A Bearingless Half-tooth Wound Switched Reluctance Motor

A switched reluctance motor and bearingless technology, which is applied in the direction of motors, electric vehicles, electrical components, etc., can solve the limitations of the bearingless switched reluctance motor's actual load capacity, low fault tolerance and reliability, and serious magnetic circuit coupling. problem, to achieve the effect of low winding difficulty, good heat dissipation, and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

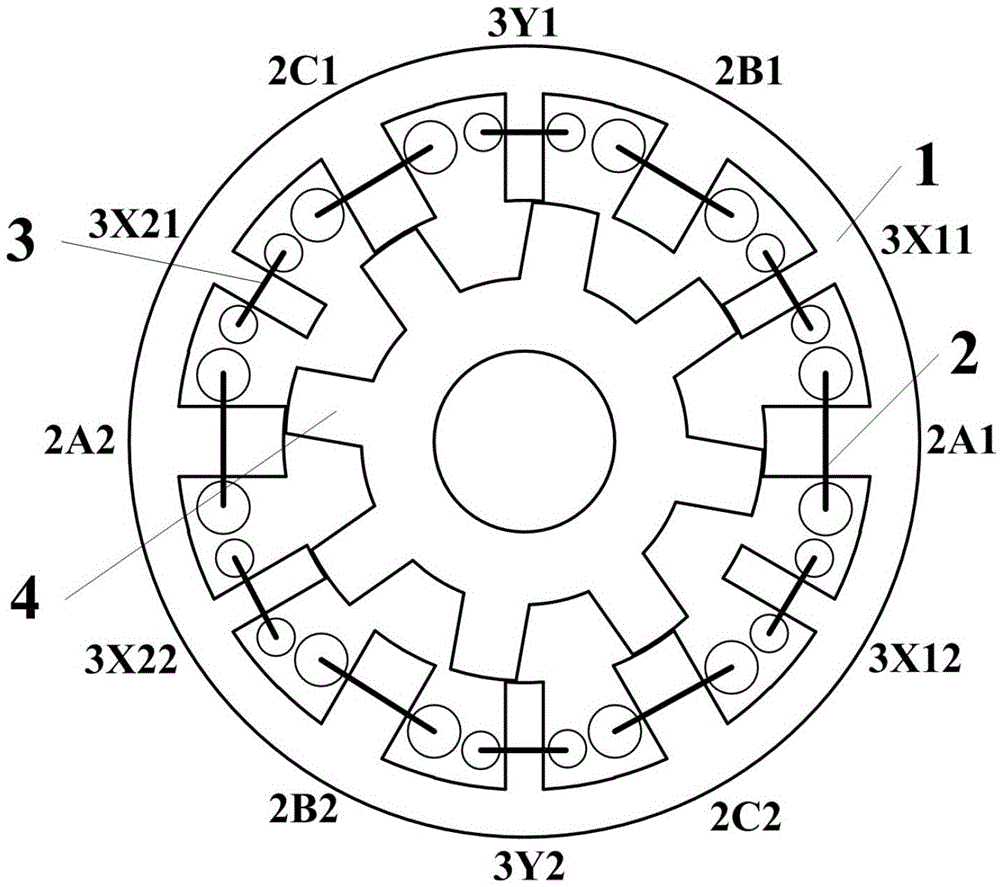

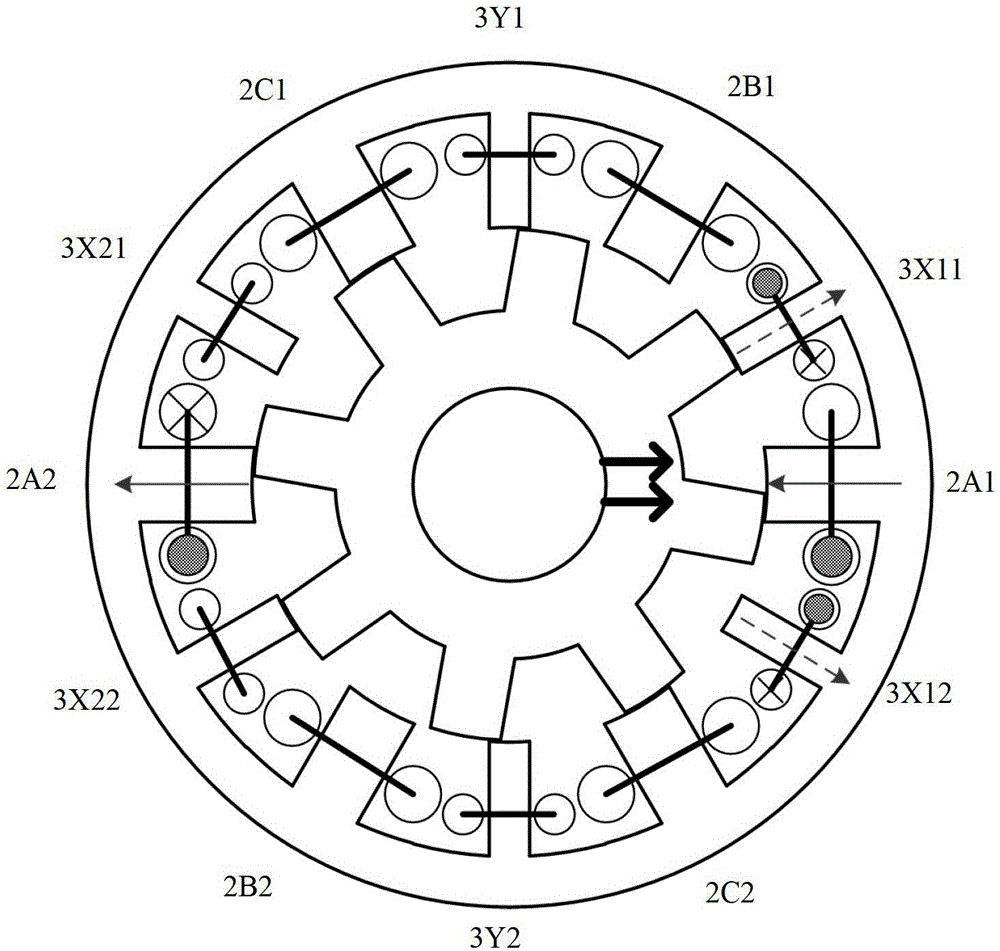

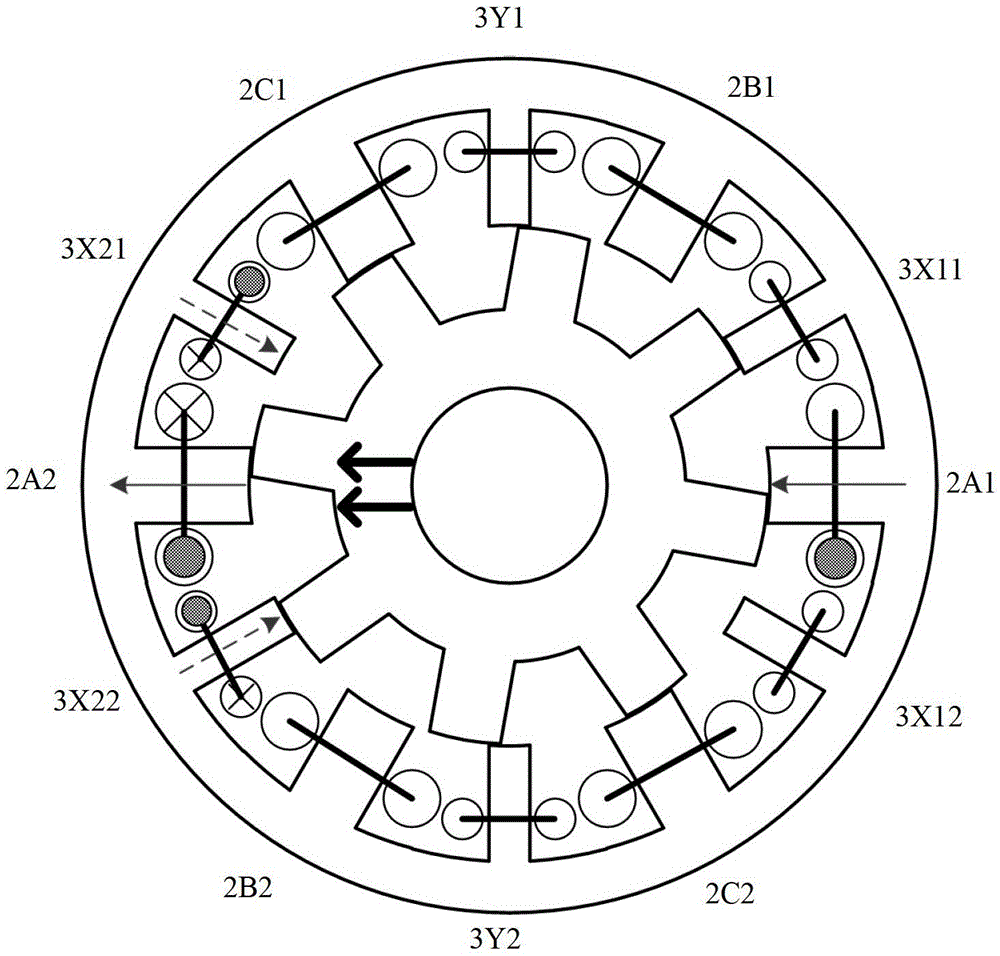

[0032] Embodiment 1: Take the structure of a three-phase stator with 12 slots / rotor with 8 poles switched reluctance motor as an example for illustration.

[0033] like figure 1 As shown, this embodiment adopts a three-phase stator with 12 slots / rotor with an 8-pole motor structure. There are 12 salient pole teeth on the stator, and a concentrated winding coil is set on each stator tooth. There are 12 coils in total. The clockwise direction is called: the first torque winding coil 2A1, the first suspension force winding coil 3X11, the second torque winding coil 2B1, the second suspension force winding coil 3Y1, the third torque winding coil 2C1, and the third suspension force coil Winding coil 3X21, fourth torque winding coil 2A2, fourth suspension force winding coil 3X22, fifth torque winding coil 2B2, fifth suspension force winding coil 3Y2, sixth torque winding coil 2C2 and sixth suspension force winding coil 3X12.

[0034]The torque winding 2 includes a first torque wind...

Embodiment 2

[0038] Embodiment 2: The structure of a four-phase stator with 8 slots / rotor with 6 poles switched reluctance motor is used as an example for illustration.

[0039] Such as image 3 As shown, this embodiment adopts a four-phase stator with 8 slots / rotor with 6 poles motor structure. There are 8 salient pole teeth on the stator, and a concentrated winding coil is set on each stator tooth. There are 8 coils in total. The clockwise direction is called: the first suspension force winding coil 3X11, the first torque winding coil 2A1, the second suspension force winding coil 3Y1, the second torque winding coil 2B1, the fourth suspension force winding coil 3X22, the fourth torque winding coil Winding coil 2A2, fifth suspension force winding coil 3Y2, and fifth torque winding coil 2B2.

[0040] The torque winding 2 comprises a first torque winding coil 2A1, a second torque winding coil 2B1, a fourth torque winding coil 2A2 and a fifth torque winding coil 2B2, the first torque winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com