Plate heat exchanger

A heat exchanger, laminated technology, applied in the field of laminated heat exchanger, can solve the problems of high manufacturing cost and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

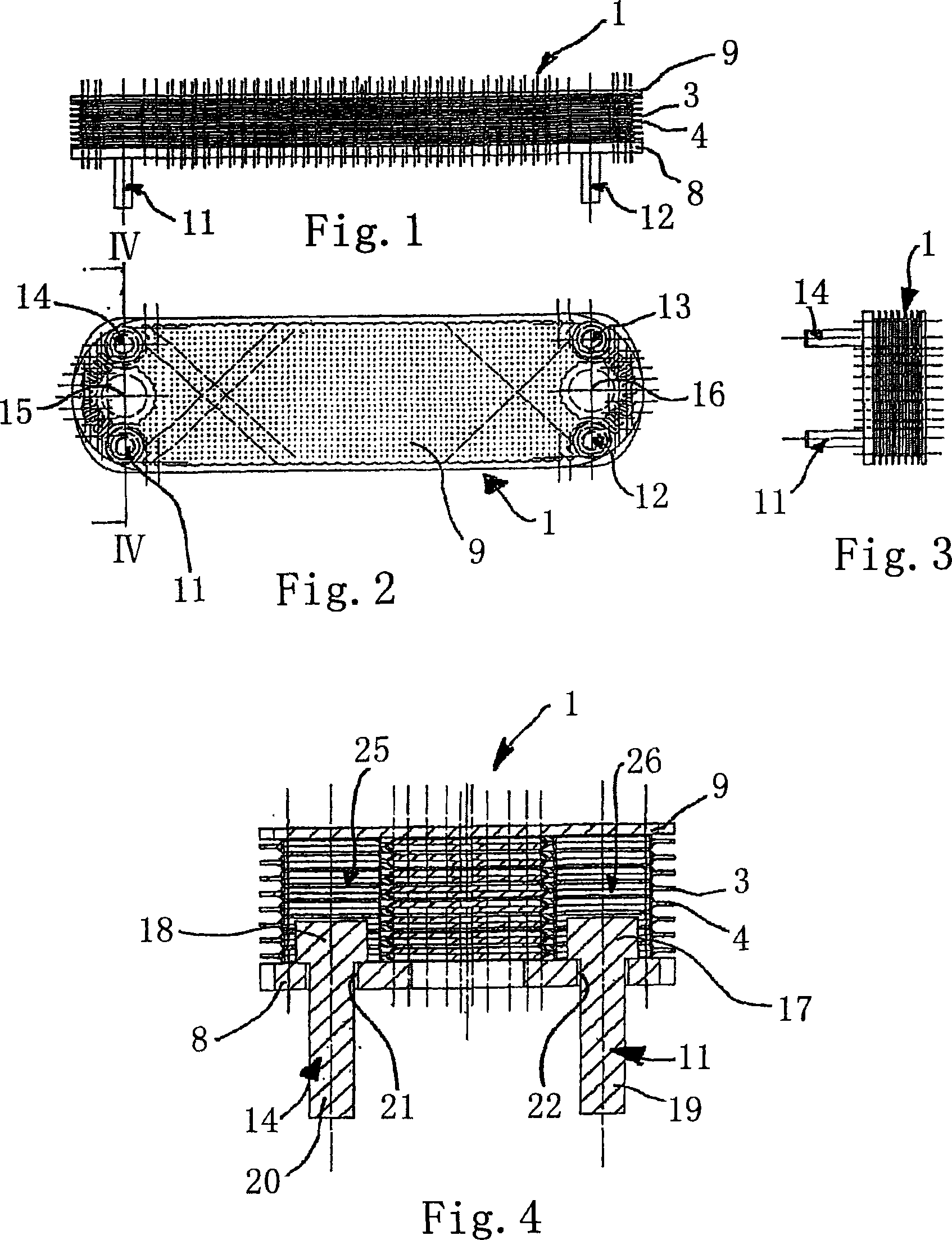

[0027] Fig. 1 is a front view of a laminated heat exchanger 1 according to the present invention. The laminated heat exchanger 1 comprises a plurality of substantially sheet-shaped flat tubes 3 , 4 which are placed one above the other between a base plate 8 and a cover plate 9 . The flat tubes 3 , 4 each have an opening at the end through which the medium to be cooled, in particular engine oil, can flow in or out. The medium to be cooled flows through the flat tubes 3 , 4 in the longitudinal direction. The flat tubes 3 , 4 are impinged on the outside by a cooling fluid which flows around the flat tubes 3 , 4 in a direction perpendicular to the plane of illustration in FIG. 1 .

[0028] FIG. 2 is a plan view of the laminated heat exchanger 1 shown in FIG. 1 . The laminated heat exchanger 1 can be fastened by four screws 11 to 14 to the engine block (not shown) of the motor vehicle or to the filter housing or filter housing cover. In FIG. 2 , through-holes 15 , 16 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com