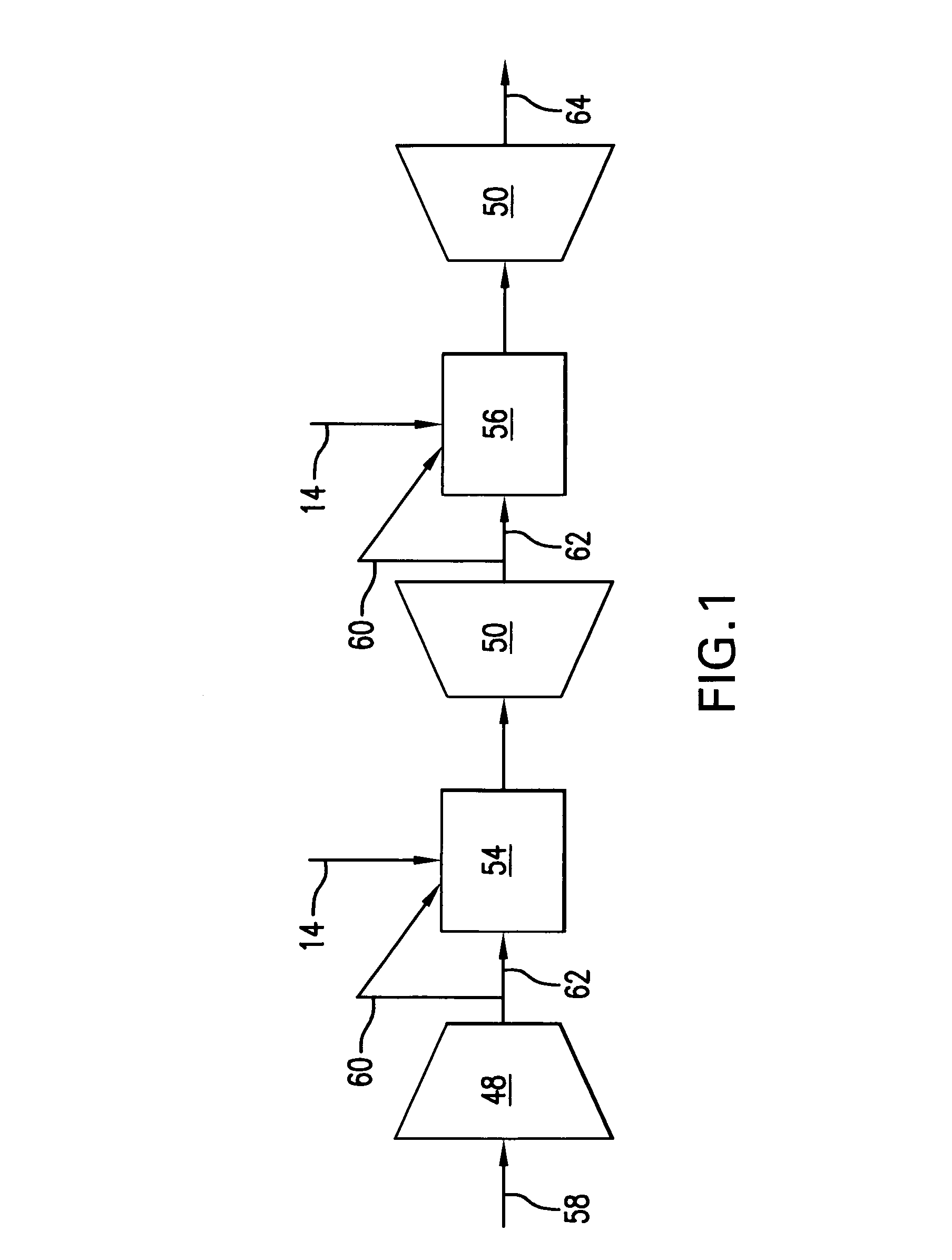

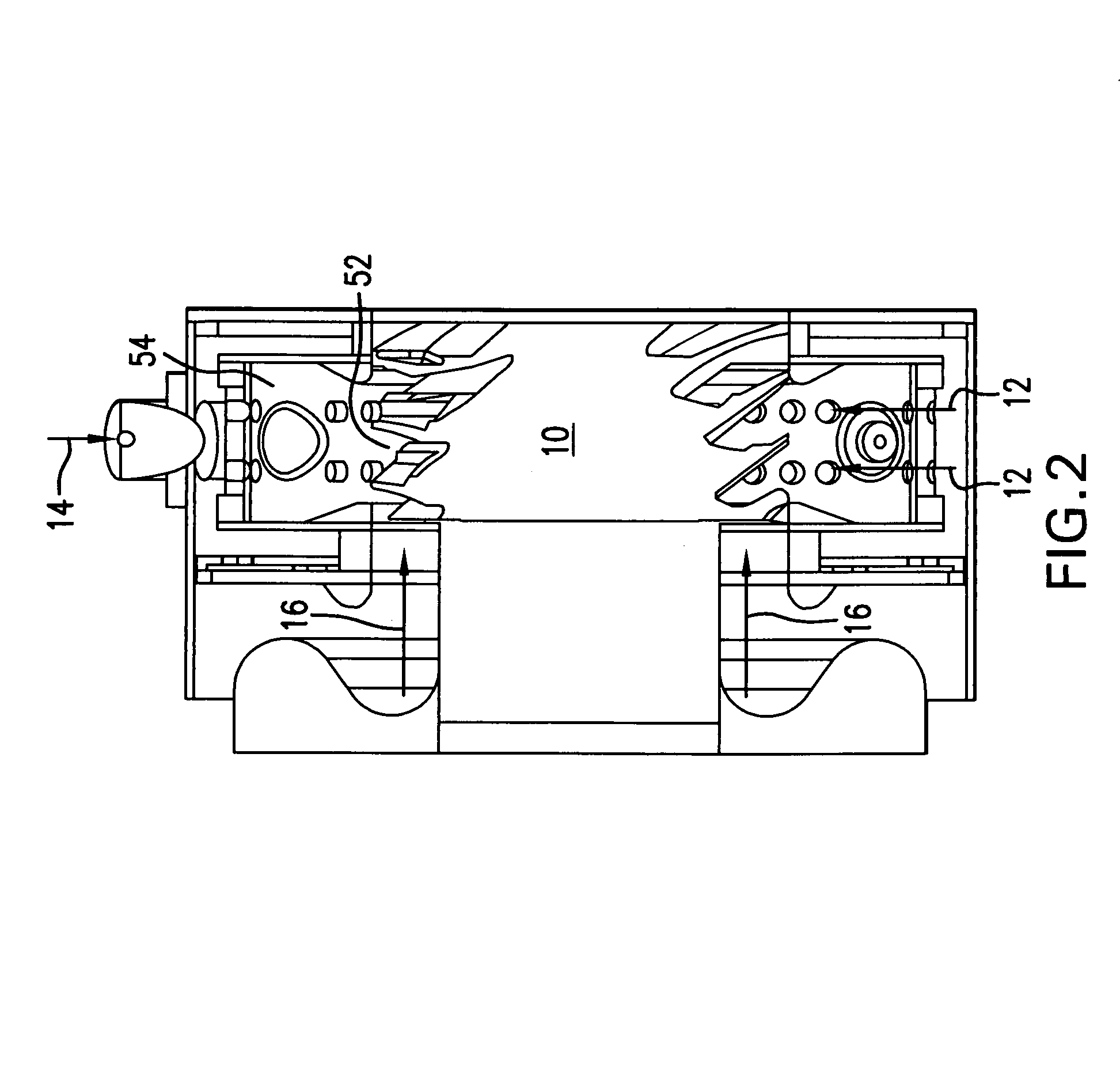

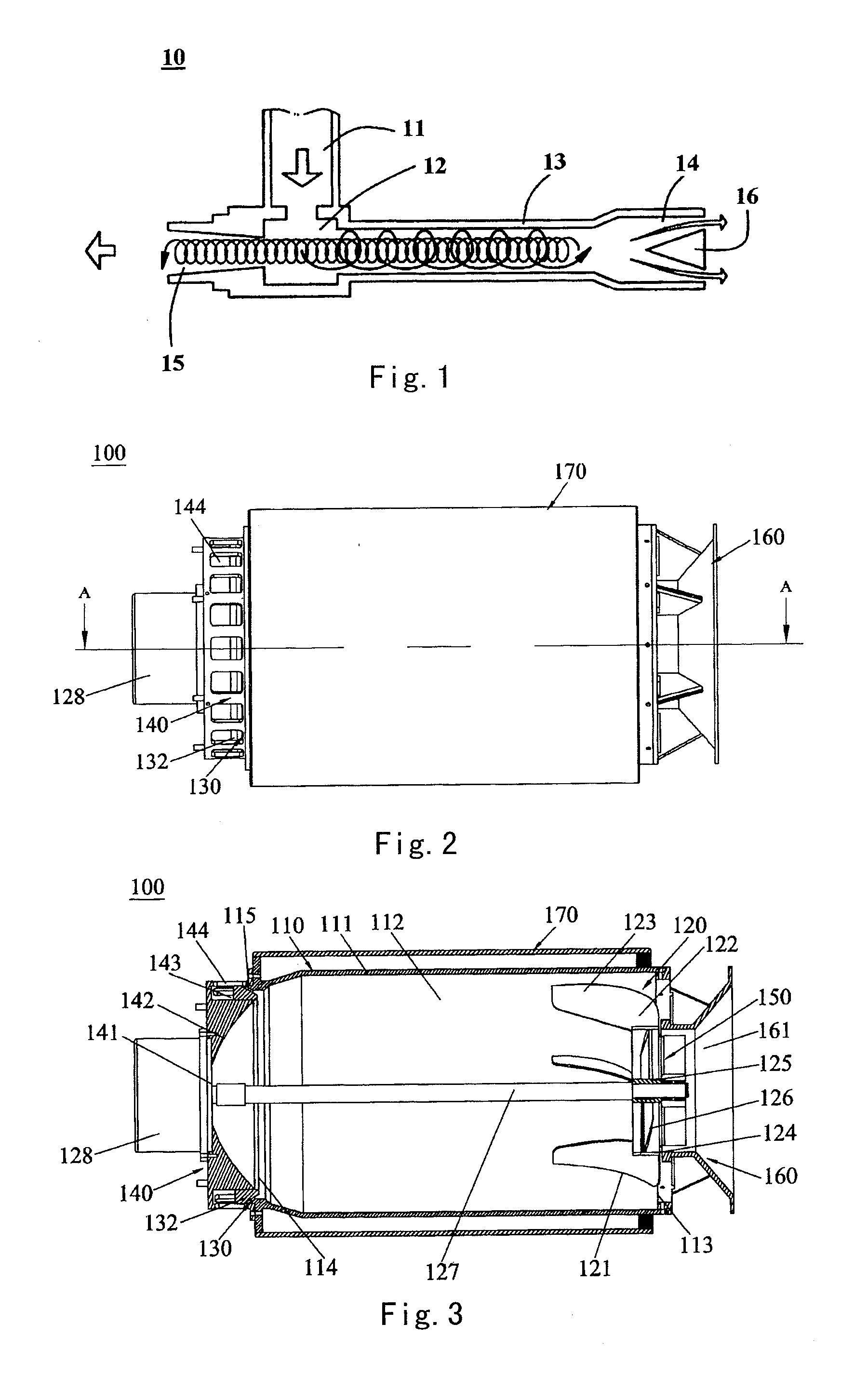

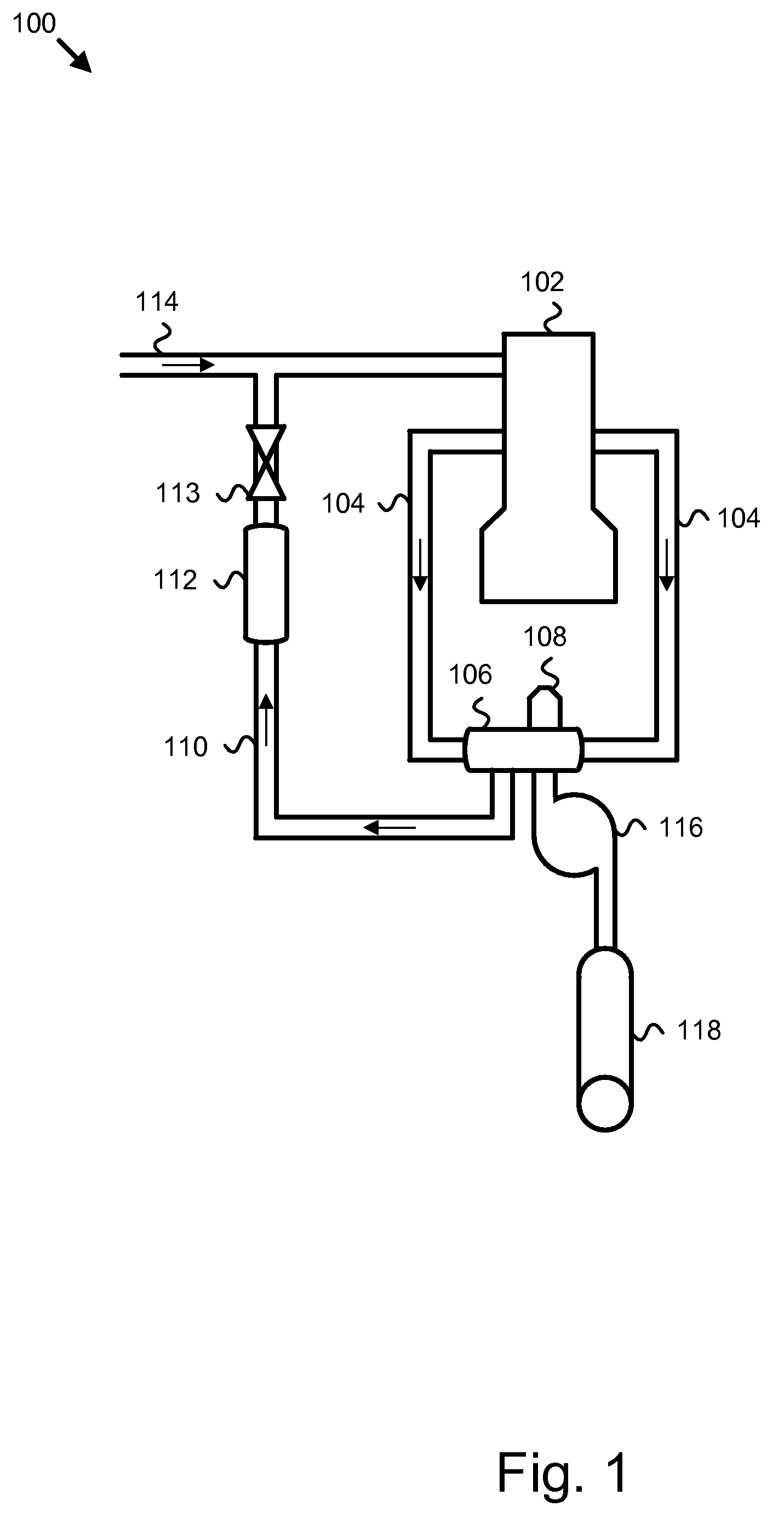

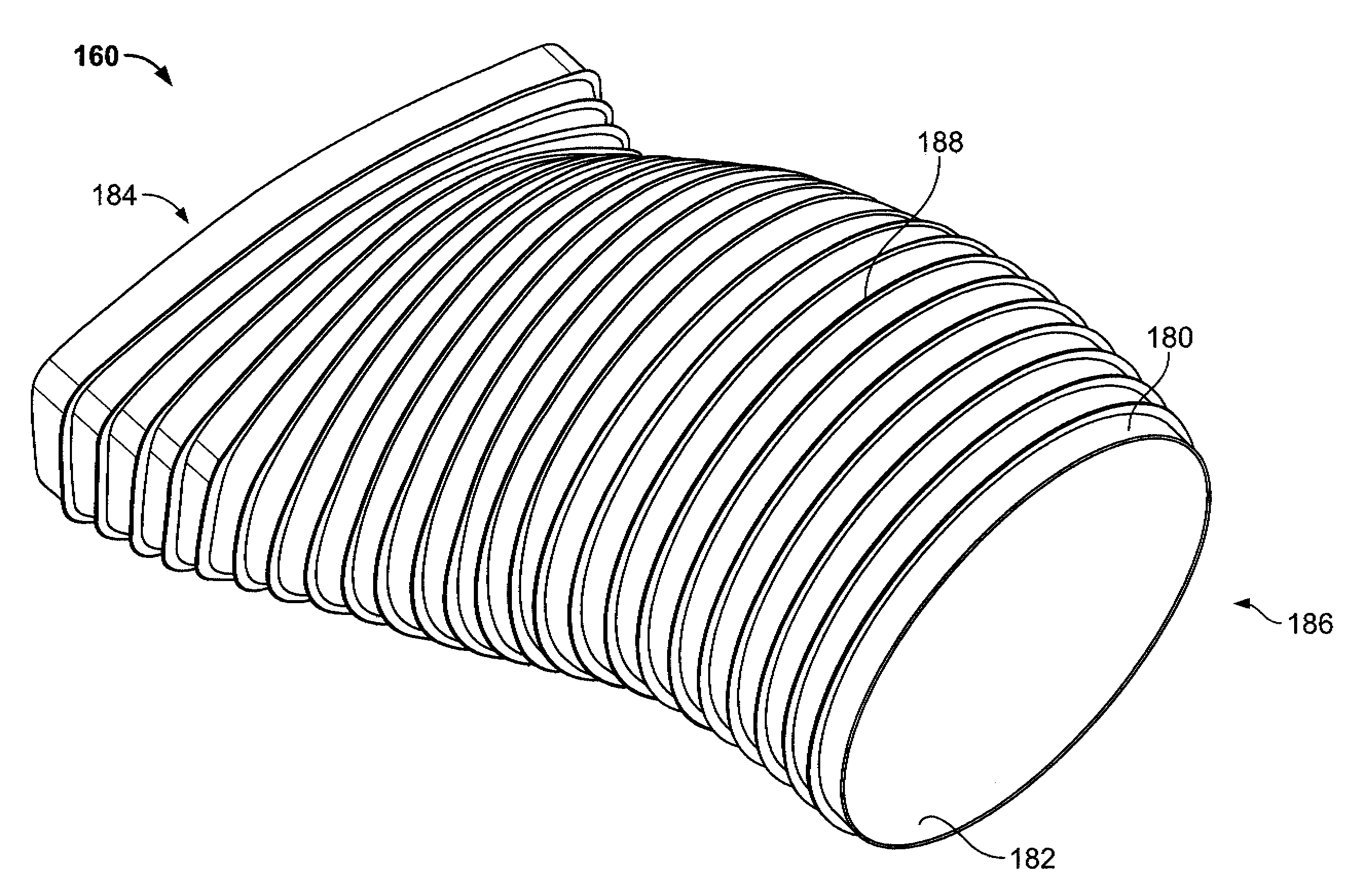

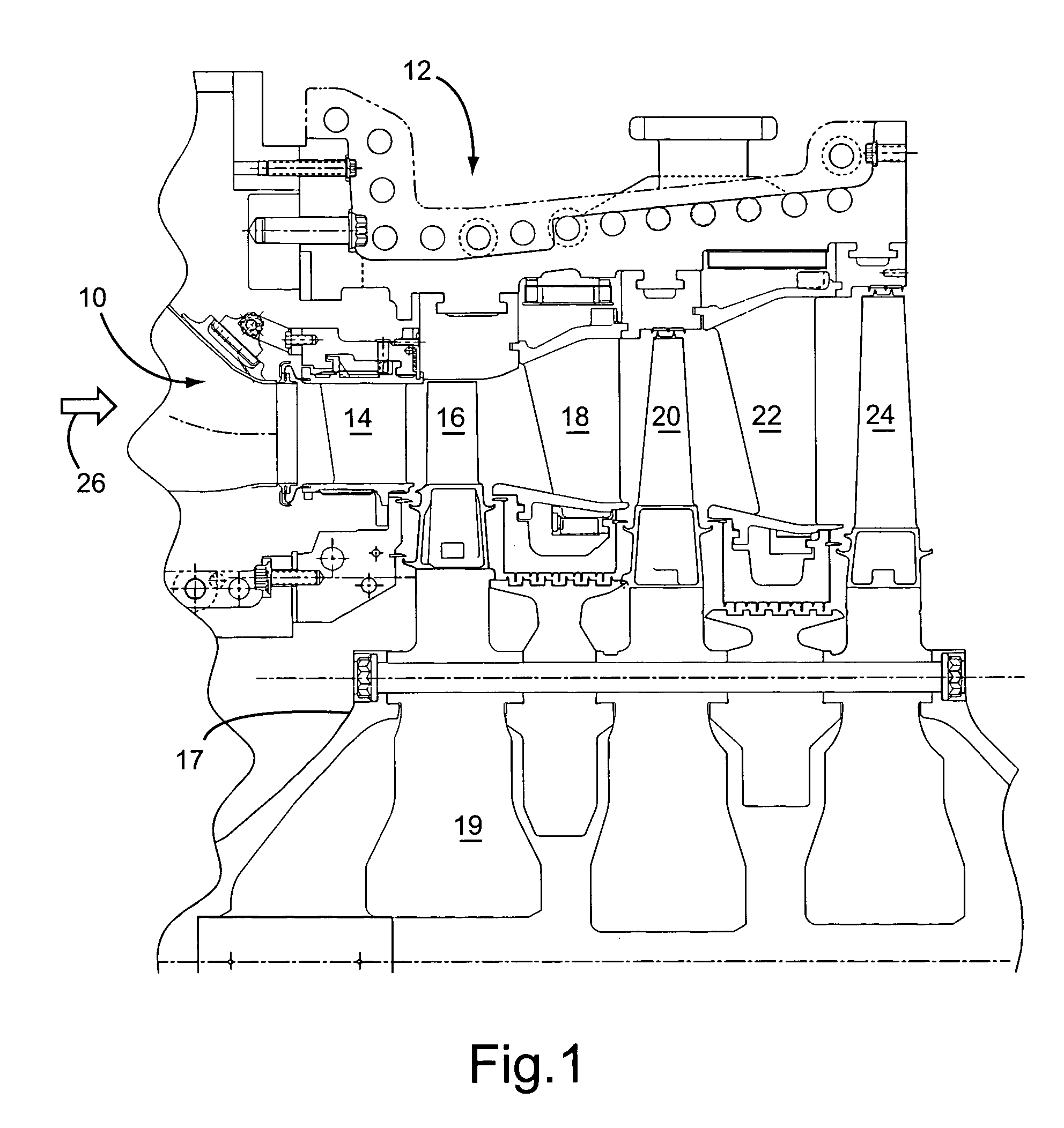

Apparatus and method for a gas turbine entrainment system

ActiveUS20090178412A1Reduce lossesFacilitate turbulenceContinuous combustion chamberEngine manufactureCombustion chamberCombustor

This invention relates to an apparatus for an entrainment system of a vortex burning combustion chamber or a vortex burning inter-turbine burner in a gas turbine. The entrainment system rapidly and thoroughly mixes hot combustion gases with non-combustion gases to reduce the gas temperature before entering a turbine. The entrainment system includes a plurality of helical vanes forming trenches and resulting in a highly helical flow path. The highly helical flow path provides an increased residence time for mixing of the combustion gases and non-combustion gases. Radial cavities in the helical vanes, canted vane angles and varying geometries further facilitate mixing while reducing losses. This invention also includes a method of mixing combustion and non-combustion gases in an entrainment system.

Owner:SPYTEK AEROSPACE CORP

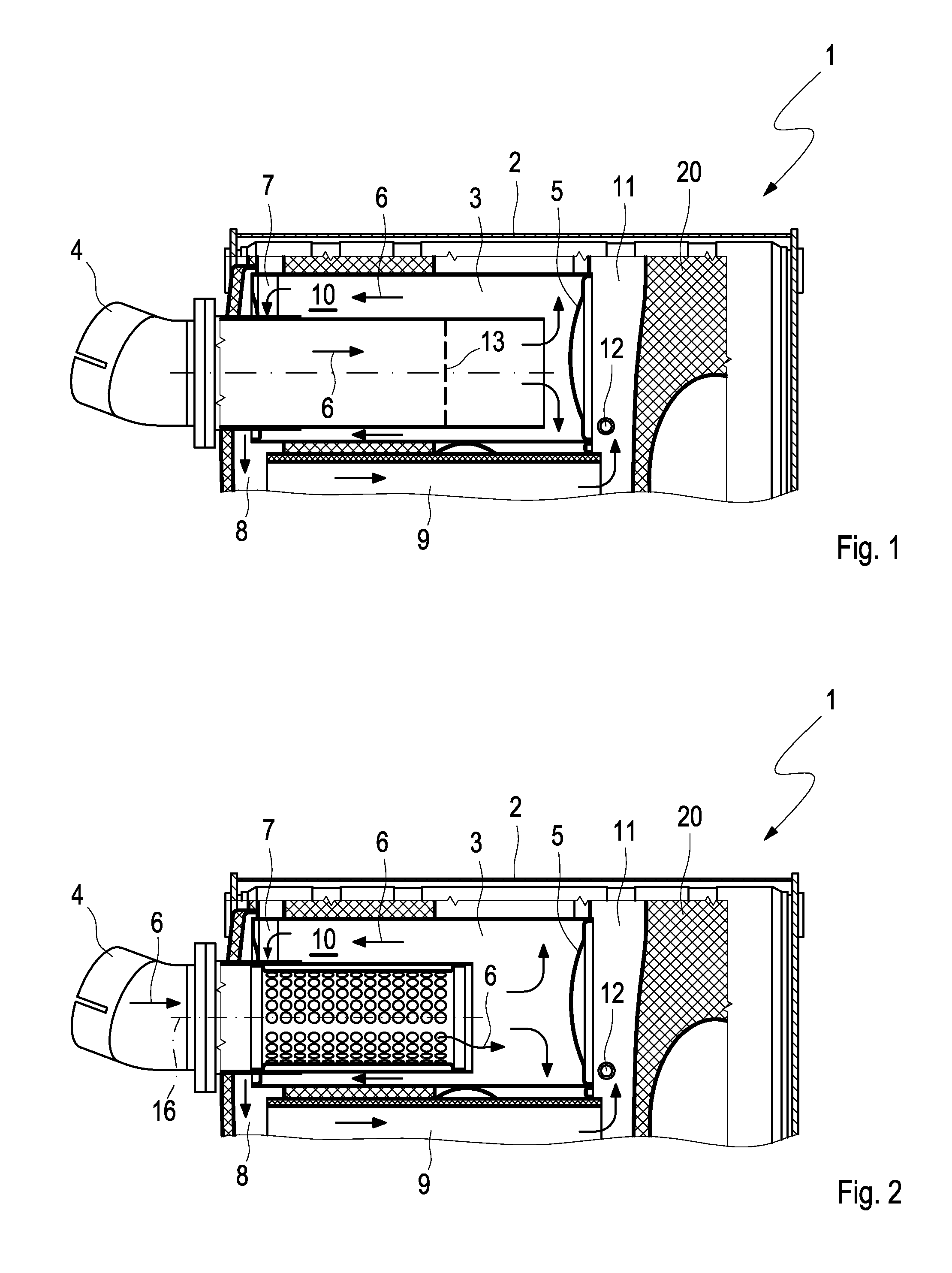

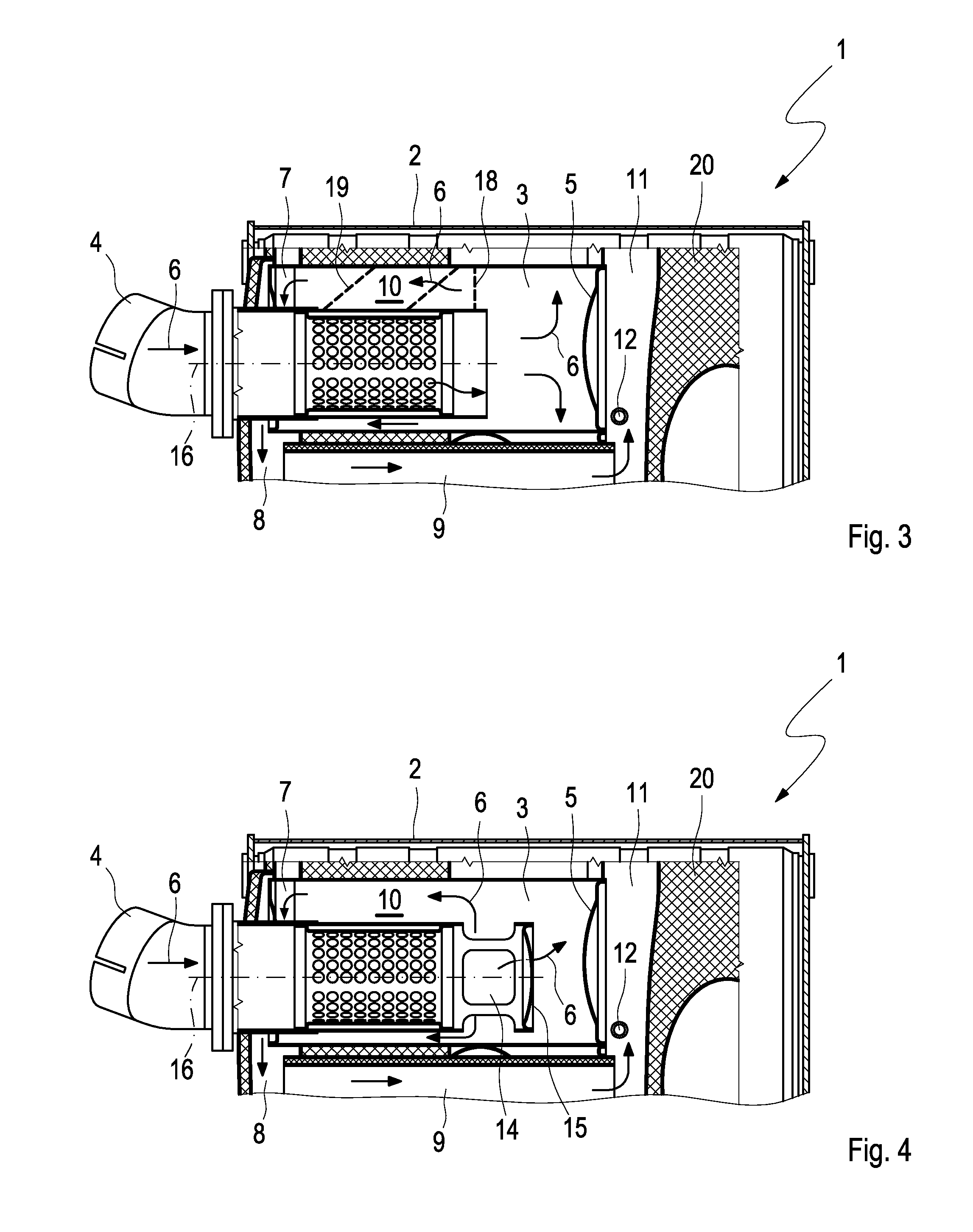

Exhaust gas aftertreatment device for an internal combustion engine

ActiveUS20070289294A1Good and thorough mixingWell and thorough mixingInternal combustion piston enginesSilencing apparatusExhaust fumesAfter treatment

The invention relates to an exhaust gas after-treatment device for an internal combustion engine, including a housing into which an exhaust pipe that opens into a mixing chamber penetrates. The mixing chamber is shaped as a pot and reverses a direction of flow of the incoming exhaust gas whereby it returns the exhaust gas radially outside of the exhaust pipe. An open end of the pot-shaped mixing chamber opens into a collecting space which is designed so that it supplies the exhaust gas to at least one downstream SCR catalytic converter.

Owner:PUREM GMBH

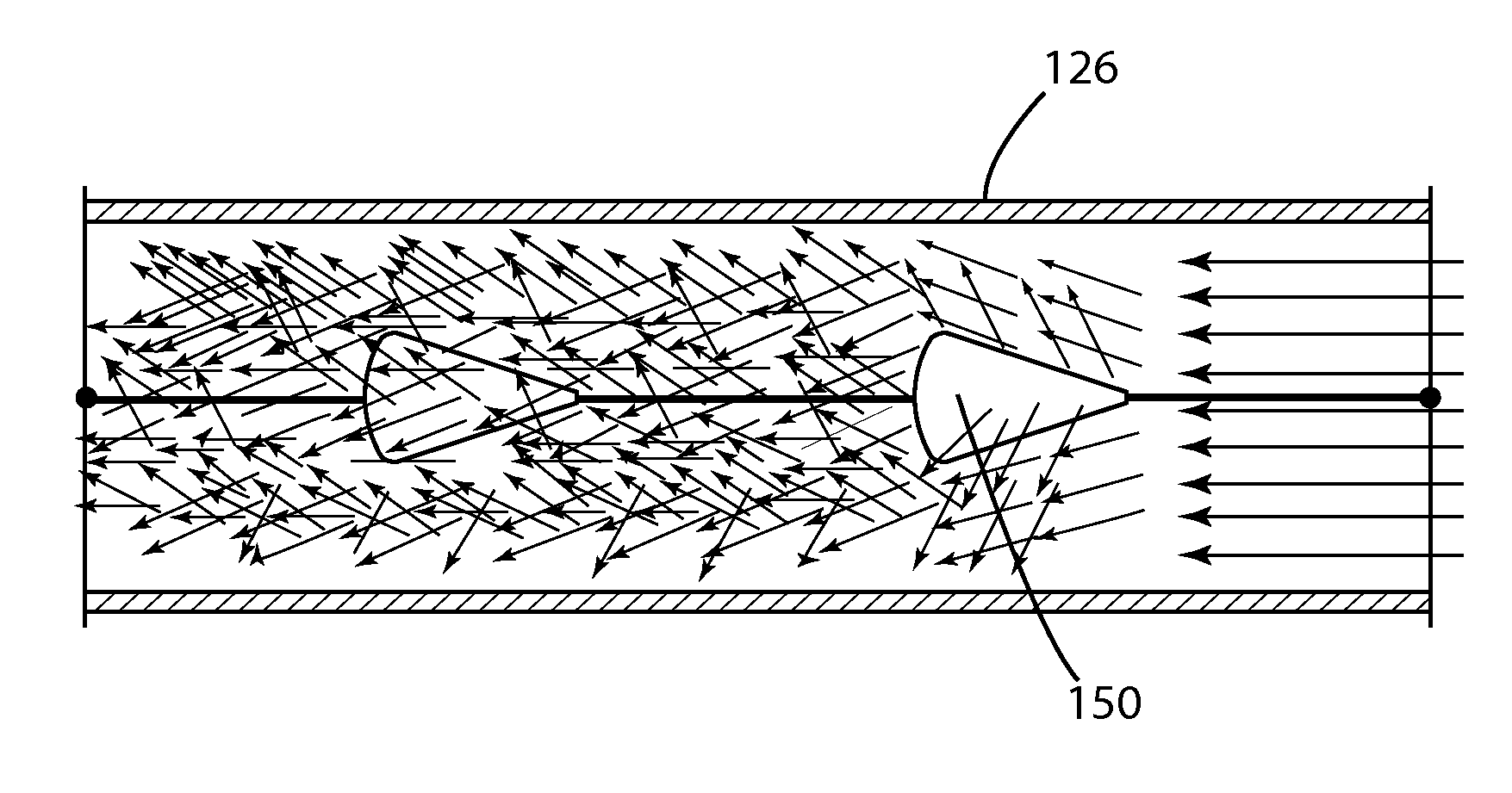

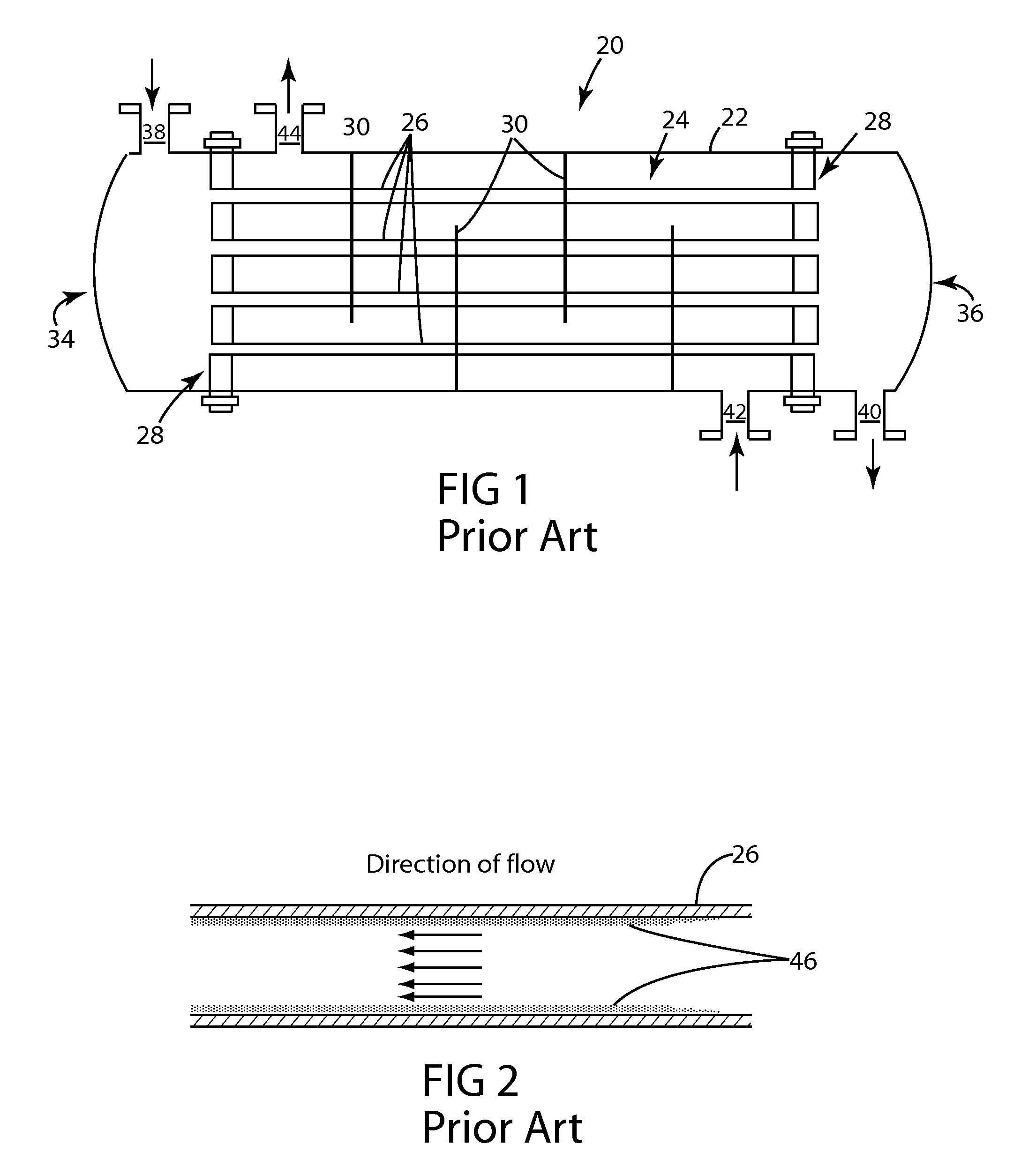

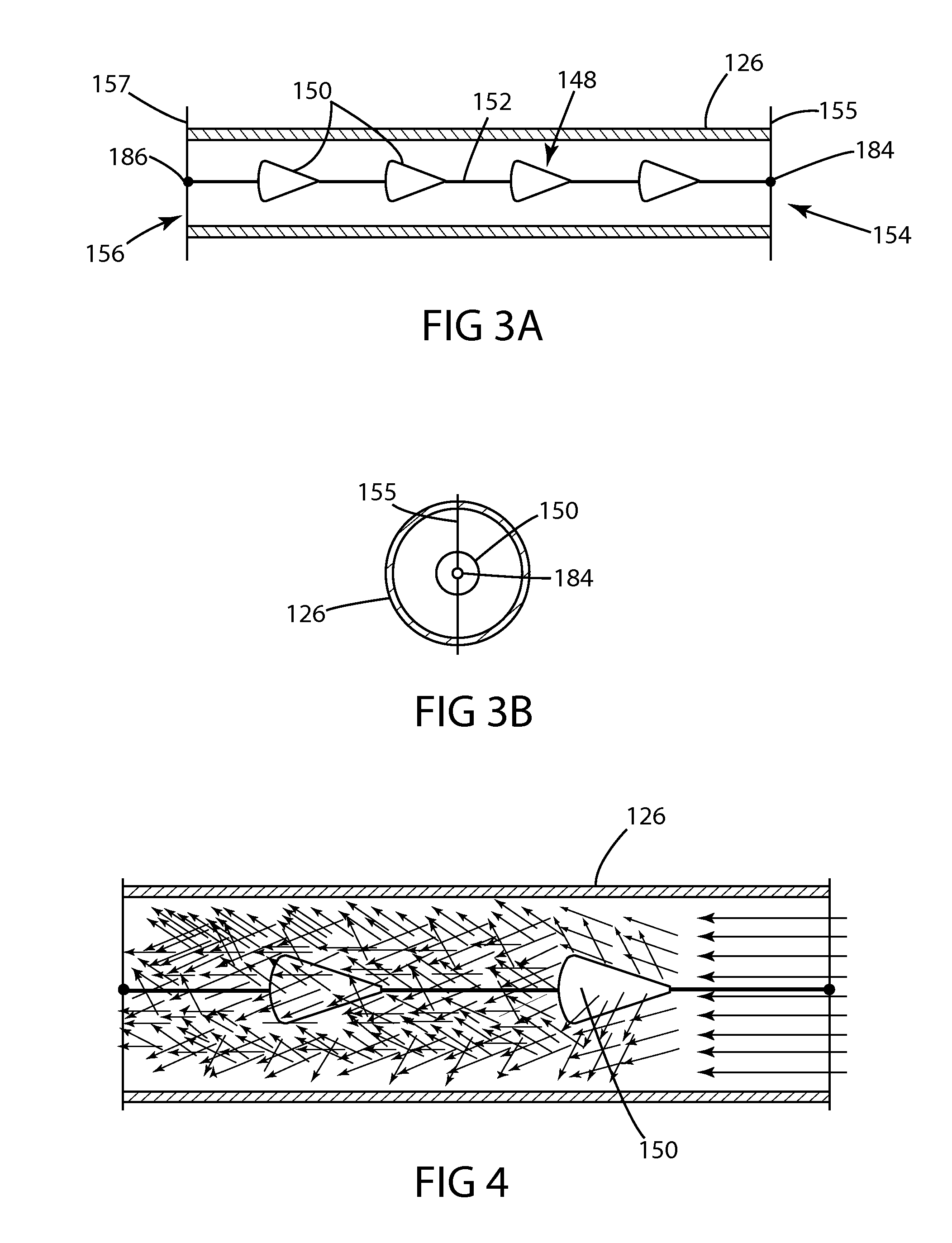

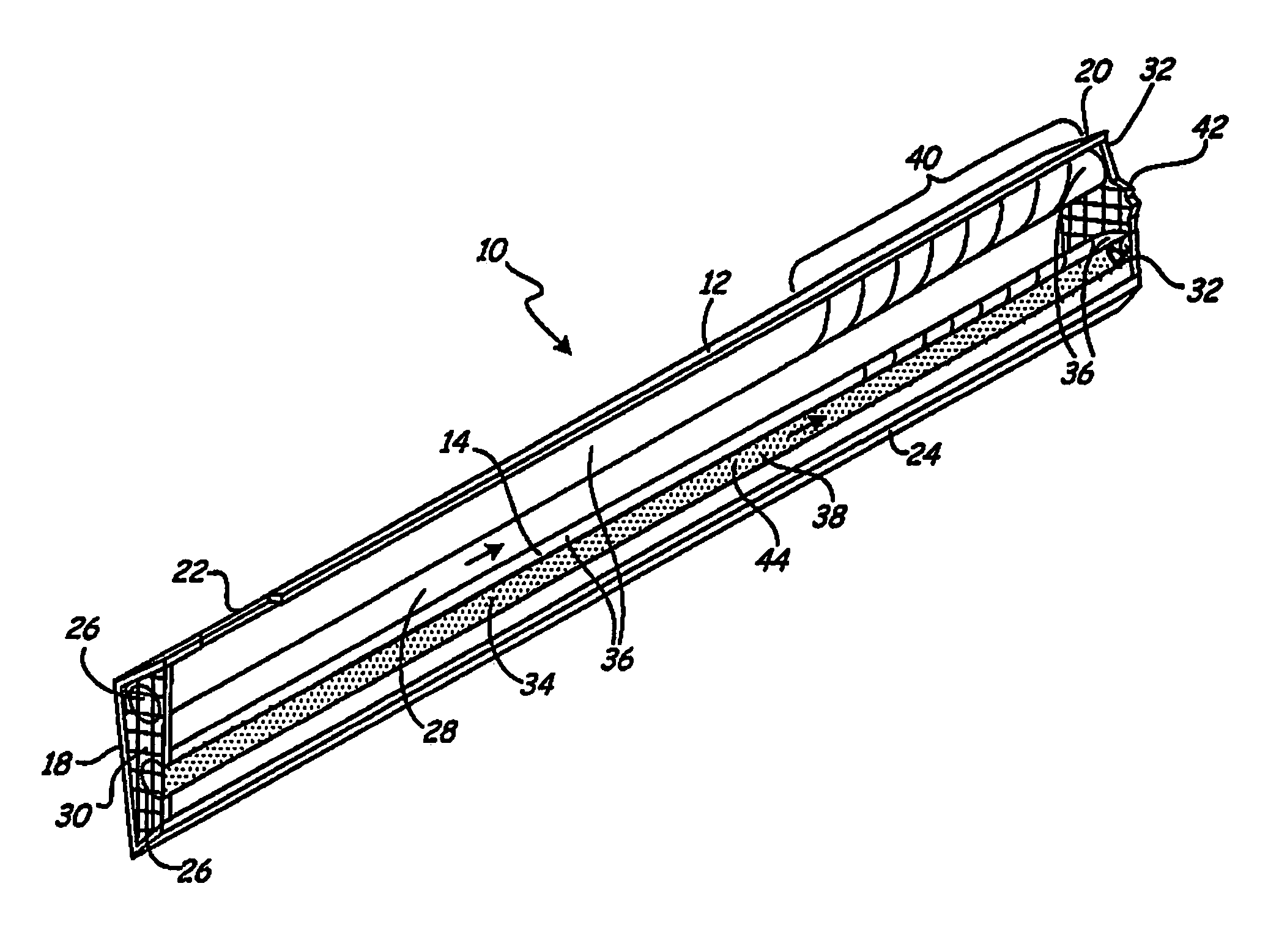

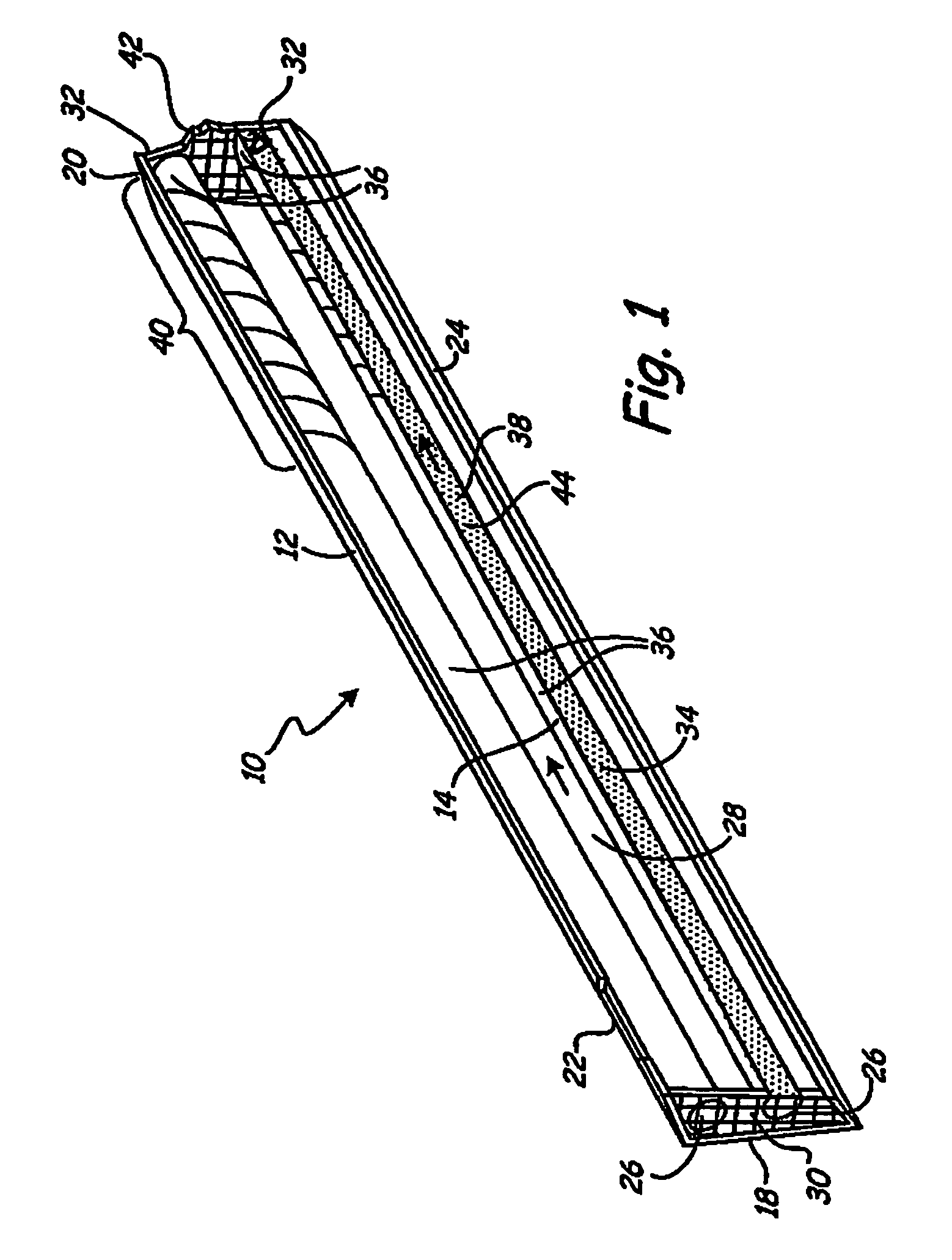

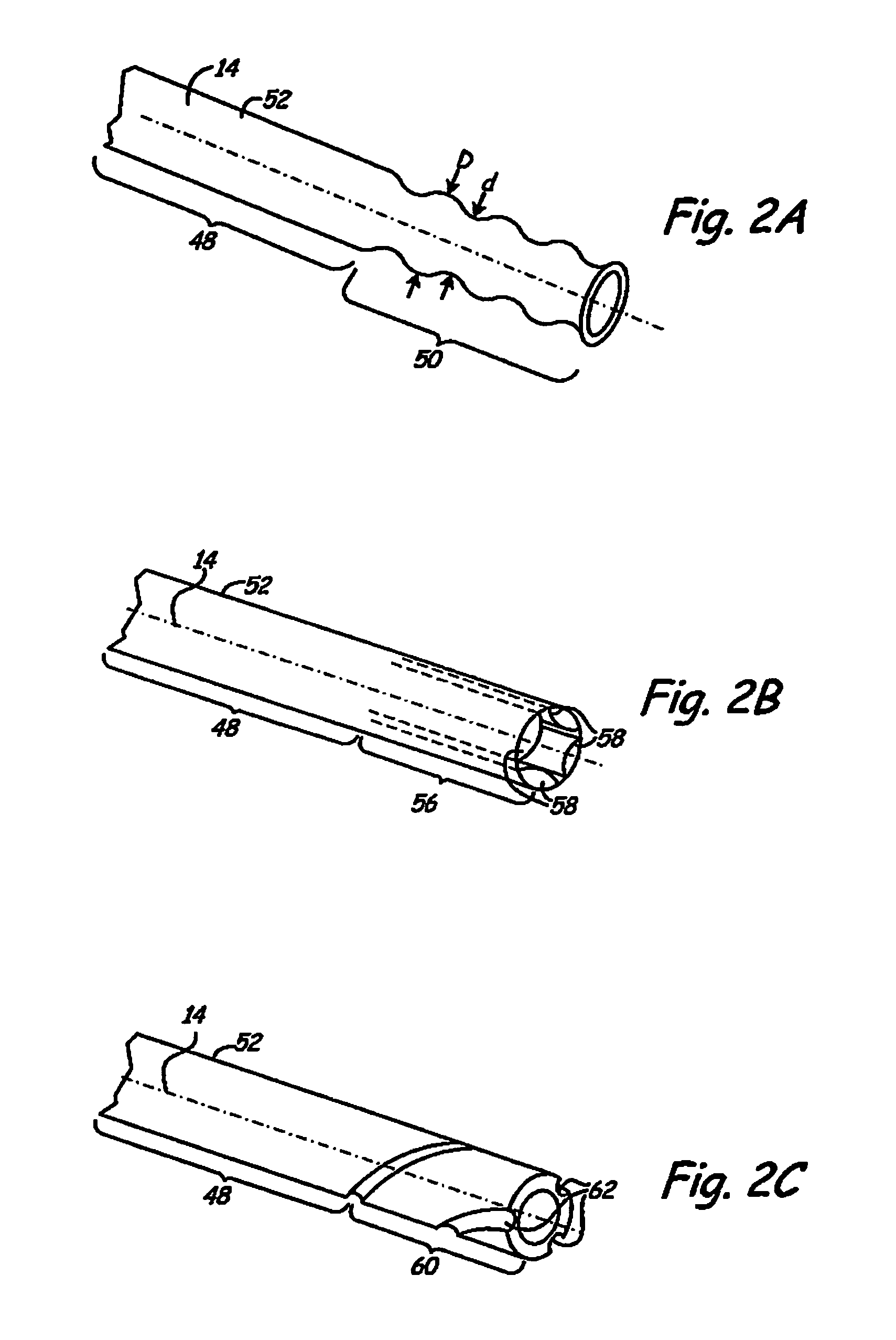

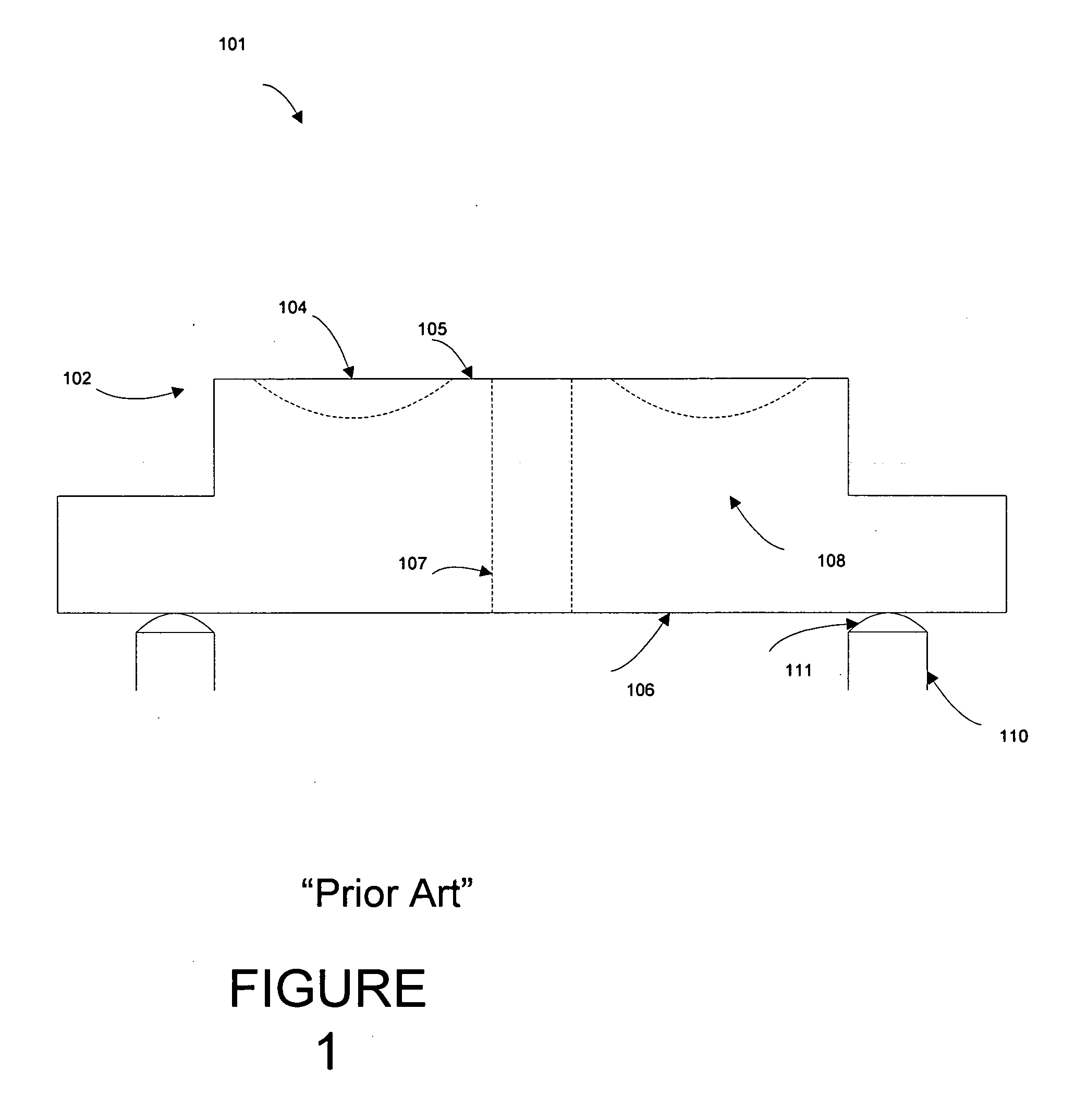

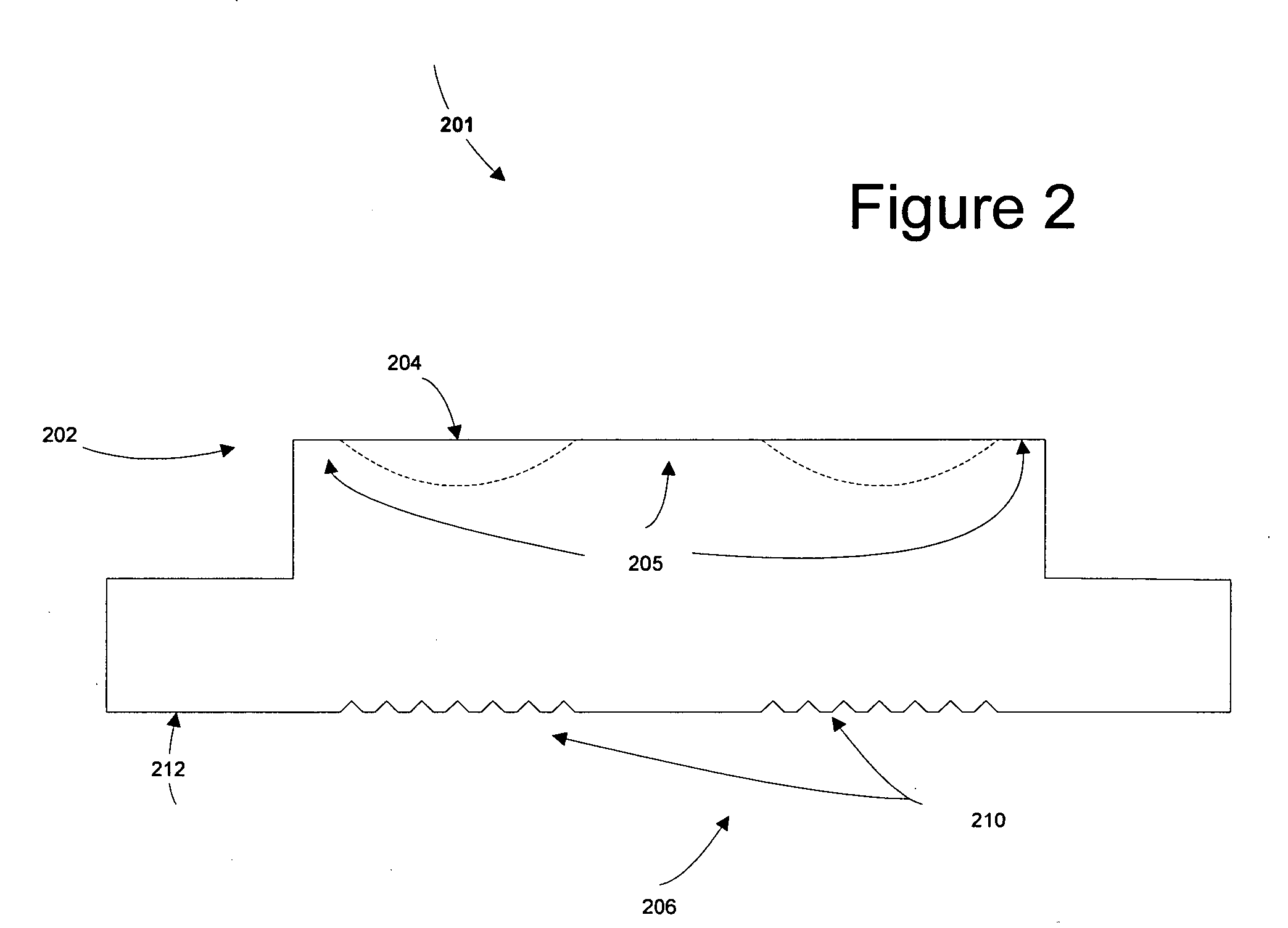

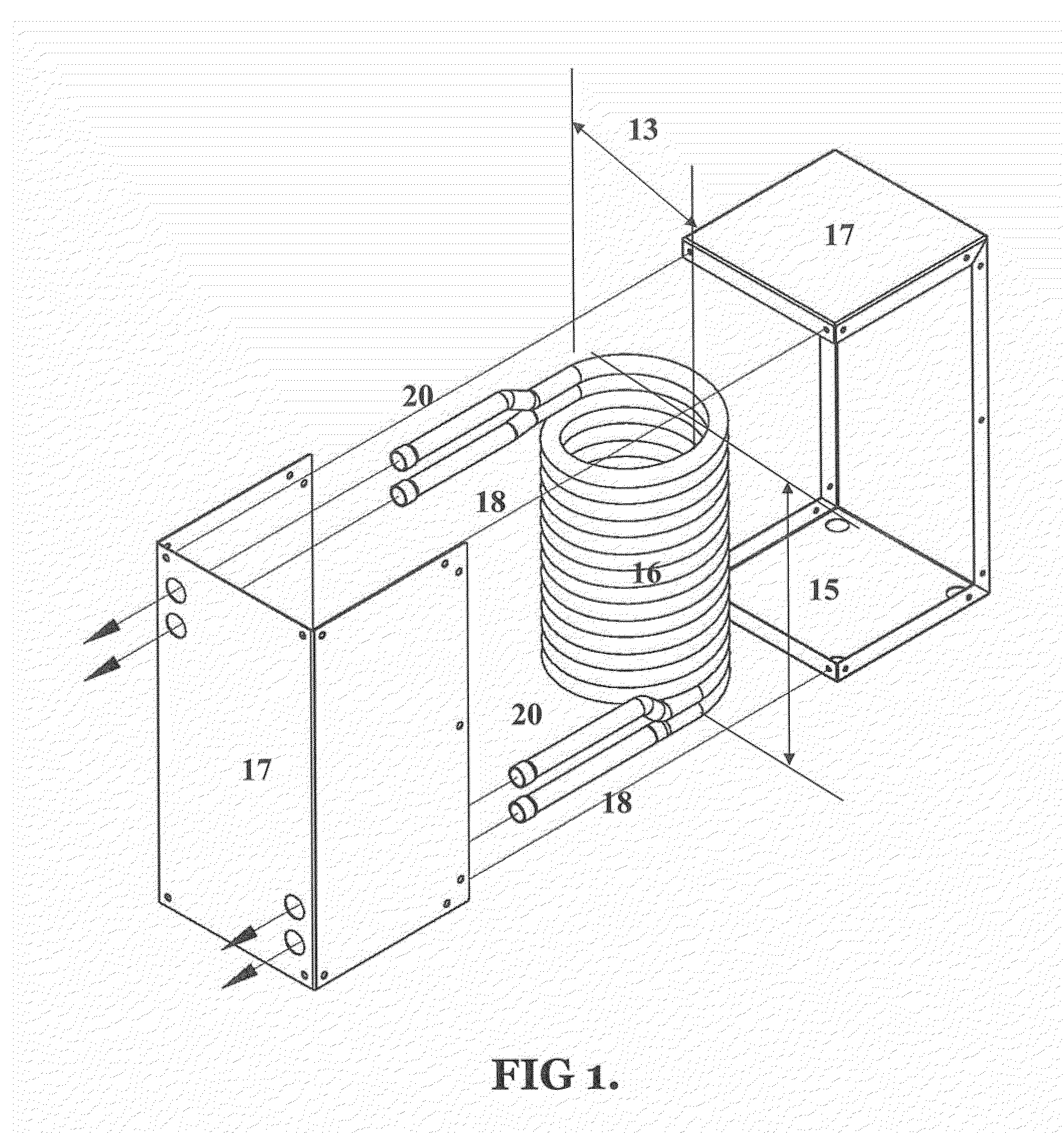

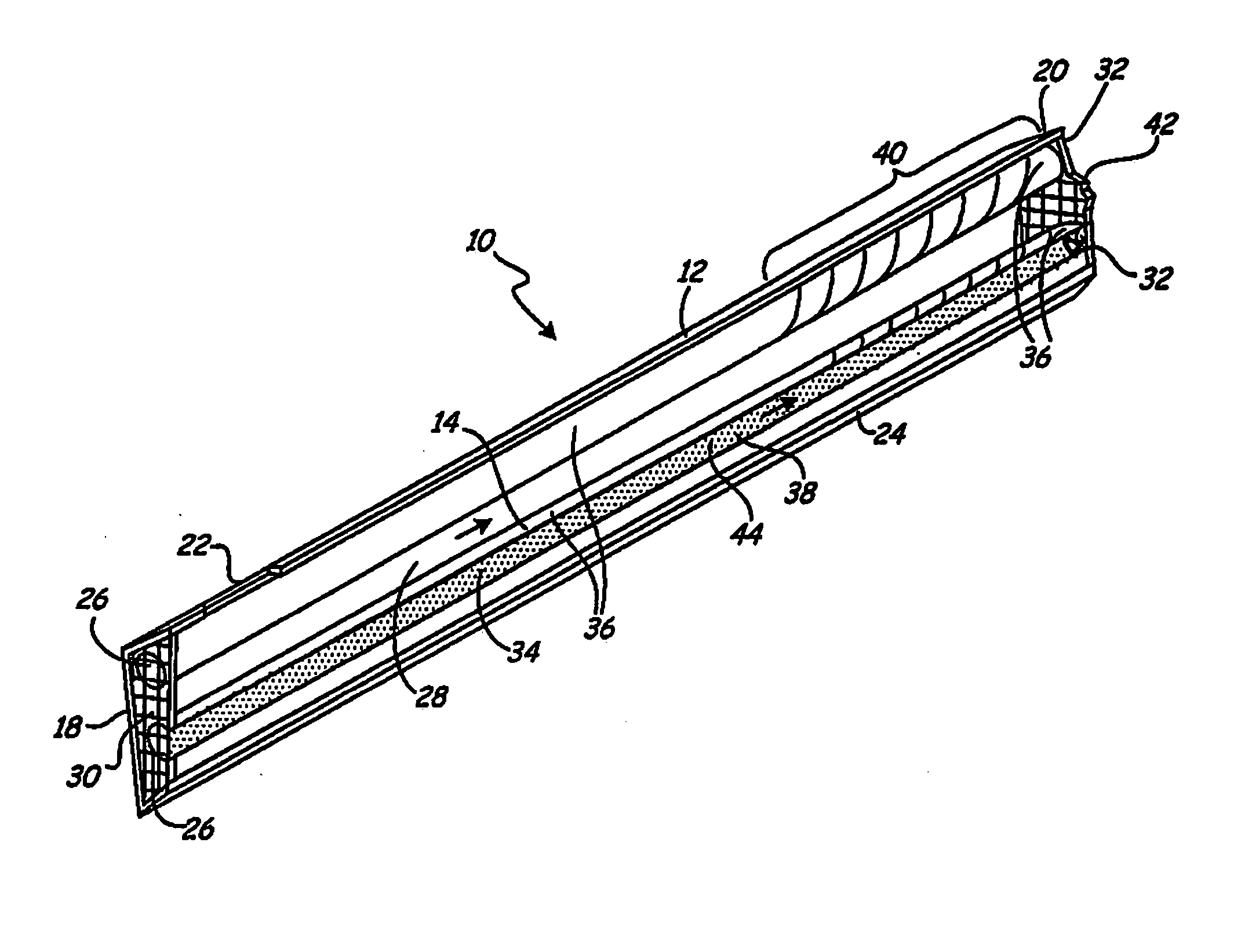

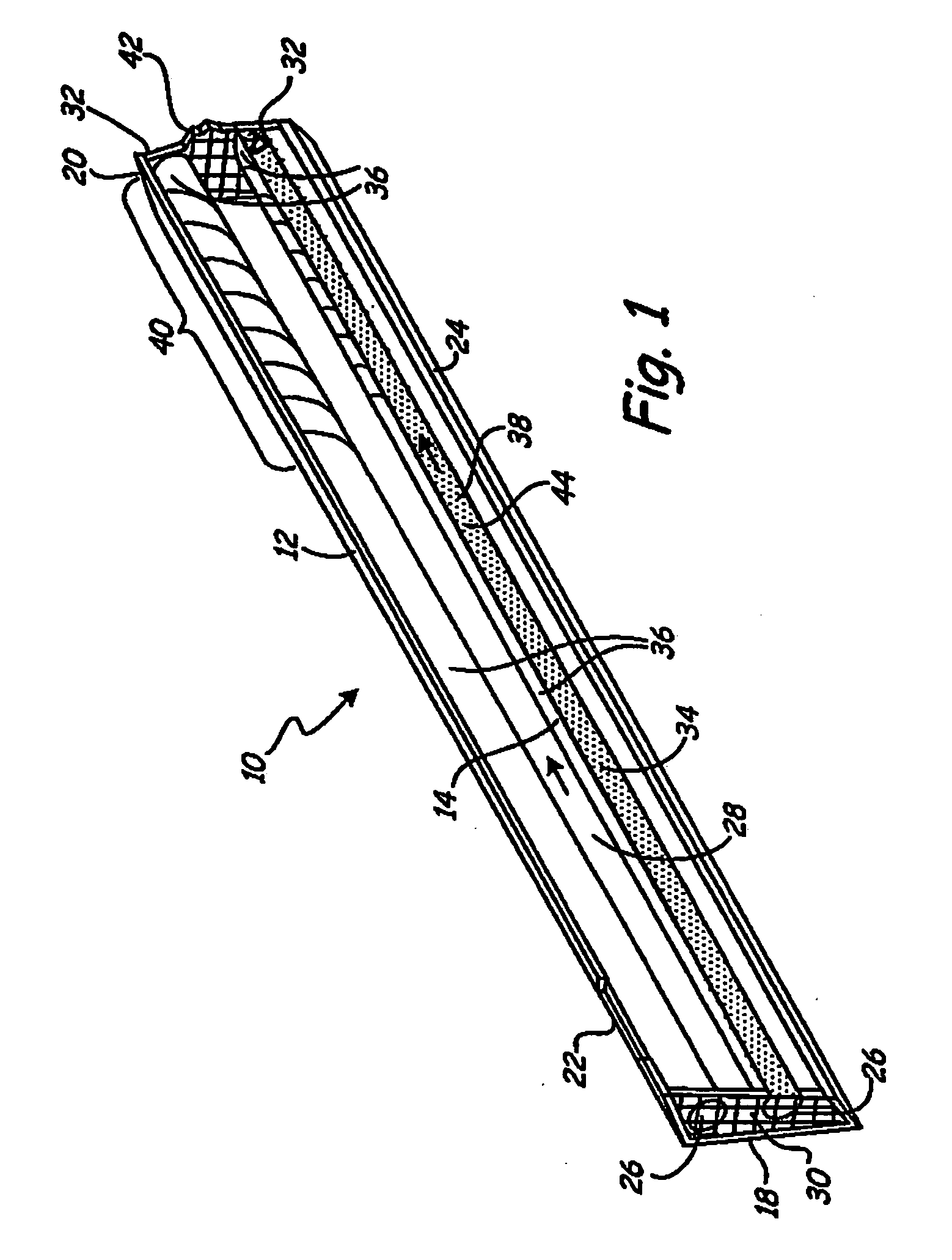

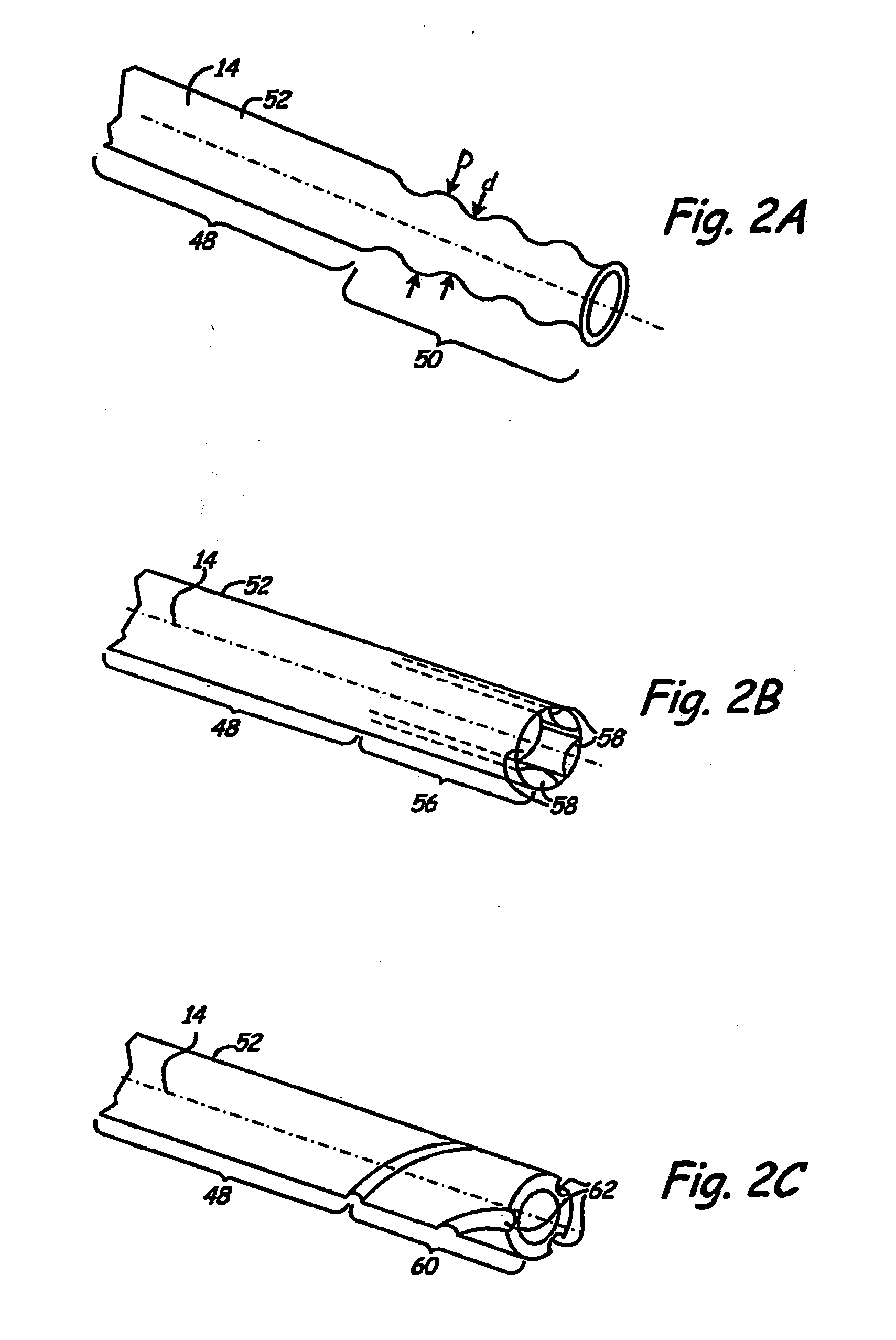

Turbulence-inducing devices for tubular heat exchangers

ActiveUS20120298340A1Promote turbulenceAvoid accumulationFluid heatersPipe elementsPlate heat exchangerEngineering

A heat exchanger tube for conveying a heat transfer fluid, into which one or more turbulence-inducing elements of prescribed configuration(s) are fixedly positioned on a supporting member extending in spaced relation along the central axis of the tube, for the purpose of inducing turbulence in the heat transfer fluids and to minimize or prevent fouling inner surface of the tube to thereby enhance or maintain the heat transfer coefficient over the operational life of the tube.

Owner:SAUDI ARABIAN OIL CO

Controllable combustion method and device

InactiveUS6938588B2High bandwidthFast energy extractionPulsating combustionFuel-injection pumpsCombustionEngineering

A method and device for controllably combusting combustible material, including a combustion device comprising an elongate combustion tube having an inlet section including an inlet for combustible material, an ignition section, including an igniter displaced along a length of the tube from the inlet section to ignite the combustible material, and at least one energy extraction device operatively coupled to the combustion tube and configured to extract energy from combustion of the combustible mixture.

Owner:SARCOS LC

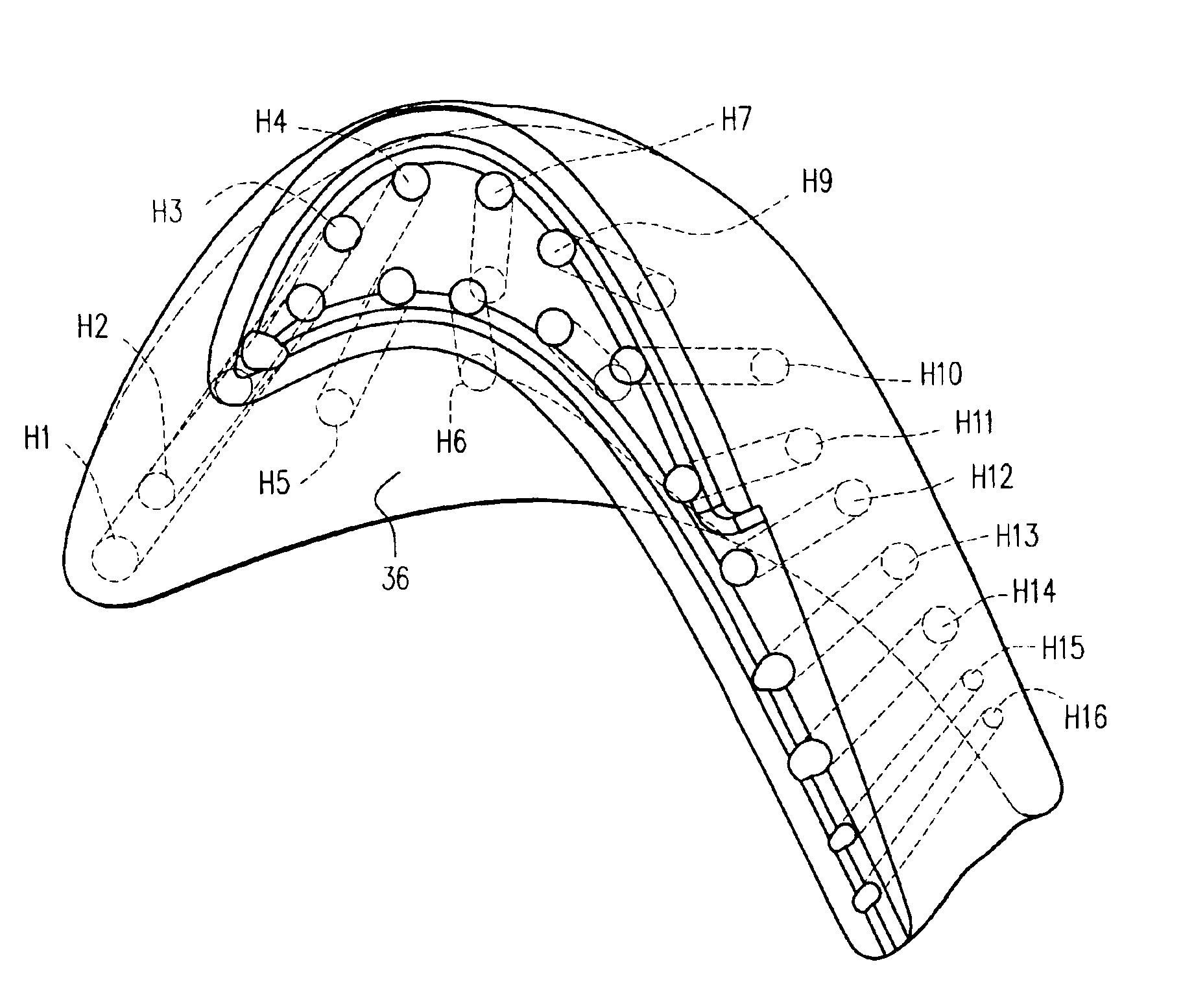

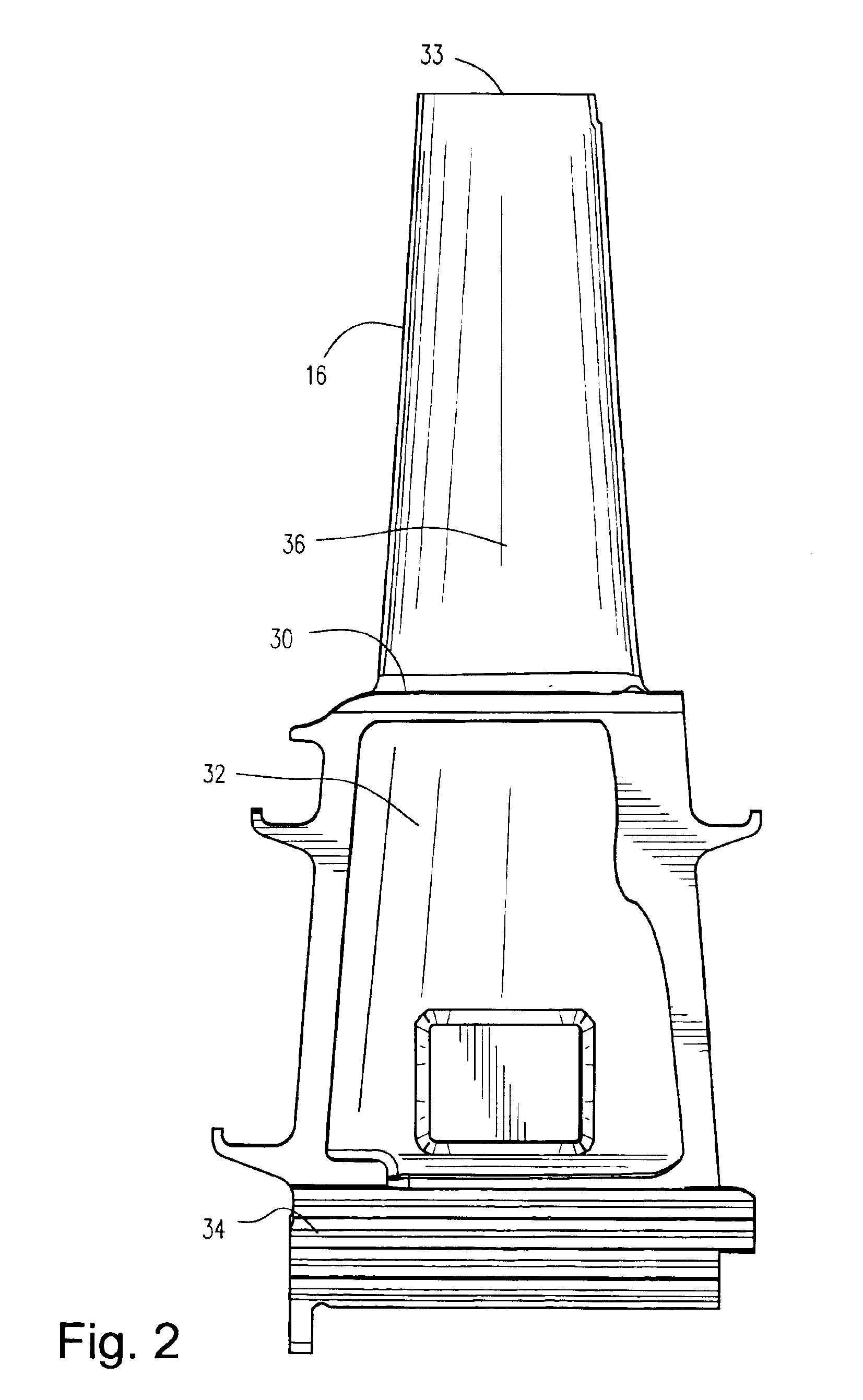

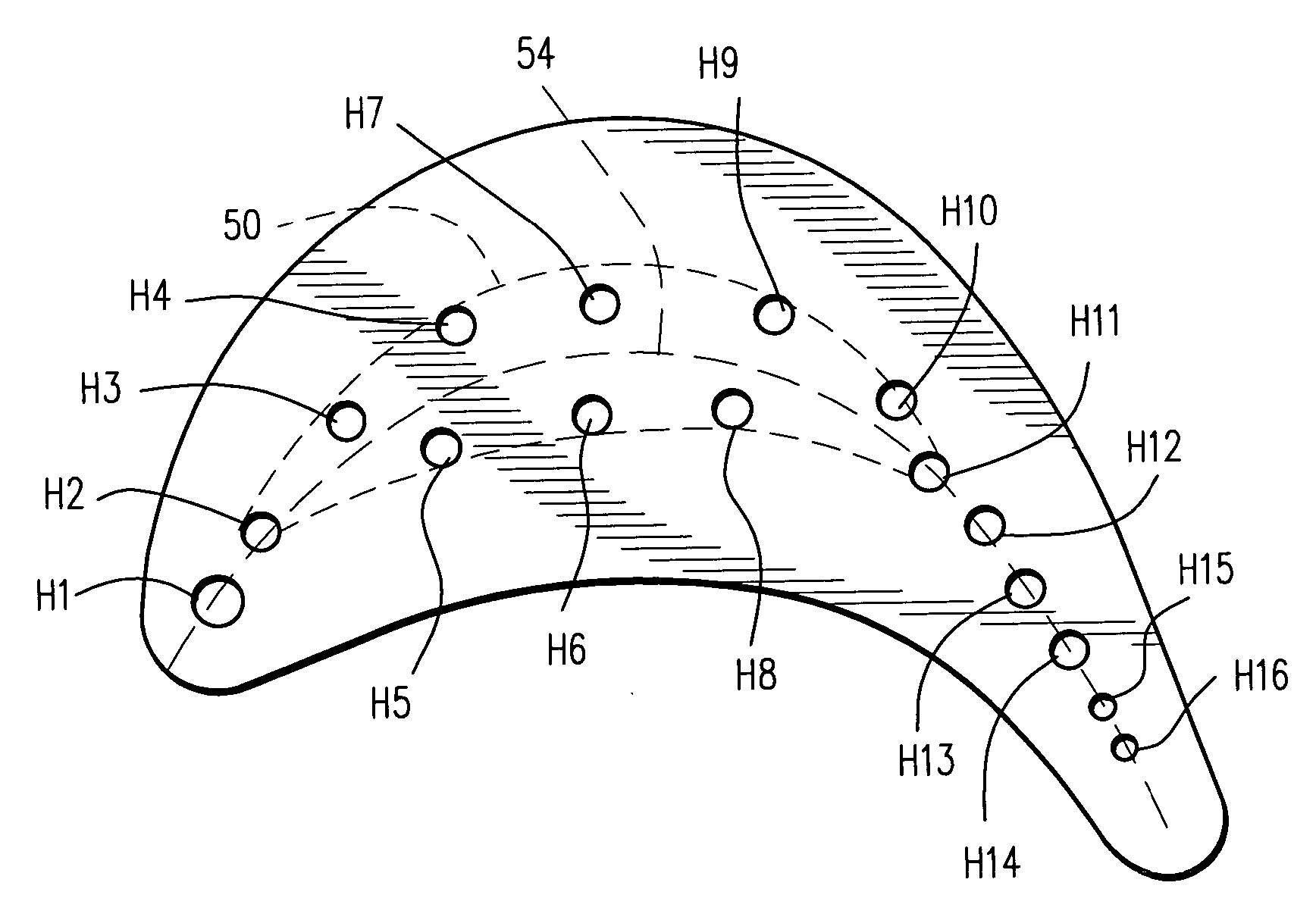

Perimeter-cooled turbine bucket airfoil cooling hole location, style and configuration

InactiveUS6923623B2Improve turbine efficiencyPromote turbulenceOther chemical processesEngine fuctionsTurbine bladeZ-Coordinate

A turbine stage one bucket has an airfoil having a plurality of cooling holes passing through the airfoil from 0% span to 100% span whereby cooling air exits the airfoil tip into the hot gas path. X and Y coordinate values are given in Table I, locating the holes relative to the airfoil profile at airfoil profile sections of 5%, 50% and 90% span, Table I also giving the hole diameters. In this manner, cooling hole optimization for this turbine bucket airfoil is achieved. The cooling holes are also located in relation to the profile of the bucket airfoil given by the X, Y and Z coordinate values of Table II, the two coordinate systems having the same origin.

Owner:GENERAL ELECTRIC CO

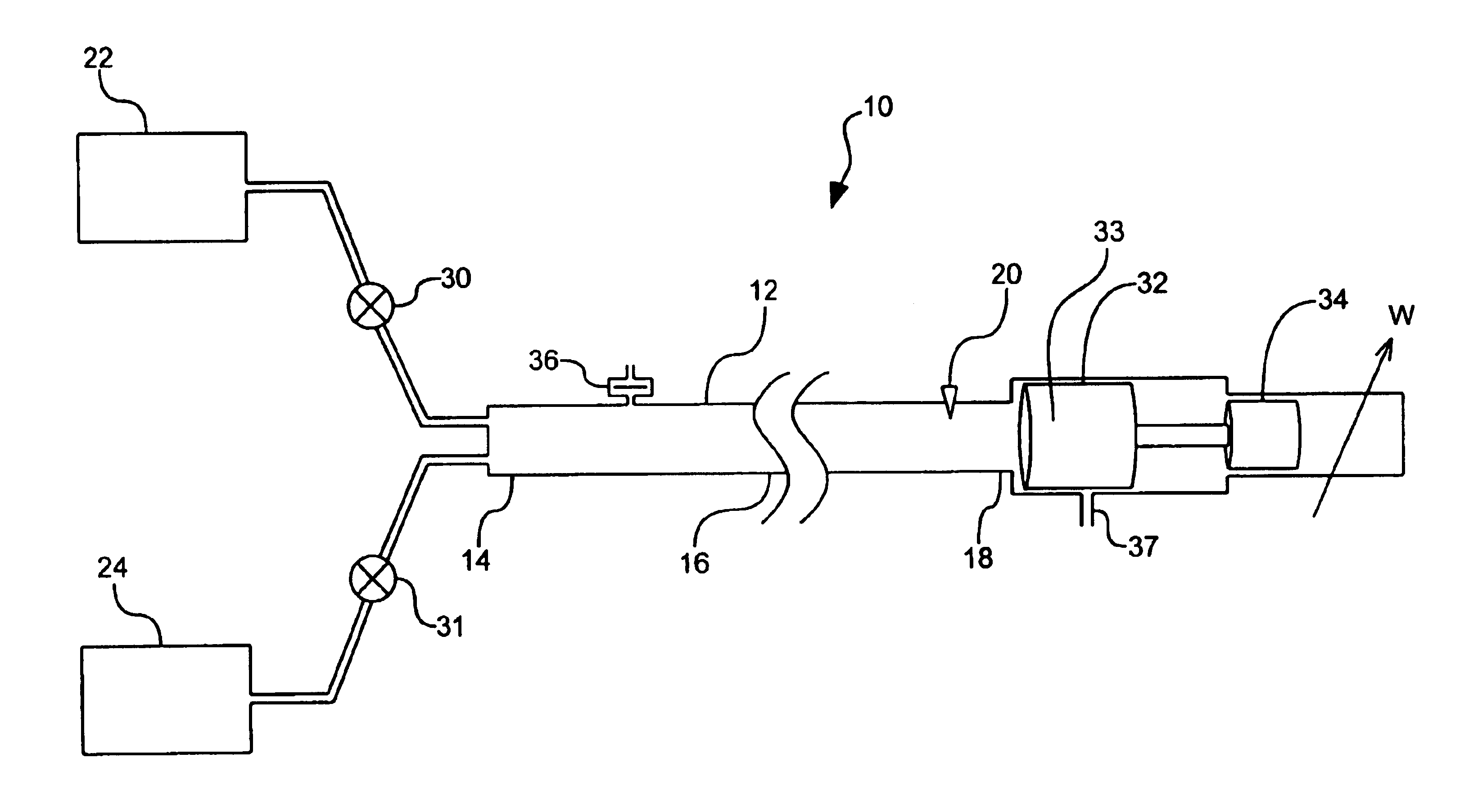

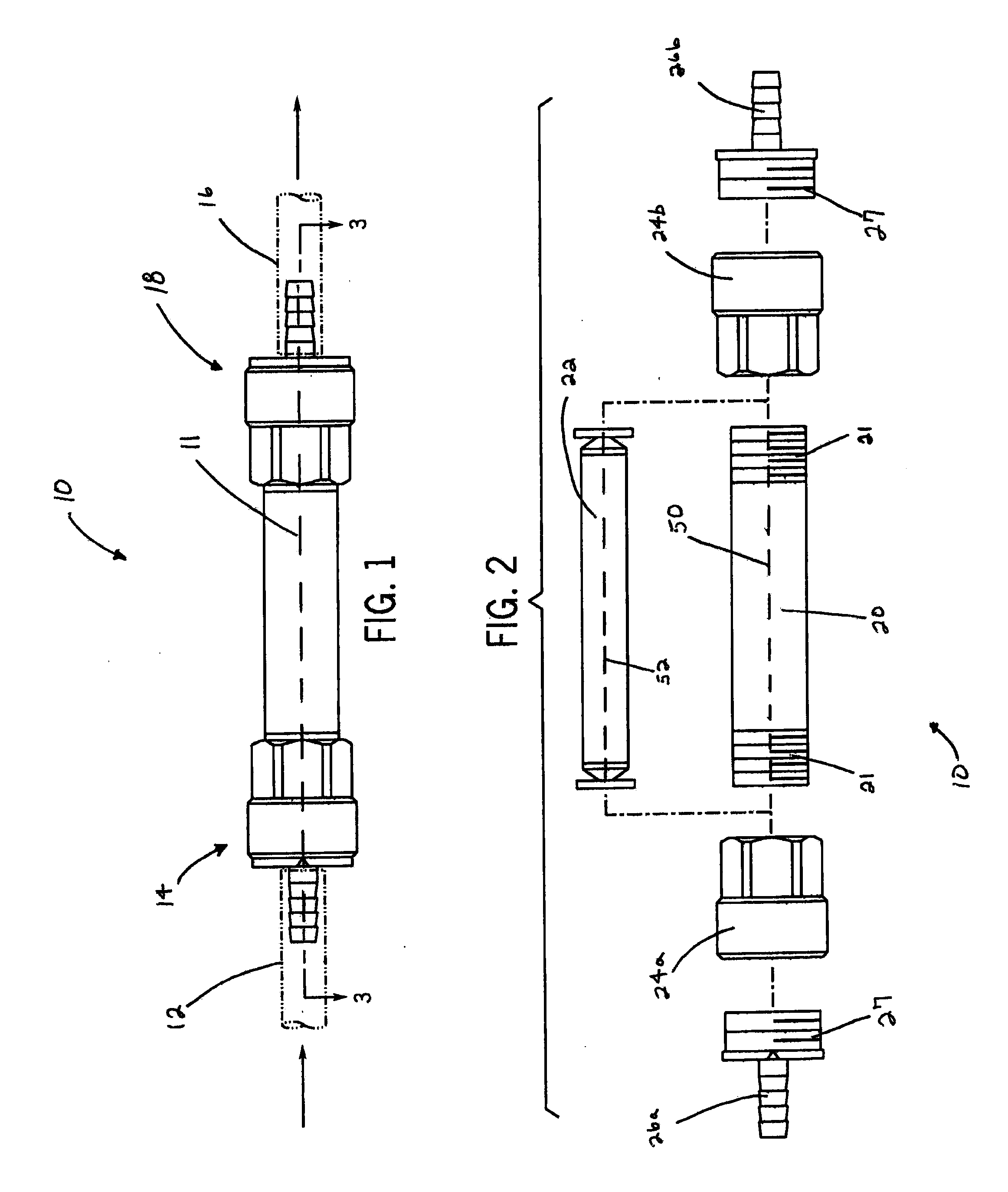

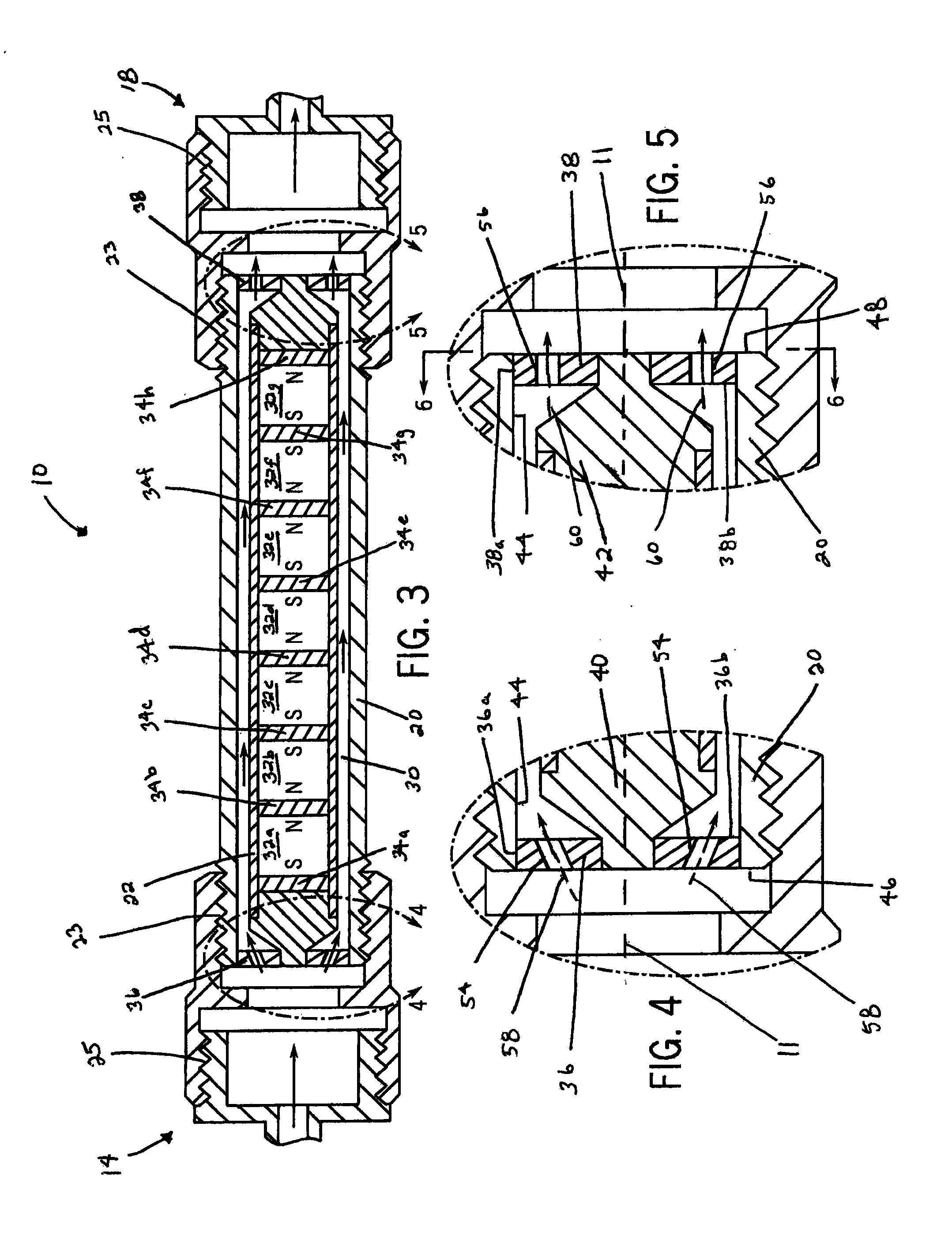

In-line fuel conditioner

ActiveUS20120067802A1Improve flammabilityEmission reductionElectrostatic separationWater/sewage treatment by magnetic/electric fieldsNuclear engineeringLiquid fuel

A fuel conditioner is provided for improving fuel combustibility and reducing emissions into the environment. The fuel conditioner may be placed in-line in a fuel delivery system for internal combustion engines and may include the following components: a first housing defining a sealed chamber, a fuel inlet in fluid communication with the sealed chamber, a second housing disposed within the sealed chamber, a magnet disposed in the second housing, a fuel outlet in fluid communication with the sealed chamber, and a flow path in the sealed chamber for flow of the liquid fuel between the fuel inlet and the fuel outlet. Along its flow path, the liquid fuel is split apart and passes through magnetic fields due to one or more magnets inside the second housing to condition the fuel to improve fuel combustibility and reduce toxic emissions.

Owner:IRVIN WALLACE TAYLOR

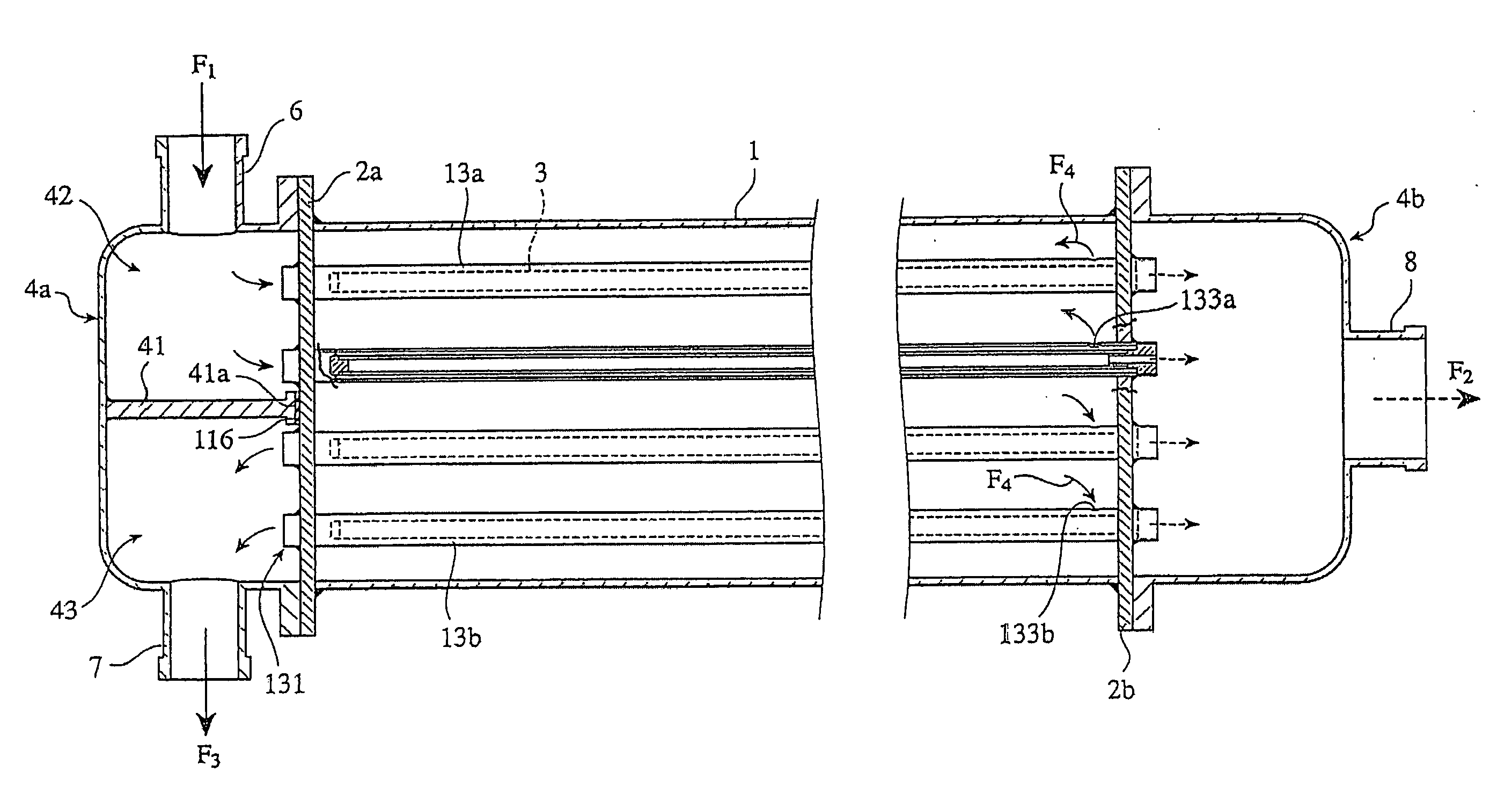

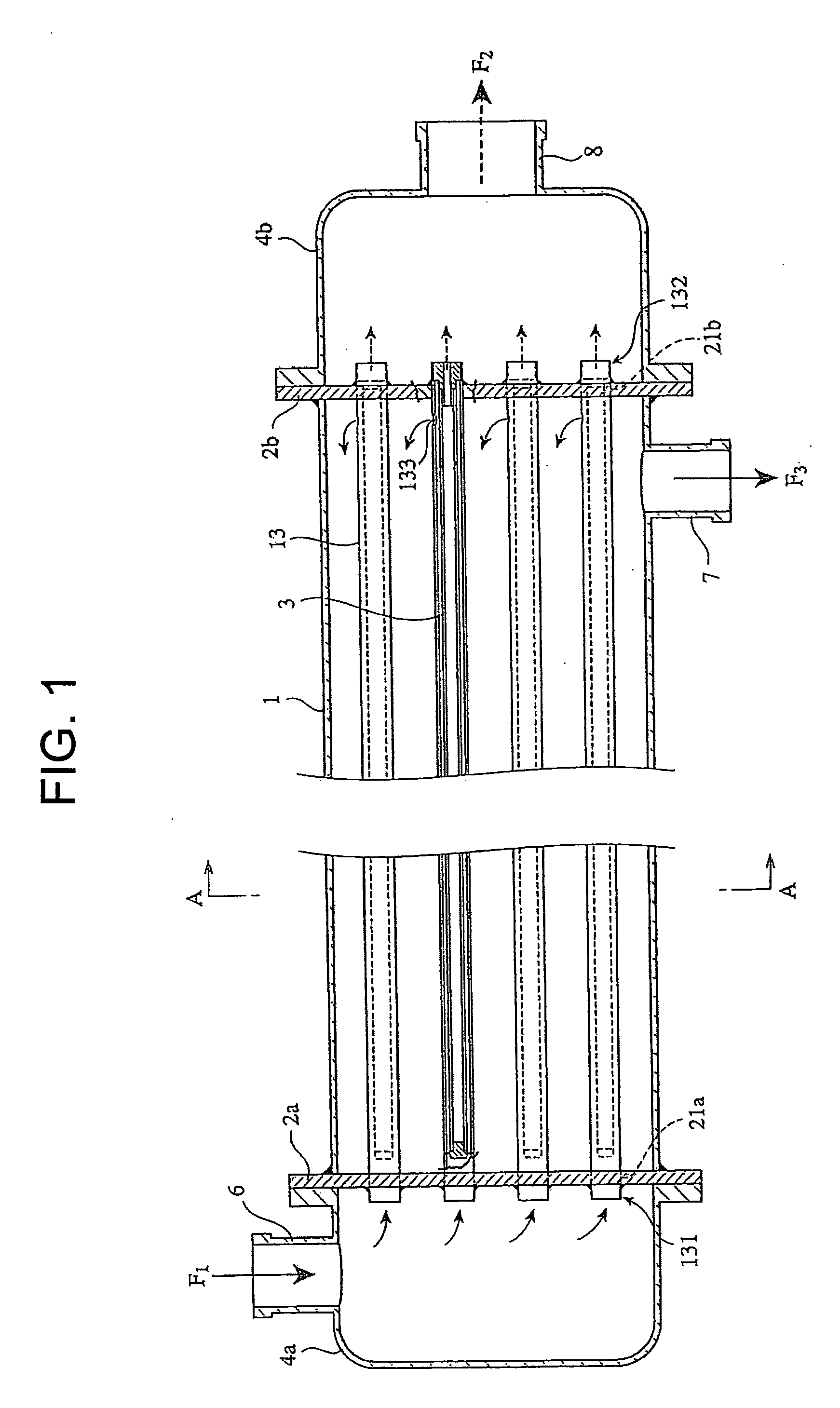

Multi-tube separation membrane module

InactiveUS20060011535A1Take advantage ofPromote turbulenceSemi-permeable membranesDispersed particle separationEngineeringTubes types

Owner:BUSSAN NANOTECH RES INST

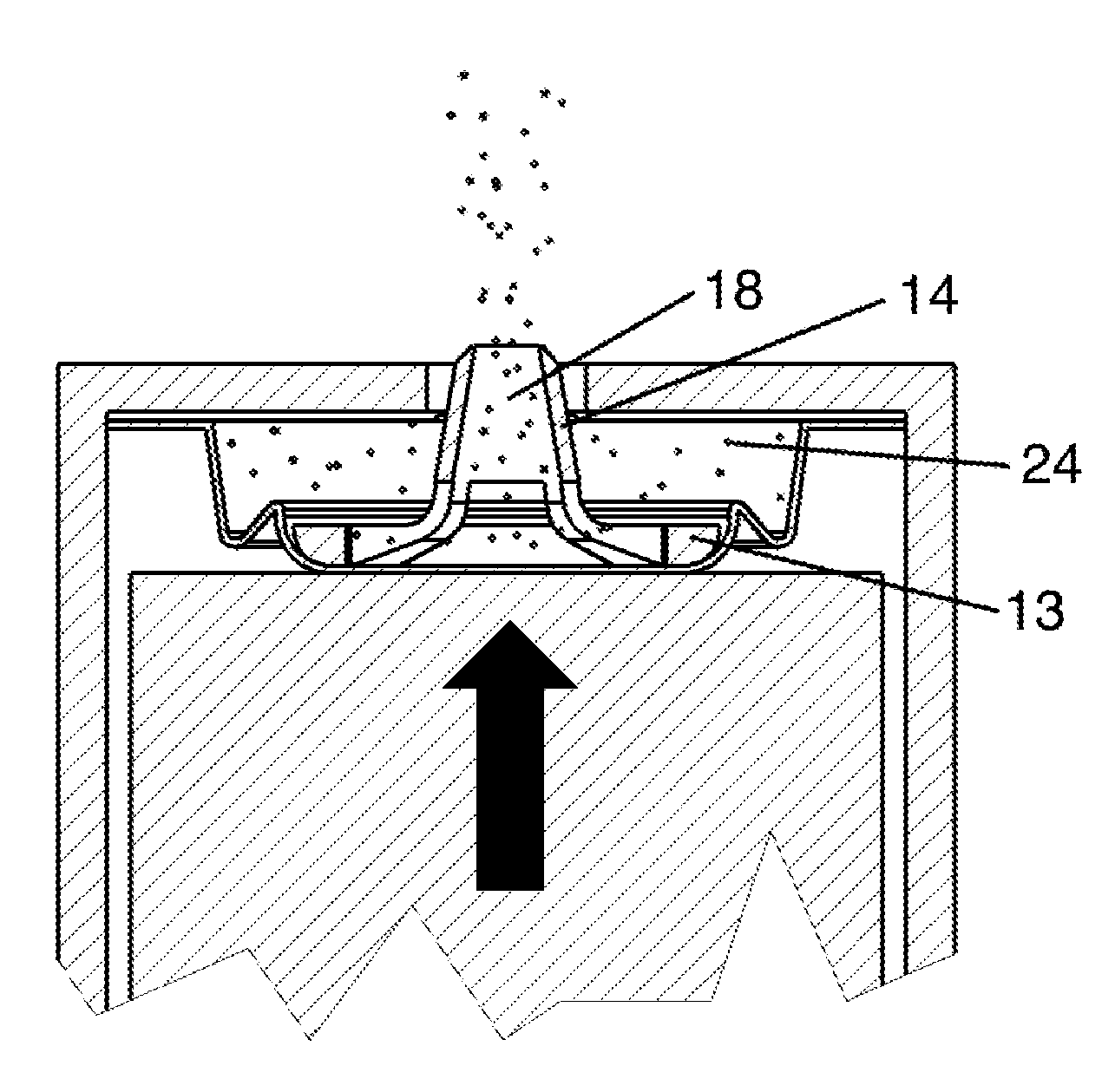

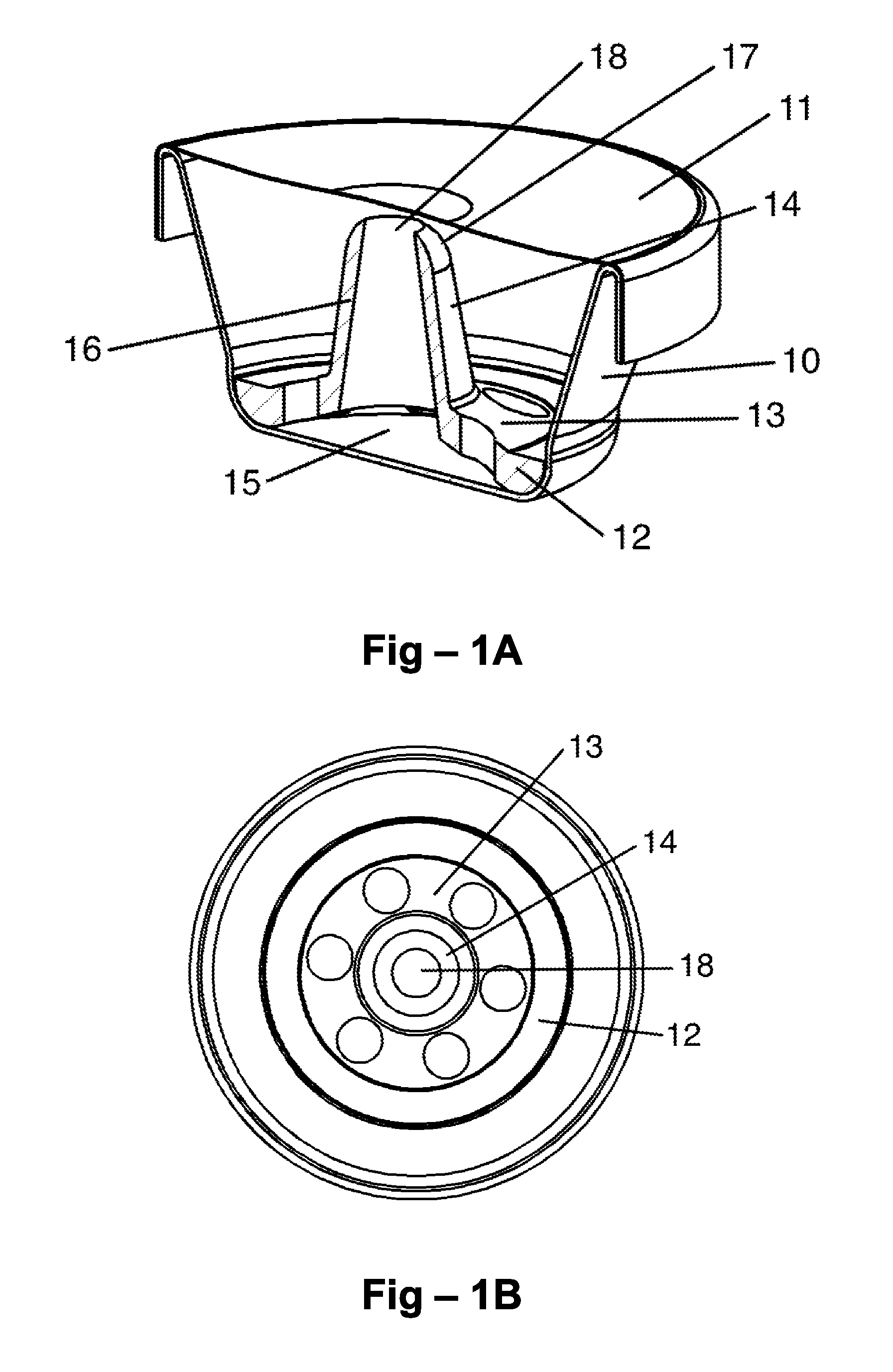

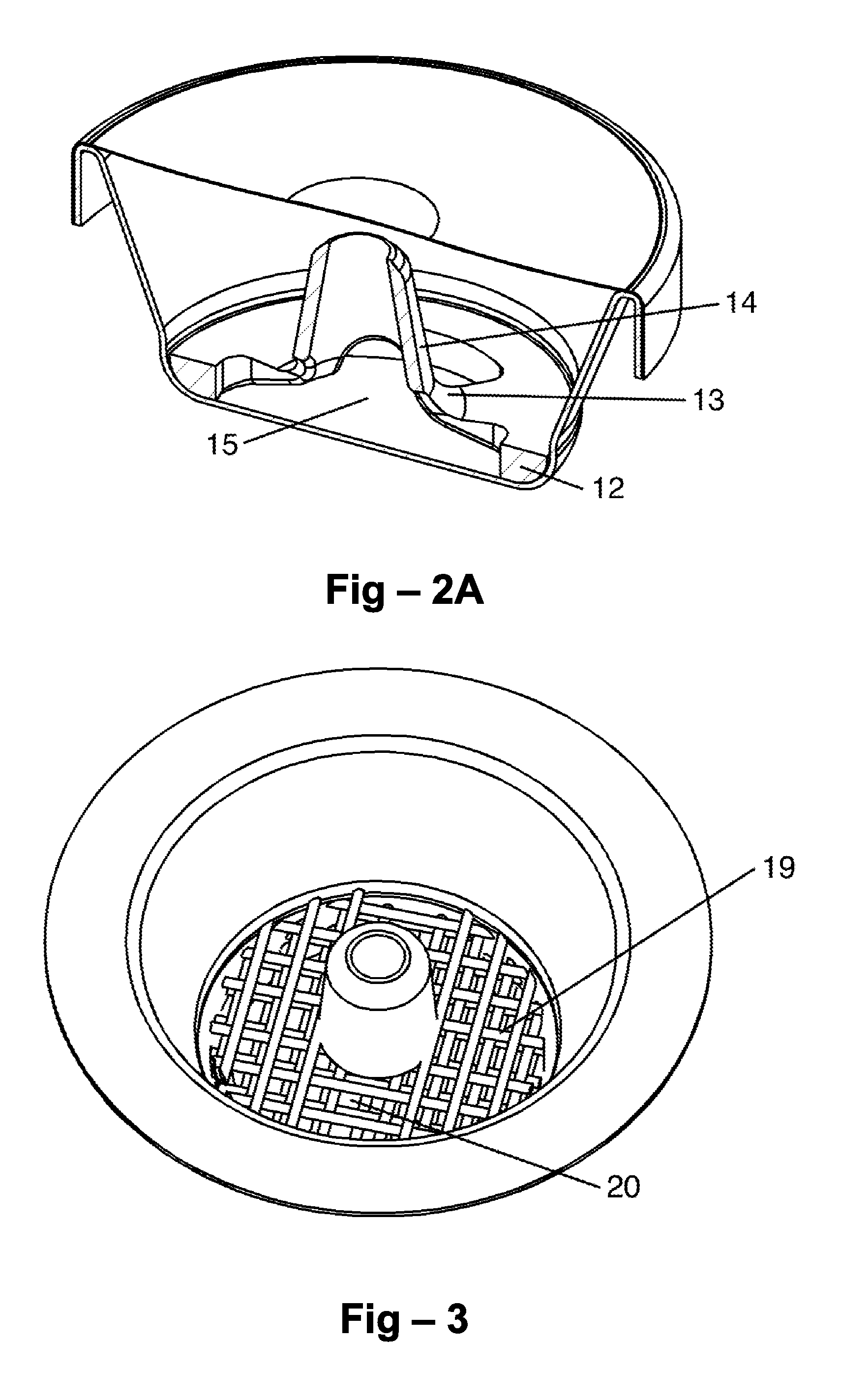

Medical devices for dispensing powders

A medical device for topical, intranasal or oral administration of dry powder medical compositions includes a unit dose blister form containing an internal piercing device that provides for agitation, dispersion and dispensation of the powder to a user.

Owner:MYSTIC PHARMA INC

Catalytic reactor with swirl

InactiveUS7727495B2Promote combustionSimple designCatalytic gas-gas reactionSemi-permeable membranesCombustorEngineering

A catalyst conduit for a catalytic reactor of a turbine combustor, the conduit comprising a tube including an inlet and an outlet, and a wall with an interior surface and an exterior surface. The tube contains a variation in its cross sectional area along at least a portion of its length to change a property of a fluid flowing adjacent the wall of the tube. An oxidation catalyst is deposited on at least a portion of the tube.

Owner:UNITED TECH CORP

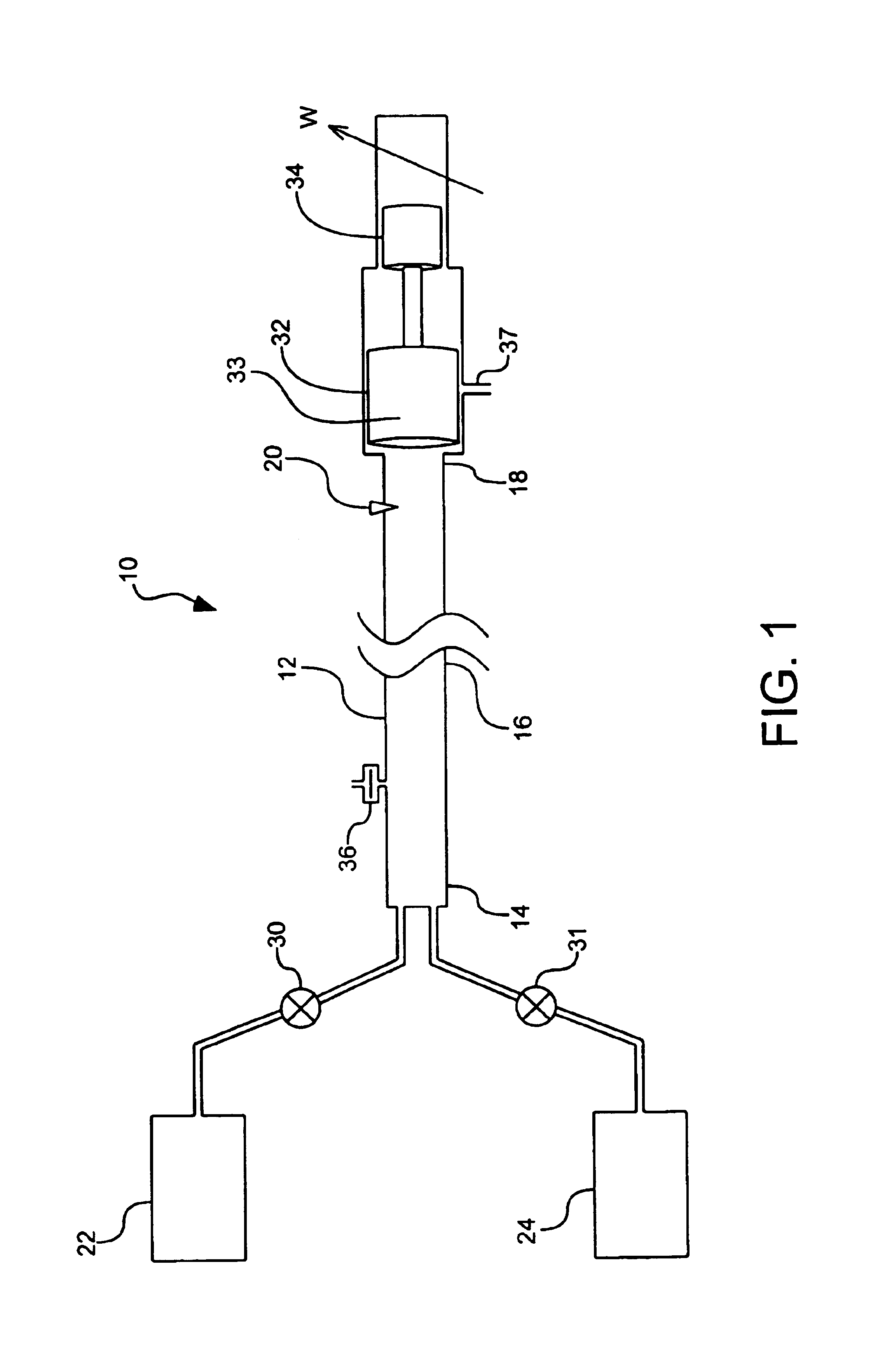

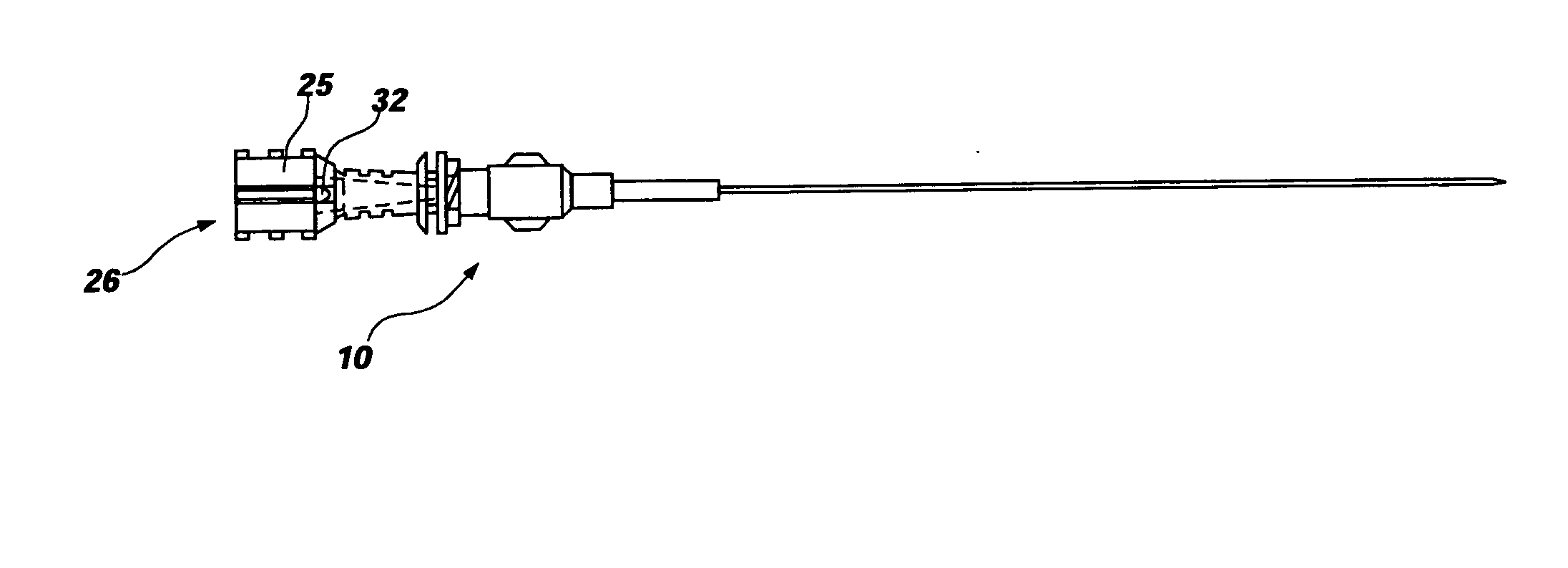

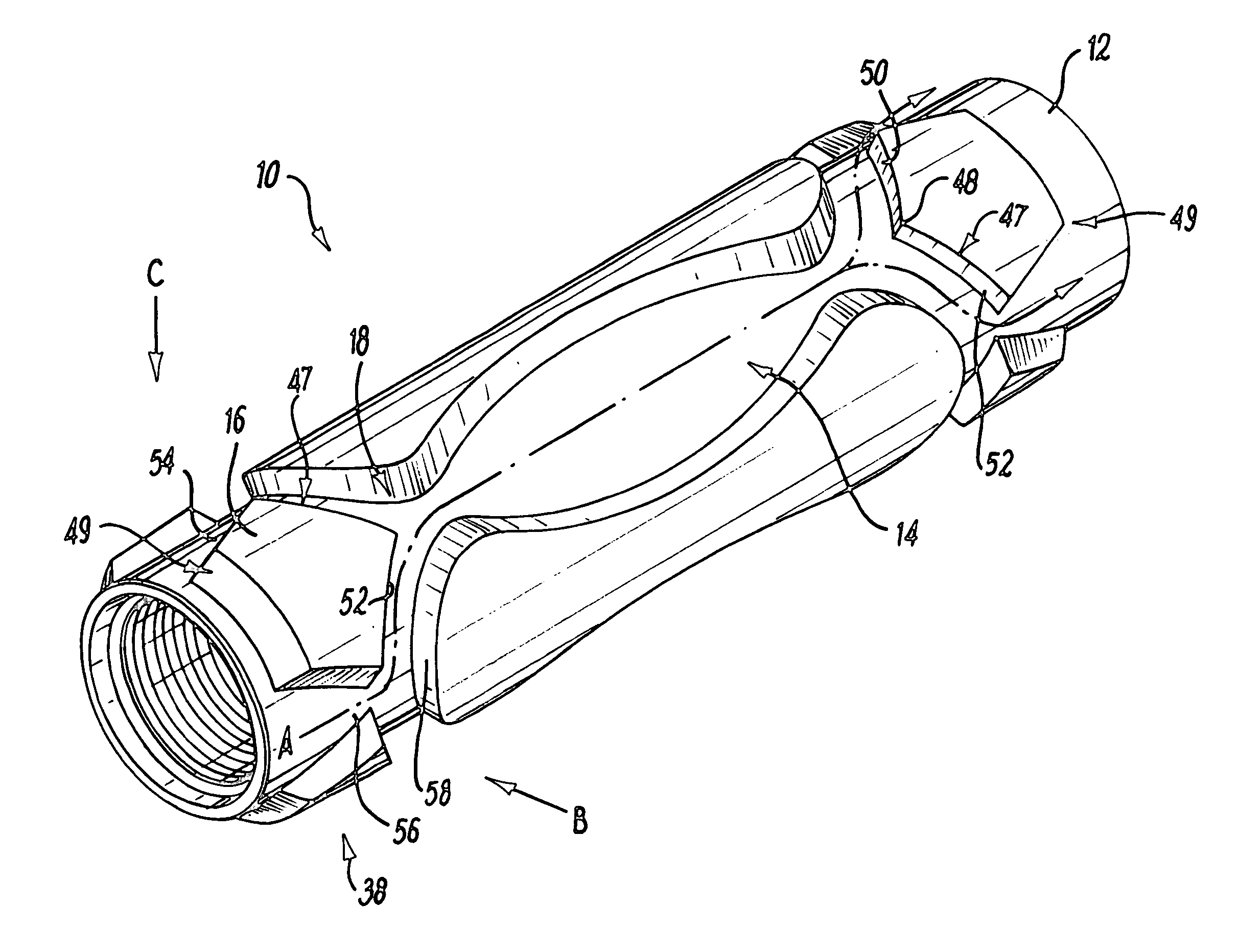

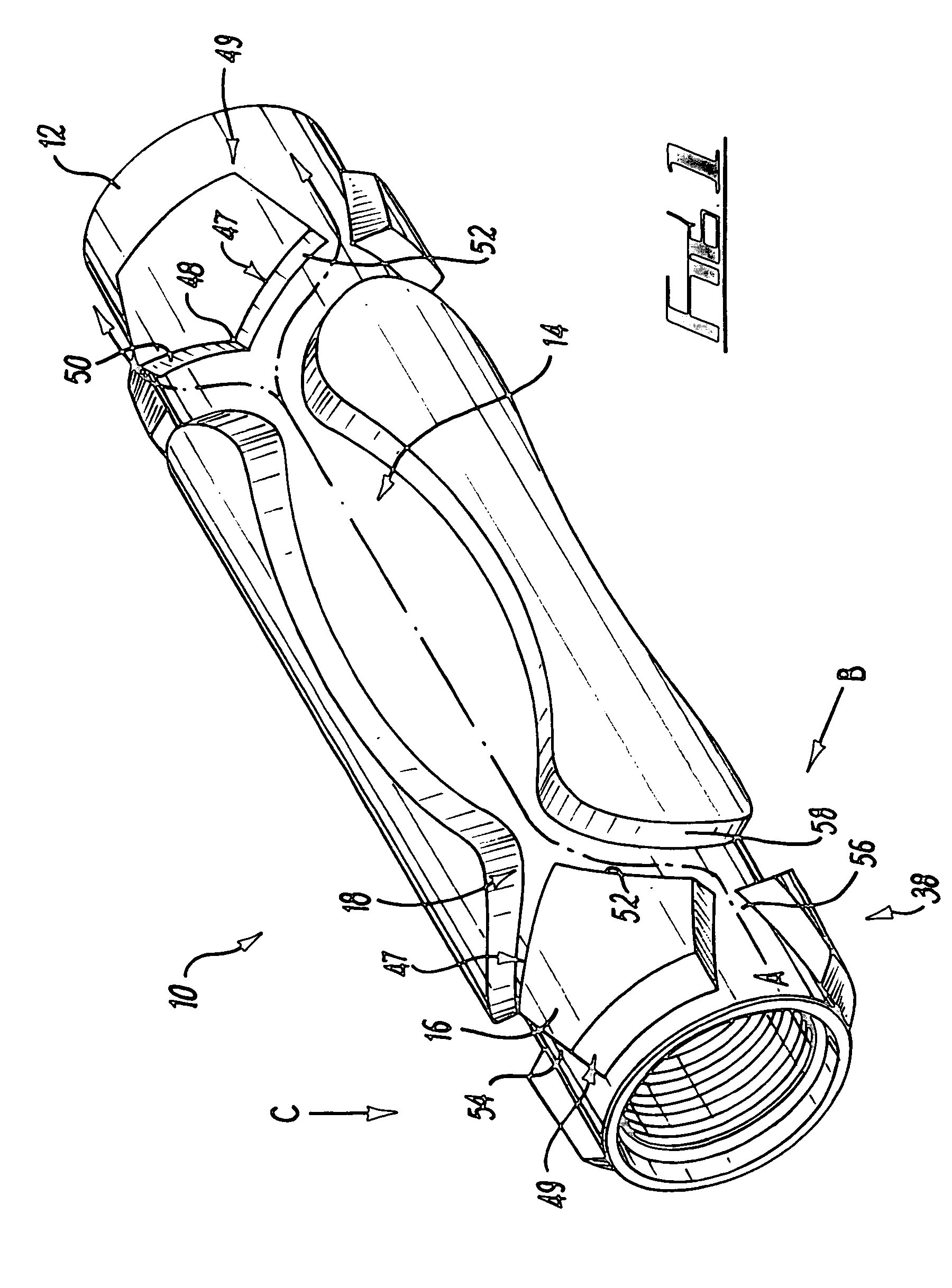

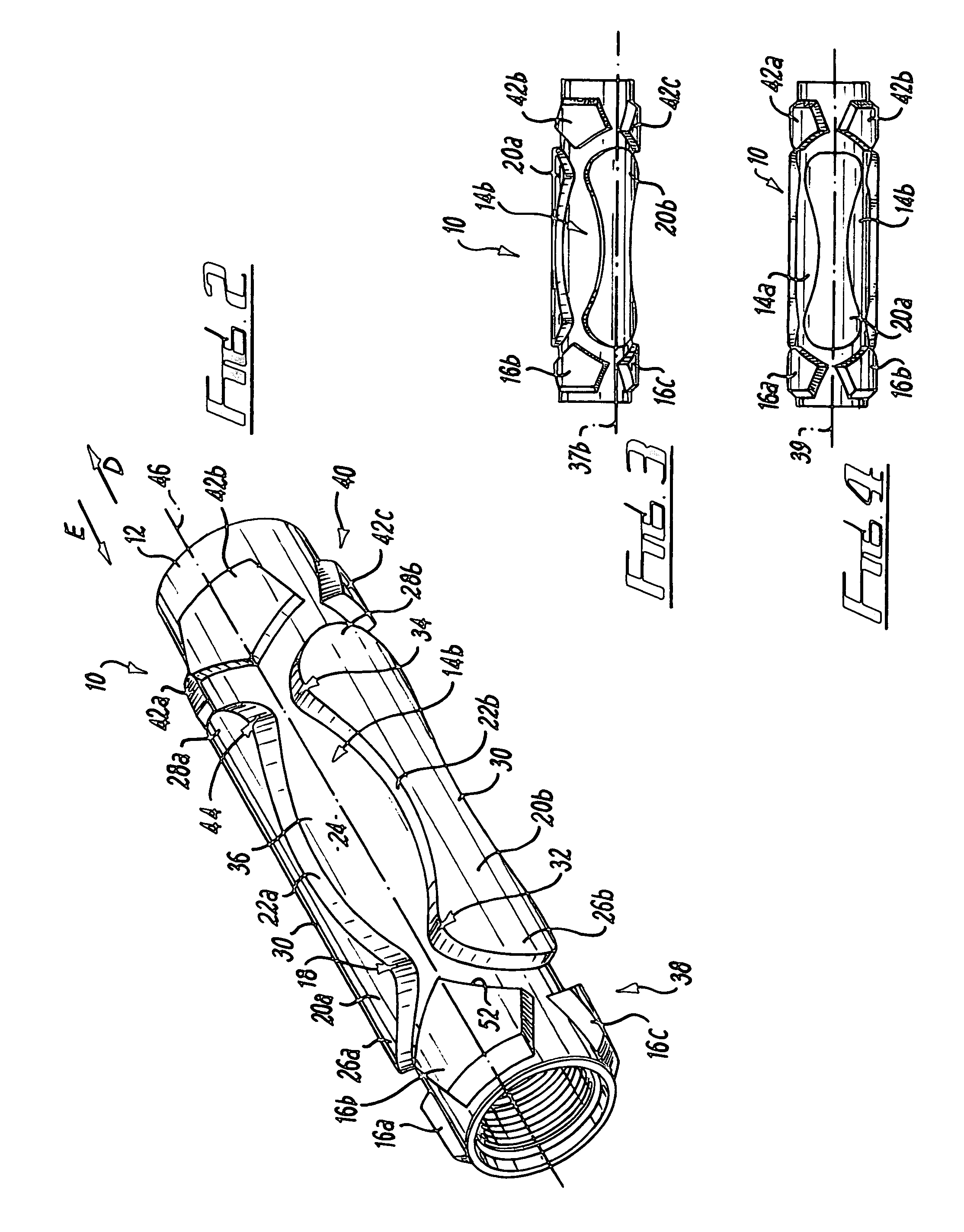

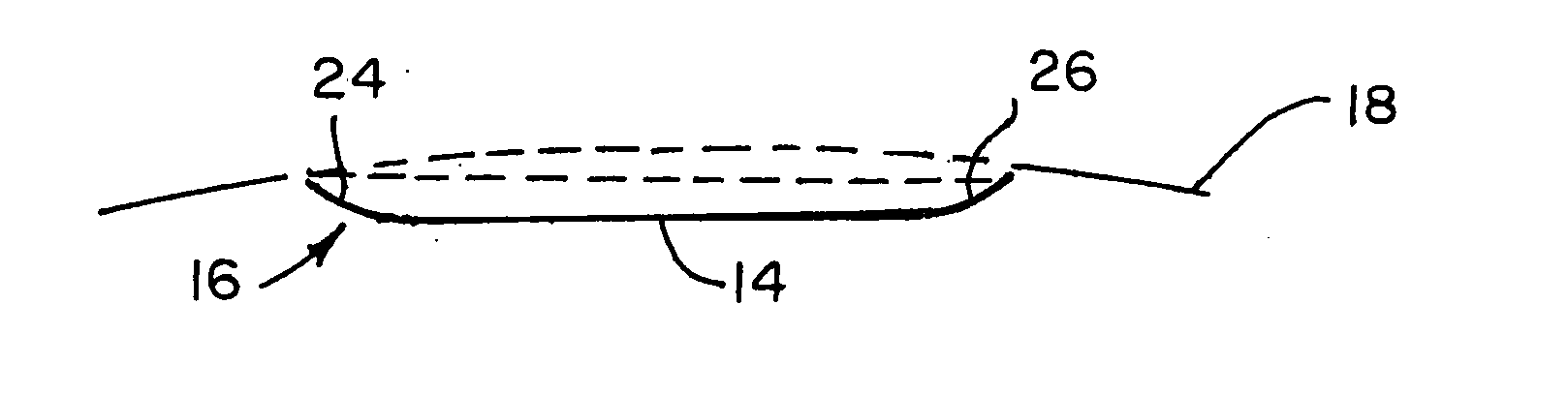

Method of using flexible spinal needle assemblies

InactiveUS20080065017A1Easy and faster flowSimple and straightforward insertionGuide needlesInfusion syringesSpinal needlesWell placement

A method of using an assembly to insert a flexible spinal needle and minimize incidence of post dural puncture headache is provided. The assembly typically includes a support needle with a non-cutting piercing tip and an exteriorly mounted flexible needle. The flexible needle gauge may be reduced, while ease of use is increased by the exterior mounting. The flexible needle provides increased flexibility allowing for movement of a patient's torso after insertion. A central stylet may be included to prevent entry of matter into the support needle opening during insertion. In other embodiments, methods for allowing single stick insertion procedures to provide better placement by allowing placement to be determined and adjusted based on physical feedback obtained during the single stick insertion.

Owner:RACZ N SANDOR +1

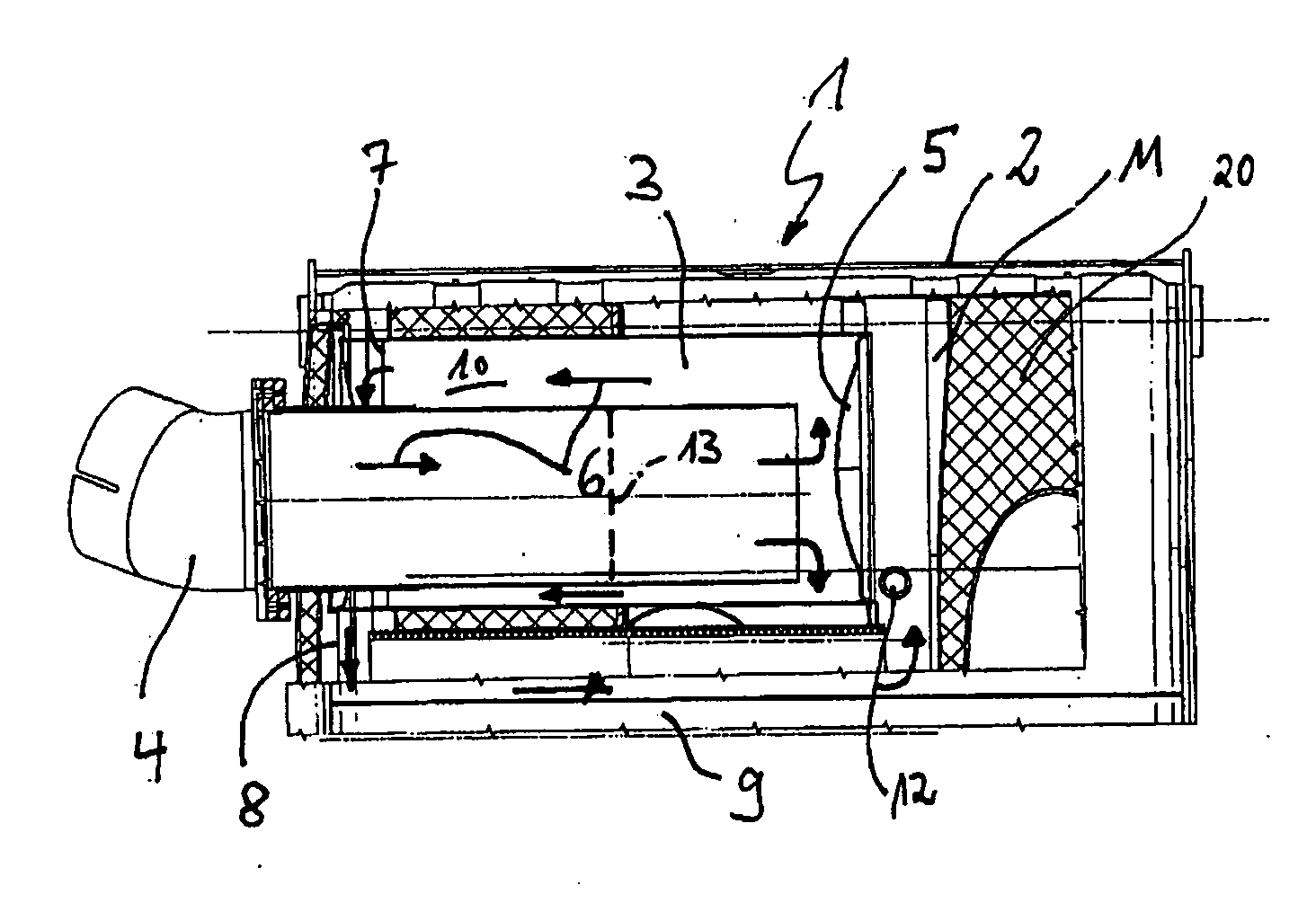

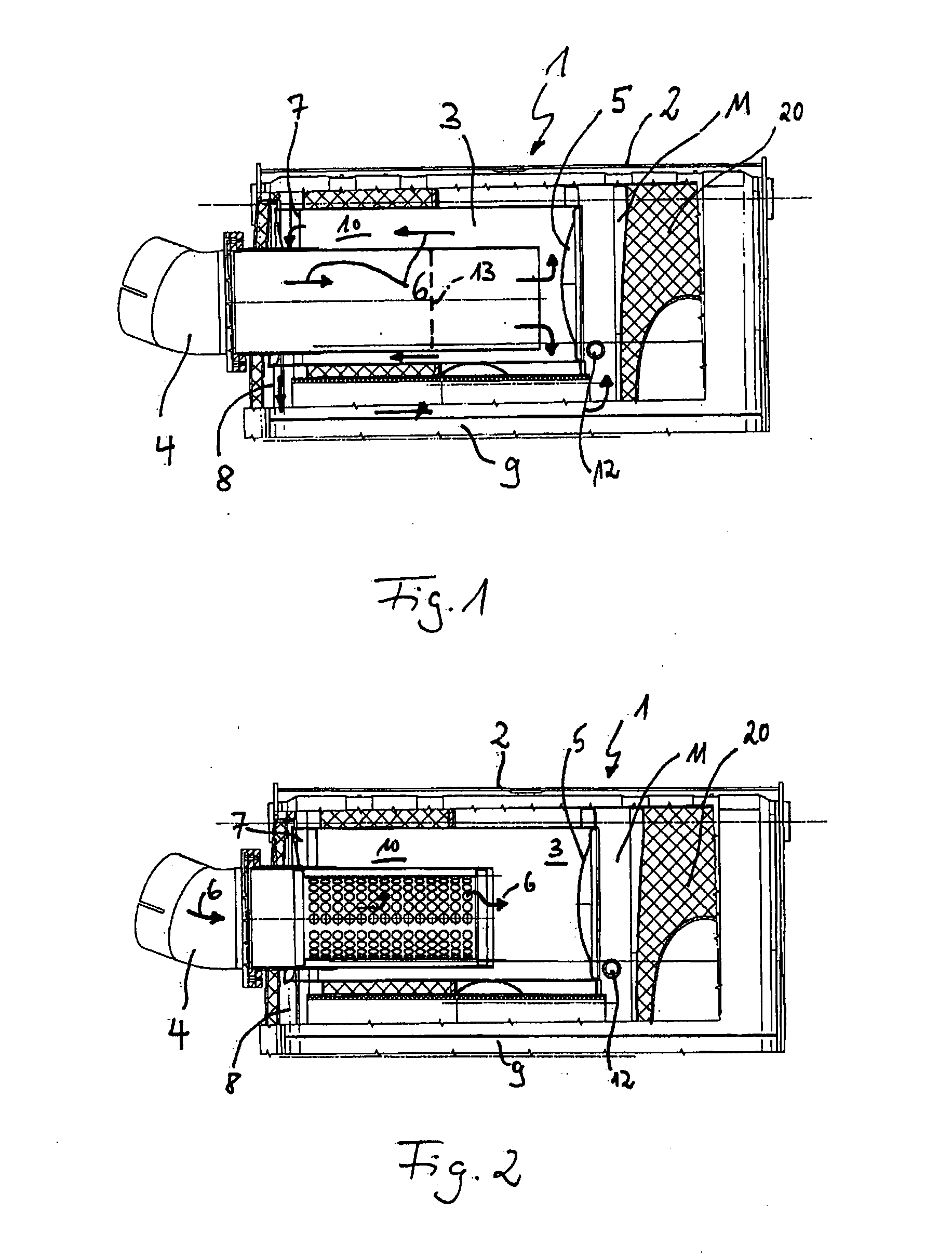

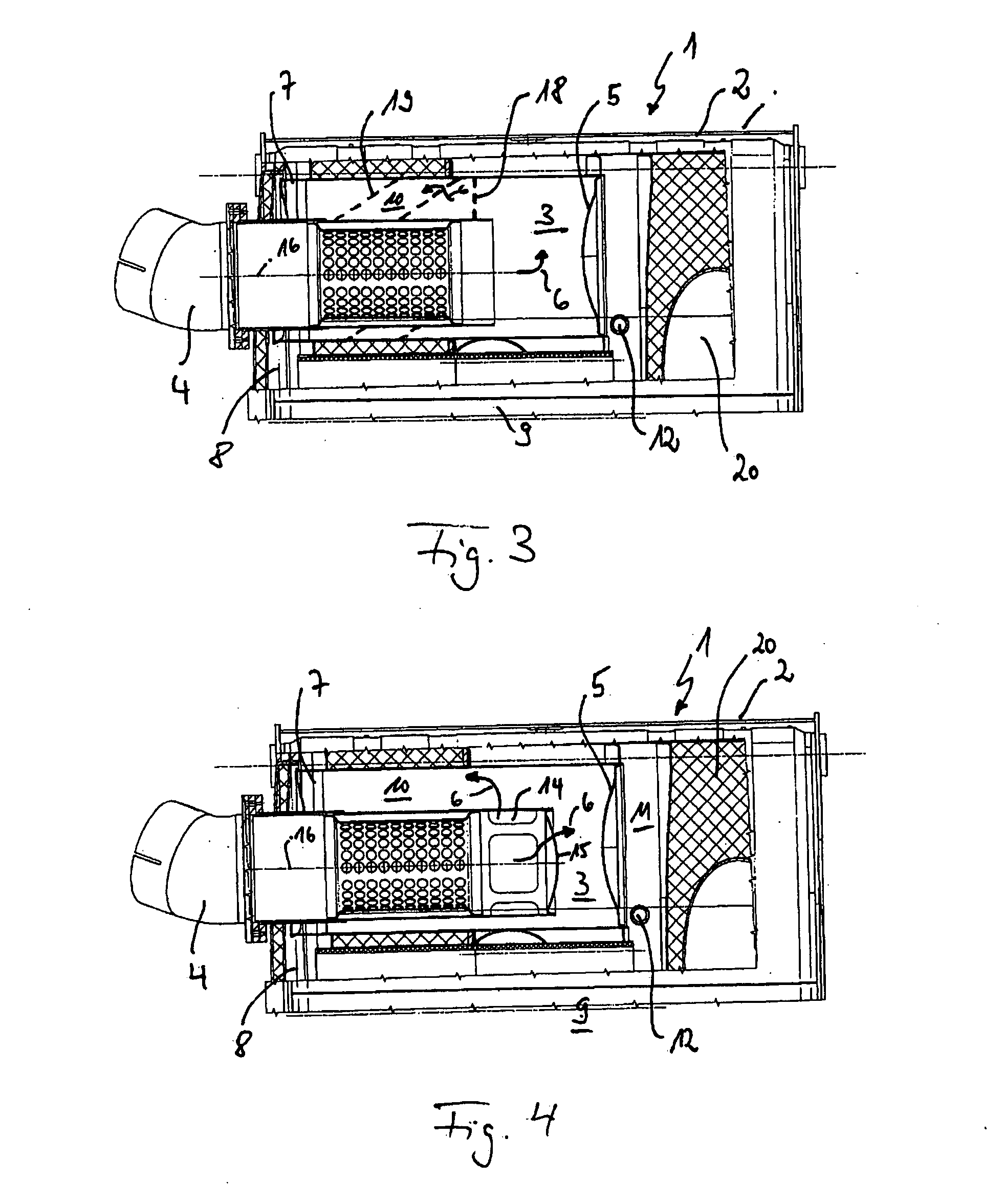

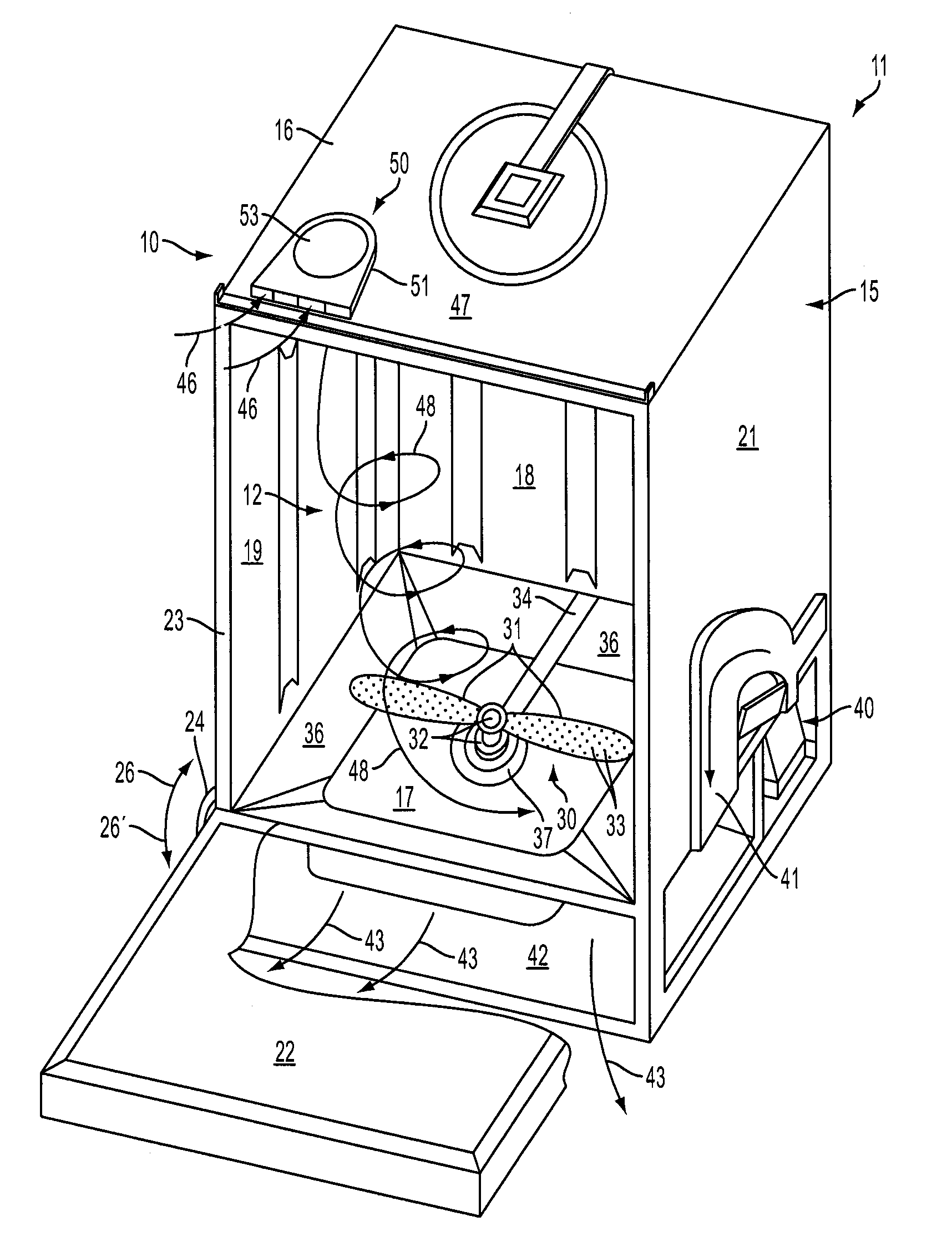

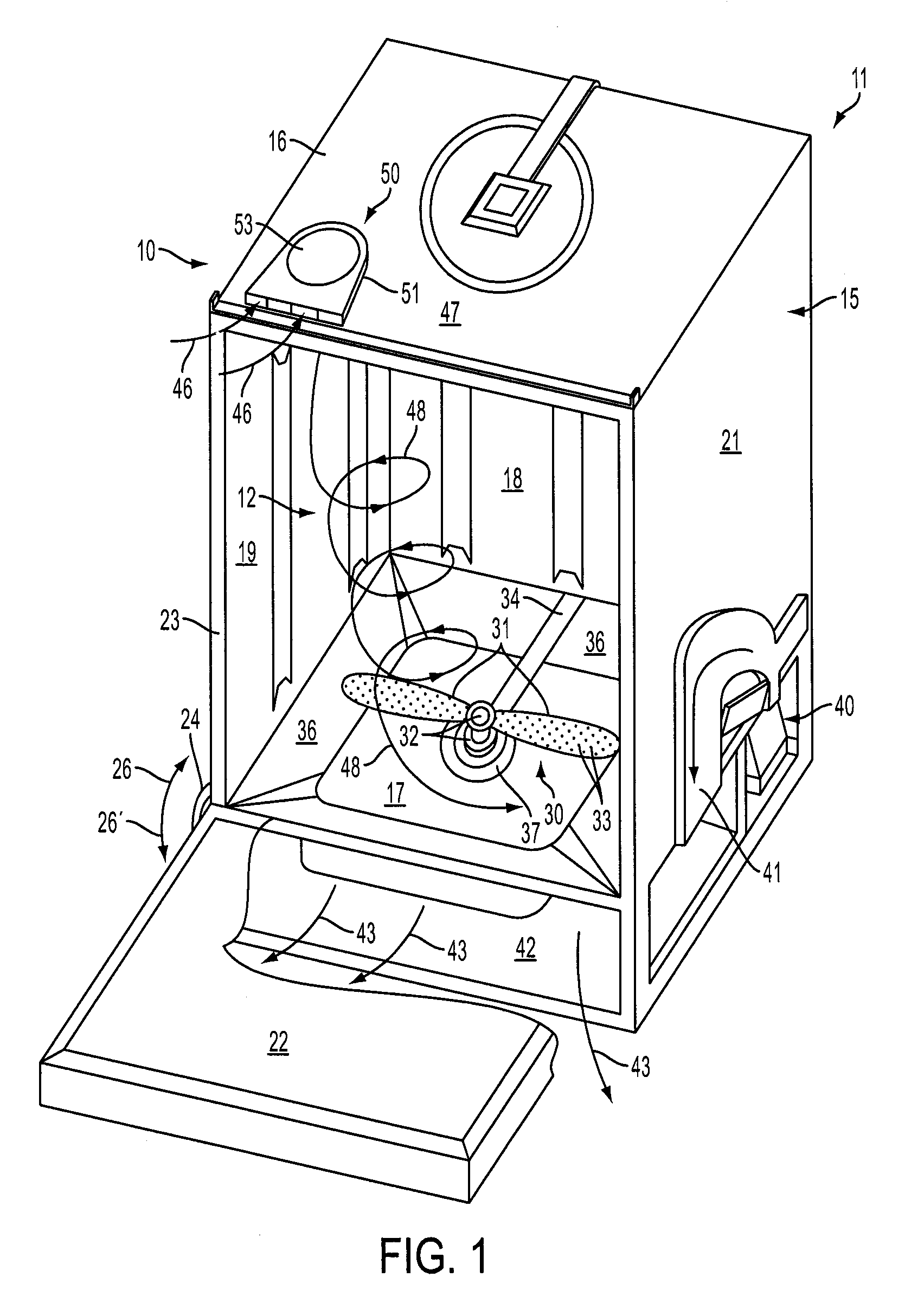

Drying system for a dishwasher

InactiveUS20130008474A1Much turbulenceFast condensation of moistureTableware washing/rinsing machine detailsDrying chambers/containersEngineeringMoisture

A drying system for a dishwasher including a passive vent assembly mounted to a top portion of the dishwasher. The passive vent assembly includes a passive vent structure having a series of air vents defined therein and through which drying air flows are drawn into the wash chamber of the dishwasher, a diffuser mounted over the air vents and including a series of fins for spreading the drying air flows across the wash chamber, and a moisture trap hood mounted over an upper surface of the passive vent structure.

Owner:VIKING RANGE

Downhole apparatus

Downhole apparatus is described having a tubular main body and at least one flow channel formed on the body. The channel has at least one non-uniform dimension. A flow guide is located adjacent an end of the channel, and the flow guide and the channel together define a flow path for flow of a downhole medium along the body. The downhole apparatus may for example be a casing reamer shoe, a drill pipe, or a motor sleeve.

Owner:STABLE SERVICES

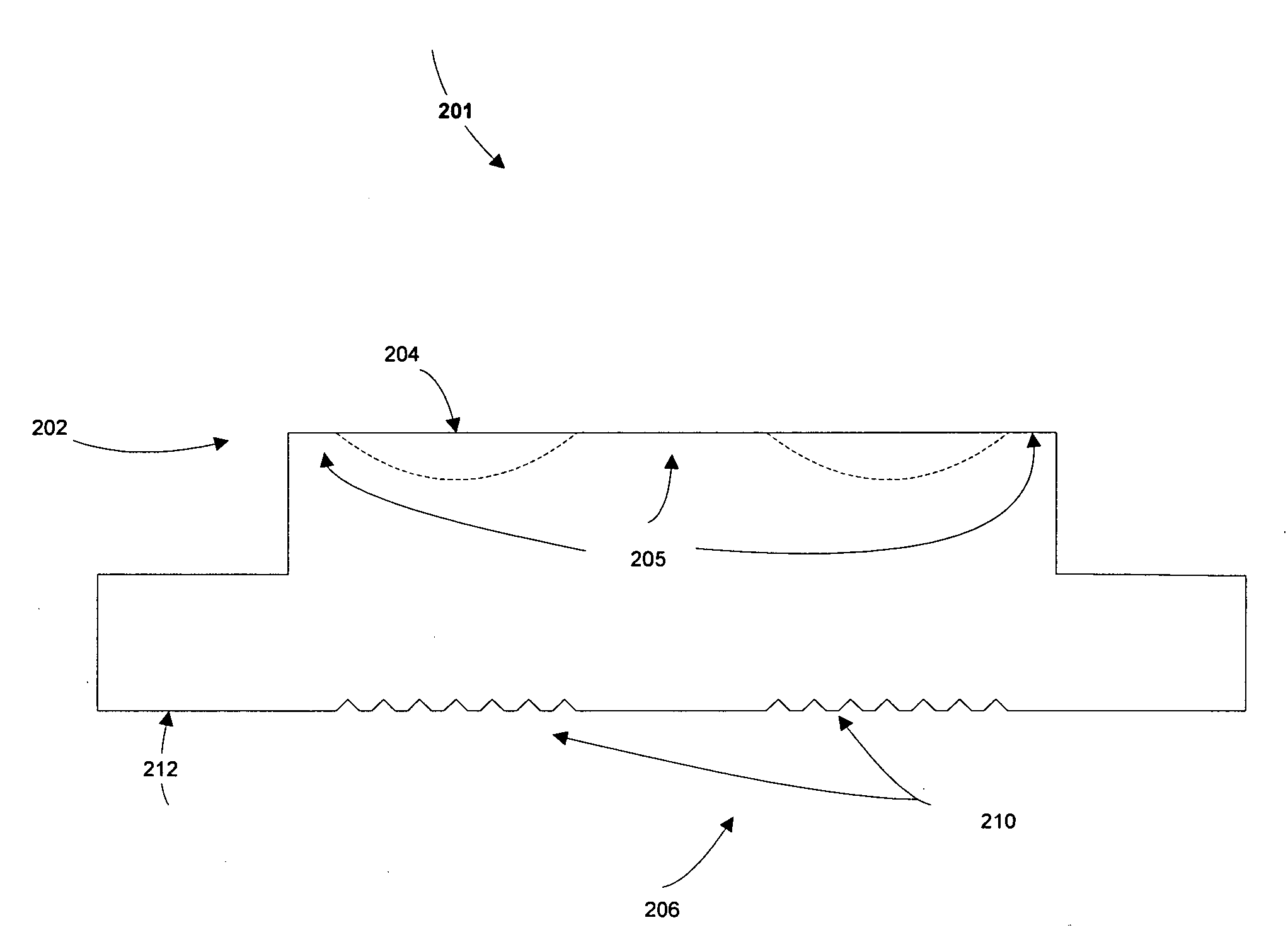

Controlled cooling of sputter targets

InactiveUS20050236270A1Increase heatIncrease volumeCellsElectric discharge tubesSputteringMaterials science

A method for manufacturing a sputter target in which cooling rates are selectively controlled, by generating a sputter surface and a backside surface obverse to the sputter surface. The backside surface includes at least a first textured region. The first textured region aids in cooling a region of the sputter target adjacent to the first textured region, by effectuating heat dissipation.

Owner:HERAEUS INC

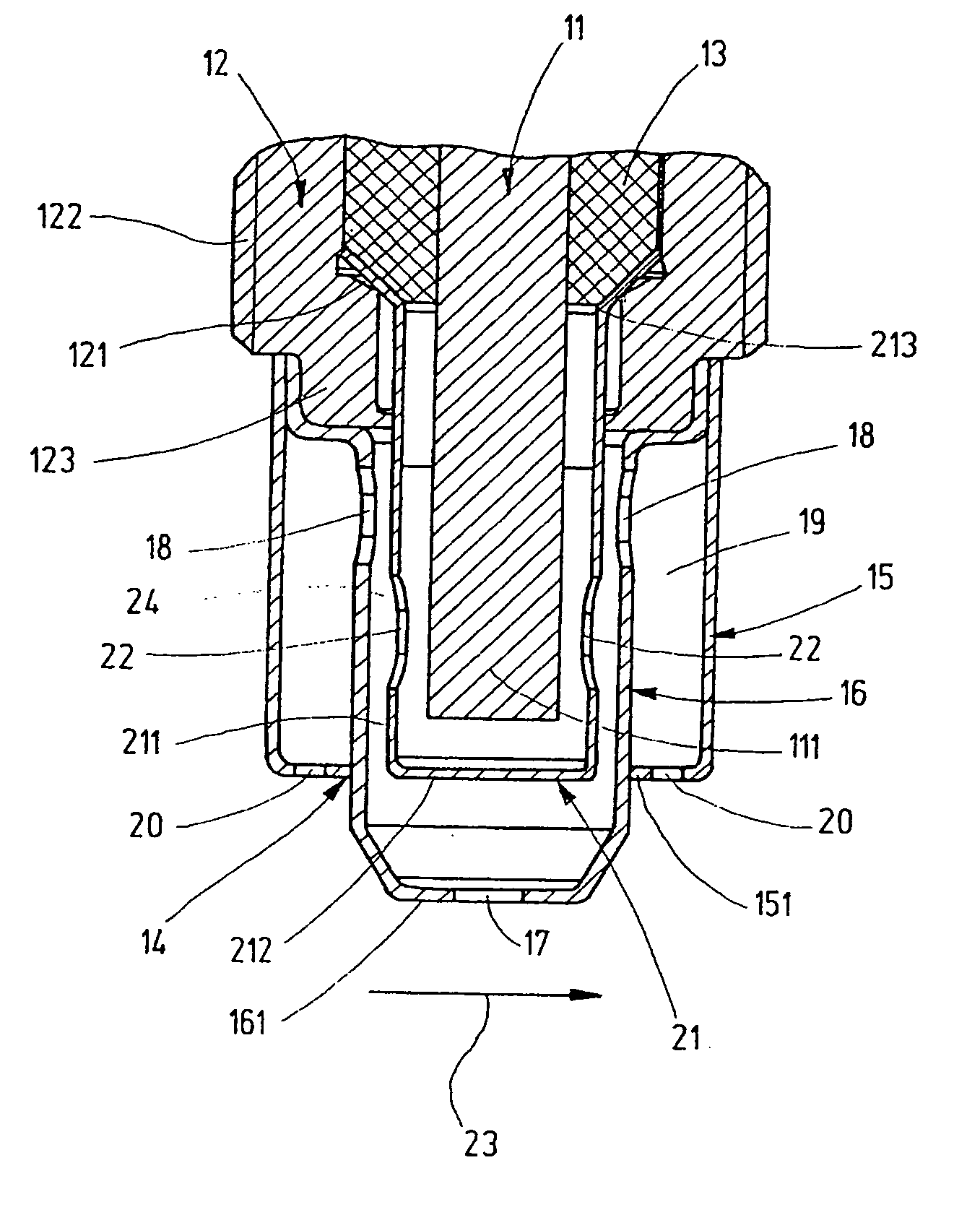

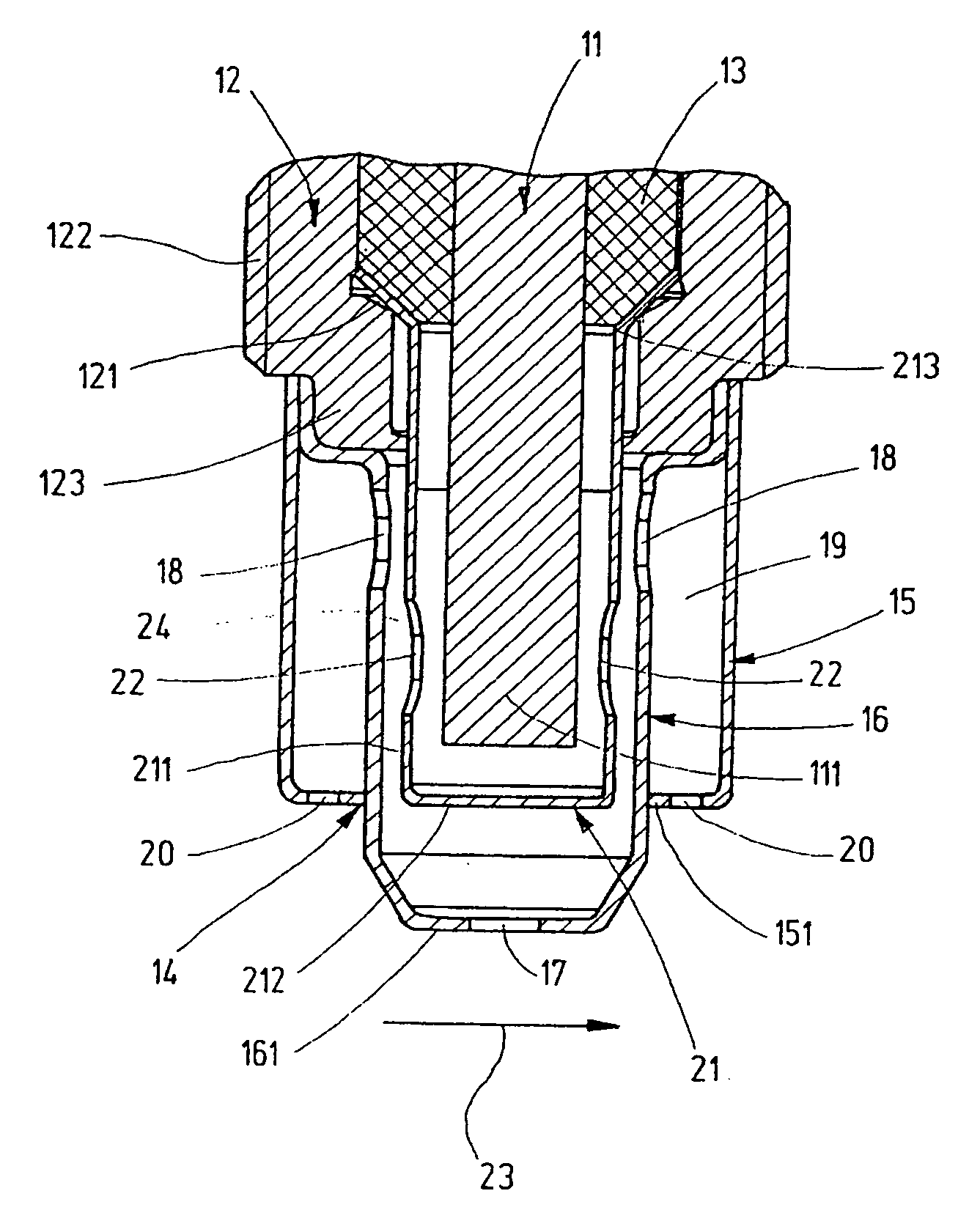

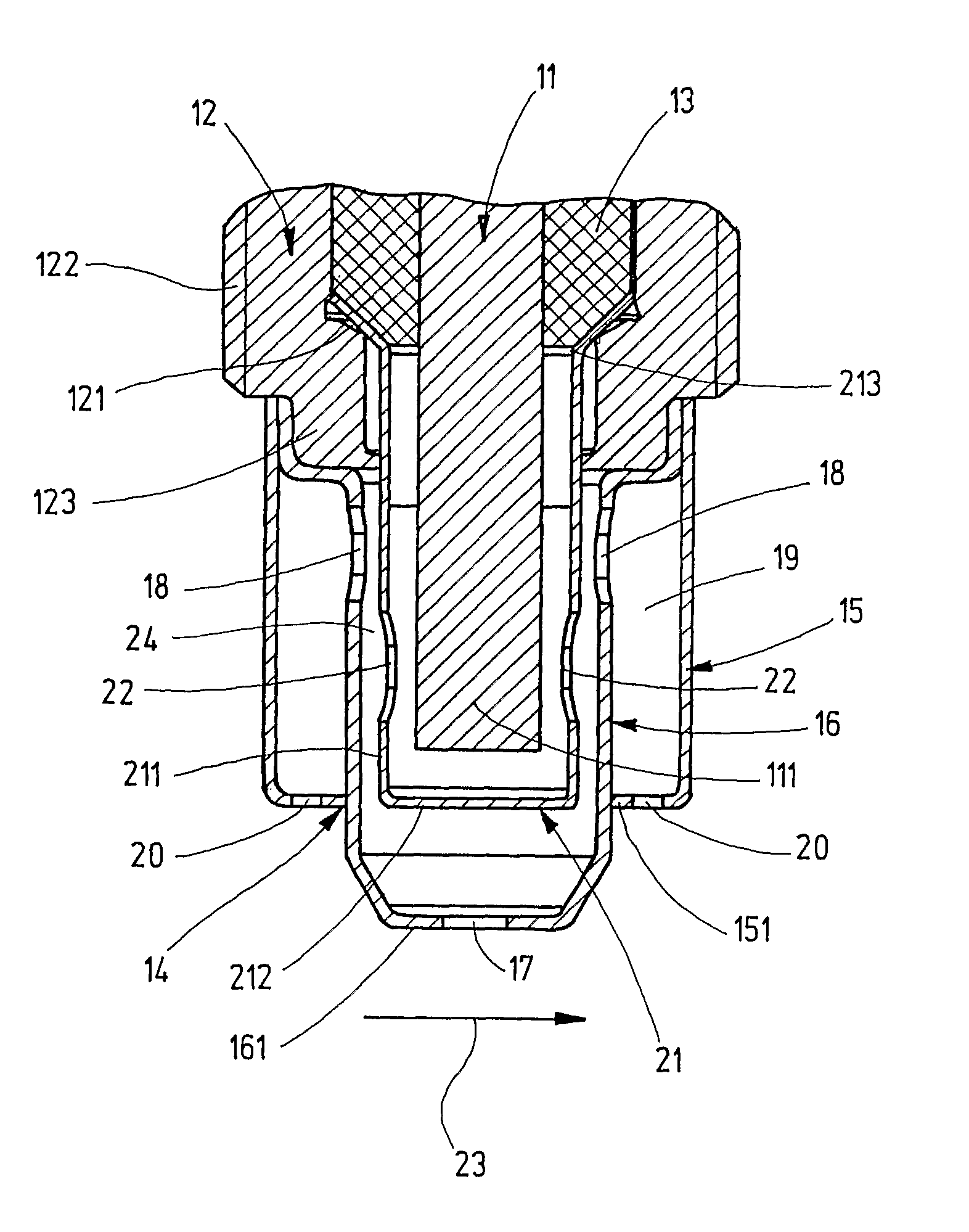

Sensor

InactiveUS20070261473A1Improve protectionReduce heat lossThermometer detailsAnalysing fluids using sonic/ultrasonic/infrasonic wavesInternal combustion engineHeating power

A sensor, in particular a gas sensor for determining a physical characteristic of a measuring gas, in particular the temperature of the concentration of a gas component, in particular in the exhaust gas of an internal combustion engine, includes a sensor element which protrudes with a gas-side end section from a sensor housing and having a double protecting tube, which encloses the gas-side end section, and has an outer tube and an inner tube. For improved protection of the sensor element against thermal shock, a reduction in the heating power for the sensor element, and sufficiently high dynamics of the sensor, a cup-shaped central protecting tube is placed over the gas-side end section, the central protecting tube being provided with gas passage apertures in the tube casing, the gas passage apertures being positioned offset to the tube bottom with respect to the gas passage apertures present in the inner tube.

Owner:ROBERT BOSCH GMBH

Apparatus and method for a gas turbine entrainment system

ActiveUS8015821B2Extended stayWell mixedContinuous combustion chamberEngine manufactureCombustion chamberCombustor

This invention relates to an apparatus for an entrainment system of a vortex burning combustion chamber or a vortex burning inter-turbine burner in a gas turbine. The entrainment system rapidly and thoroughly mixes hot combustion gases with non-combustion gases to reduce the gas temperature before entering a turbine. The entrainment system includes a plurality of helical vanes forming trenches and resulting in a highly helical flow path. The highly helical flow path provides an increased residence time for mixing of the combustion gases and non-combustion gases. Radial cavities in the helical vanes, canted vane angles and varying geometries further facilitate mixing while reducing losses. This invention also includes a method of mixing combustion and non-combustion gases in an entrainment system.

Owner:SPYTEK AEROSPACE CORP

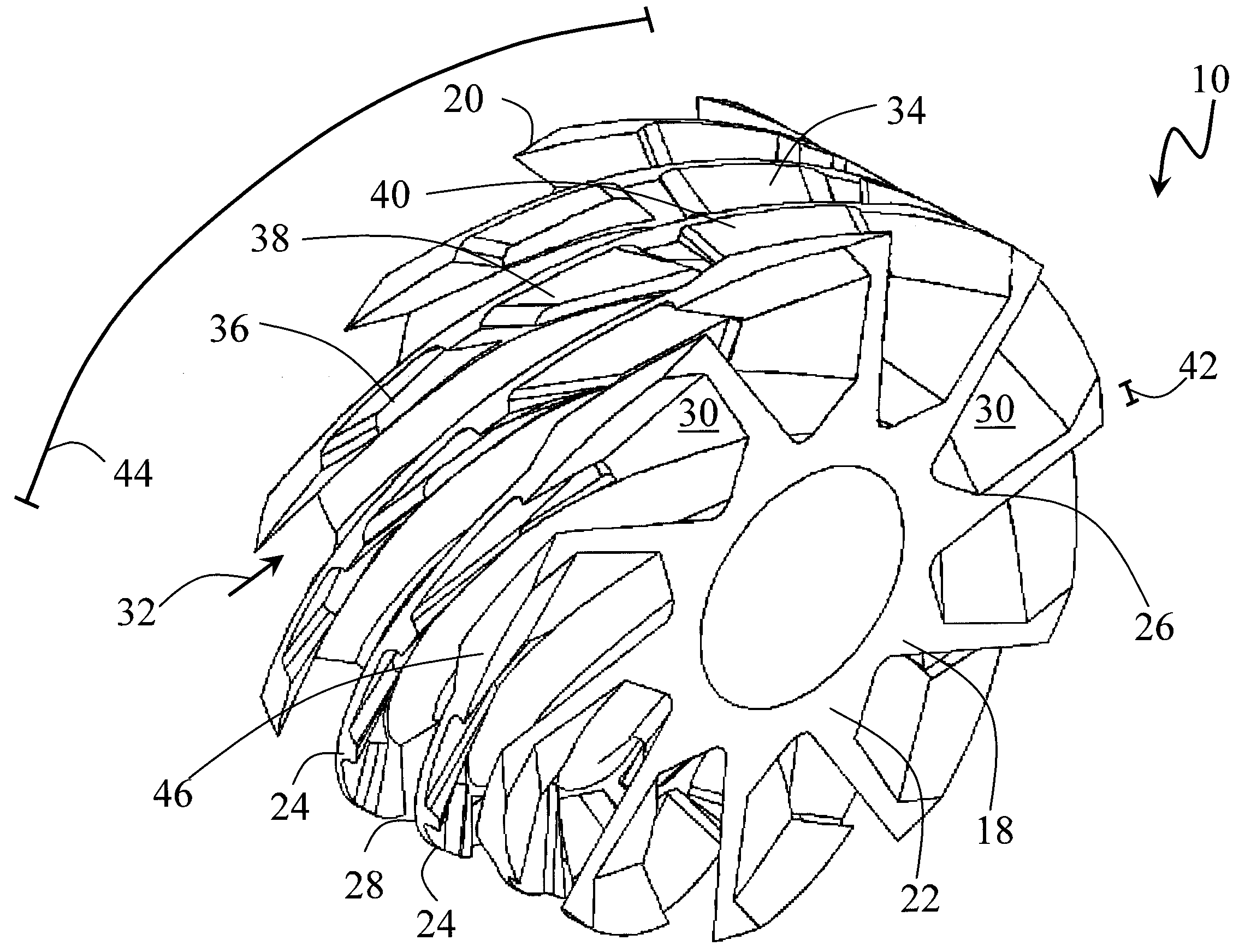

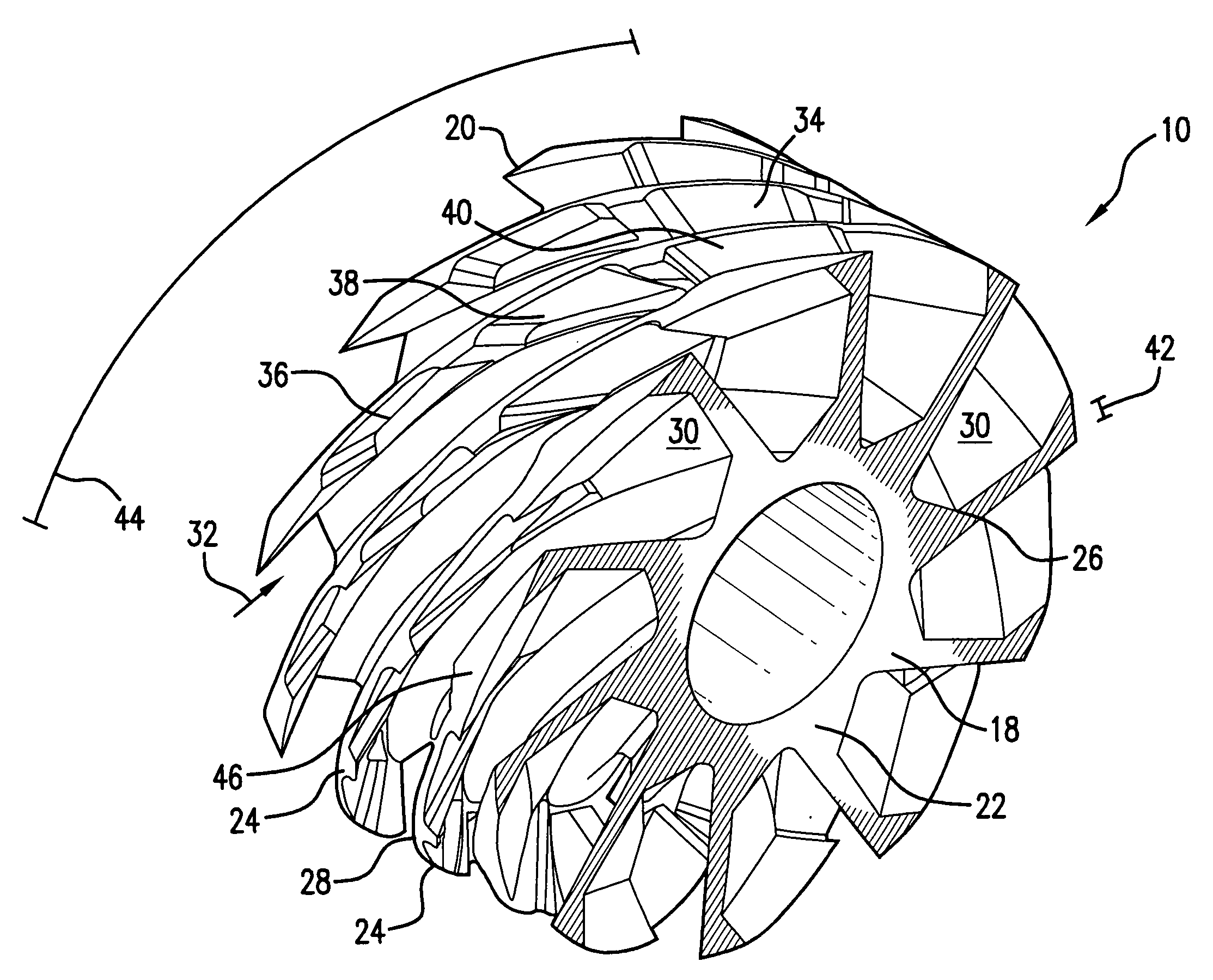

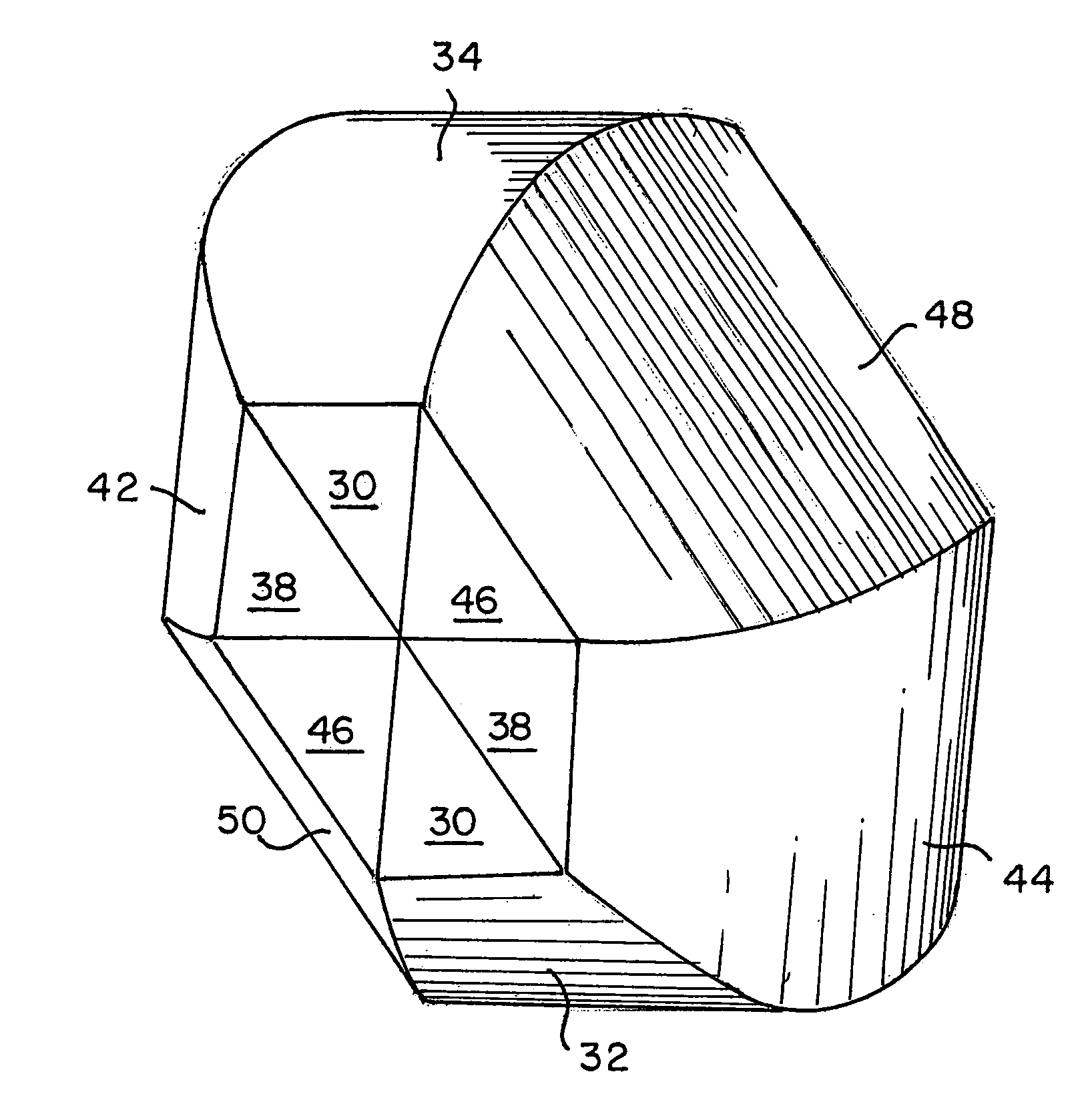

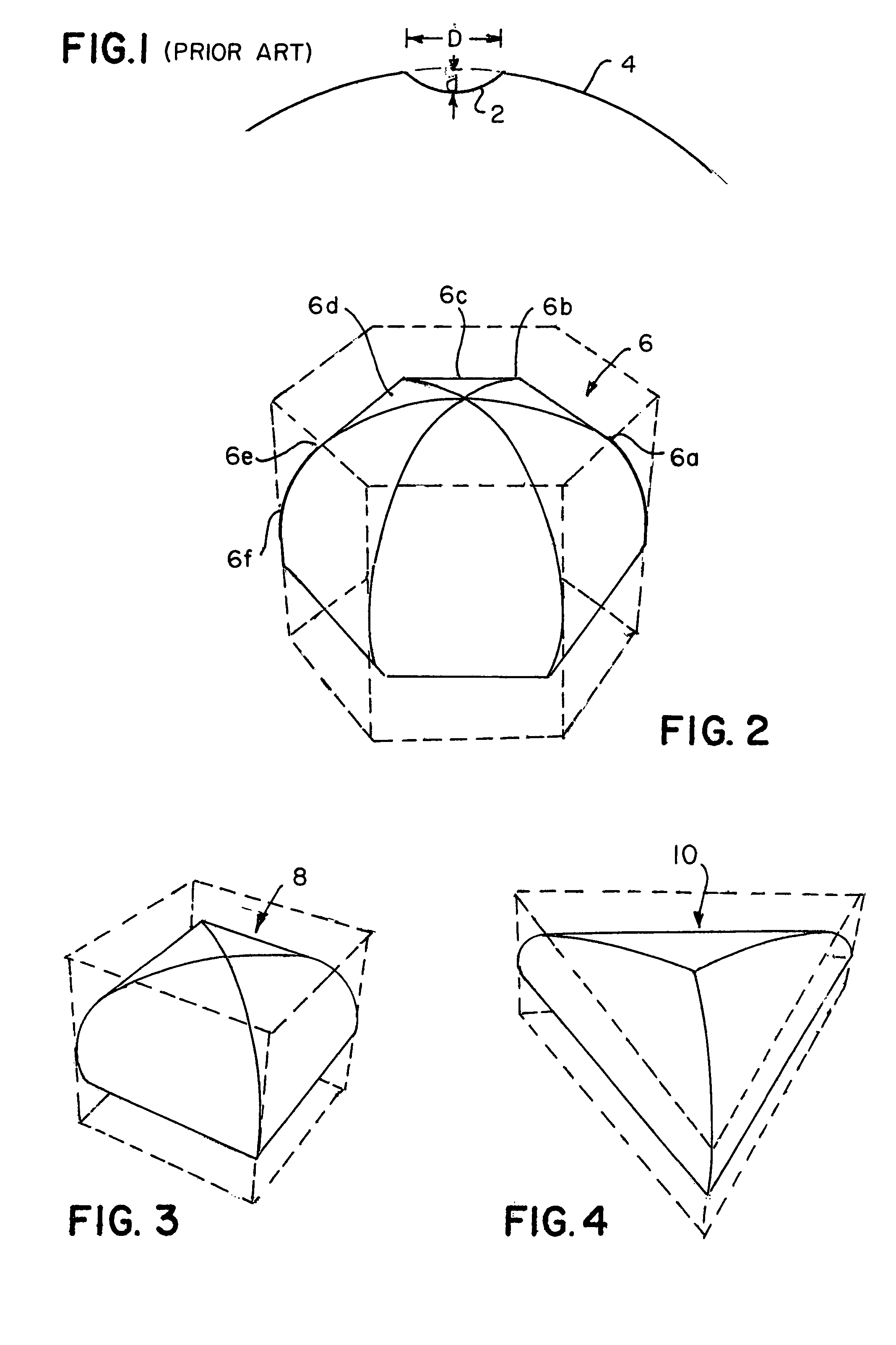

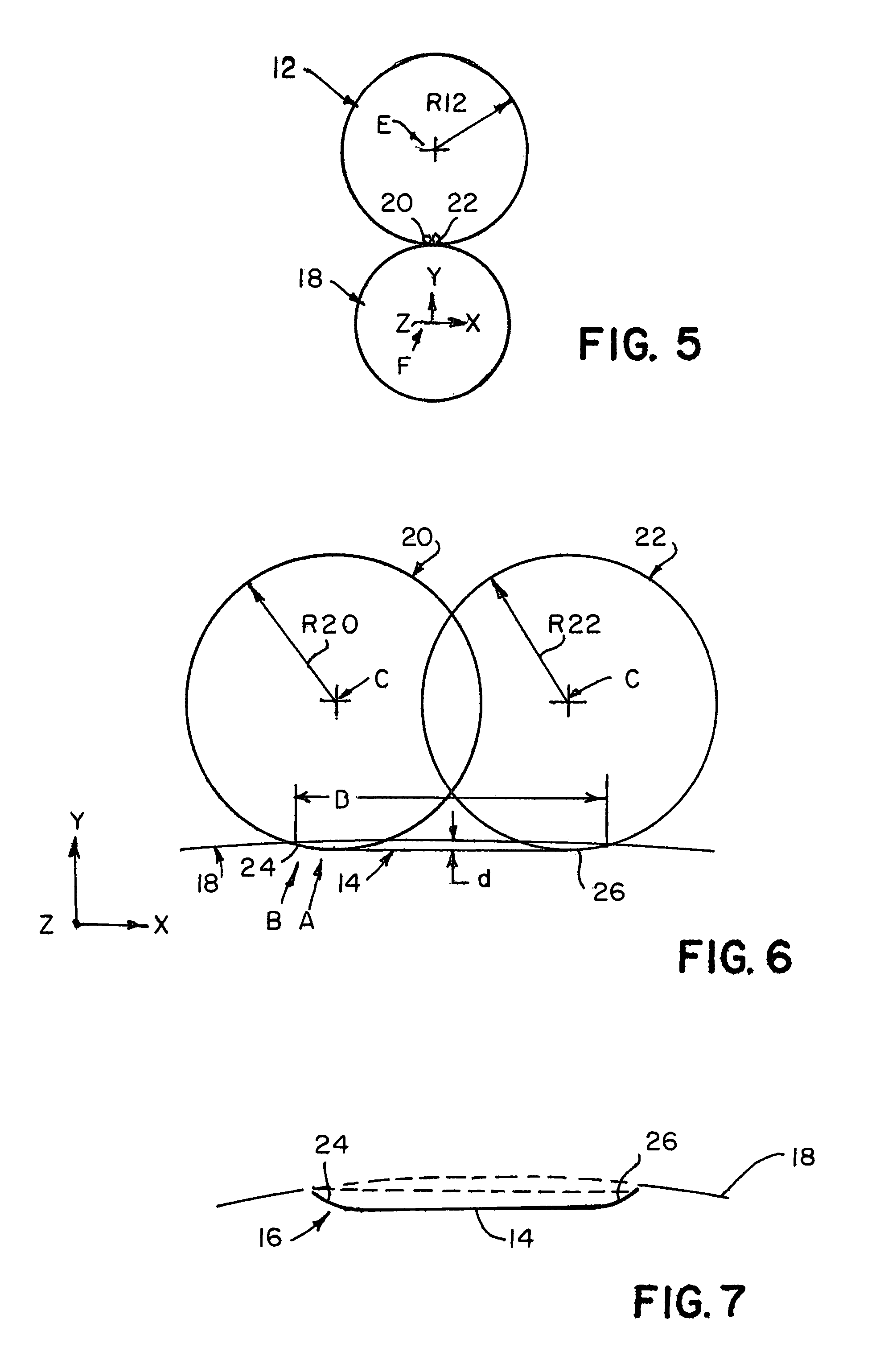

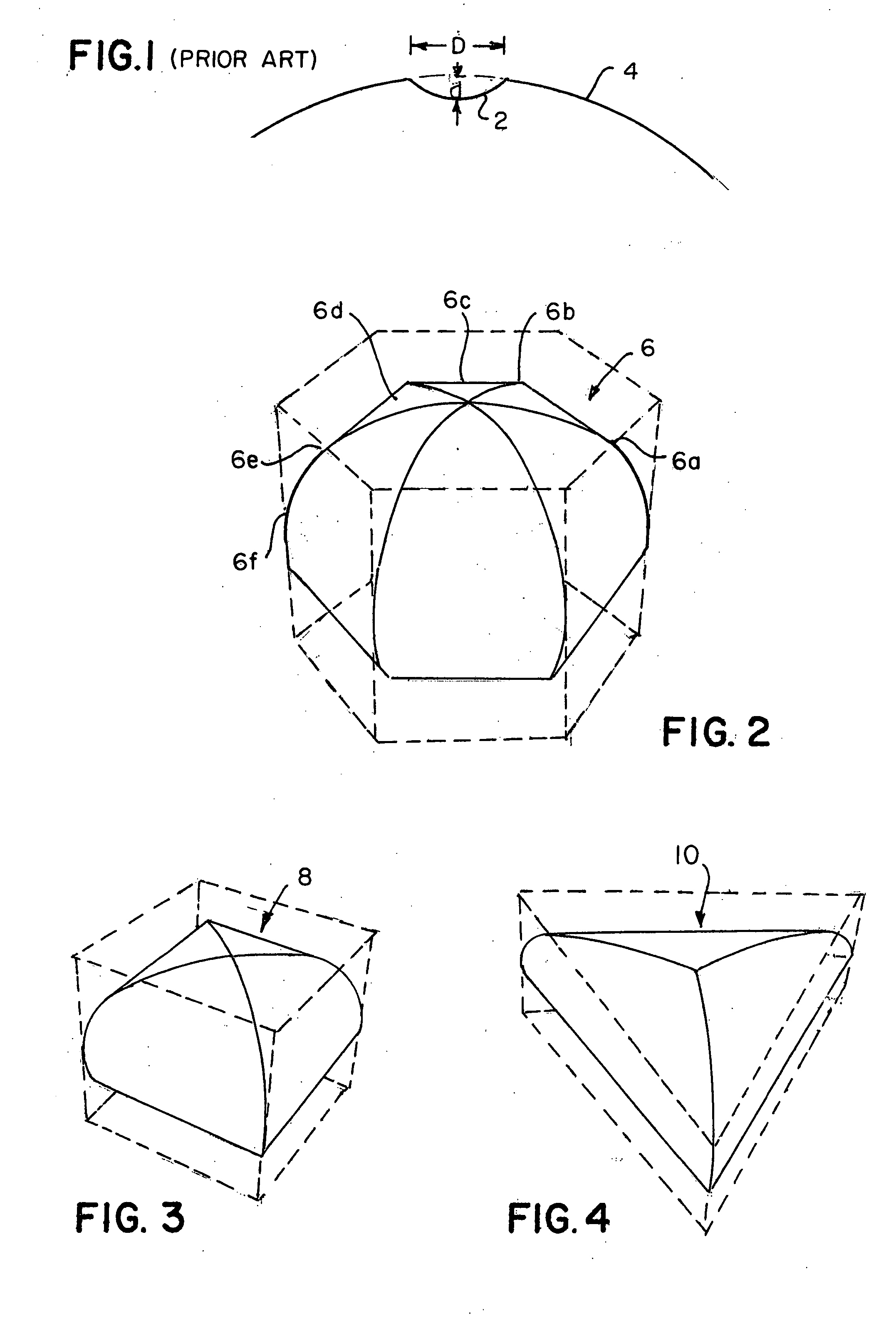

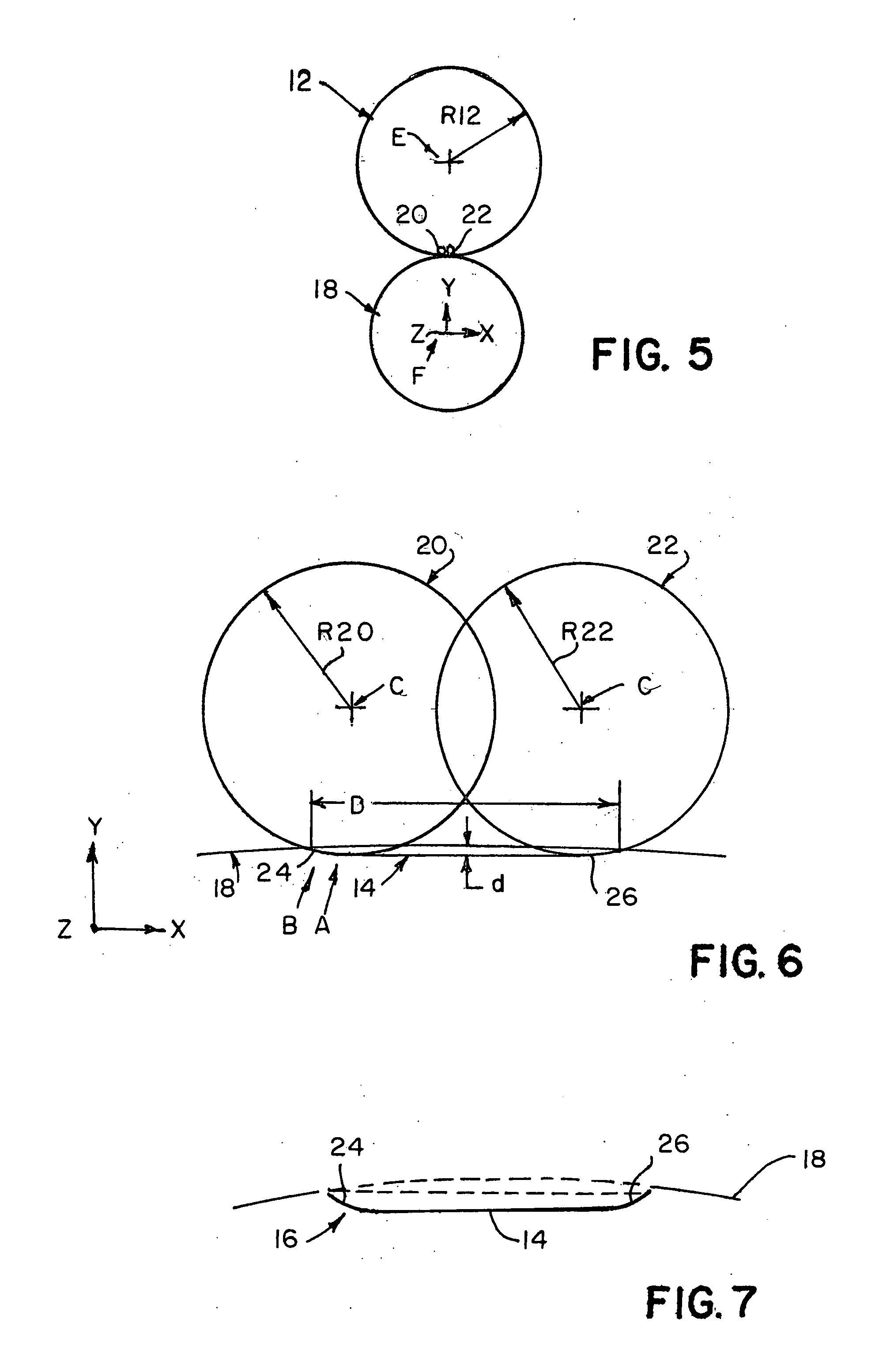

Dimples comprised of two or more intersecting surfaces

A golf ball with a dimple pattern designed to maximize flight characteristics employs dimples which are created by joining two or more intersecting surfaces. The invention provides for single radius or dual radius dimples, preferably including smaller radius cylinders tangentially arranged along the side of the larger cylinders. The intersection of the cylinders forms tri-cylinders, tri-semicylinders, bi-cylinders, quad-semicylinders, penta-semicylinders, or more generally n-cylinders depending upon the number of intersecting cylinders. The golf ball includes a plurality of single or dual radius dimples created by intersecting n-cylinders to create maximum turbulence on the ball during flight.

Owner:TOPGOLF CALLAWAY BRANDS CORP

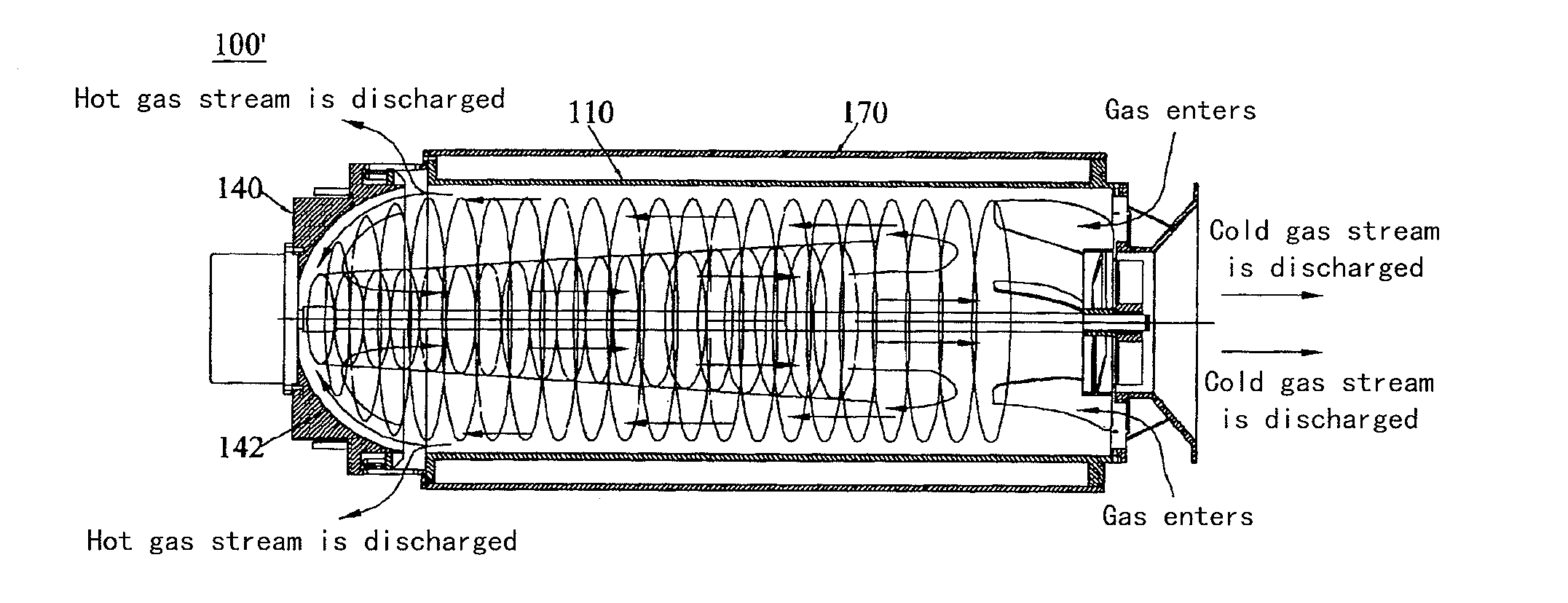

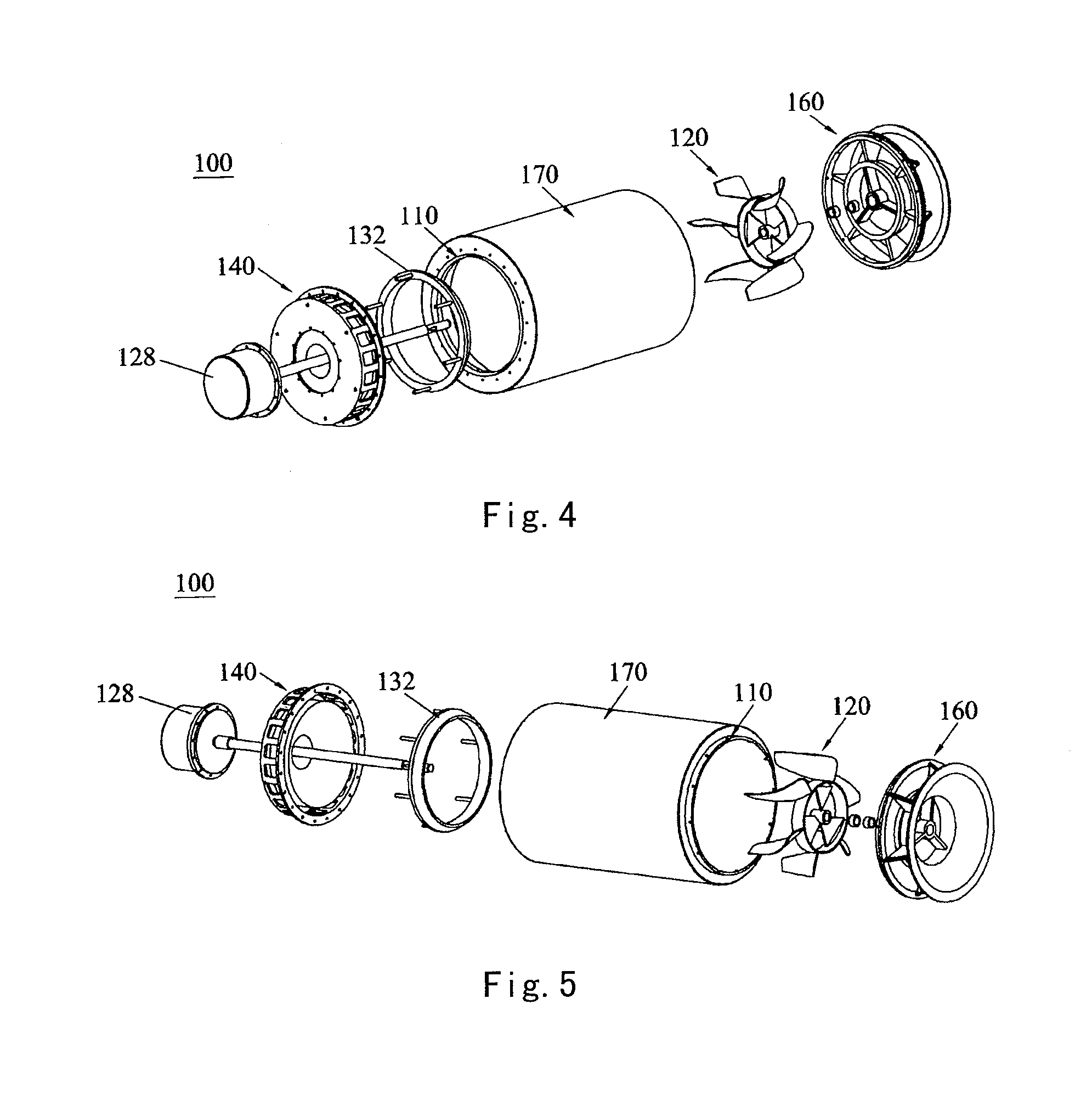

Vortex device for separating cold gas and hot gas

ActiveUS20140020348A1Promote turbulenceUniform flow rateCombination devicesAuxillary pretreatmentProduct gasEngineering

A vortex type cold and hot gas separating device (100) includes a body (110) having a cylindrical inner wall surface (111), the inner wall surface (111) defining a cylindrical inner chamber (112) having a first end (113) and a second end (114); an intake and agitation fan device (120) attached to the body (110) at the first end (113) which sucks external gas into the cylindrical inner chamber (112) and agitates the external gas to form a first vortex traveling towards the second end (114); a hot gas stream discharge port (130) located at or adjacent to an edge of the second end (114) to discharge a part of gas of the first vortex traveling to the hot gas stream discharge port (130) out of the cylindrical inner chamber (112); a vortex return device (140) located at the second end (114) to return the remaining gas of the first vortex which is not discharged from the hot gas stream discharge port (130), thereby forming a second vortex traveling towards the first end (113) of the cylindrical inner chamber (112) through a cyclone core of the first vortex; and a cold gas stream discharge port (150) located at a radial center of the first end (112) of the cylindrical inner chamber or located adjacent to and around the radial center. A temperature of the gas discharged from the hot gas stream discharge port (130) is higher than a temperature of the gas discharged from the cold gas stream discharge port (150).

Owner:BEIJING ROSTAR TECH

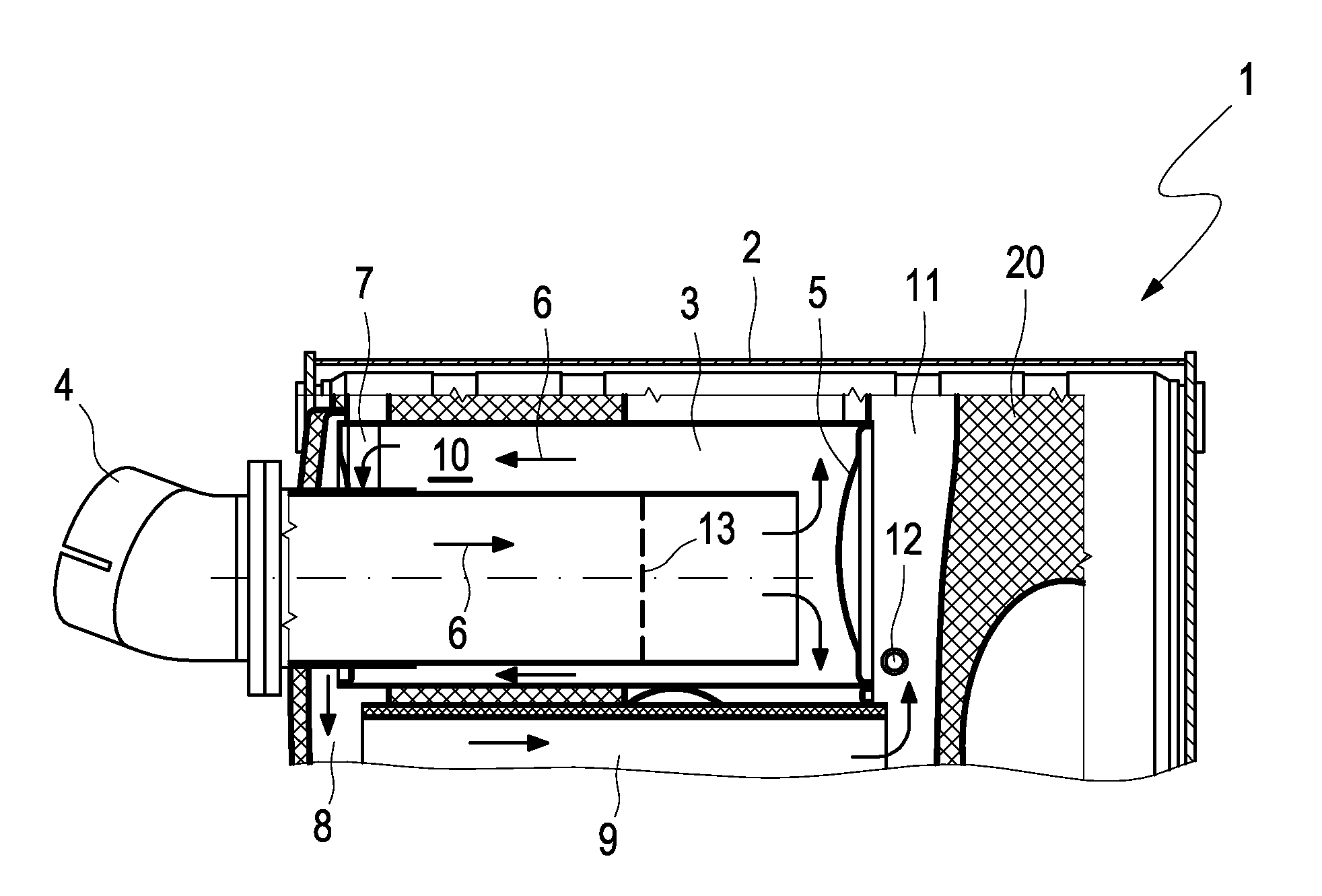

Exhaust gas aftertreatment device for an internal combustion engine

ActiveUS8220253B2Promotes thorough mixingReduction of the nitrogen oxidesInternal combustion piston enginesSilencing apparatusAfter treatmentExternal combustion engine

The invention relates to an exhaust gas after-treatment device for an internal combustion engine, including a housing into which an exhaust pipe that opens into a mixing chamber penetrates. The mixing chamber is shaped as a pot and reverses a direction of flow of the incoming exhaust gas whereby it returns the exhaust gas radially outside of the exhaust pipe. An open end of the pot-shaped mixing chamber opens into a collecting space which is designed so that it supplies the exhaust gas to at least one downstream SCR catalytic converter.

Owner:PUREM GMBH

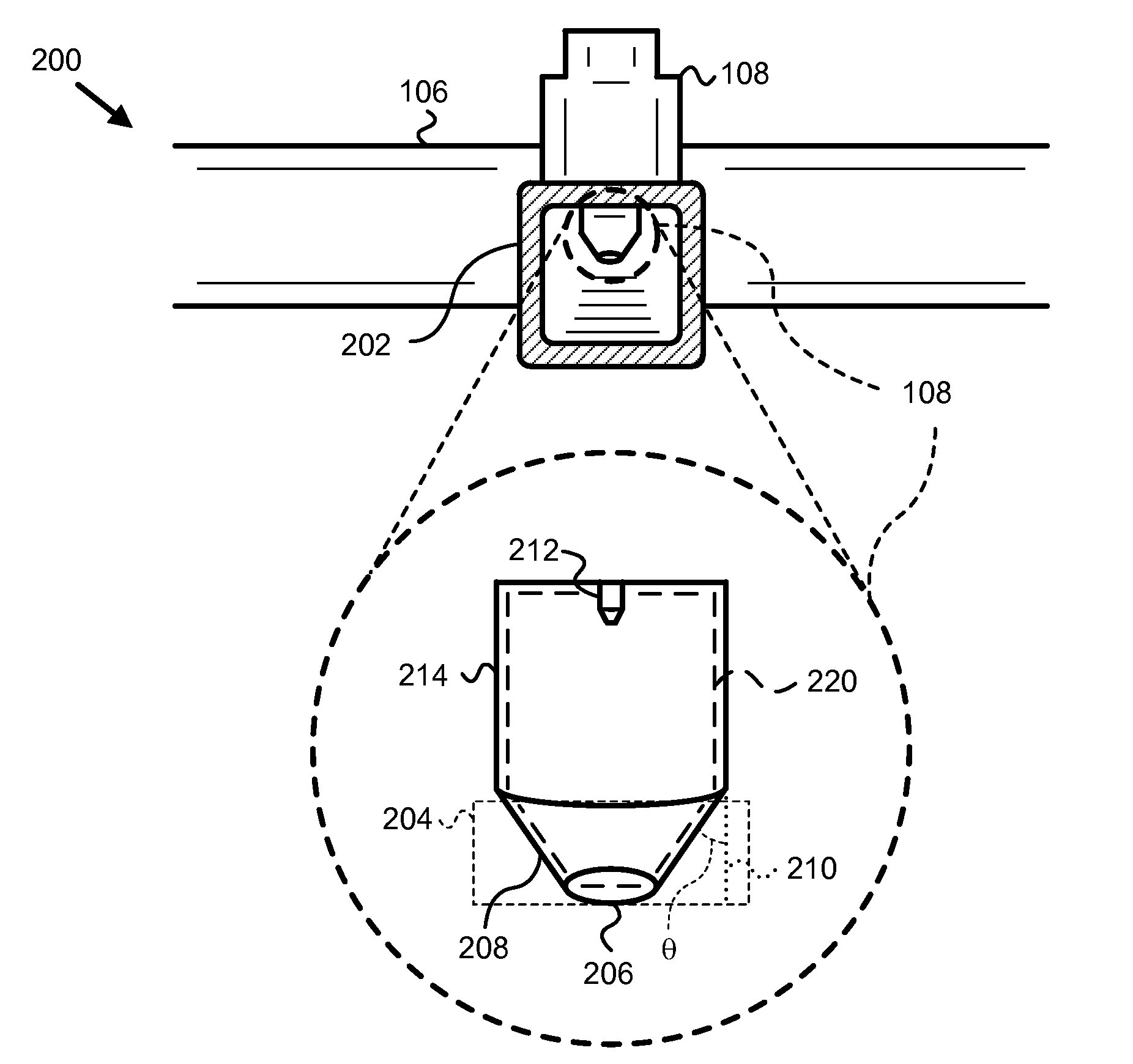

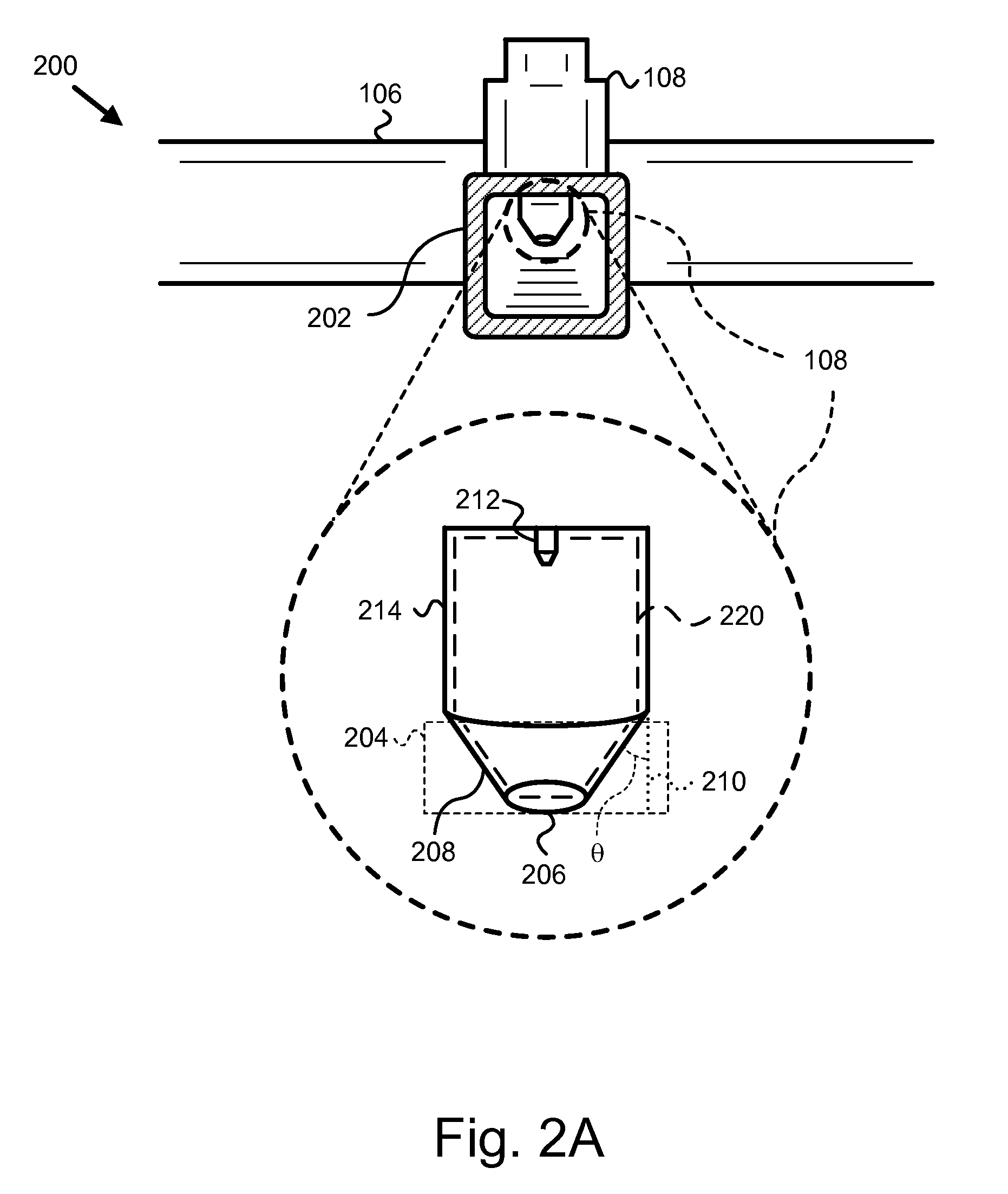

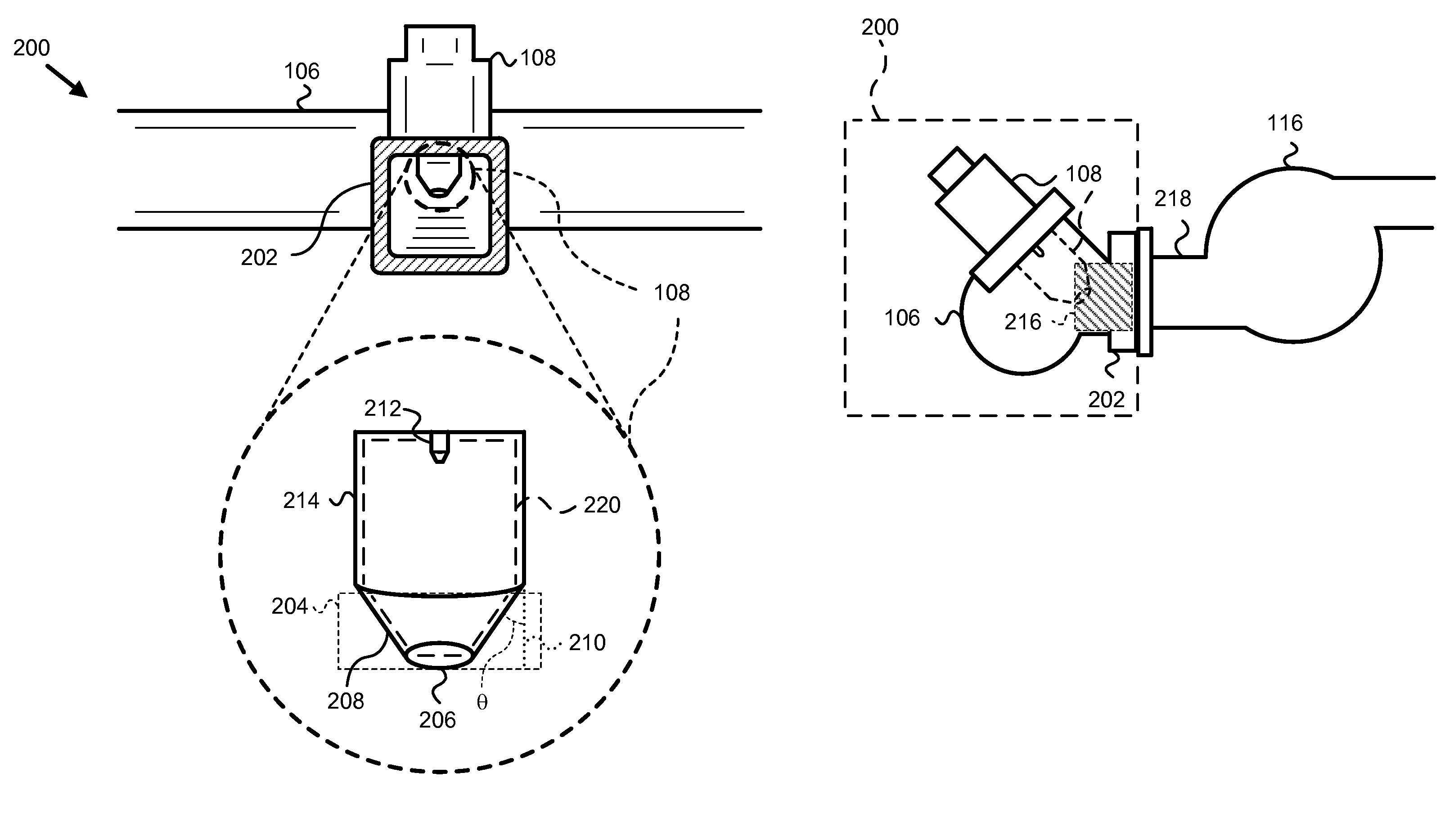

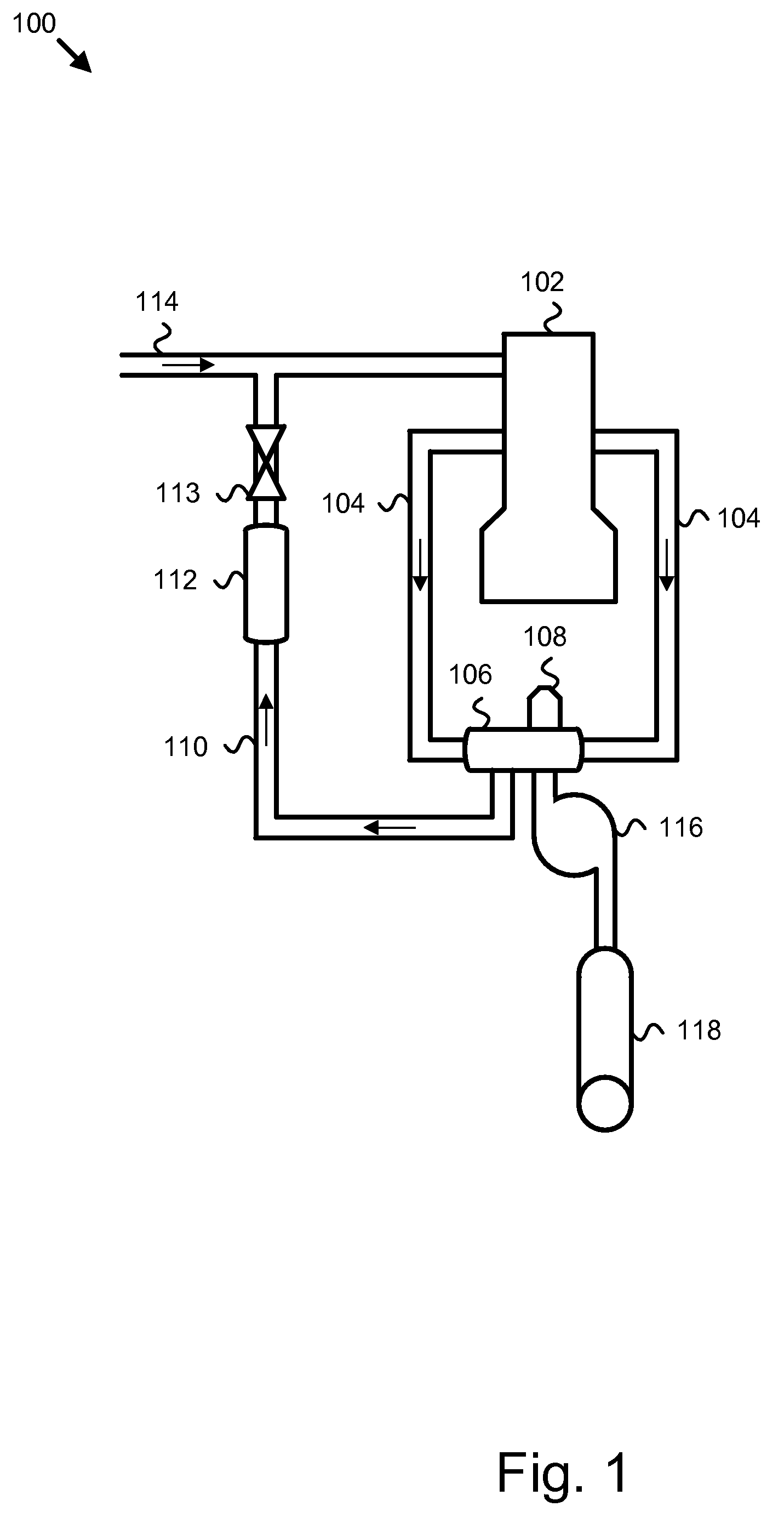

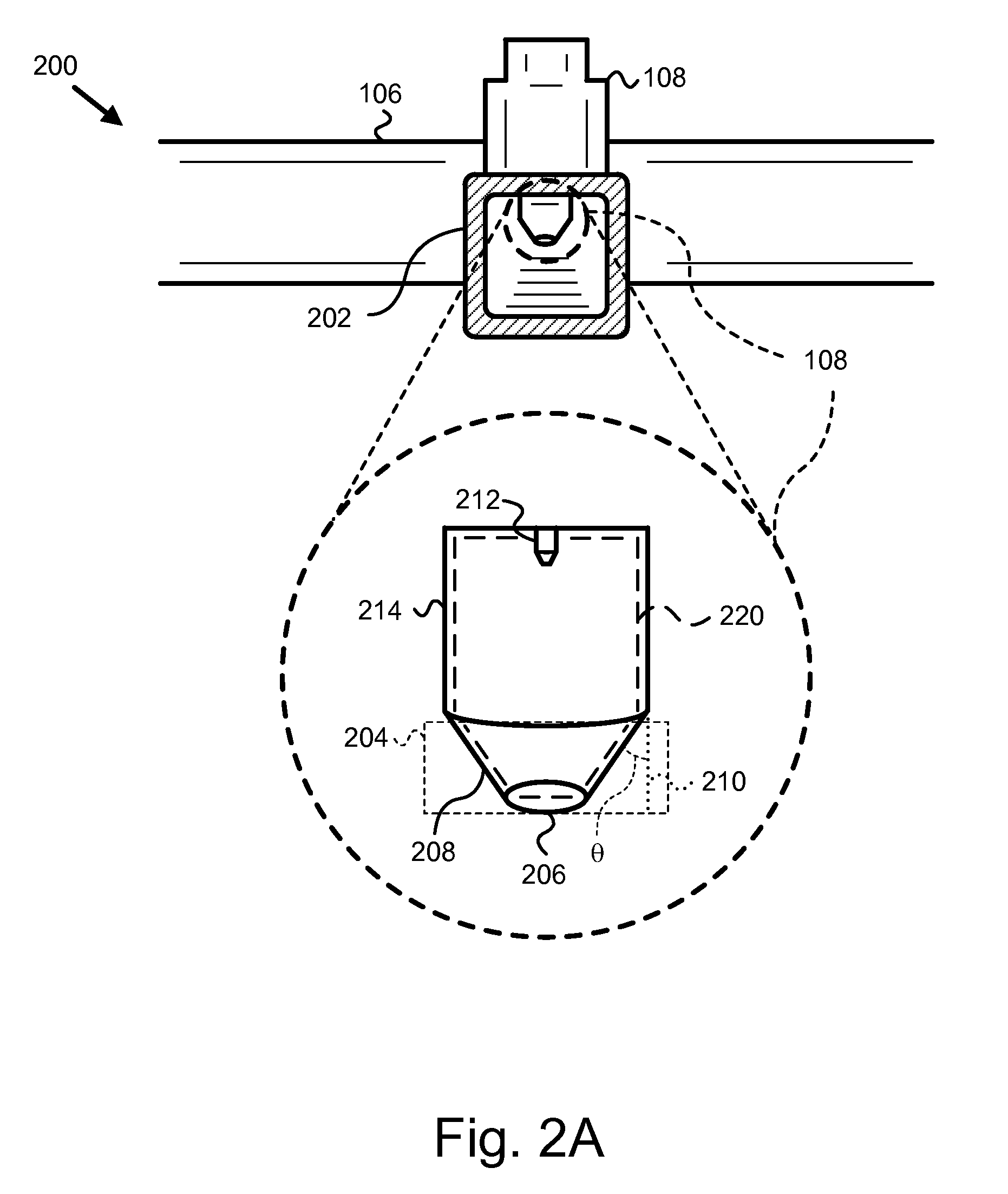

Apparatus and system for enhancing aftertreatment regeneration

ActiveUS20090064668A1Enhance aftertreatment regenerationIncreased turbulenceNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerExhaust fumes

An apparatus and system are disclosed for enhancing aftertreatment regeneration. The system includes an internal combustion engine and an exhaust manifold directing the engine exhaust to an aftertreatment system. The system may further include an exhaust gas recycle system and a turbocharger. The system further includes a fuel injector mounted on the exhaust manifold that provides fuel to assist in regenerating an aftertreatment component. The fuel injector is mounted in an apparatus also including a flow dampener, an extender, and a residence chamber. The apparatus allows the fuel to be injected in a high temperature location where it will experience residence time at temperature, and experience shear forces passing through the turbocharger. The extender allows the fuel to be injected at a place in the exhaust manifold where recycling of injected fuel into the engine is minimized.

Owner:CUMMINS INC

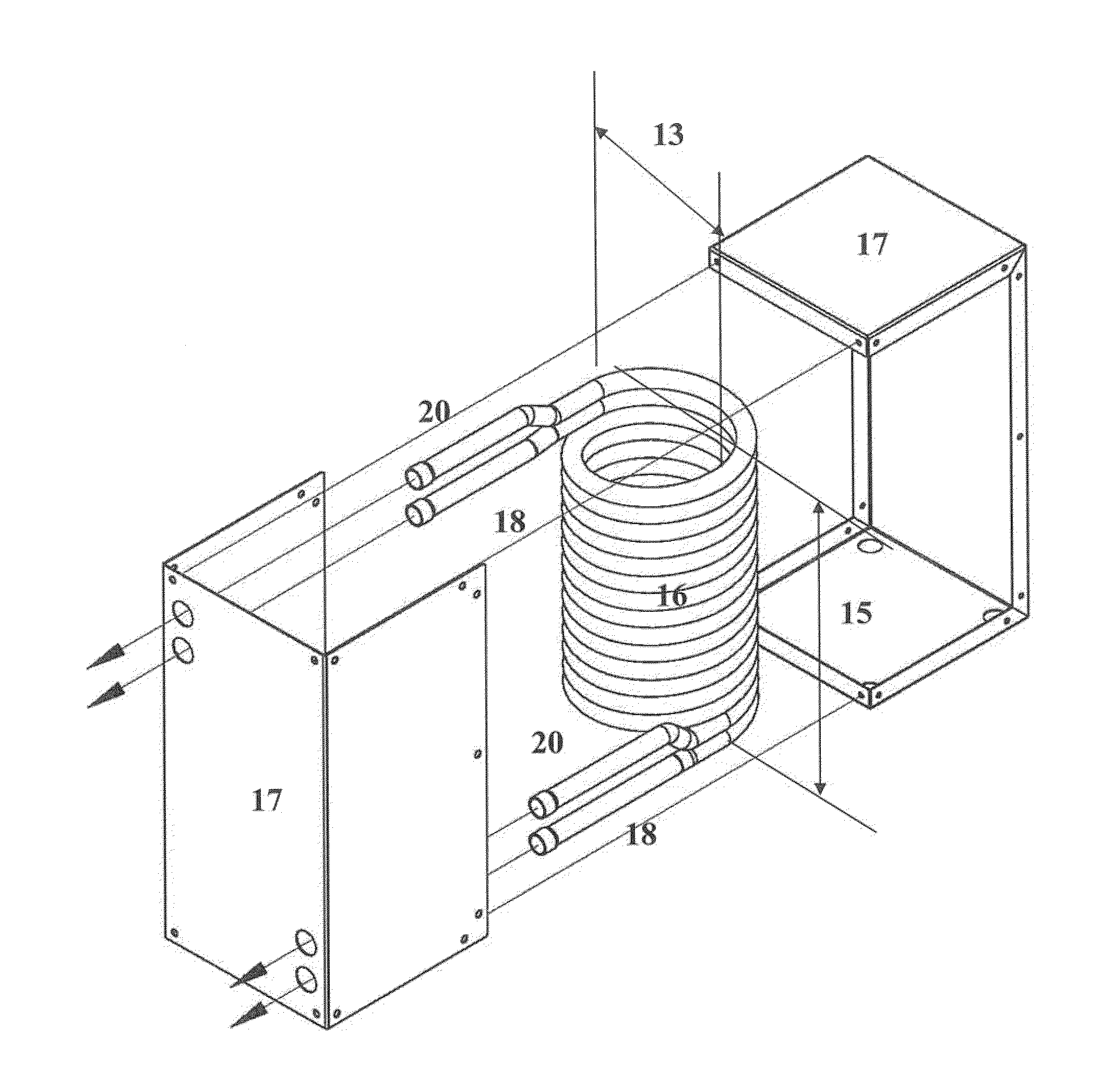

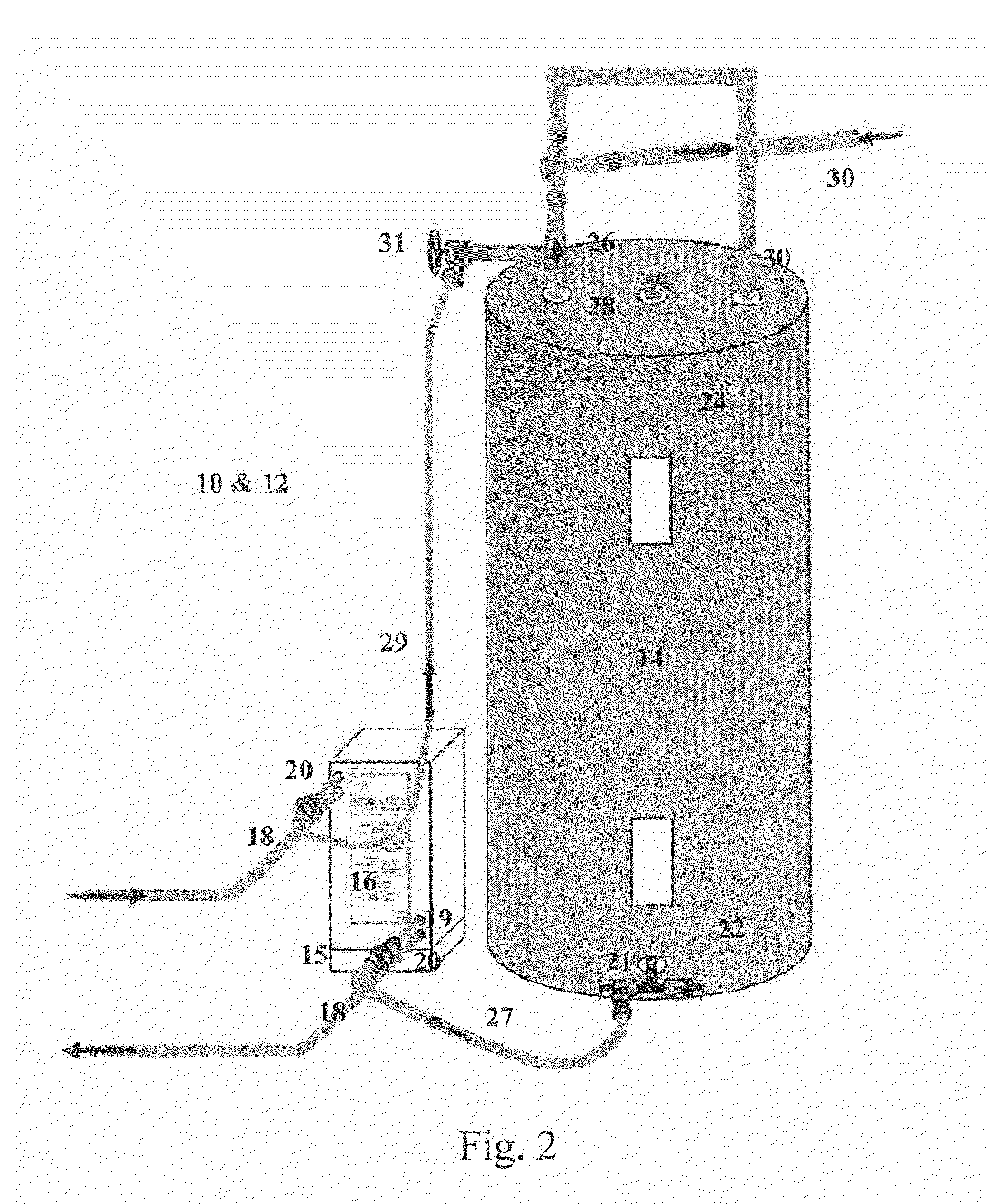

Thermosyphon Heat Recovery

ActiveUS20120261102A1Easy to installEasy to mergeFluid heatersHeat recovery systemsEngineeringRefrigerant

A thermosyphonic heat recovery unit for thermosyphonic heat transfer of heat from a hotter first fluid to a cooler second fluid comprising a heat exchanger including a first fluid conduit and a second fluid conduit, optimized means for connecting fluids to the two conduits to optimize heat transfer and fluid flow, a pressurized cold fluid input and hot fluid output, whereby the second fluid thermosyphonically flows through said second conduit as the first fluid flows through said first conduit. Said system having an optimized heat exchanger tube-on tube spirally wound, with wind direction to take advantage of the Coriolus force effect, for optimized refrigerant and other fluid turbulence and therefore optimized heat transfer, and optimum location of said heat exchanger and sizes of connecting tubes to minimize refrigerant friction related pressure loss, and to optimize heat transfer, refrigerant flow and thermosyphonic second fluid flow through said heat exchanger.

Owner:OLIVE TREE PATENTS 1

Dimples comprised of two or more intersecting surfaces

A golf ball with a dimple pattern designed to maximize flight characteristics employs dimples which are created by joining two or more intersecting surfaces. The invention provides for single radius or dual radius dimples, preferably including smaller radius cylinders tangentially arranged along the side of the larger cylinders. The intersection of the cylinders forms tri-cylinders, tri-semicylinders, bi-cylinders, quad-semicylinders, penta-semicylinders, or more generally n-cylinders depending upon the number of intersecting cylinders. The golf ball includes a plurality of single or dual radius dimples created by intersecting n-cylinders to create maximum turbulence on the ball during flight.

Owner:TOPGOLF CALLAWAY BRANDS CORP

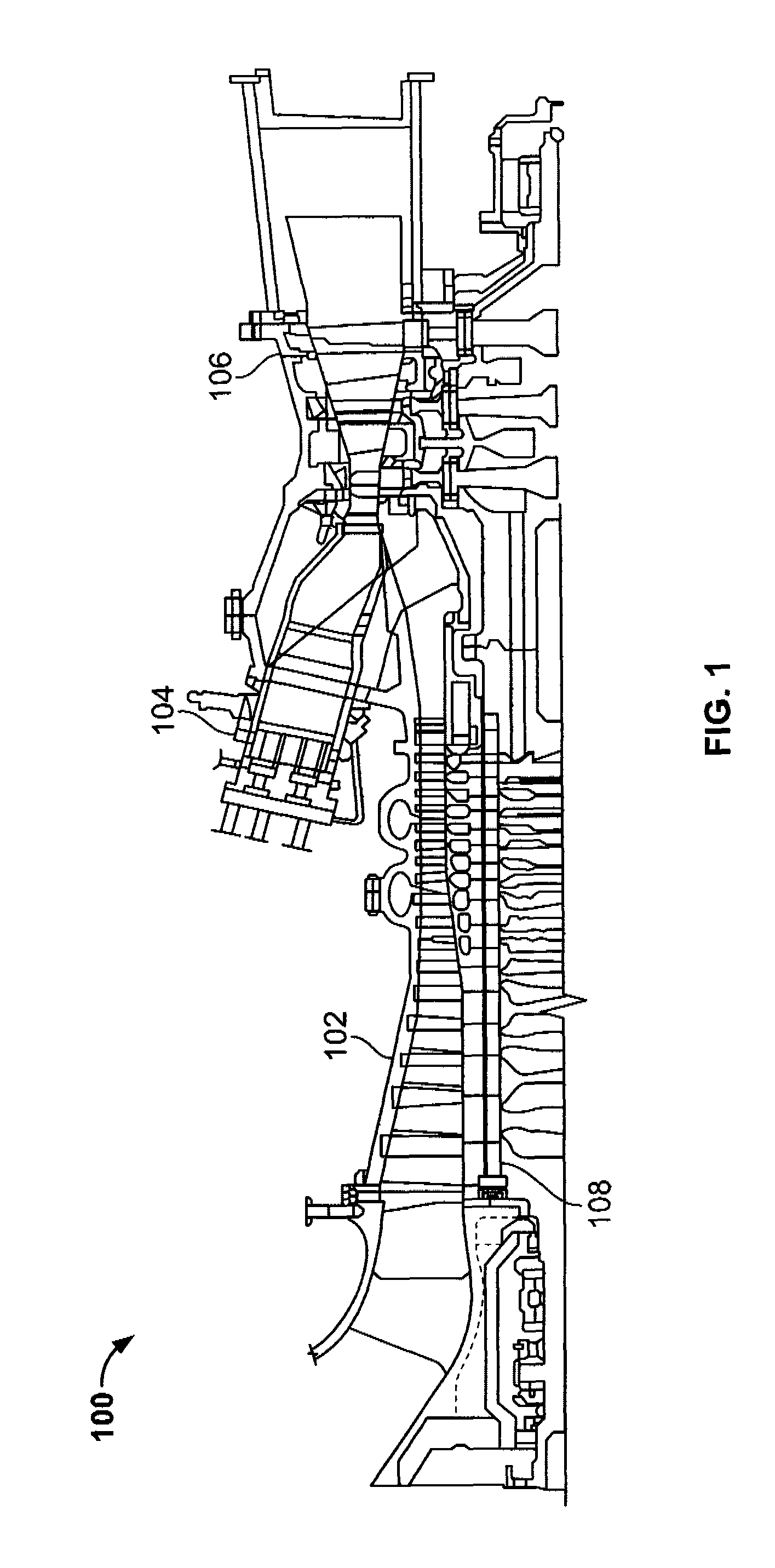

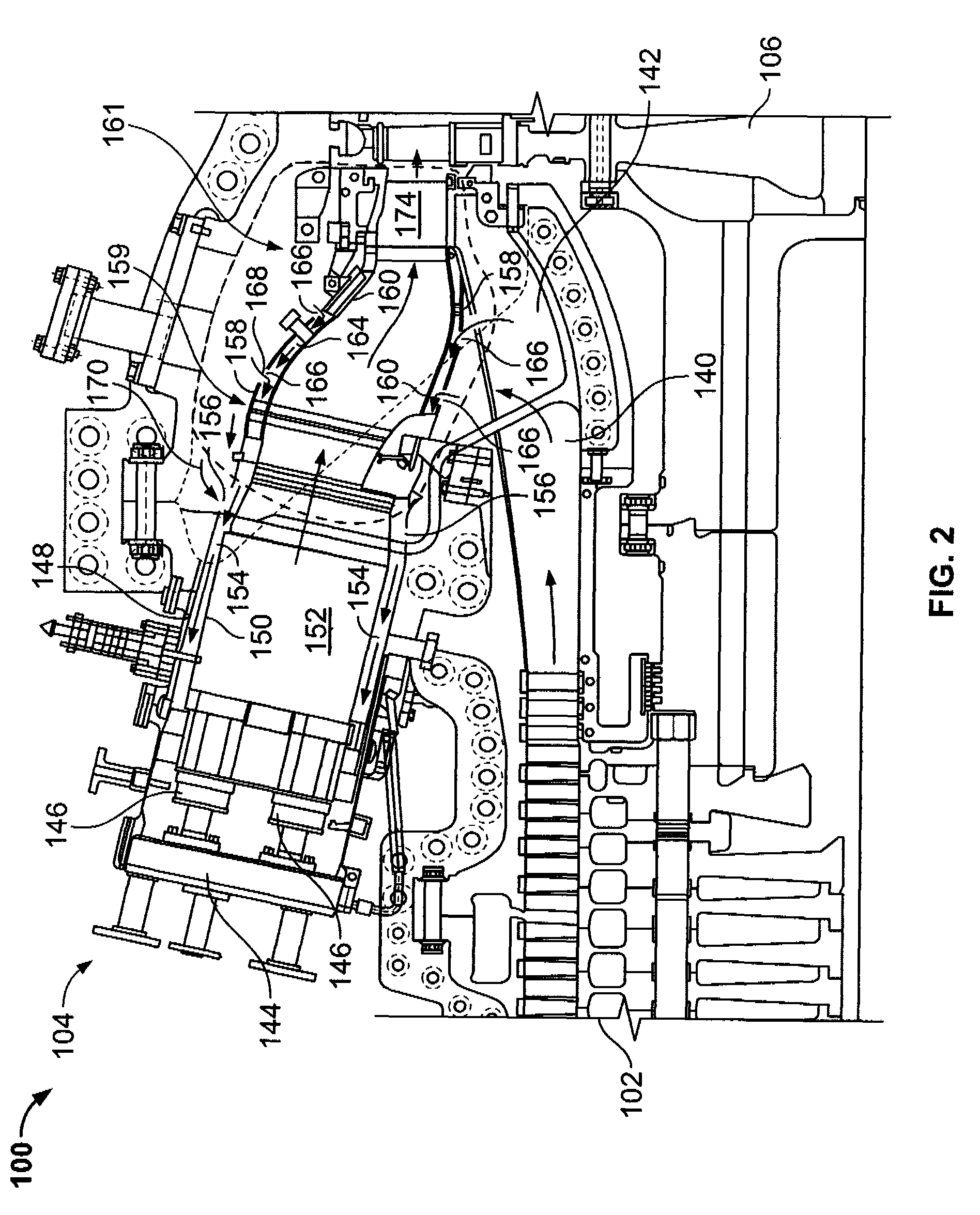

Method and apparatus to facilitate cooling turbine engines

InactiveUS7757492B2Easy to assemblePromote turbulenceEngine fuctionsTurbine/propulsion engine coolingCombustorTurbine

Owner:GENERAL ELECTRIC CO

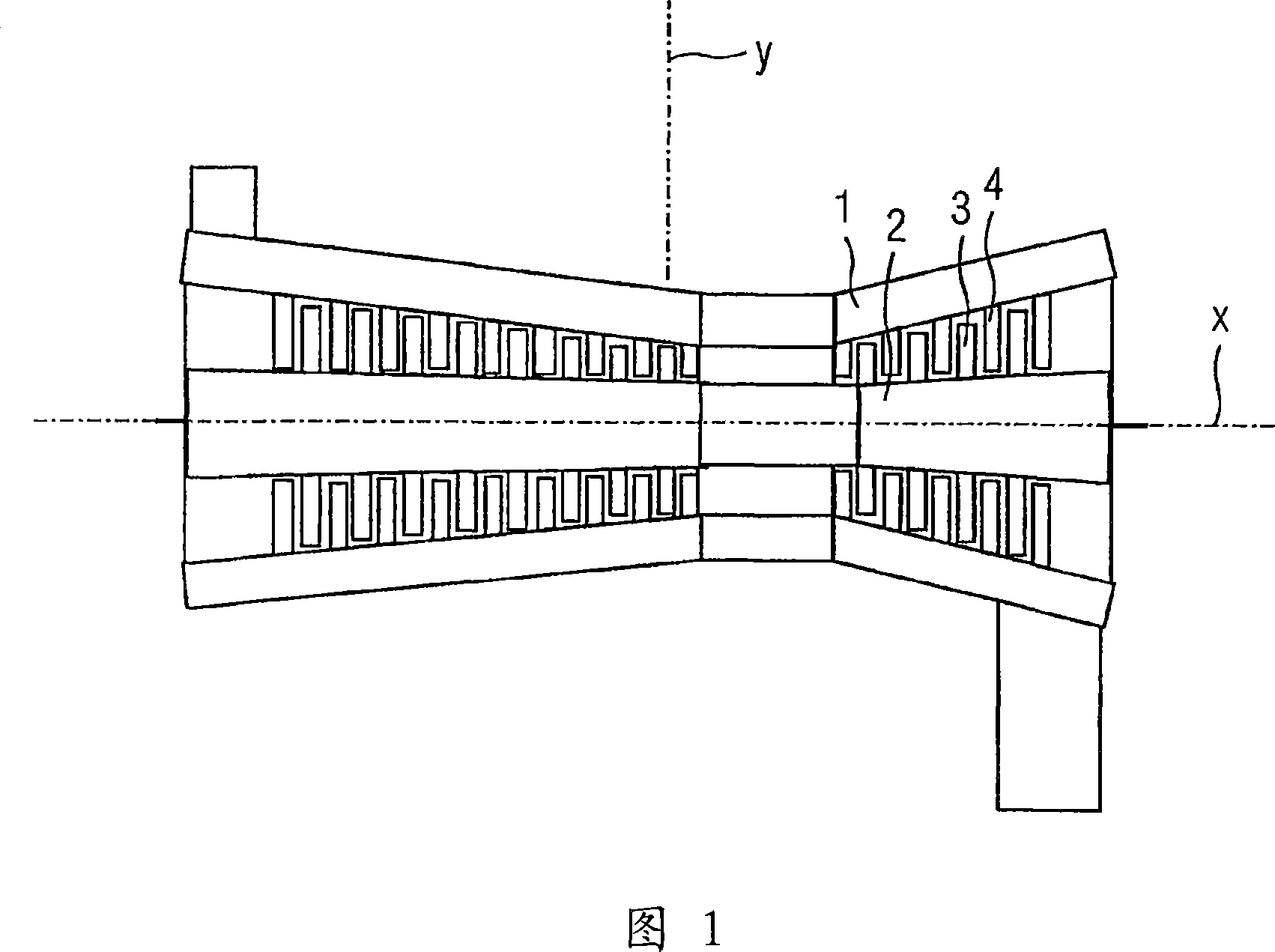

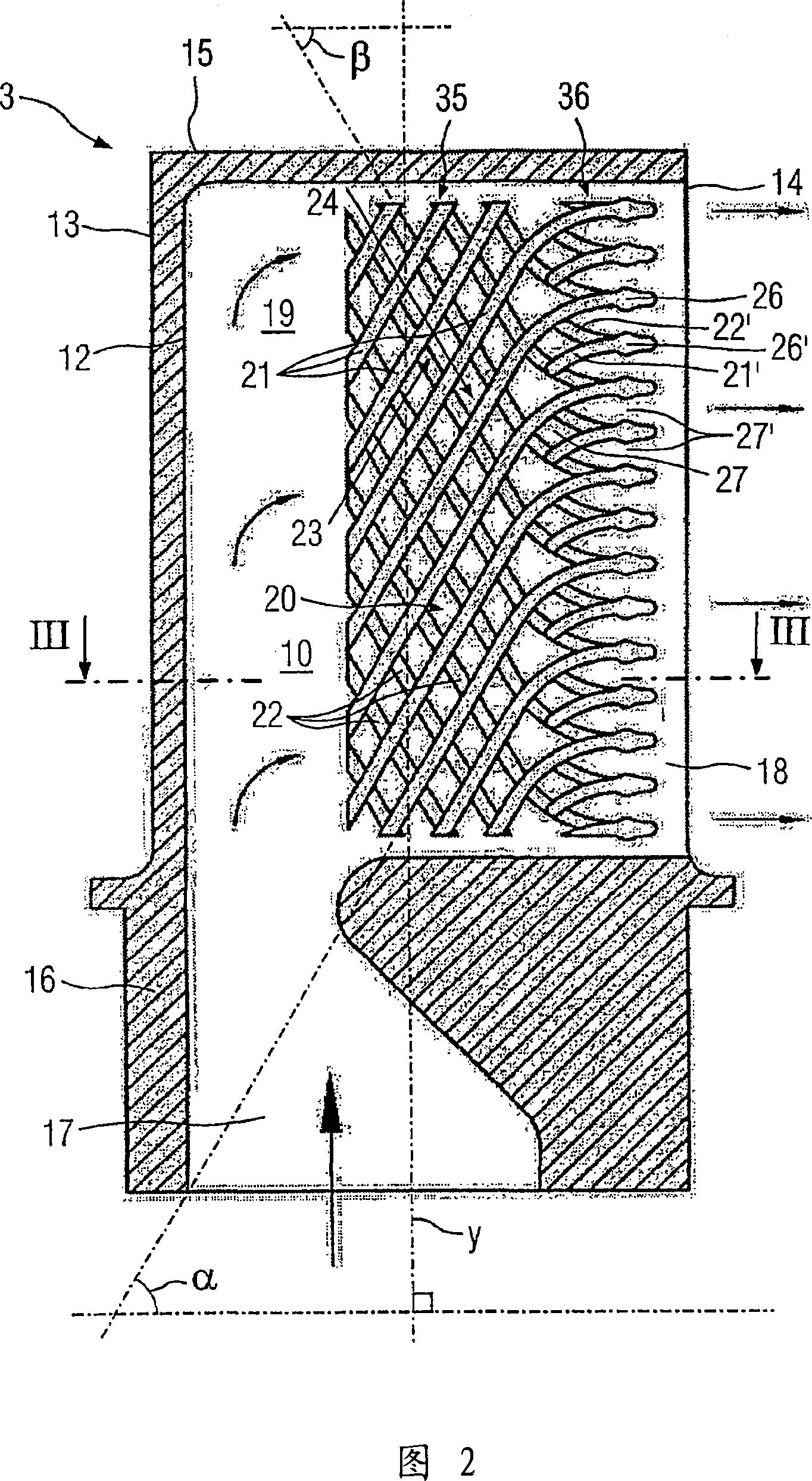

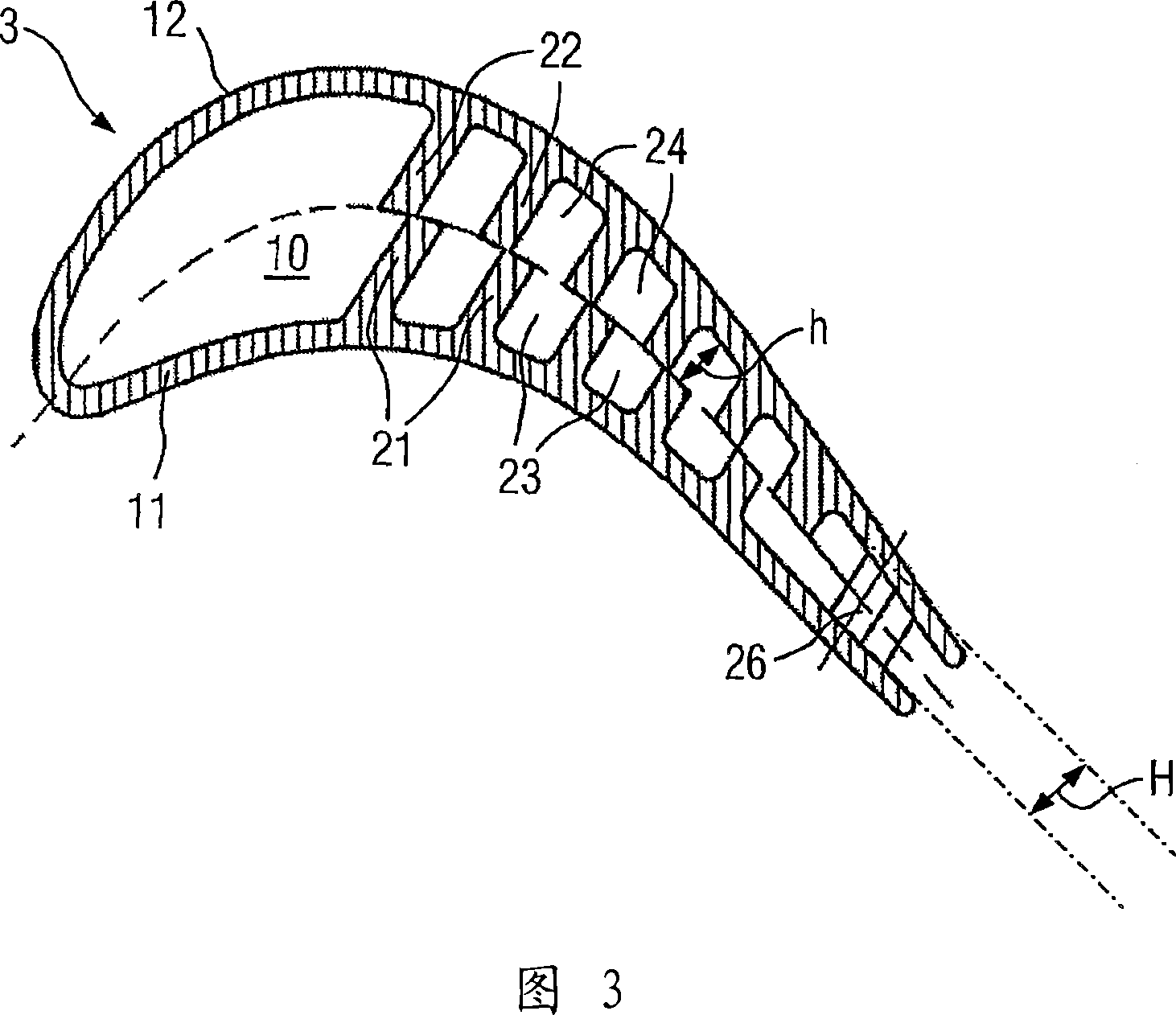

Blade or vane for a rotary machine

InactiveCN1997810AReduce cloggingIncrease contact areaEngine fuctionsBlade accessoriesInterior spaceEngineering

A component defines a blade or a vane for a rotor rotatable about a rotary axis (x). An inner space (10) of the component is limited by first and second walls (12), and forms a passage for a cooling fluid. First and second ribs (21, 22) project form the first and second walls, respectively, and extend in parallel to each other to form channels for the fluid from a leading end to a trailing end of the ribs. The ribs extend along a first and a third direction, respectively, in the proximity of the leading end and along a second direction and fourth direction, respectively, in the proximity of the trailing end. The first direction is inclined in relation to the second direction. The third direction is inclined in relation to the fourth direction. The first direction intersects with the third direction. The ribs extend from the leading end to the trailing end along a continuously curved path.

Owner:SIEMENS AG

Sensor

InactiveUS7810375B2Improve protectionReduce heat lossThermometer detailsAnalysing fluids using sonic/ultrasonic/infrasonic wavesEngineeringInternal combustion engine

A sensor, in particular a gas sensor for determining a physical characteristic of a measuring gas, in particular the temperature of the concentration of a gas component, in particular in the exhaust gas of an internal combustion engine, includes a sensor element which protrudes with a gas-side end section from a sensor housing and having a double protecting tube, which encloses the gas-side end section, and has an outer tube and an inner tube. For improved protection of the sensor element against thermal shock, a reduction in the heating power for the sensor element, and sufficiently high dynamics of the sensor, a cup-shaped central protecting tube is placed over the gas-side end section, the central protecting tube being provided with gas passage apertures in the tube casing, the gas passage apertures being positioned offset to the tube bottom with respect to the gas passage apertures present in the inner tube.

Owner:ROBERT BOSCH GMBH

Apparatus and system for enhancing aftertreatment regeneration

ActiveUS7797932B2Well mixedKeep for a long timeNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerExhaust fumes

An apparatus and system are disclosed for enhancing aftertreatment regeneration. The system includes an internal combustion engine and an exhaust manifold directing the engine exhaust to an aftertreatment system. The system may further include an exhaust gas recycle system and a turbocharger. The system further includes a fuel injector mounted on the exhaust manifold that provides fuel to assist in regenerating an aftertreatment component. The fuel injector is mounted in an apparatus also including a flow dampener, an extender, and a residence chamber. The apparatus allows the fuel to be injected in a high temperature location where it will experience residence time at temperature, and experience shear forces passing through the turbocharger. The extender allows the fuel to be injected at a place in the exhaust manifold where recycling of injected fuel into the engine is minimized.

Owner:CUMMINS INC

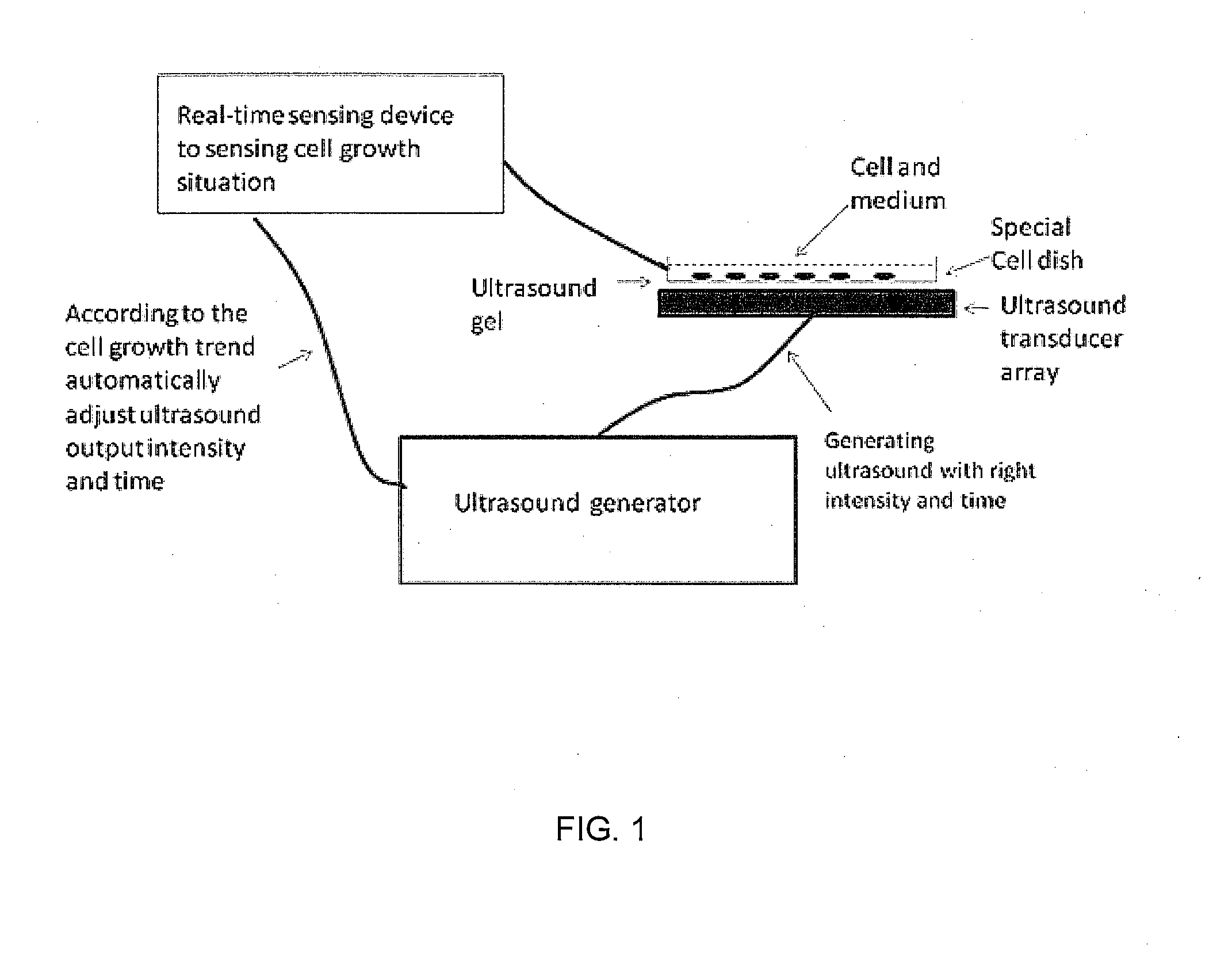

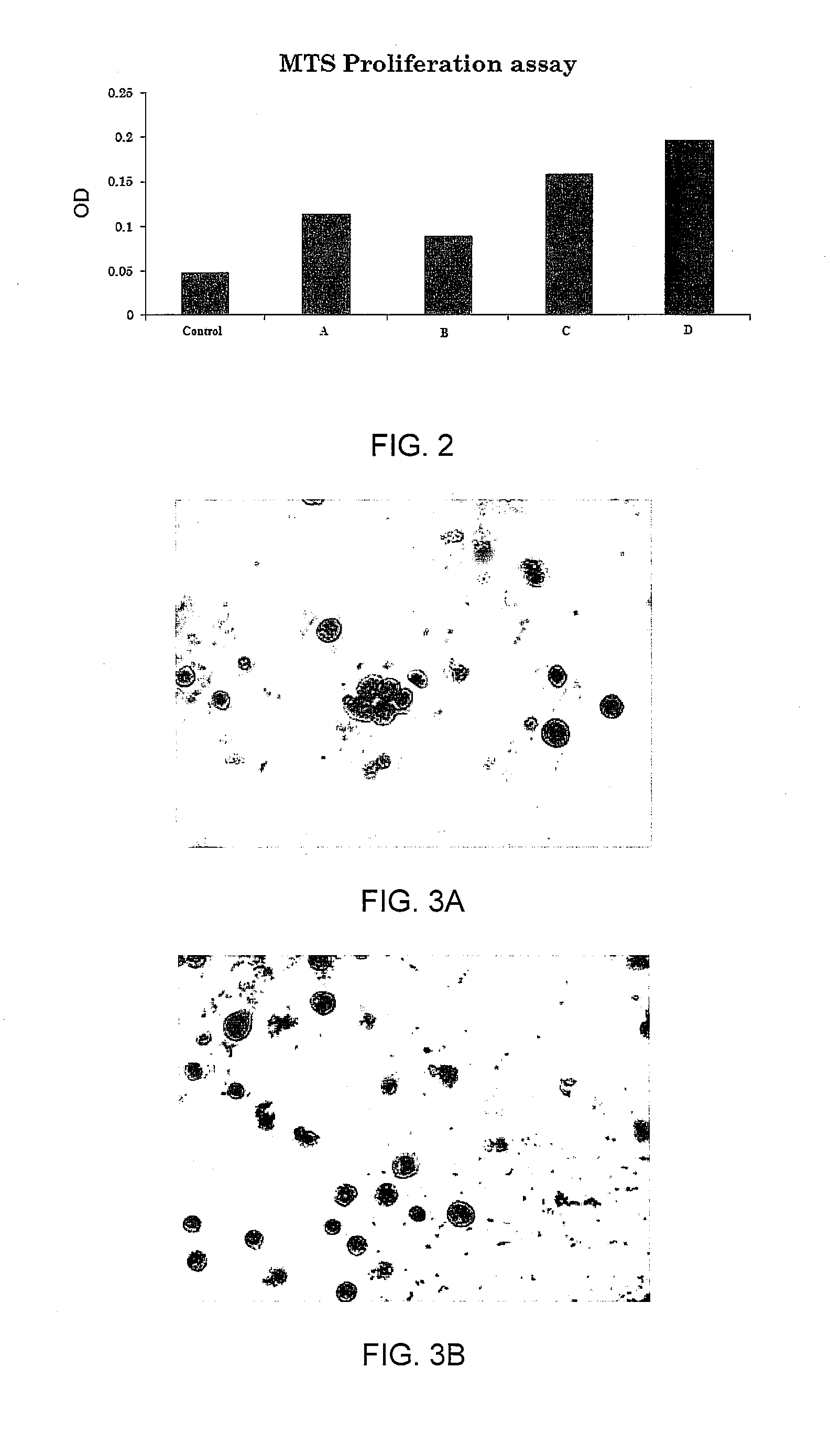

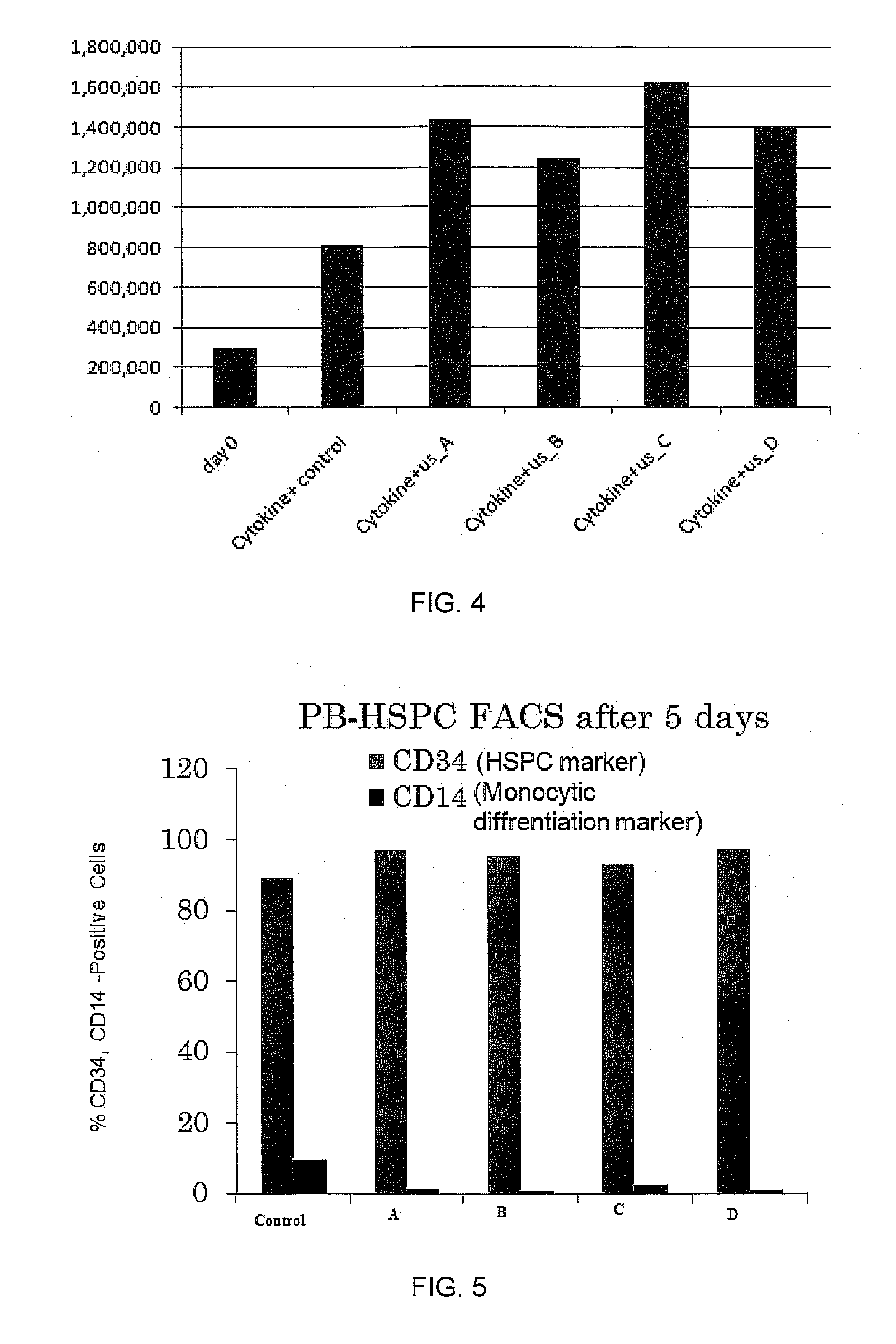

Enhanced animal cell growth using ultrasound

ActiveUS20130022957A1Enhancing of monoclonal antibody productionMinimize temperature increaseMicrobiological testing/measurementCulture processCell growthBiology

A method of increasing animal cell growth and monoclonal antibody production in an animal cell or cell culture includes the use of ultrasound at a frequency greater than about 1 MHz.

Owner:HIDACA

Catalytic reactor with swirl

InactiveUS20070237693A1Promote combustionSimple designCatalytic gas-gas reactionSemi-permeable membranesCombustorEngineering

A catalyst conduit for a catalytic reactor of a turbine combustor, the conduit comprising a tube including an inlet and an outlet, and a wall with an interior surface and an exterior surface. The tube contains a variation in its cross sectional area along at least a portion of its length to change a property of a fluid flowing adjacent the wall of the tube. An oxidation catalyst is deposited on at least a portion of the tube.

Owner:UNITED TECH CORP

Perimeter-cooled turbine bucket airfoil cooling hole location, style and configuration

InactiveUS20050031449A1Improve turbine efficiencyPromote turbulenceOther chemical processesEngine fuctionsTurbine bladeZ-Coordinate

A turbine stage one bucket has an airfoil having a plurality of cooling holes passing through the airfoil from 0% span to 100% span whereby cooling air exits the airfoil tip into the hot gas path. X and Y coordinate values are given in Table I, locating the holes relative to the airfoil profile at airfoil profile sections of 5%, 50% and 90% span, Table I also giving the hole diameters. In this manner, cooling hole optimization for this turbine bucket airfoil is achieved. The cooling holes are also located in relation to the profile of the bucket airfoil given by the X, Y and Z coordinate values of Table II, the two coordinate systems having the same origin.

Owner:GENERAL ELECTRIC CO

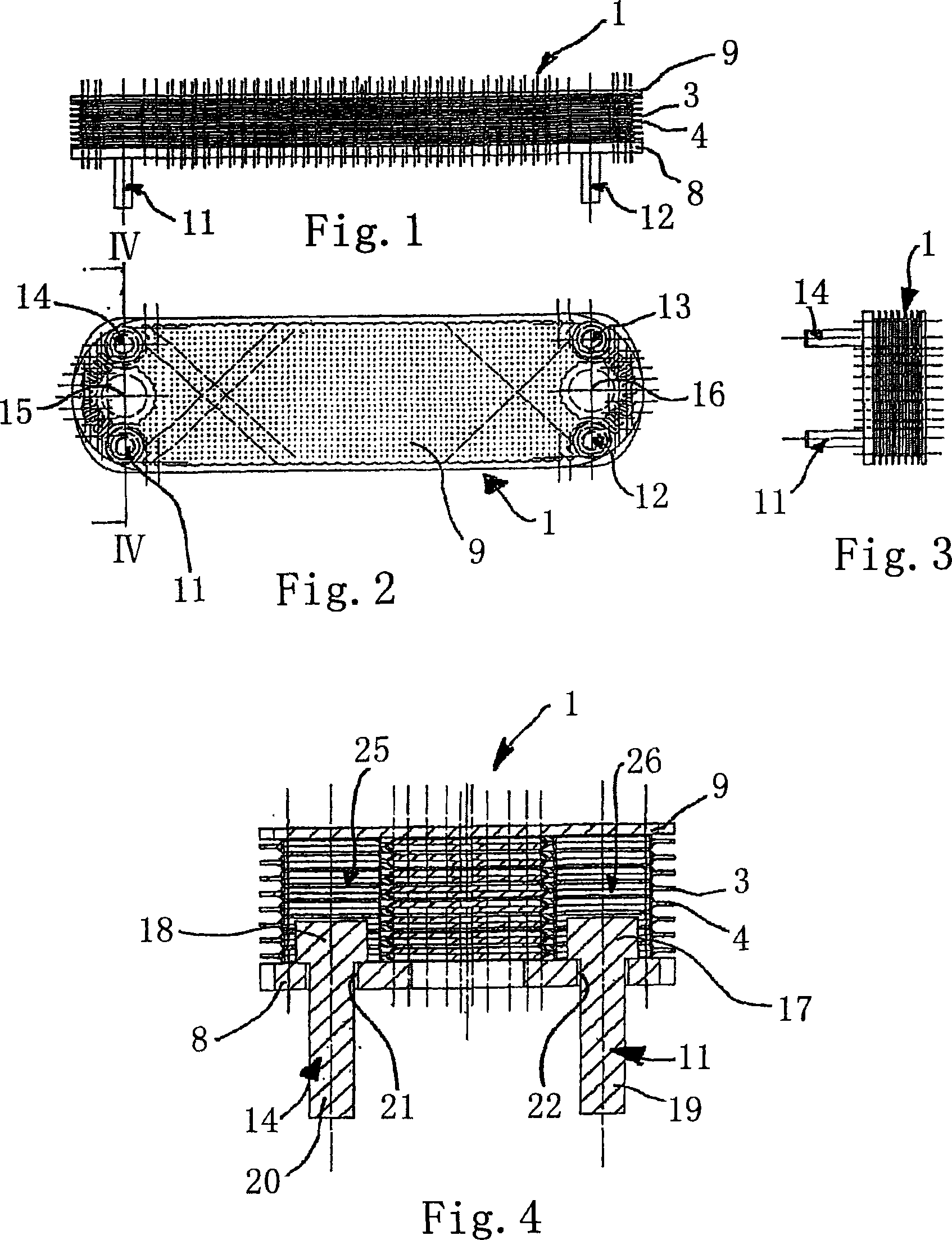

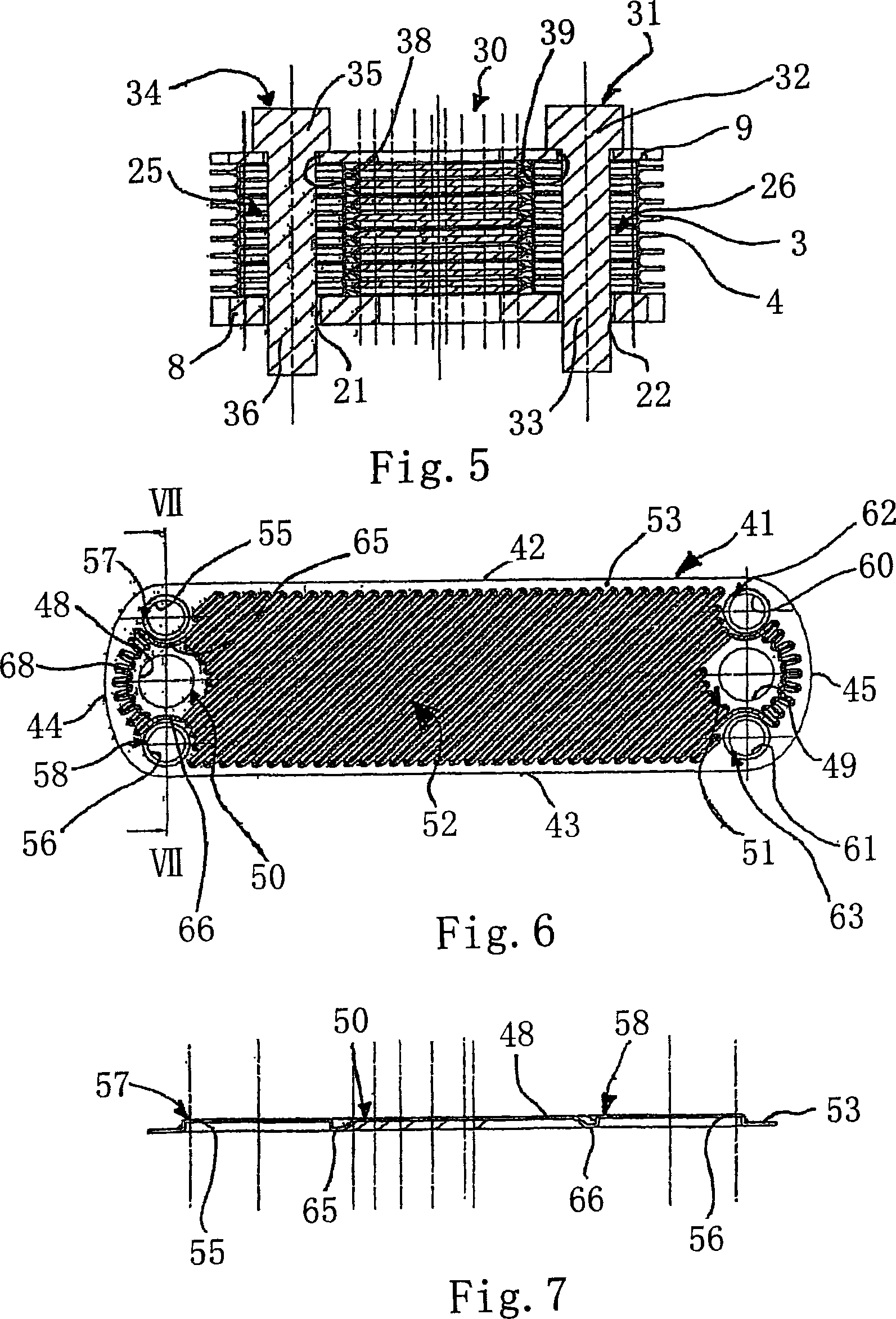

Plate heat exchanger

InactiveCN101103242AImprove brazing characteristicsReduce spacingHeat exchanger casingsLaminated elementsPlate heat exchangerEngineering

The invention relates to a plate heat exchanger, especially for a motor vehicle, comprising several conducting devices (3, 4), above all flat pipes, in the form of elongate disks which are stacked on top of each other, are interconnected, particularly soldered together, and are composed of two elongate half disks (41) that form a hollow space for conducting a medium therethrough. Each end of said half disks (41) is provided with a first through-hole (48; 49) for feeding or discharging the medium, said through-hole (48; 49) being disposed between two other through-holes (55, 56; 60, 61) from the perspective of the transversal direction of the half disks. In order to create a plate heat exchanger that has a simple design and can be produced at a low cost, an edge region (57, 58; 62, 63) of the other through-holes (55, 56; 60, 61) is embodied in a raised manner and is substantially provided with the shape of a pot encompassing a bottom in which the associated through-hole is recessed.

Owner:BEHR GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com