A graphite fiber tape stranding system

A graphite fiber and strand-making machine technology, which is applied in cable/conductor manufacturing, rope-making auxiliary devices, textiles and papermaking, and can solve problems such as low twisting efficiency and continuous production of strand-making machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

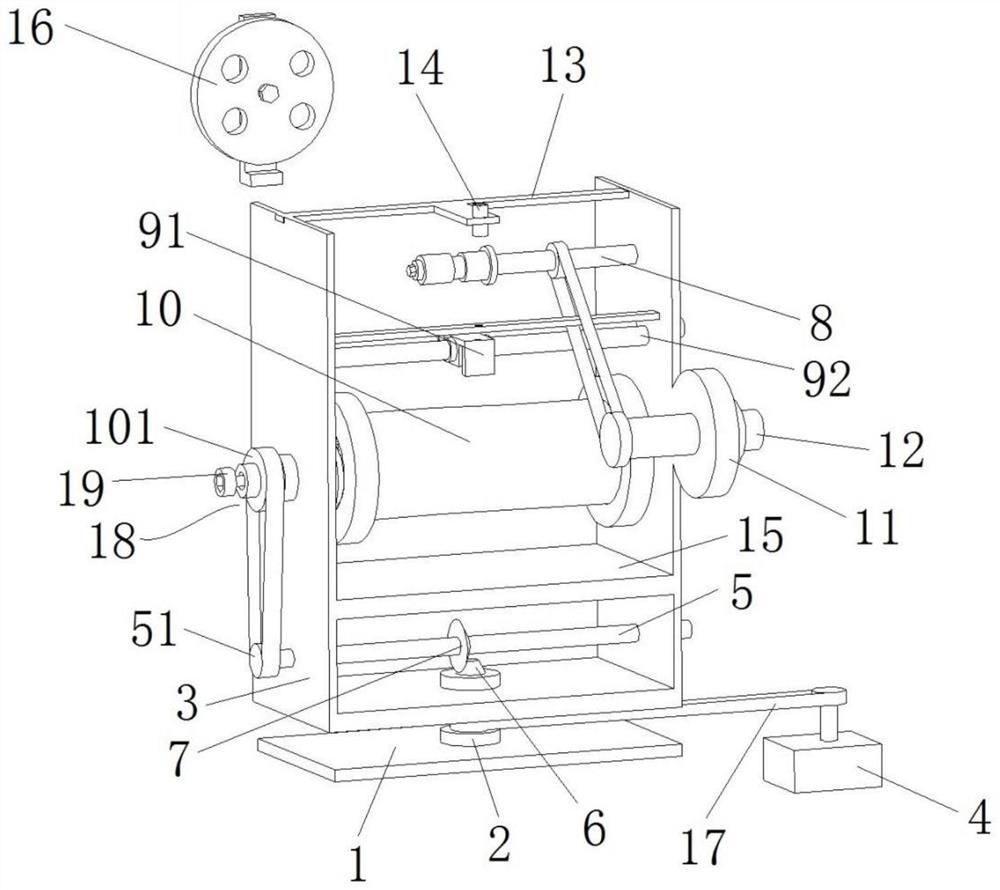

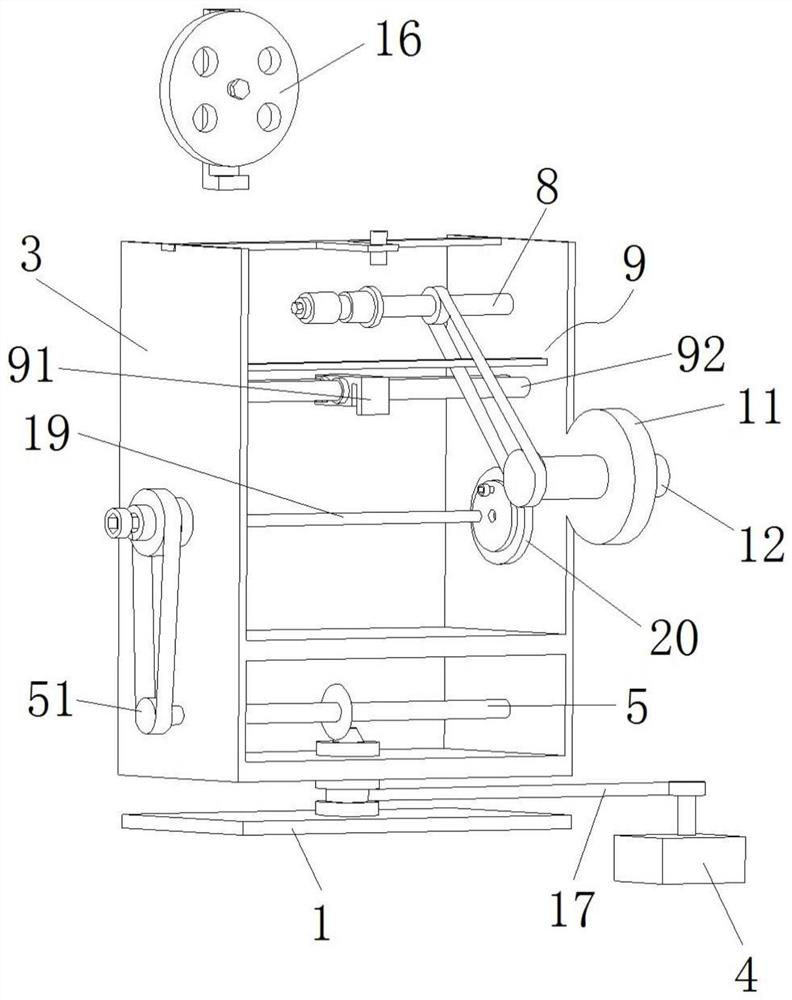

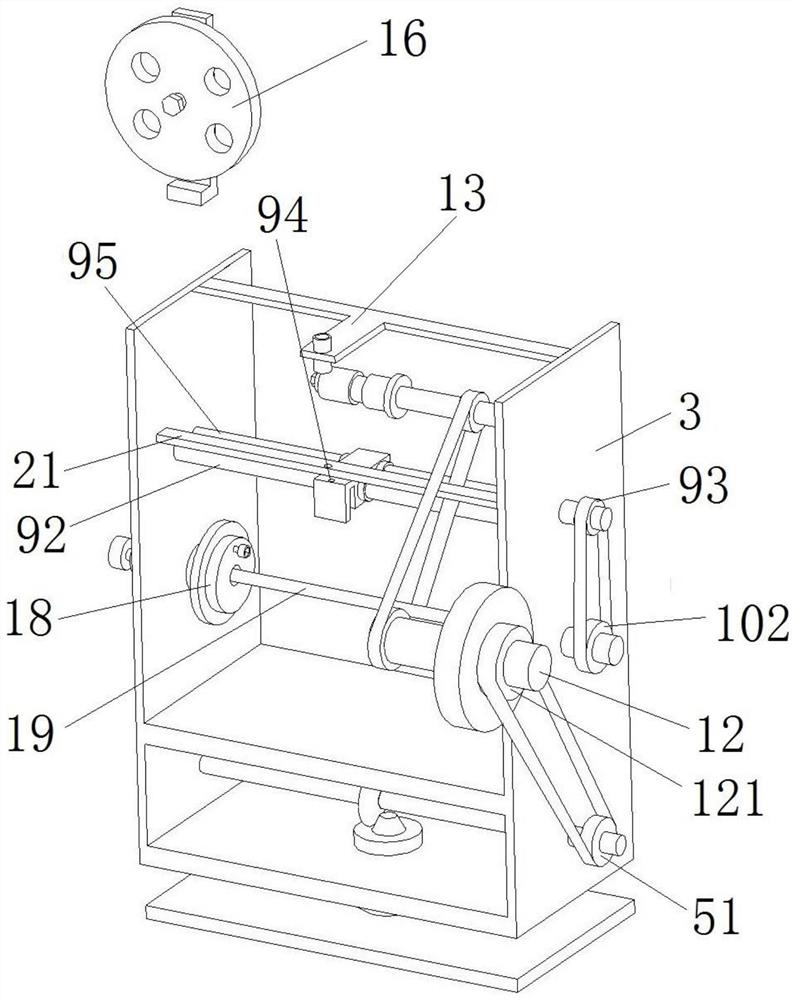

[0033] Such as Figure 1 to Figure 5 As shown, the graphite fiber tape strand-making system includes a strand-making machine and a material tray 16 located above the strand-making machine and spaced from the strand-making machine. The material tray 16 is wound with a strip-shaped graphite fiber ribbon during use. The material tray 16 is arranged by the mounting bracket when in use, and the strand making machine needs to rotate, and the graphite fiber strips released in the material tray 16 can be twisted to form graphite fiber lines by the relative rotation of the two. It should be noted that the arrangement of the material disc 16 referred to in the present invention means that the material disc 16 does not move or revolve as a whole, but the material disc 16 can rotate around its own axis.

[0034] It should be pointed out that there is still a large distance between the material tray 16 and the strand making machine, and a twisting cone will be arranged between the two (the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com