A magnetic winding type two-for-one twist spinning method

A winding and magnetic technology, which is applied in the field of two-for-one twist spinning and magnetic winding two-for-one twist spinning, to achieve the effect of improving twisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

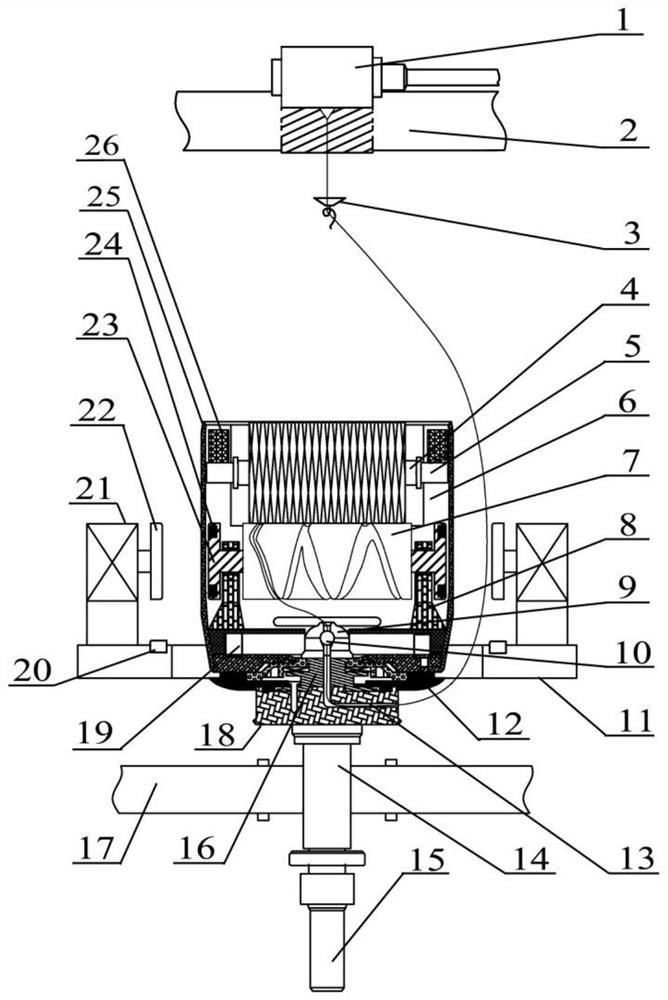

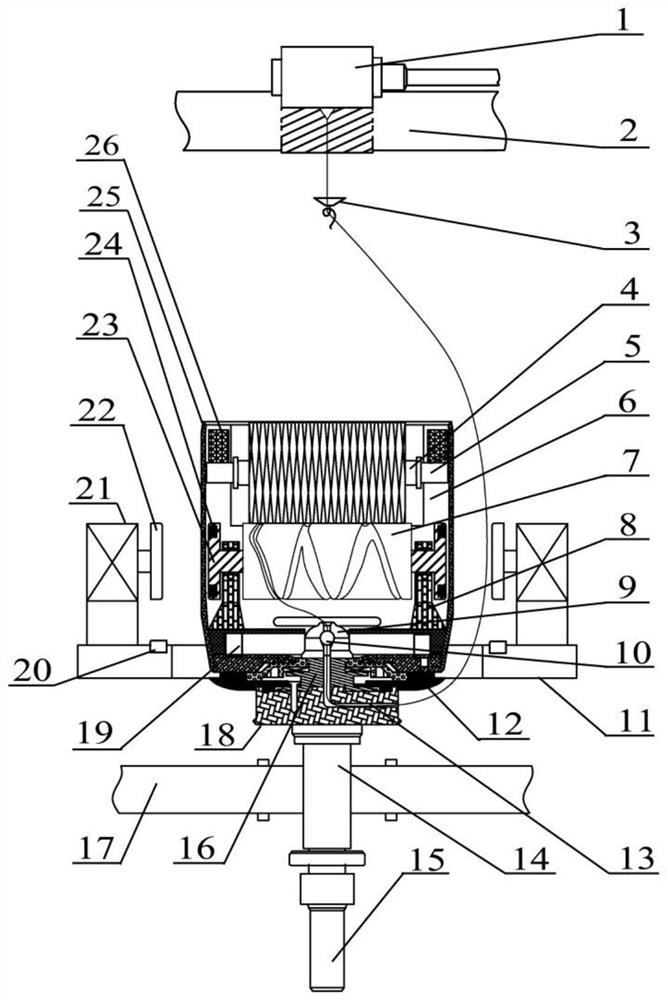

[0013] A magnetic winding type two-for-one twist spinning method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] see Attachment.

[0015]A magnetic winding two-for-one-twisting spinning method is an improvement on the original technical solution of "Chinese Patent Publication No. CN109457334A, publication date 2019.03.12, invention name is a two-for-one-twisting spinning method", the original The technical solution is the spinning frame drafting system composed of rear rollers, rear top rollers, upper middle rollers, lower middle rollers, upper middle aprons, lower middle aprons, upper pins, lower pins, front rollers 2, and front top rollers 1. In the front, there are spindle belt 17, spindle base 15, spindle bar 14, twisting disk 18, yarn feeding pipe 13, spindle disk 12, rotor assembly 16, stationary disk, yarn storage tank 25, inner magnetic steel 19, positioning sleeve Tube 9, tensioner 10, yarn ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com