Cooling device used for solid thermal carrier waste heat utilization system

A solid heat carrier and cooling device technology, which is applied in the field of waste heat recovery and waste heat recovery and utilization of solid heat carriers, can solve the problems of insufficient cooling and cooling of high-temperature solid heat carriers, and achieves promotion of cooling and cooling, heat recovery, and increased airflow disturbance. , the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

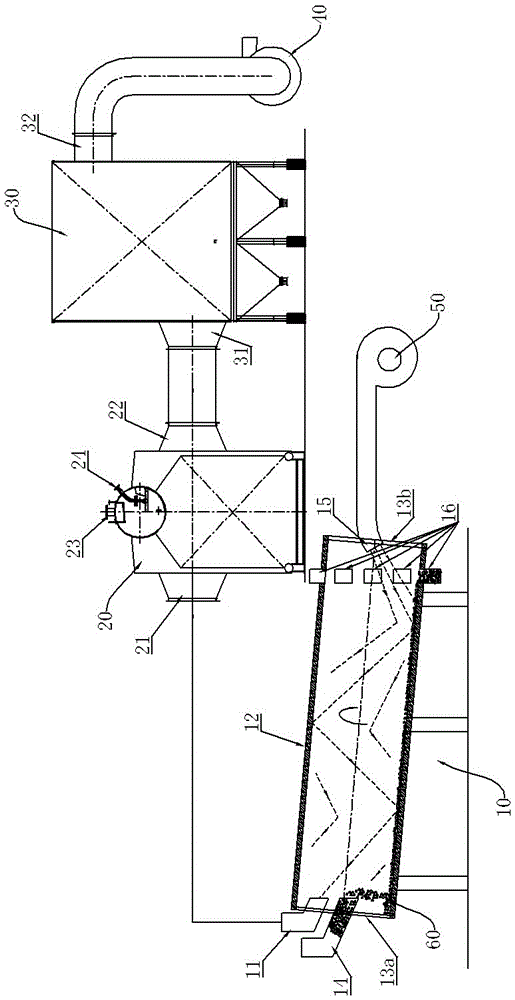

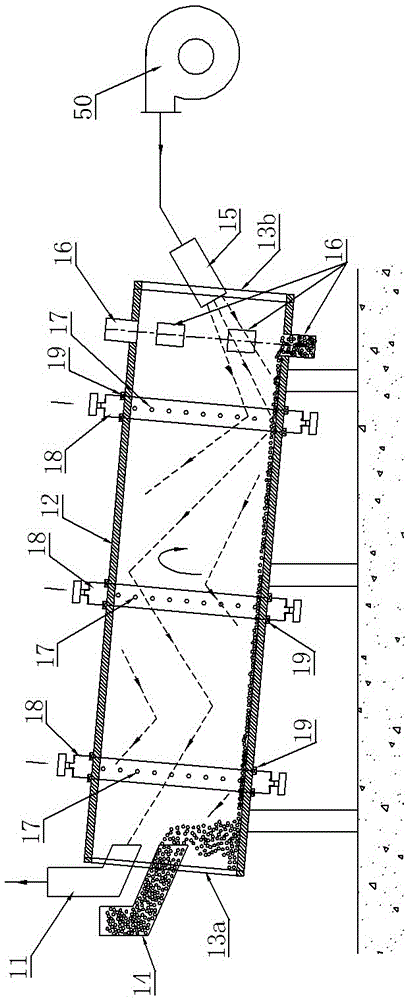

[0014] See figure 2 , the cooling device 10 for the solid heat carrier waste heat utilization system, which includes a rotary kiln 12, the two ends of the rotary kiln 12 are respectively sealed by end covers 13a, 13b and the rotary kiln 12 and the two end covers 13a, 13b can be relatively Turning, the end cover 13a is provided with a heat carrier inlet 14 and a high-temperature flue gas outlet 11, the end cover 13b is provided with a cooling air inlet 15, and the cooling air inlet 15 is connected to the blower 50, and the side of the rotary kiln 12 close to the cooling air 15 inlet is provided with a The heat carrier outlet 16; the outer periphery of the rotary kiln 12 is provided with a number of air inlet holes 17 distributed along the circumferential direction in rows. In this embodiment, three rows of air inlet holes 17 are arranged. Ring-shaped air inlet bins 18 are installed at the positions, and the annular air inlet bins 18 and the rotary kiln 12 can be relatively rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com