Intelligent control oxygen-enriched firing system and method for kiln

An intelligent control system and oxygen-enriched system technology, applied in the direction of combustion methods, furnaces, burners, etc., can solve the problems affecting the stability of the thermal system of the kiln firing system, the increase of NOx in flue gas emissions, and insufficient pulverized coal combustion, etc. problems, to achieve the effect of reducing the fluctuation of the kiln system, reducing the generation and emission of NOx, and facilitating safe transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

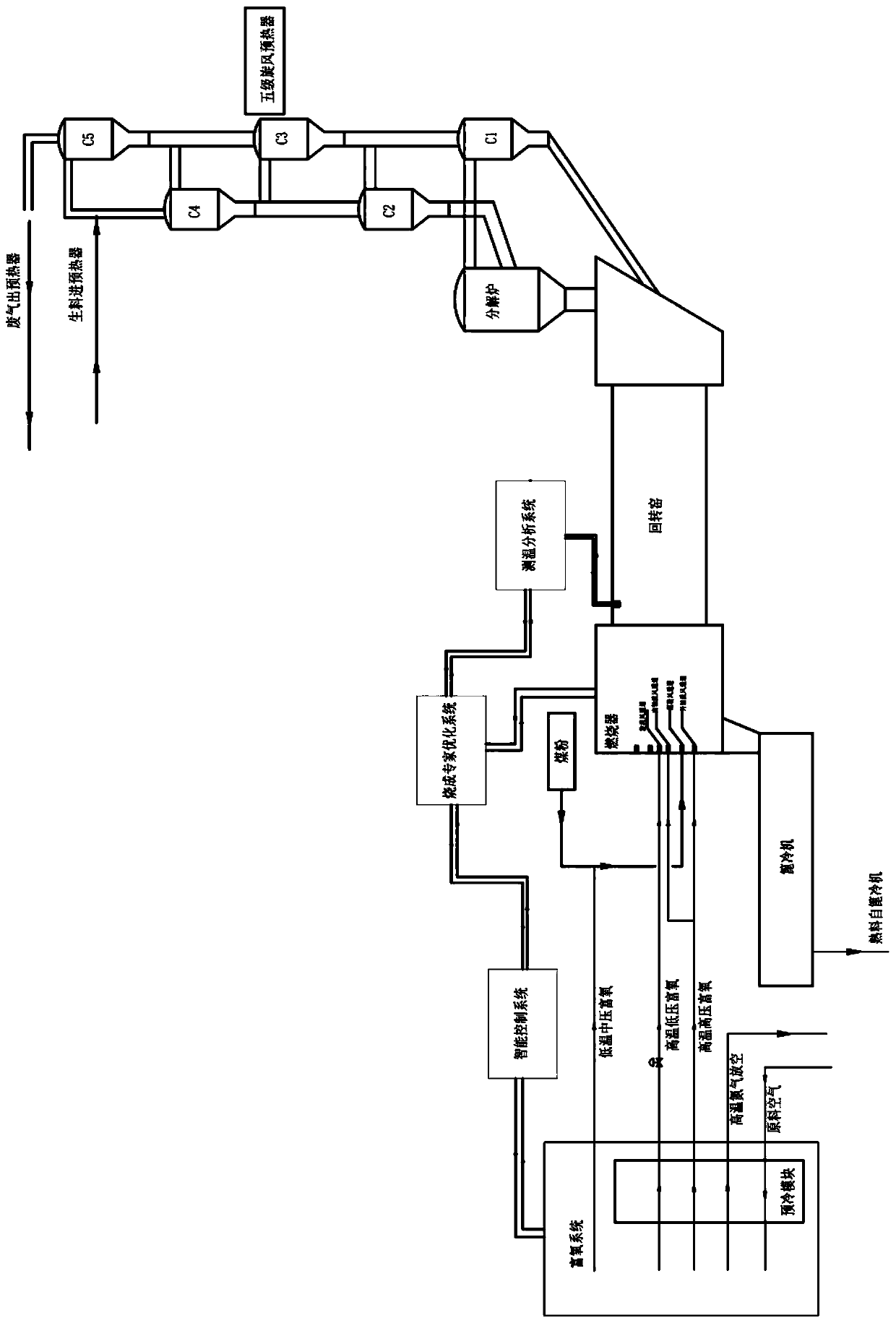

[0055] An intelligent control oxygen-enriched firing system for a kiln, such as figure 1 As shown, it includes oxygen-enriched system, oxygen-enriched burner, temperature measurement and analysis system, firing expert optimization system and intelligent control system.

[0056] The oxygen-enriched system can simultaneously produce low-temperature and medium-pressure oxygen-enriched products, high-temperature and low-pressure oxygen-enriched products, and high-temperature and high-pressure oxygen-enriched products, which are respectively used for coal feeding air, swirling air, and axial air (outer axial air and inner air) of cement kilns. axial wind).

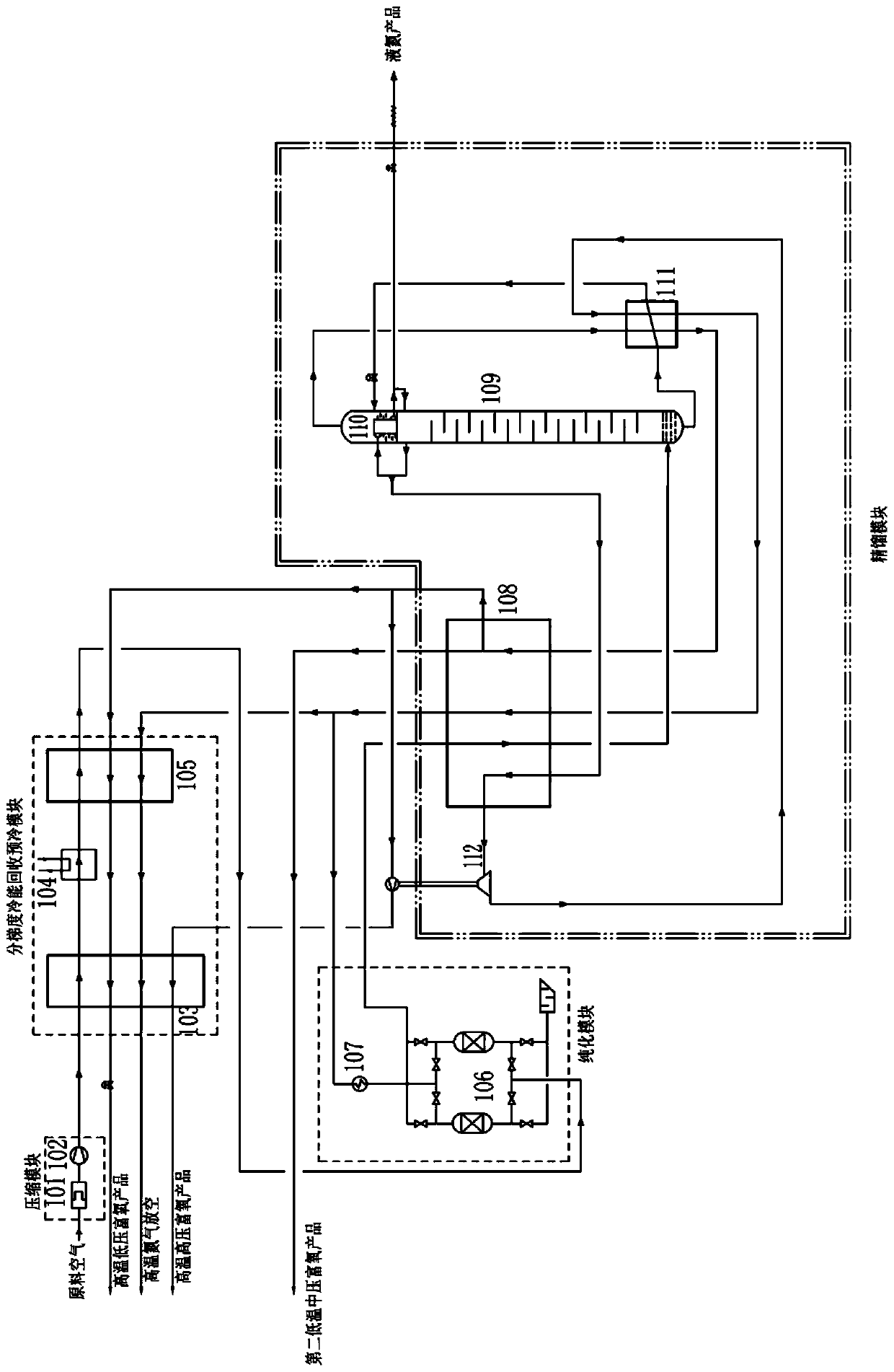

[0057] Such as figure 2 As shown, the oxygen enrichment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com