Adjustable large-area floor channel steel formwork system and its construction method

A large-area, adjustable technology, applied in the field of formwork/formwork/work frame, construction components on-site preparation, construction, etc., can solve the problem of poor appearance of large-area floor concrete, large error in surface layer flatness, formwork The support and reinforcement are not strong enough to achieve the effect of low price, convenient production and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

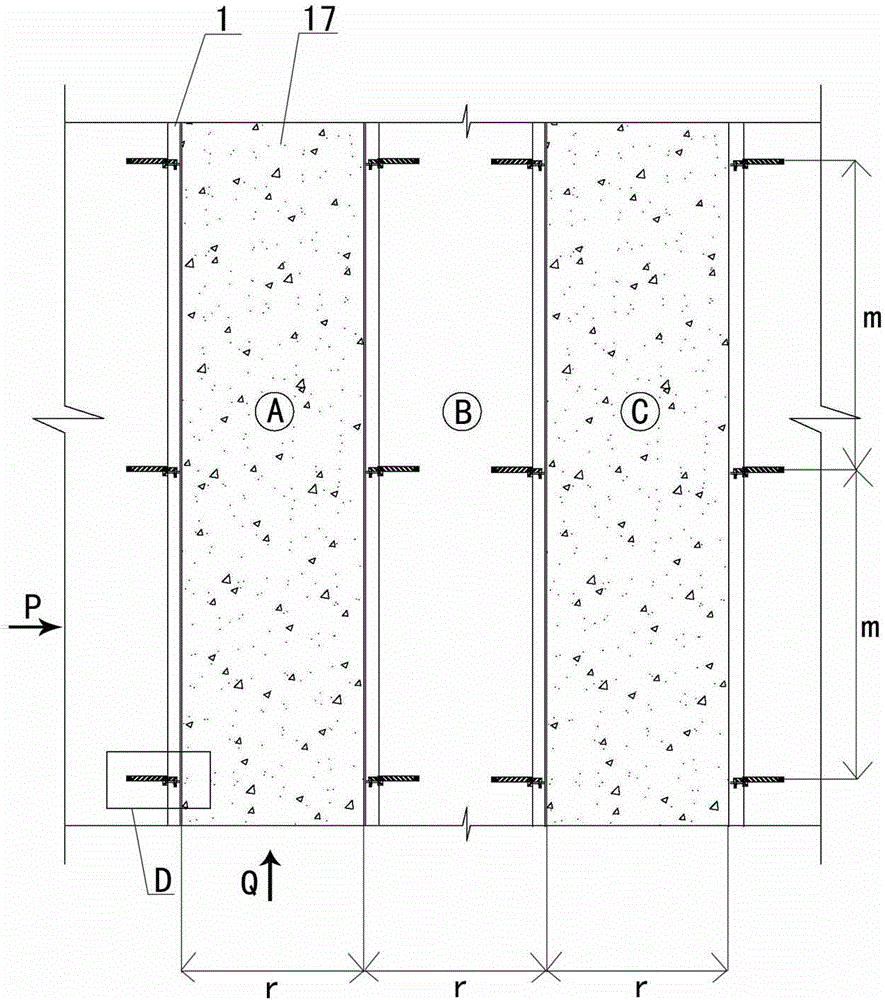

[0048] Examples see figure 2 As shown, taking the design thickness a of the large-area floor concrete as 200mm as an example, the fabrication and construction process of the channel steel formwork system will be described in detail. For the marked length, see Figure 8-10 shown.

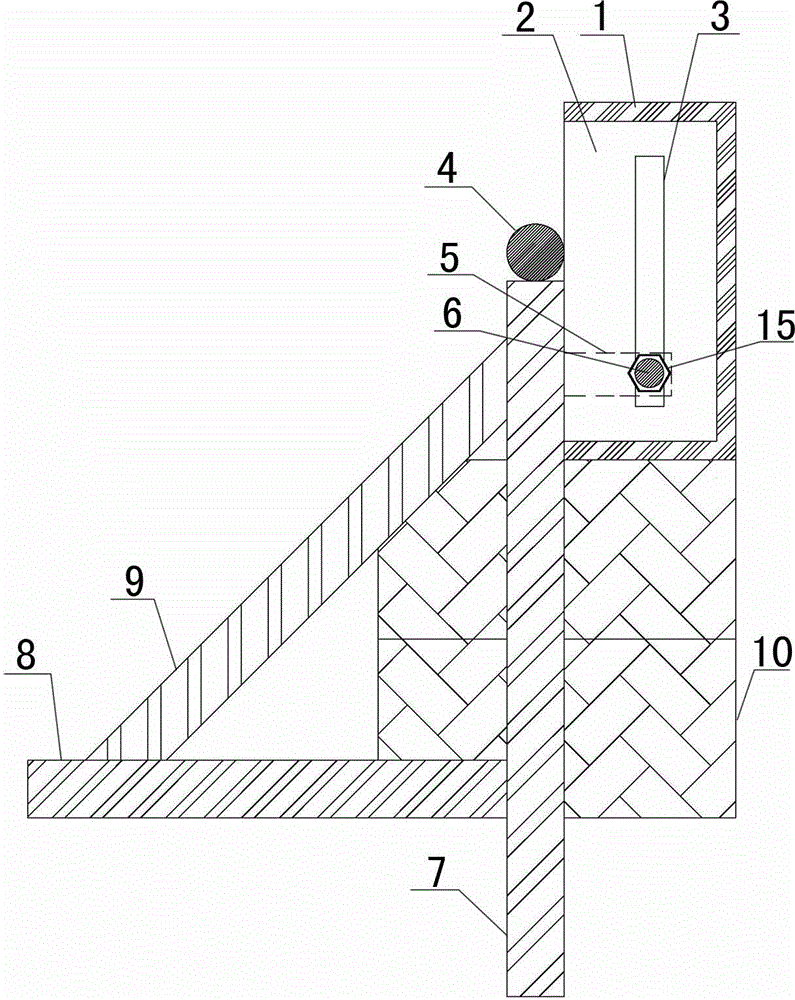

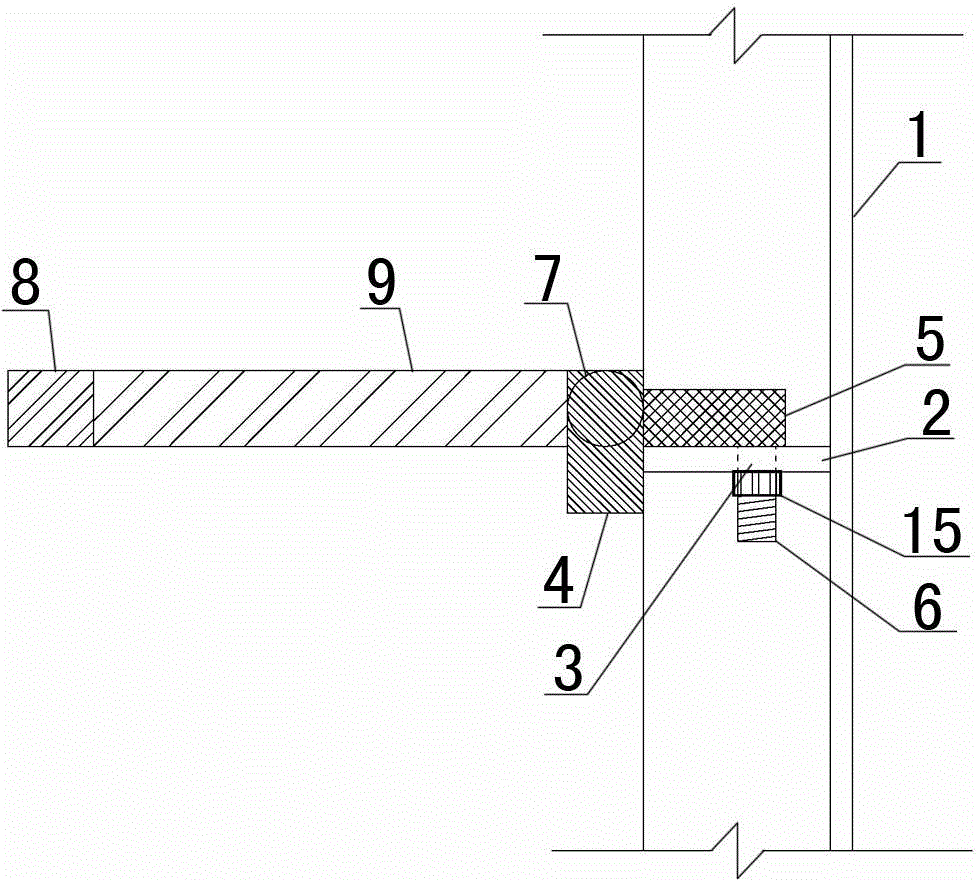

[0049] see Figure 1~5 As shown, an adjustable large-area floor channel steel formwork system includes channel steel formwork 1 for the upper concrete on both sides of the pre-constructed large-area floor concrete 17 symmetrically, a support frame and a lower part of the channel steel formwork back side The wooden side formwork 10 of concrete, the cross-section height of the channel steel formwork 1 is less than the thickness of the large-area floor concrete 17, and a plurality of stiffening plates 2 with vertically adjusting long holes 3 are welded in the groove, and the stiffening plates and the The support frames are arranged at intervals along the length direction of the formwork and correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com