Preparation method of double-twisted galvanized steel cord

A technology of galvanized steel and steel cords, applied in textiles, papermaking, yarn, etc., can solve problems affecting tire quality, slow rope making speed, easy deformation, etc., to increase anti-aging and fatigue resistance, and good control , Strengthen the effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a double-twisted galvanized steel cord, comprising the following preparation steps:

[0023] (1) Select high-quality wire rods, draw the wire rods with a wire drawing machine to obtain steel wires of the same specification, and hot-dip galvanize the steel wires to obtain galvanized steel wires;

[0024] (2) Pull the galvanized steel wire through the water tank again for 25 times of low compression ratio to obtain a drawn steel wire with a diameter of 0.30-0.37mm;

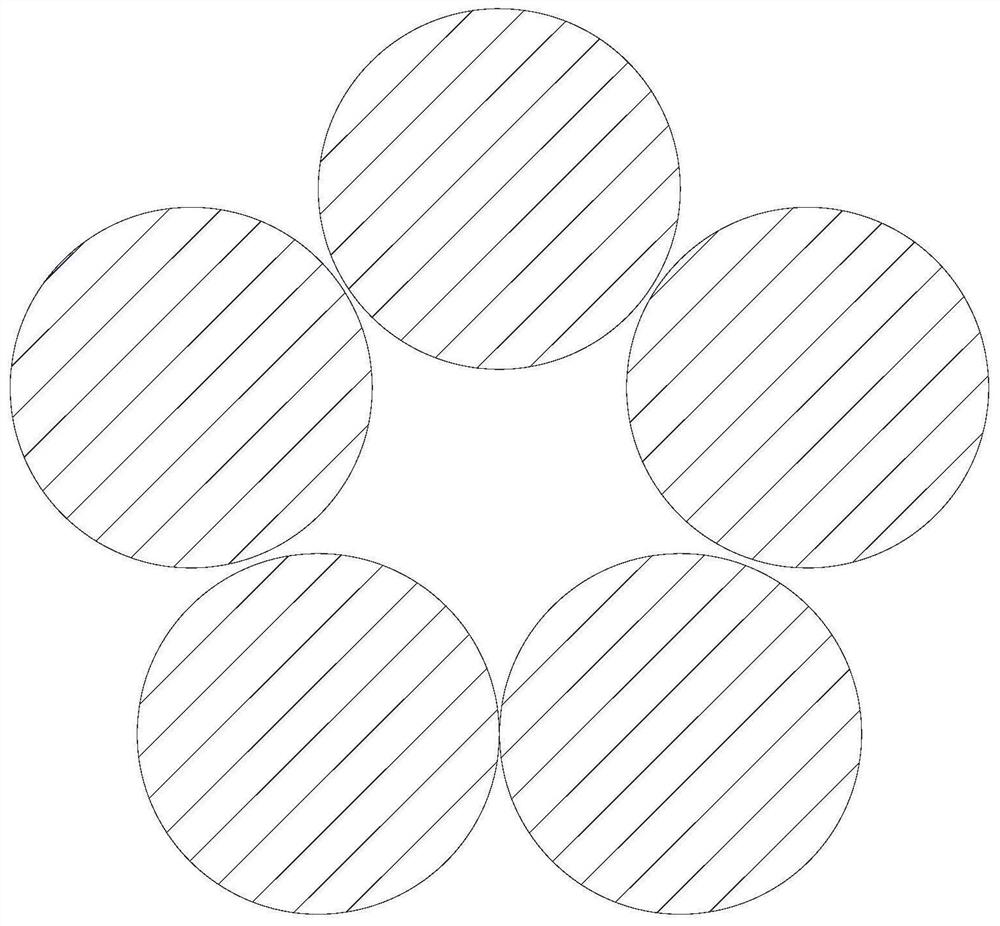

[0025] (3) Choose five equal-diameter drawing steel wires, use a standard rope frame to carry out pre-deformation to five monofilaments through a deformation wheel with a diameter of 6mm, to obtain pre-deformed monofilaments;

[0026] (4) Twist the five pre-deformed monofilaments in the S-twisting direction S with a 550-650g pay-off tension and a 12.5mm lay length on a ply double twister with a six-axis pay-off model, and at the same time use ATC automatic residua...

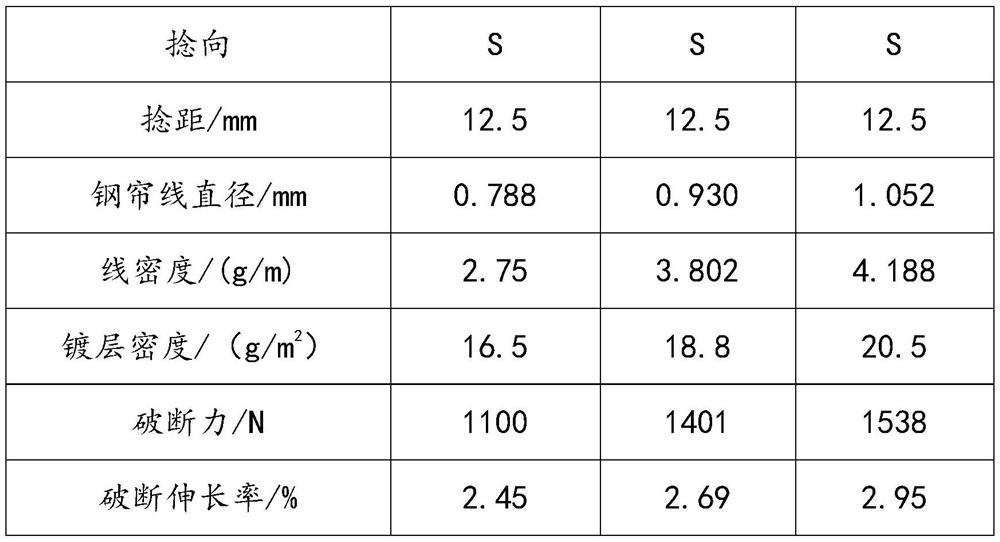

Embodiment 1

[0030] The preparation method of the double-twisted galvanized steel cord of the present embodiment comprises the following steps:

[0031] (1) Select high-quality wire rods, draw the wire rods with a wire drawing machine to obtain steel wires of the same specification, and hot-dip galvanize the steel wires to obtain galvanized steel wires;

[0032] (2) The galvanized steel wire is drawn through the water tank again for 25 times of low compression ratio to obtain a drawn steel wire with a diameter of 0.30mm;

[0033] (3) Choose five equal-diameter drawing steel wires, use a standard rope frame to carry out pre-deformation to five monofilaments through a deformation wheel with a diameter of 6mm, to obtain pre-deformed monofilaments;

[0034] (4) Twist the five pre-deformed monofilaments in the S-twisting direction with a six-axis pay-off type double-twist machine with a pay-off tension of 550g and a twist length of 12.5mm, and use ATC automatic residual torsion control at the s...

Embodiment 2

[0038] The preparation method of the double-twisted galvanized steel cord of the present embodiment comprises the following preparation steps:

[0039] (1) Select high-quality wire rods, draw the wire rods with a wire drawing machine to obtain steel wires of the same specification, and hot-dip galvanize the steel wires to obtain galvanized steel wires;

[0040] (2) The galvanized steel wire is drawn through the water tank again for 25 times of low compression ratio to obtain a drawn steel wire with a diameter of 0.35 mm;

[0041] (3) Choose five equal-diameter drawing steel wires, use a standard rope frame to carry out pre-deformation to five monofilaments through a deformation wheel with a diameter of 6mm, to obtain pre-deformed monofilaments;

[0042] (4) The five pre-deformed monofilaments are twisted in the S-twisting direction with a six-axis pay-off type double-twist machine with a pay-off tension of 600g and a twist length of 12.5mm. At the same time, ATC automatic resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com