Crushing method for nitrided ferrovanadium

A technology of ferrovanadium nitride and crushing method, applied in the field of ferroalloy processing, can solve problems such as limited application scope, and achieve the effects of reducing crushing cost, reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

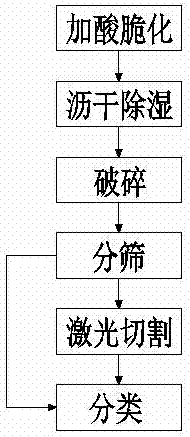

Method used

Image

Examples

Embodiment 1

[0032] In the acidification pond in the described step a, the pH value is 1.0, and when draining in the described step b, the iron vanadium nitride after the acidification is placed statically on the drying drain net at 0.3, and then the ferrovanadium nitride is dried with hot air, In the step d, the ferrovanadium nitride is classified according to the particle size, and every 50mm is a classification group, and the ferrovanadium nitride greater than 100mm is placed separately. In the step f, the nitrided ferrovanadium after cutting Vanadium iron blocks are placed separately as a classification group according to the particle size, and the particle size value is placed every 3mm. The above method can classify and process the ferrovanadium nitride blocks produced by crushing and cutting during the crushing operation of the ferrovanadium nitride, and can improve the processing efficiency of the ferrovanadium nitride lumps.

Embodiment 2

[0034] The pH value in the acidification pool in the step a is 3.0, and when draining in the step b, the acidified ferrovanadium nitride is placed on the dry drain net for 0.5h, and then the ferrovanadium nitride is dried with hot air , in the step d, the ferrovanadium nitride is classified according to the particle size, and every 50mm is a classification group, and the ferrovanadium nitride greater than 100mm is placed separately. In the step f, the vanadium nitride after cutting According to the size of the iron powder, every 10mm is used as a classification group, and the crushed ferrovanadium nitride block is separated from the ferrovanadium nitride block cut in step e. The difference between this method and the above-mentioned method is only that by comprehensively classifying the crushed vanadium iron blocks and the cut vanadium iron blocks, the work intensity of the classification work of vanadium iron blocks can be reduced, and the nitriding process can be improved. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com