A slab with a hollow cloudwood structure

A hollow, cloud wood technology, applied in the direction of sheet/board, building components, building structure, etc., can solve the problems of affecting the appearance, the flatness of the wall panel surface cannot be effectively controlled, etc., to achieve reasonable structure, high durability and practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

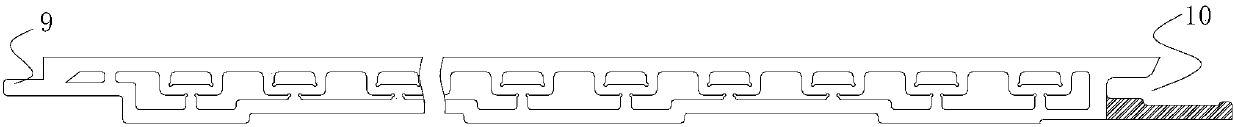

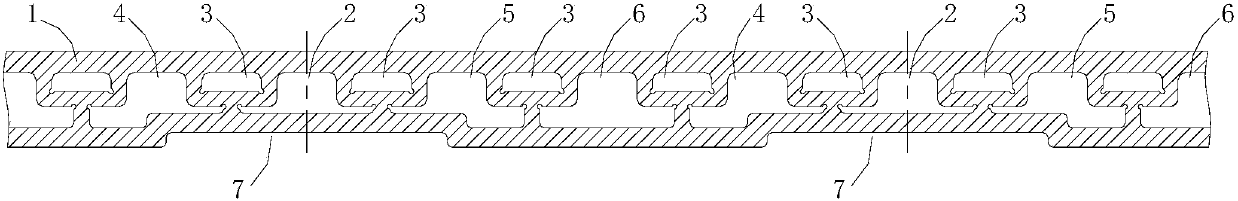

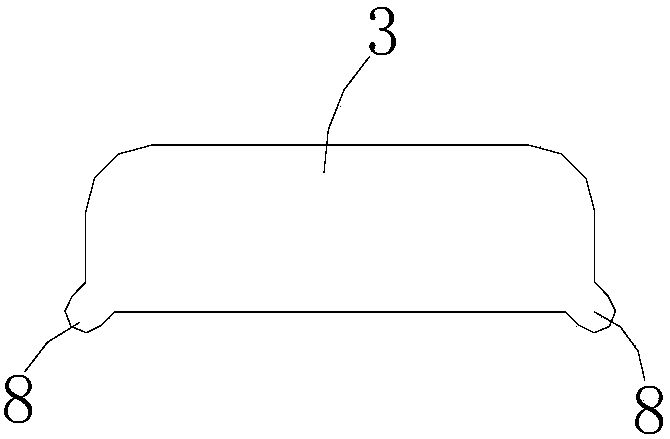

[0033] The embodiment of the present invention is a flat plate with a hollow cloud wood structure. The visible width of the plate body 1 after installation is 350 mm, the width of the groove 7 is 28.99 mm, and the distance between two adjacent grooves 7 is 33 mm. The thickness from the upper end surface of the plate body to the first hollow structure 2, the second hollow structure 3, the third hollow structure 4, the fourth hollow structure 5 and the fifth hollow structure 6 is 2.2 mm, and the lower end surface of the plate body 1 to the first hollow structure The thickness of the structure 2, the second hollow structure 3, the third hollow structure 4, the fourth hollow structure 5 and the fifth hollow structure 6 is 2mm, the distance between the adjacent second hollow structure 3 is 31mm, and the thickness of the first hollow structure 2 The height on both sides of the lower end is 0.7mm.

[0034] refer to Figure 7 , the embodiment of the present invention is a flat panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com