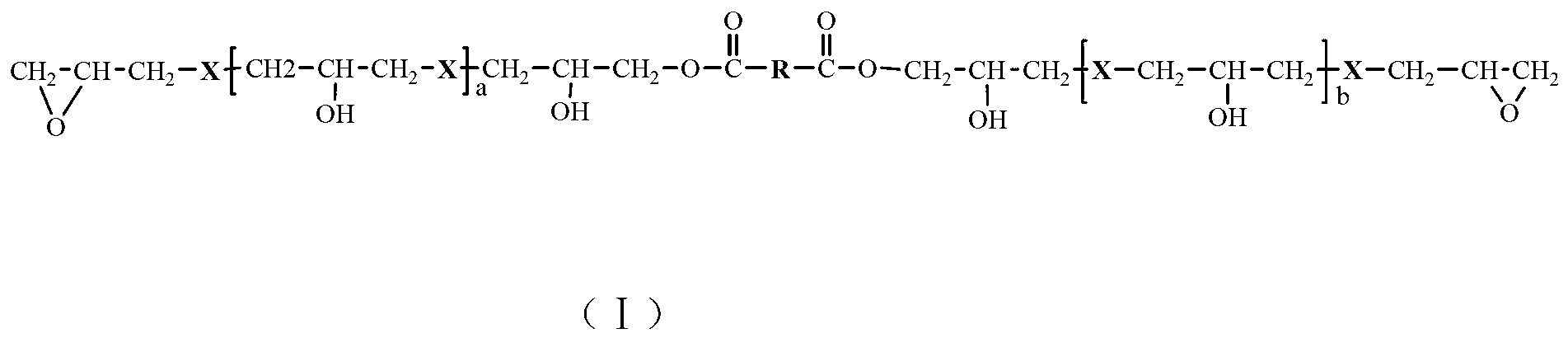

Fatty acid modified epoxy resin and preparation method thereof

A fatty acid modification, epoxy resin technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of high brittleness, easy cracking, and poor gloss of the coating film, and improve the toughness of the coating film. , the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

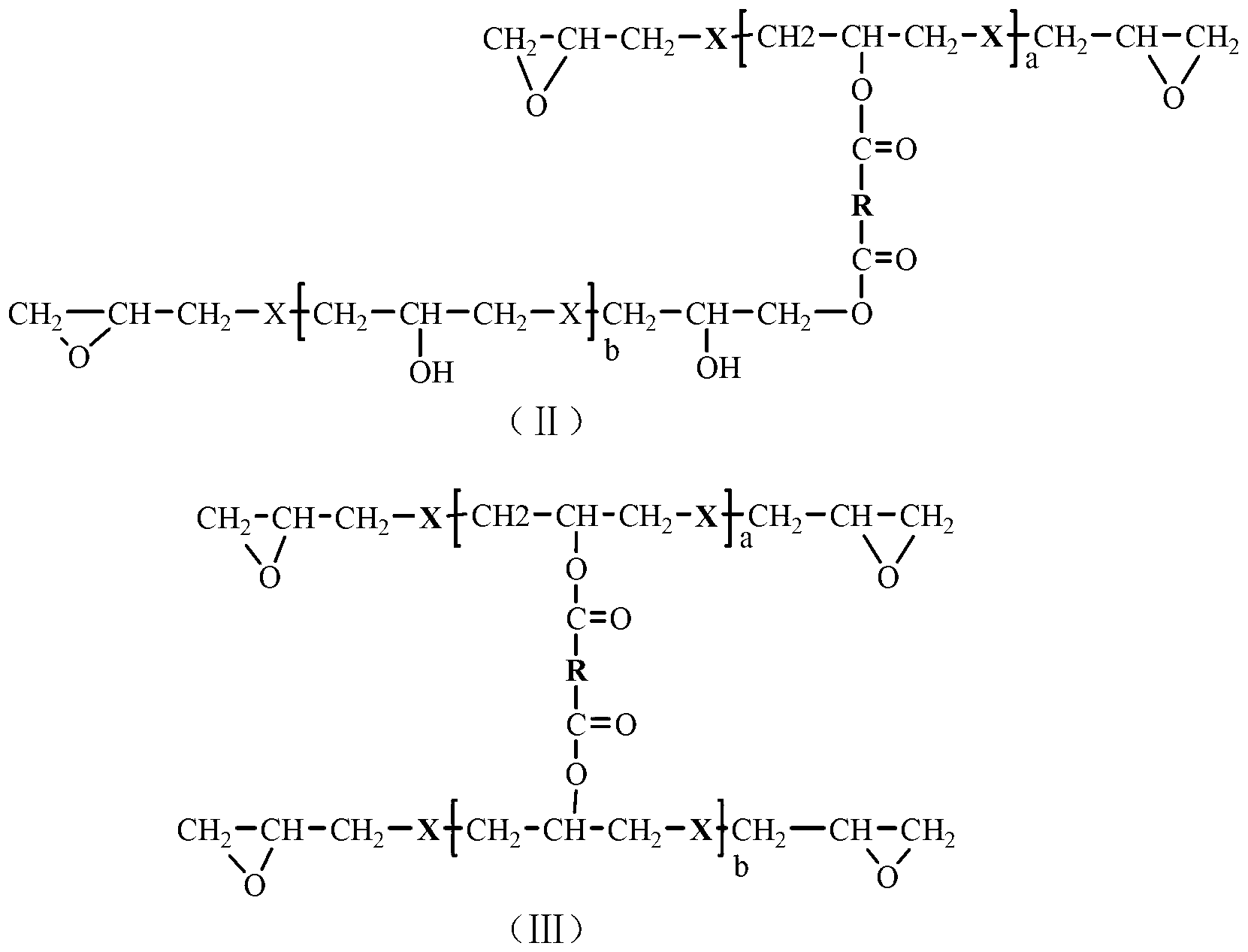

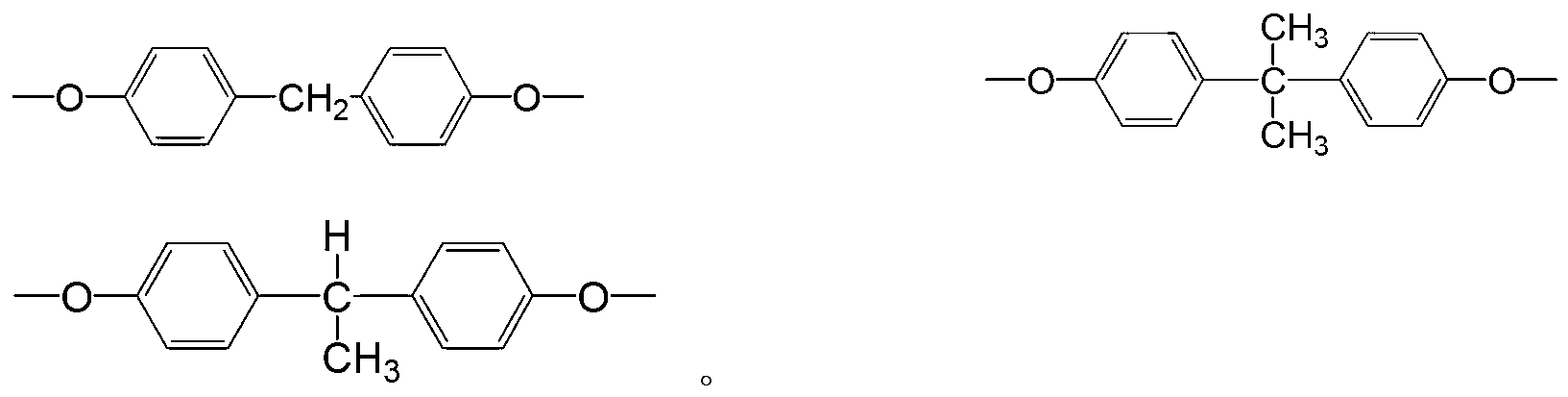

[0026] Put 70 parts by weight of liquid epoxy resin and 7 parts by weight of dimer acid into a four-port glass reaction tank equipped with a thermometer, a stirring device, a nitrogen gas injection pipe, and a heating device, stir evenly and rise from normal temperature to 80°C , add a catalyst amount of dimethylimidazole, raise the temperature to 150°C for 2 hours, take a sample to test the epoxy equivalent, stop heating when the tested epoxy equivalent value reaches 200-280g / eq, and add solvent when the temperature is lower than 90°C Dissolved into a fatty acid modified epoxy resin solution with a solid content of 90%.

Embodiment 2

[0028] In the same reaction device as in Example 1, 75 parts by weight of liquid bisphenol A epoxy resin and 10 parts by weight of dimer acid were respectively added, stirred evenly and raised from normal temperature to 85°C, and a catalyst amount of 2-ethyl -4-Methylimidazole, heat up to 155°C and keep the temperature for 2 hours, take a sample to test the epoxy equivalent, when the tested epoxy equivalent value reaches 200-280g / eq, stop heating, when the temperature is lower than 90°C, add xylene solution to dissolve A fatty acid modified epoxy resin solution with a solid content of 90%.

Embodiment 3

[0030] In the reaction device identical with embodiment 1, drop into the liquid bisphenol A epoxy resin of 60 weight parts, the dimer acid of 5 weight parts respectively, stir evenly and rise to 90 ℃ by normal temperature, add the tetramethyl chloride of catalyst amount ammonium chloride, heat up to 160°C and keep the temperature for 2.5h, take samples to test the epoxy equivalent, when the tested epoxy equivalent value reaches 200-280g / eq, stop heating, when the temperature is lower than 90°C, add acetone solution to dissolve to a solid content of 90% fatty acid modified epoxy resin solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com