Printed paper product recycling method

A technology for printing paper and products, which is applied in the field of recycling and processing of printed products. It can solve problems such as delaying work progress, limited rotation range, and short service life, and achieves the effects of improving distribution uniformity, shortening time spent, and reducing the difficulty of crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

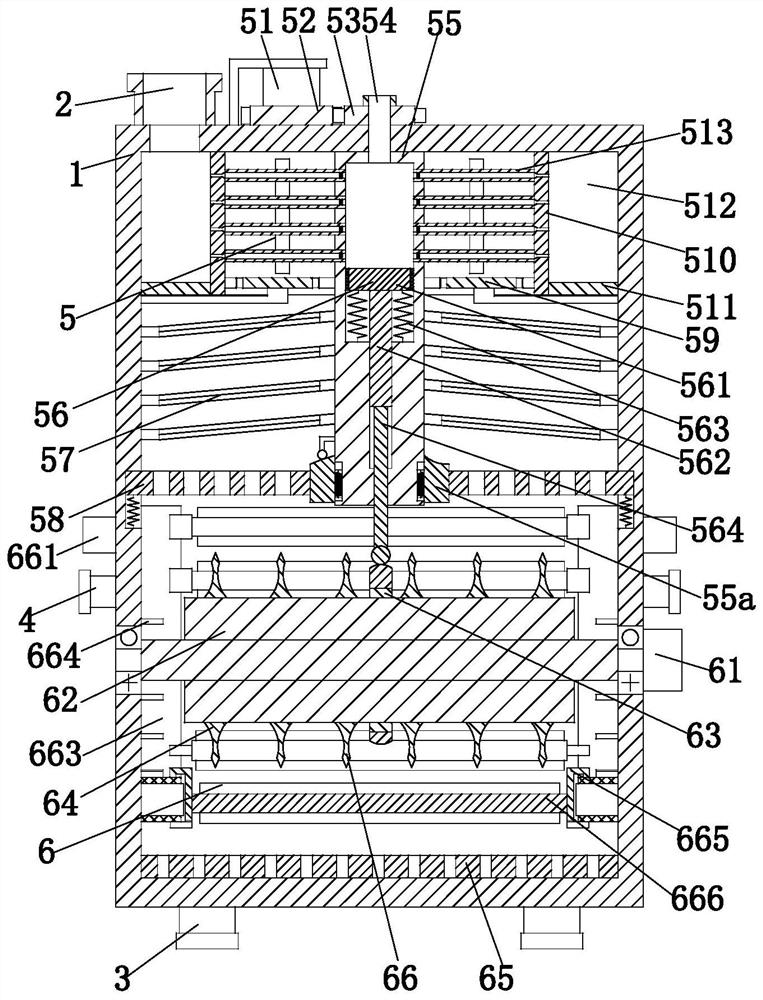

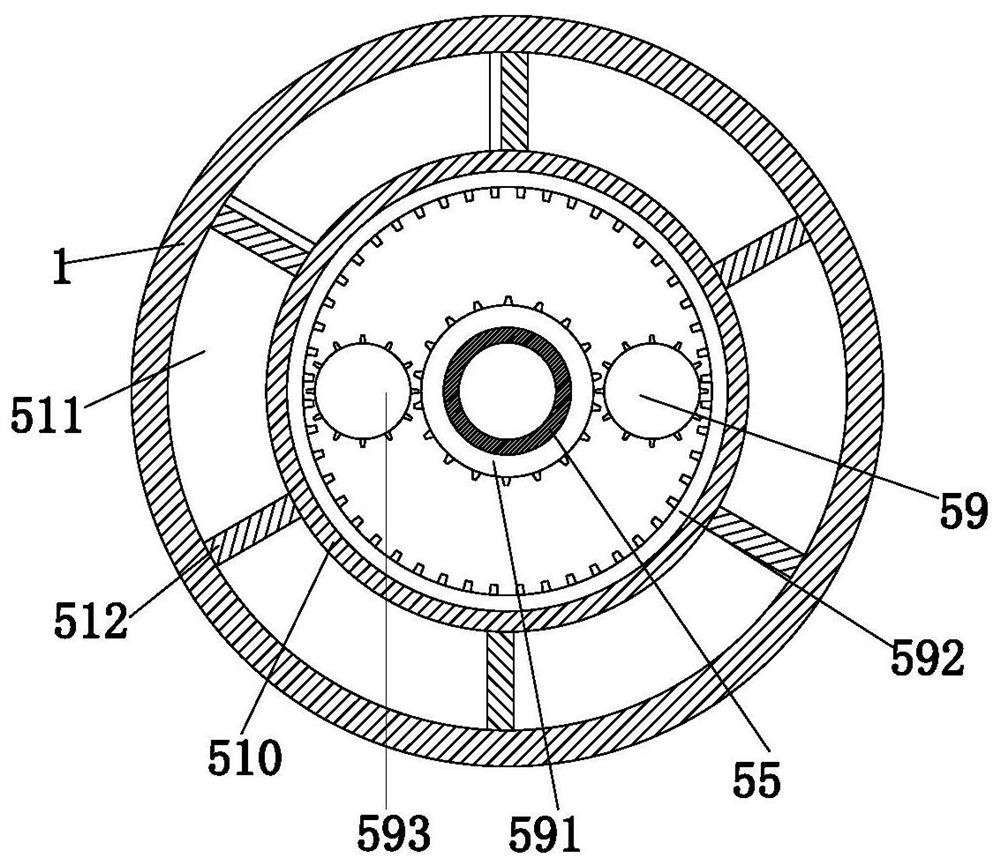

[0037] Such as Figure 1 to Figure 6 As shown, a printing paper product recycling method, which uses a pulping equipment, the pulping equipment includes a housing 1, a feed pipe 2, a discharge pipe 3, an inlet pipe 4, a crushing device 5 and a crushing device. Pulp device 6, the specific method when using the above-mentioned pulping equipment to recycle printed paper products is as follows:

[0038] S1. Sorting and recycling: carry out classified recycling according to the actual category of printed paper products, and carry out synchronous processing of printed paper products of the same category in the follow-up process;

[0039] S2. Crushing and pulping: After the printed paper product is preliminarily crushed by the crushing device 5, the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com