Efficient crusher

A crusher and high-efficiency technology, which is applied in the field of concrete, can solve the problems of high energy consumption and difficulty in uniformly crushing particle structures, and achieve the effect of reducing the difficulty of crushing and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

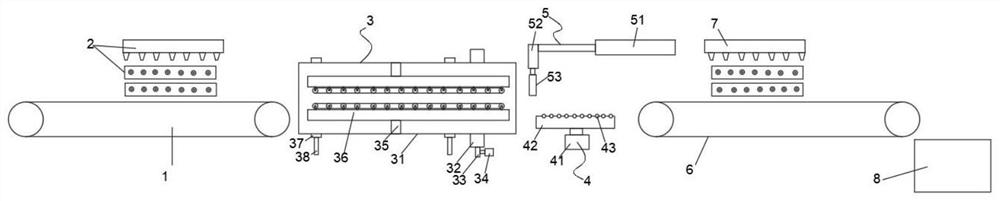

[0019] Such as figure 1 A highly efficient crusher, including the first transmission device 1, both the top and both sides of the first transmission device 1, and the first water knife 2 is attached, and the first transmission device 1 is attached to the end mounting device 3, flip The device 3 is mounted with a torsion device 4, and the torsion device 4 is mounted with a push device 5. The torsion device 4 is mounted having a second conveying device 6, and the top and both sides of the second conveying device 6 have a second water. The knife 7 is mounted with a crusher body 8 at the end of the second conveyor 6.

[0020] The first transmitting device 1 and the second conveying device 6 are all conveyor belts.

[0021] The flip device 3 includes a drum 31, and an outer ring ring 32 is fixed outside the drum 31. The outer teeth 32 mesh, and the gear 33 is connected to the power rotating device 34; the top and bottom of the drum 31 are mounted with a stretch device 35. The stretchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com