A textile steam cleaning device

A cleaning device and steam technology, applied in the textile field, can solve problems such as unfavorable printing and dyeing, waste of water resources, easy wrinkling of cloth, etc., and achieve the effects of convenient and direct winding, improving cleaning effect and saving water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

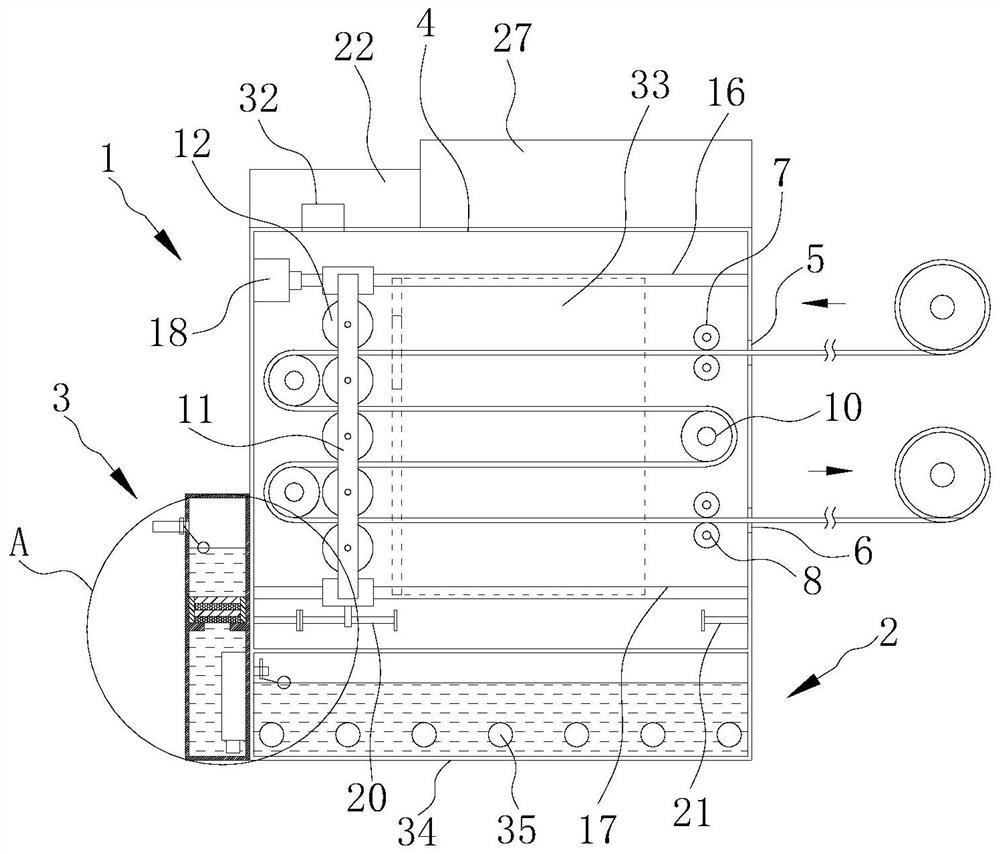

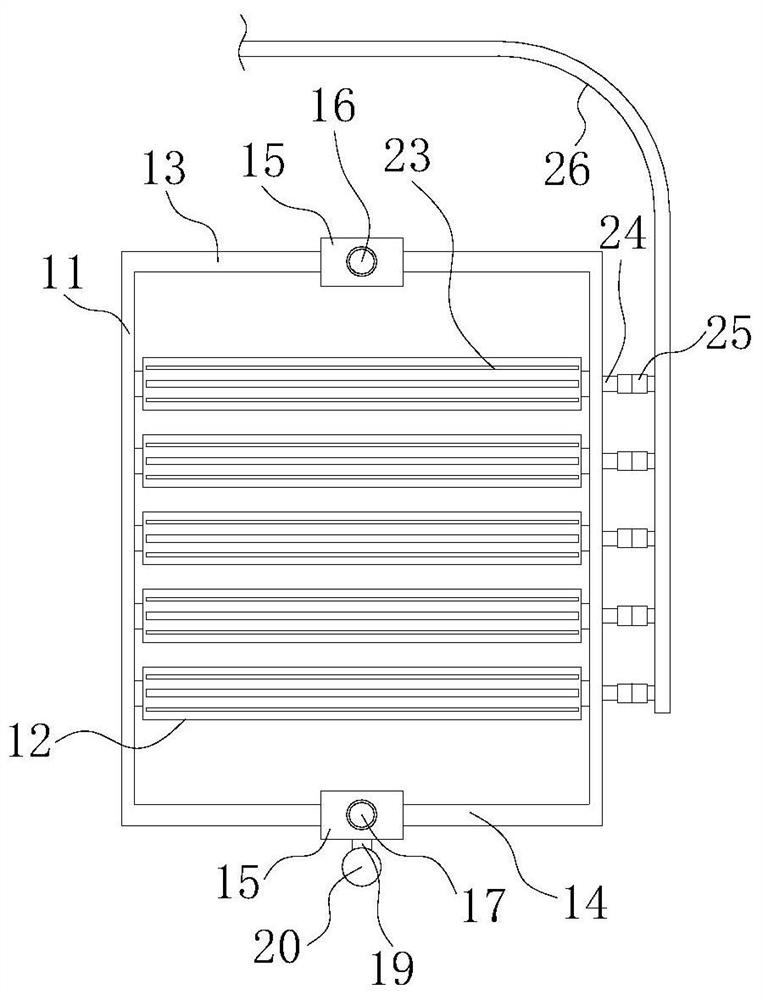

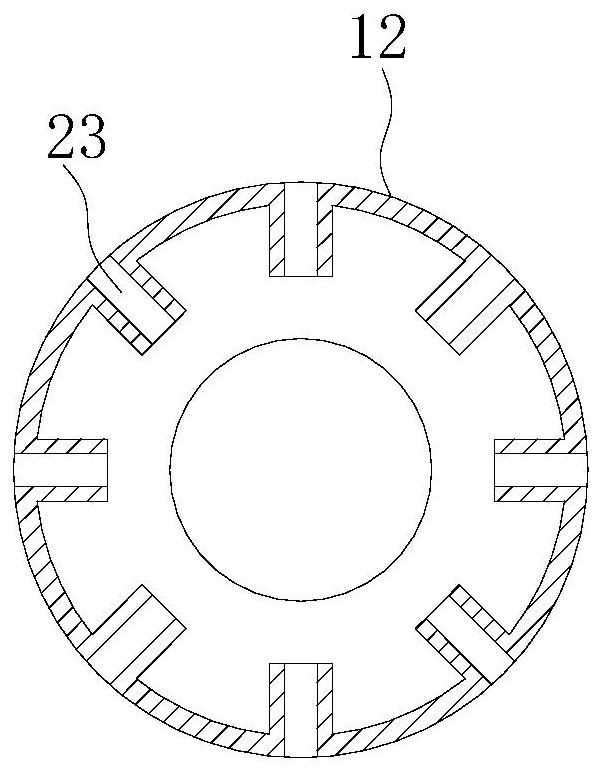

[0024] Such as Figure 1-6 A textile steam cleaning device shown includes a steam cleaning box 1 , a steam generator 2 for supplying steam to the inside of the steam cleaning box 1 , and a water purification filter 3 for supplying clean water to the steam generator 2 . The steam cleaning box 1 is the main place where the cloth is cleaned by steam in the present invention, that is to say, the cloth is cleaned while passing through the steam cleaning box 1, and the steam generator 2 is used to generate steam, And the steam is discharged into the steam cleaning box 1 to clean the cloth. The function of the water purification filter 3 is to filter the tap water to prevent the steam generator 2 from scaling during the boiling of water. The simplest steam cleaning box 1 of the present invention can be exactly a box body, and the left and right sides of box body are provided with cloth inlet, cloth outlet, and cloth is cleaned by the steam inside when crossing box body. The simplest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com