Control device of flatness and elevation of cast-in-place concrete ground surface and method for construction

A construction method and technology of a control device, which are applied in the processing of building materials, roads, and road repairs, etc., can solve the problems that cannot meet the construction of large-area concrete ground, the surface flatness of channel steel formwork is not enough, and the control accuracy of supporting formwork elevation is poor, etc. The problem is to prevent the elevation deviation from being too large, the structure is simple, and the overall flatness is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

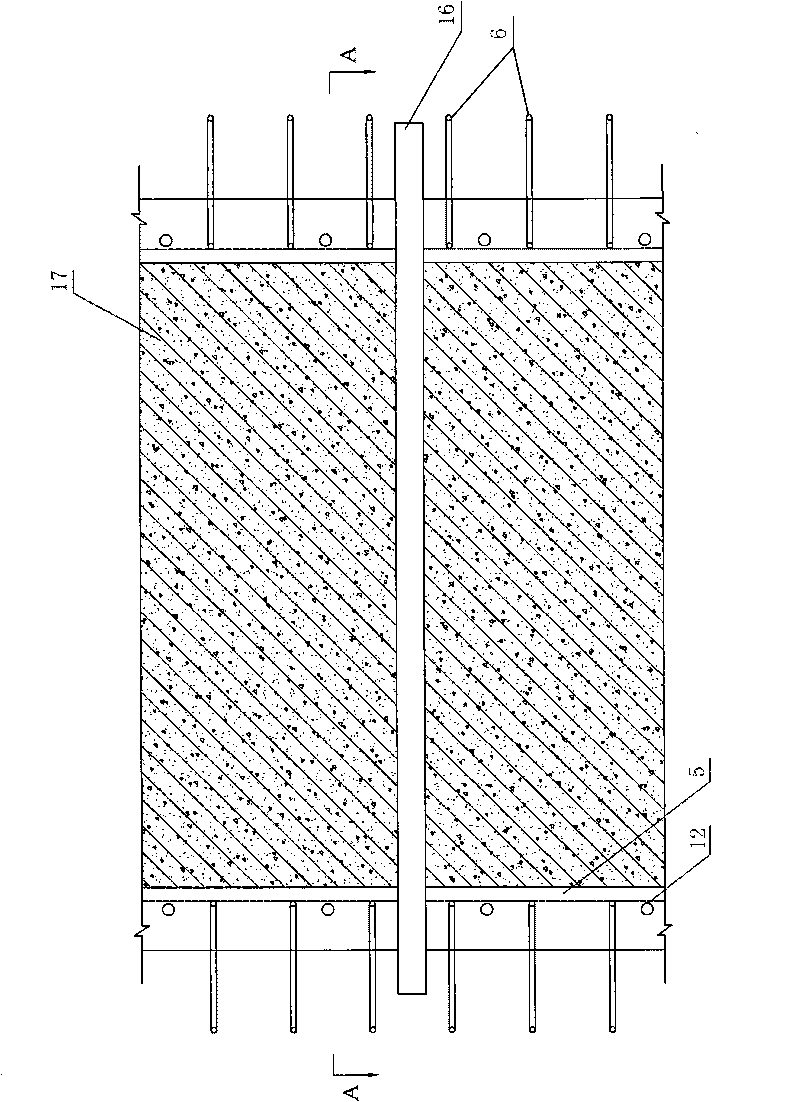

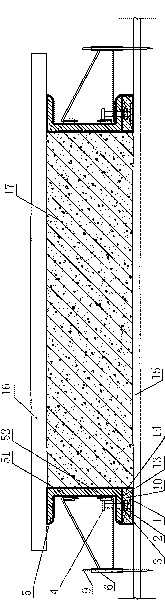

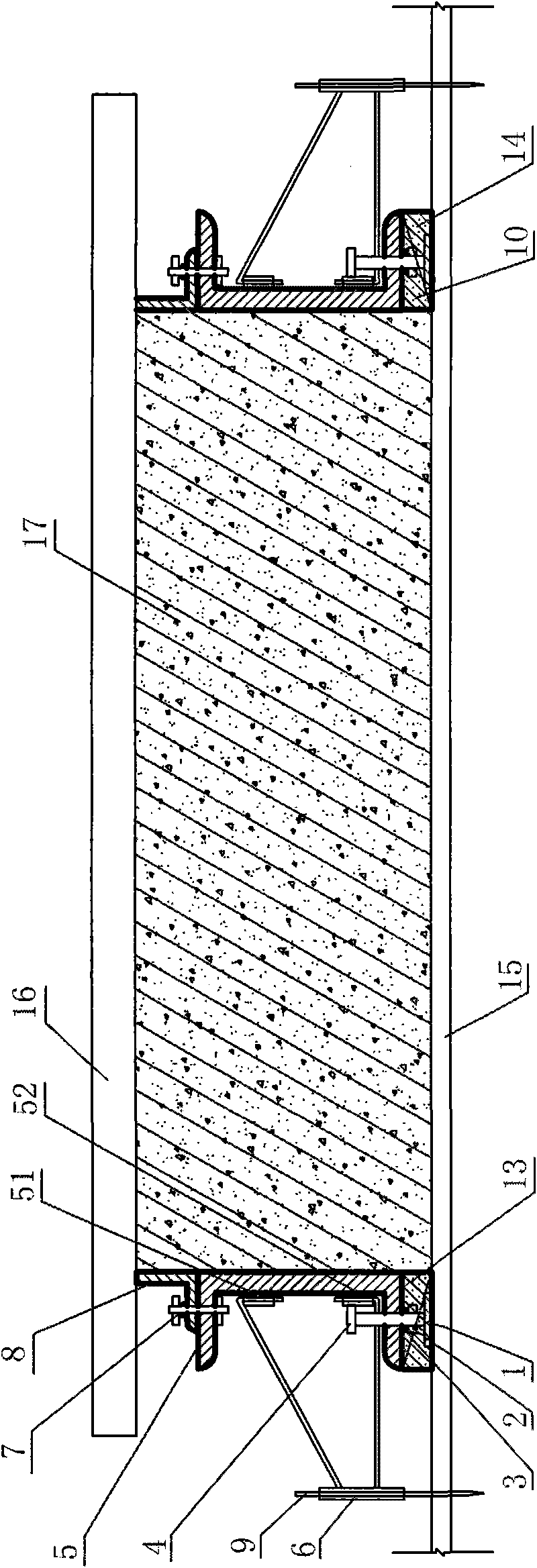

[0033] A device for controlling the flatness and elevation of cast-in-place concrete ground and a construction method used for controlling the flatness and elevation of the cast-in-place concrete ground.

[0034] Such as figure 1 , figure 2 As shown, the cast-in-situ concrete floor flatness and elevation control device includes a main channel steel formwork 5, a main channel steel support 6 for fixing the main channel steel formwork 5, and a bracket fixing member 9, on which the main channel steel formwork 5 is installed N groups of template height adjustment mechanism, each group of template height adjustment mechanism includes a supporting backing plate and a set of adjusting bolts composed of supporting screw 4, fastening washer 3 and adjusting nut 2. The supporting backing plate 1 is placed on the main channel steel In the gap between the template 5 and the foundation layer 15, the support screw 4 has a fixed hexagon head at the upper end, and its lower end passes through the...

Embodiment 2

[0056] A cast-in-place concrete floor flatness and elevation control device with additional angle steel formwork and a construction method for the cast-in-place concrete floor flatness and elevation control.

[0057] The basic structure of the cast-in-place concrete floor flatness and elevation control device with additional angle steel formwork in this embodiment is the same as that of the first embodiment. The difference is that: an additional angle steel formwork 8 is installed on the main channel steel formwork 5 by connecting bolts 7 , The outer side of the additional angle steel template 8 and the outer side of the main channel steel template 5 are in the same plane, and the horizontal end surface is planed. The main channel steel template 5 is drilled with bolt holes 11 for mounting and connecting bolts, between the bolt holes 11 With a distance of 2000mm, the main channel steel formwork 5 and the additional angle steel formwork 8 are connected to form an overall formwork f...

Embodiment 3

[0063] A construction method for super-wide, super-long and large-area cast-in-situ concrete ground flatness and elevation control. The basic steps are the same as those in the first or second embodiment. The difference is: in A, foundation treatment, the ground is divided into points The grid bin and the filling bin pop up the ground concrete dividing grid line; for the ground concrete in the grid bin, after pouring and constructing according to the steps B~H of the above method, curing for three days, and then the following steps:

[0064] I: Pouring and filling the floor concrete: first remove the template around the floor concrete of the compartment, place the vibrating leveling roller rolling equipment directly on the concrete of the two compartments that have been poured, pour the concrete in the compartment, and vibrate Rolling rollers are used for leveling to lift the slurry, flattened and smoothed or napped according to the design, and sealed with a film for watering and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com