Ultra-large full-face rectangular pipe jacking tunneling construction method

A technology of rectangular pipe jacking and construction method, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of difficult control, inability to guarantee construction quality and safety, and unstable construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

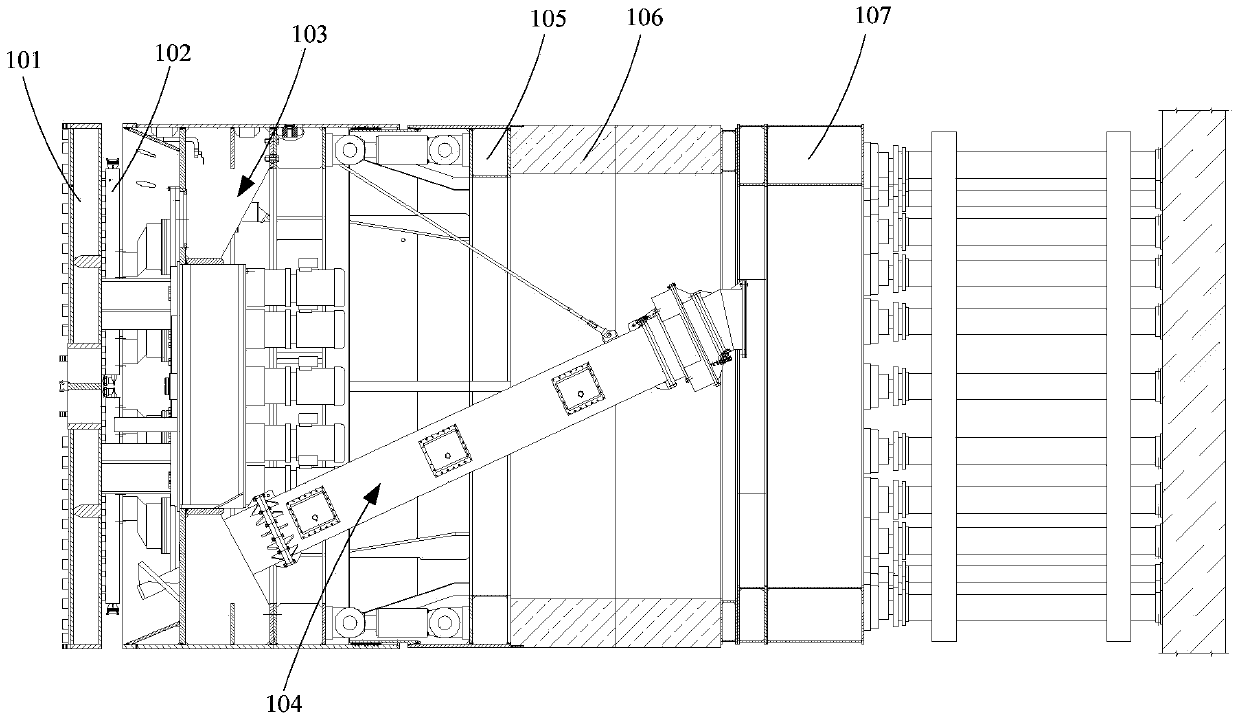

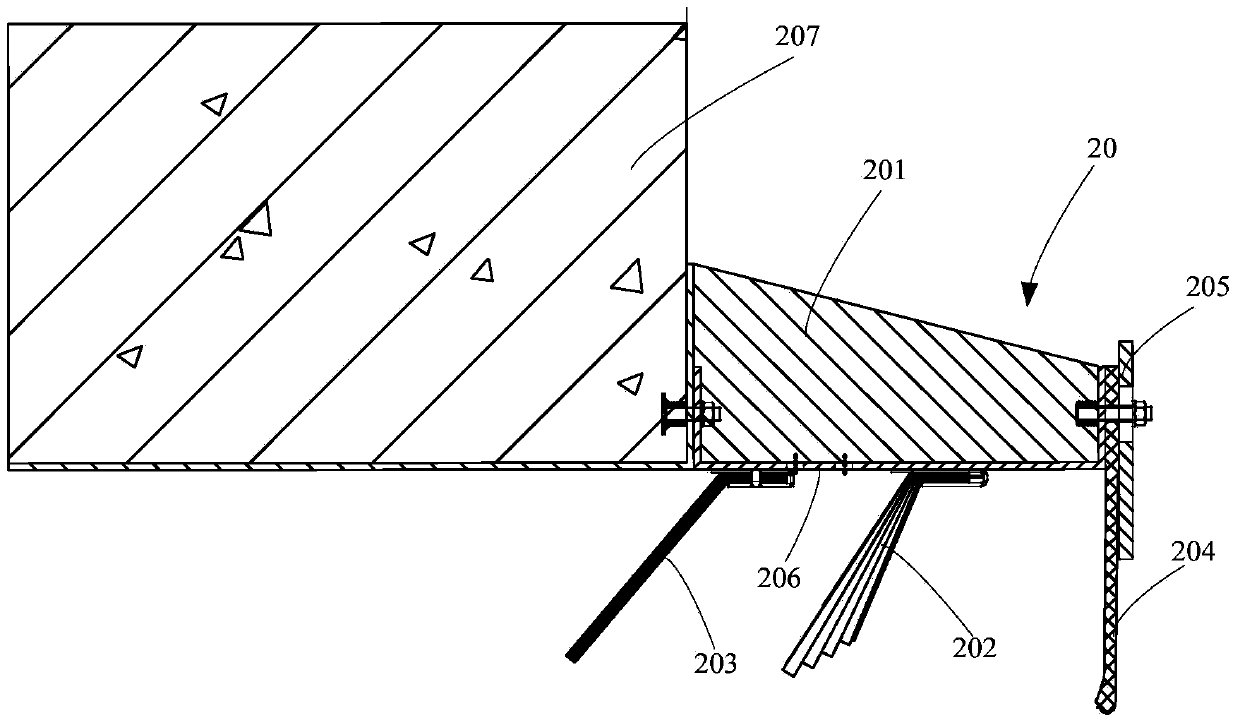

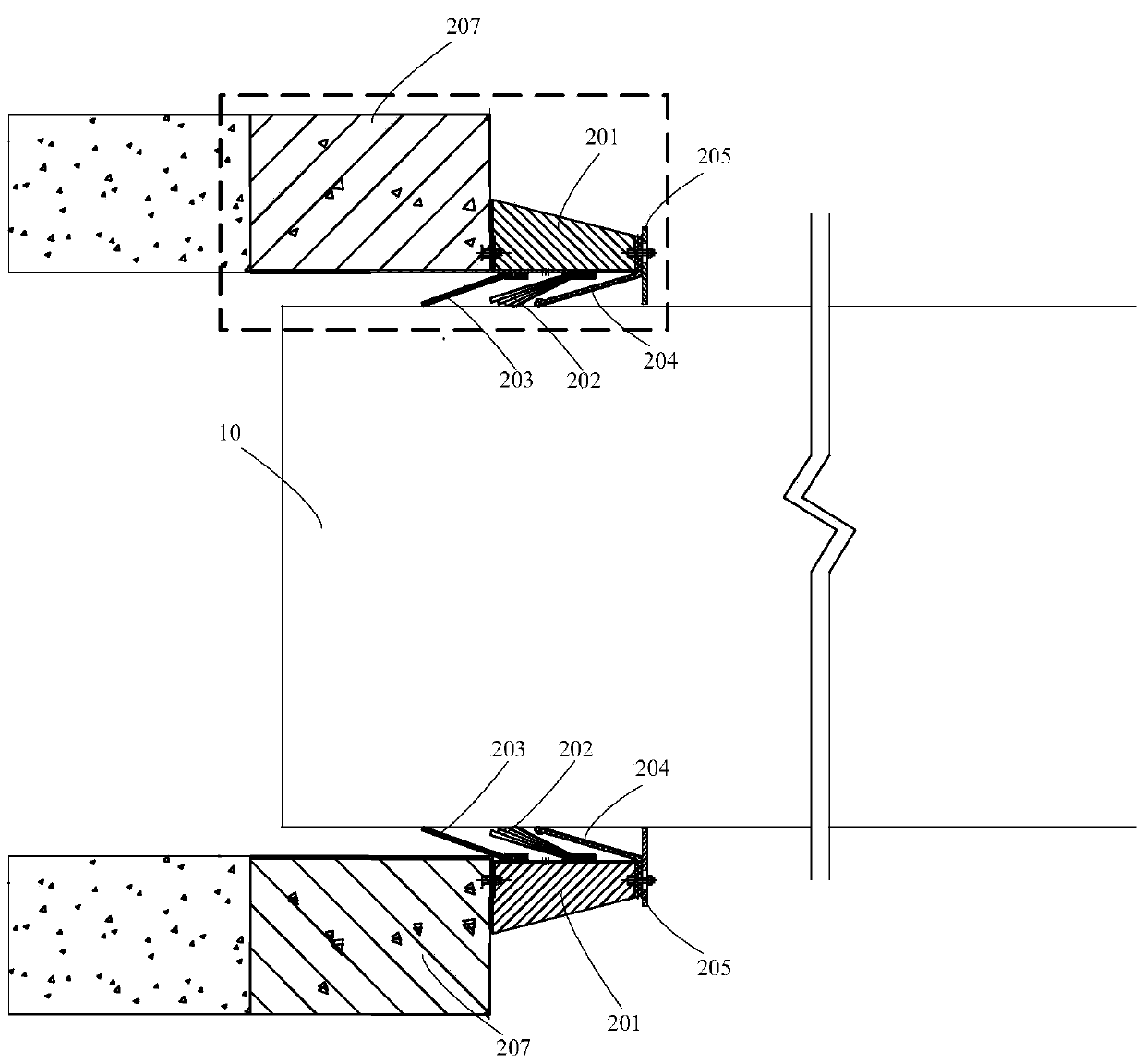

[0062] refer to Figure 13 , shows the flow chart of the super-large full-section rectangular pipe jacking construction method of the present invention. The ultra-large full-section rectangular pipe jacking construction method of the present invention, through tunnel design, special rectangular pipe jacking machine equipment and pipe jacking start and receive construction, in the hole water stop device, combined cutterhead full-section cutting soil, automatic pipe joints Innovative methods have been put forward on specific technical measures such as lifting and turning devices, specific back-stop devices, control of surrounding soil deformation, angle control of pipe jacking machines, soil improvement, grouting and solidification of soil after tunnel penetration, making the rectangular Pipe jacking construction has reached a new level in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com