Environment-friendly non-fraying printed label tape and manufacturing method thereof

A manufacturing method and technology of trademark tapes, applied in textiles and papermaking, fabric surface trimming, etc., can solve the problems of time-consuming and high cost, easy damage to human skin, non-applicability and other problems, and achieve low production cost and no fluorescence Residue and Contamination Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

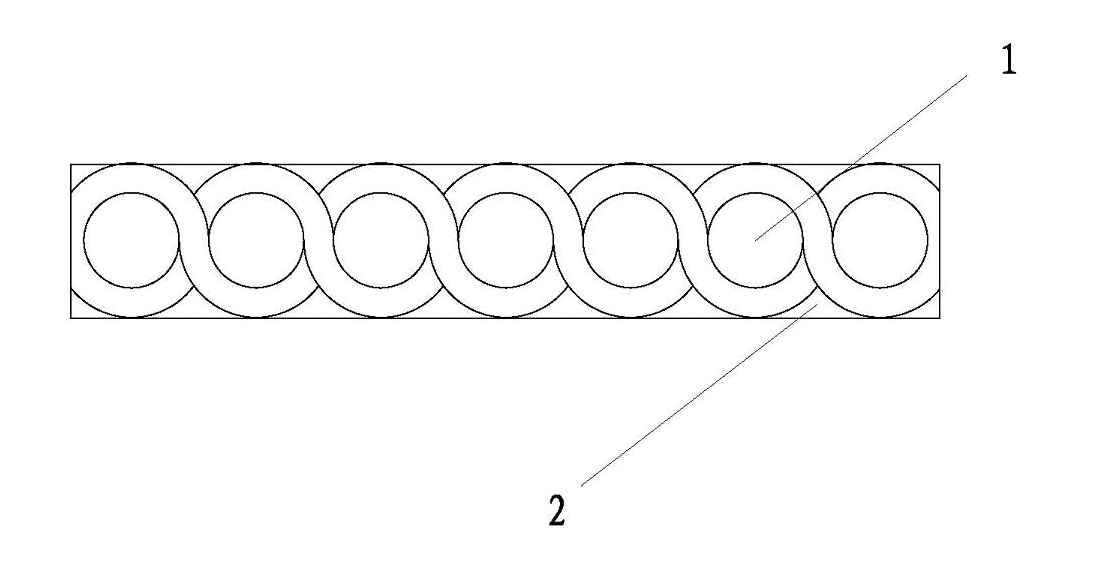

[0037] An environment-friendly non-scattering printed trademark tape, which includes a substrate layer 1 and an adhesive layer 2, and its thickness is 170 μm; its whiteness is 70-80%; its pH is 5-7.5; the formaldehyde content is <75.0mg / kg, in line with Oeko-tex standard 100 (formaldehyde content requirements for clothing in direct contact with the skin); the adhesive layer is an acrylic resin squeegee layer; Polyester-cotton cloth, the gray cloth has a yarn count of 20s, a warp density of 180, and a weft density of 60.

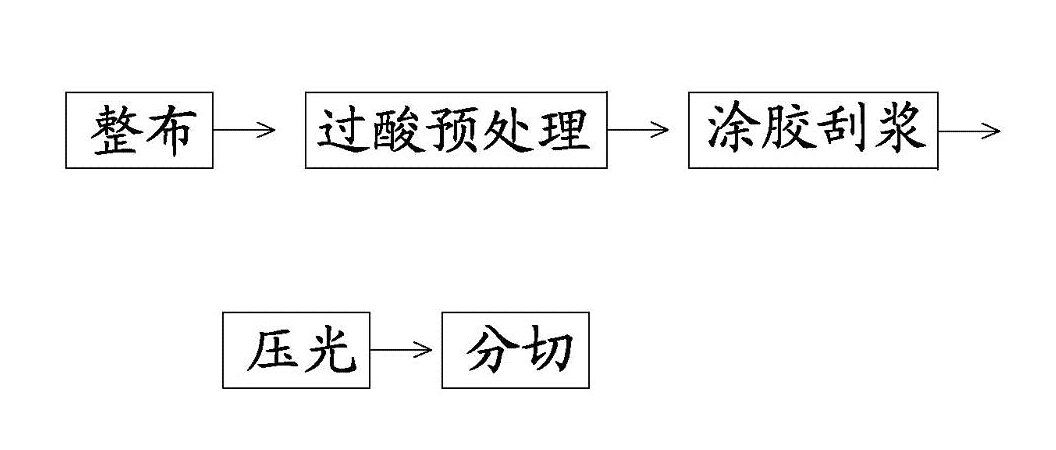

[0038]The above-mentioned environmentally friendly non-scattering printed trademark tape is made by the following method:

[0039] ①Peracid pretreatment

[0040] First add acidic substances to the pretreatment water so that the pH of the pretreatment water is <4, and then soak the gray cloth in the pretreatment water;

[0041] ② Glue and squeegee

[0042] Apply glue to the gray cloth, and the amount of glue applied is controlled at 20g / m 2 ;After gluing,...

Embodiment 2

[0048] An environmentally friendly non-scattering printed trademark tape, which includes a substrate layer 1 and an adhesive layer 2, its thickness is 180 μm; its whiteness is 70-80%; its pH is 5.5-7; the formaldehyde content is <60.0mg / kg; the adhesive layer is a polyurethane resin squeegee layer; the gray cloth cloth for the base material layer is a polyester-cotton cloth obtained by plain weaving, the yarn count of the gray cloth is 25s, the warp density is 190, and the weft density for 65.

[0049] The above-mentioned environmentally friendly non-scattering printed trademark tape is made by the following method:

[0050] ①Peracid pretreatment

[0051] First add acidic substances to the pretreatment water so that the pH of the pretreatment water is <3, and then soak the gray cloth in the pretreatment water;

[0052] ② Glue and squeegee

[0053] Apply glue to the gray cloth, and the amount of glue applied is controlled at 25g / m 2 ; After gluing, use squeegee equipment t...

Embodiment 3

[0059] An environment-friendly printing label tape with non-scattering edges, which includes a base material layer 1 and an adhesive layer 2, and its thickness is 190 μm; its whiteness is 70-80%; its pH is 5-6.5; the formaldehyde content is <40.0mg / kg; the adhesive layer is an acrylic resin squeegee layer; the gray cloth cloth for making the base material layer is a polyester-cotton cloth obtained by plain weaving, the yarn count of the gray cloth is 30s, the warp density is 200, and the weft density for 70.

[0060] The above-mentioned environmentally friendly non-scattering printed trademark tape is made by the following method:

[0061] ①Peracid pretreatment

[0062] Add acidic substances to the pretreatment water to make the PH of the pretreatment water <2, and then soak the gray cloth in the pretreatment water;

[0063] ② Glue and squeegee

[0064] Apply glue to the gray cloth, and the amount of glue applied is controlled at 40g / m 2 ; After gluing, use squeegee equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com