Stator punching sheet of combination structure

A stator punching and combined structure technology, applied in the magnetic circuit shape/pattern/structure, magnetic circuit static components, etc., can solve the problems of time-consuming, laborious, narrow, and high material cost in embedding work, and reduce end leakage reactance. , the effect of simplifying the process and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

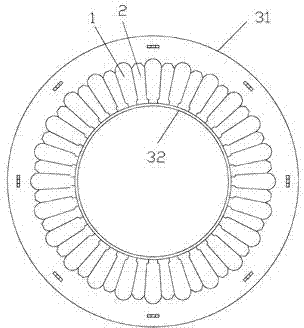

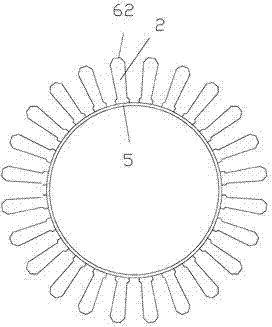

[0024] Such as figure 1 In the shown embodiment 1, a stator punching sheet with a combined structure has a hollow inner circular hole in the middle of the stator punching sheet, and 24 radially distributed holes are arranged between the outer edge of the stator punching sheet and the inner circular hole. Punching slots 1, between adjacent punching slots 1 on the stator punching sheet are 24 punching columns 2 for coil winding. punching tank such as Figure 4 As shown, a groove top 71 , a groove body 72 , a groove shoulder 73 and a groove 74 are included. The stator stamping is divided into a first stamping part 31 and a second stamping part 32 at the end of the stamping column 2 .

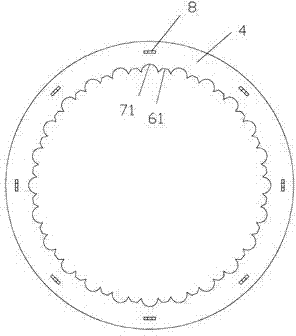

[0025] The first punching unit 31 such as figure 2 As shown, including the outer ring body 4, the inner ring portion of the outer ring body is provided with an annular array of concave sides 61 for separating and forming, and arc-shaped sides are arranged between adjacent concave-shaped sides 6...

Embodiment 2

[0031] The difference from Embodiment 1 is that the concave side and the convex side used for separation are arc-shaped locking structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com