aps/mes lean manufacturing management system

A management system and lean technology, applied in the direction of instruments, etc., can solve problems such as unclear production site bottleneck procedures, reduce enterprise competitiveness, slow work efficiency, etc., improve capital turnover speed and market sensitivity, and solve manufacturing synchronization problems , Improve the effect of reaction speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

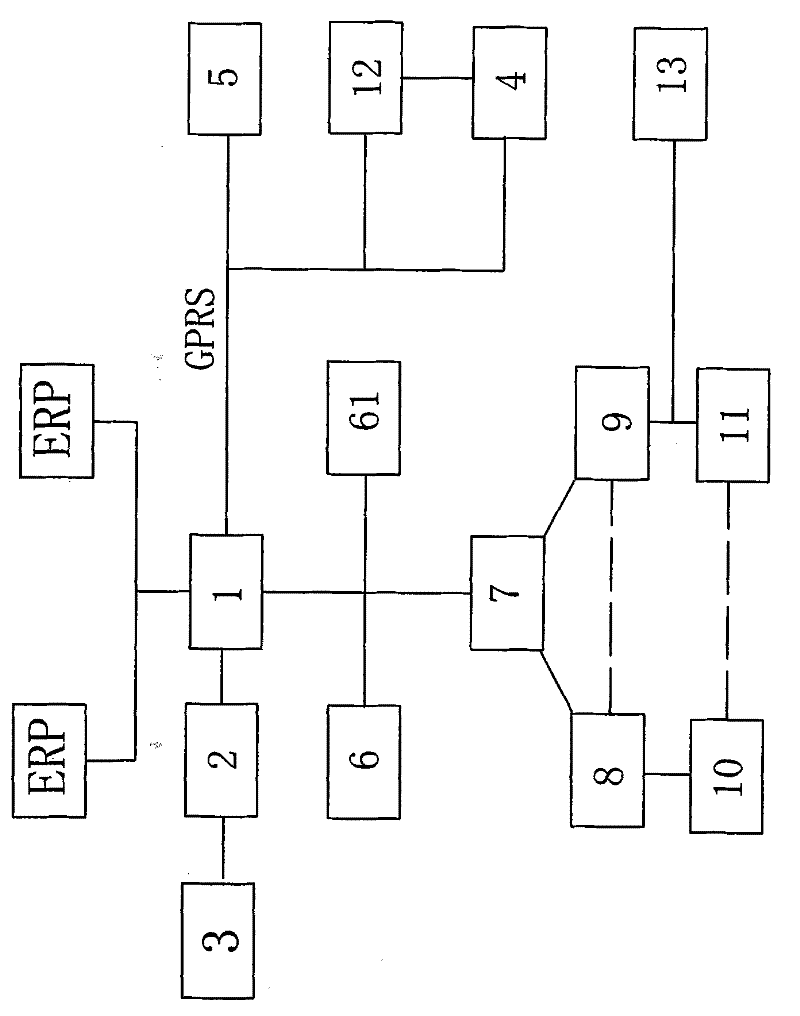

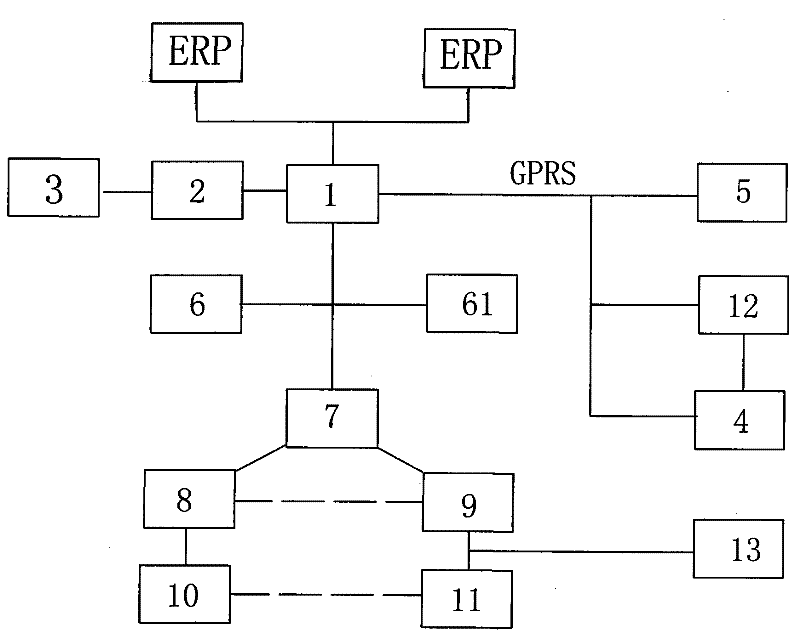

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: as figure 1 shown

[0027] figure 1 It is the schematic diagram of the present invention. exist figure 1 Among them, APS / MES lean manufacturing management system, host server 1 (plan general scheduling platform and production resource operation management platform) is connected with industrial touch all-in-one machine 2, and industrial touch all-in-one machine 2 can call relevant data in host server 1 in real time. (Relevant persons in charge can also perform processing operations on the industrial touch all-in-one machine 2 through instructions), and at the same time, the host server 1 is also connected to the electronic display board 3, and the electronic display board 3 can display relevant information of each department in real time (can be disclosed), The host server 1 is also connected with the REID card reader material distribution card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com