Clothes drying system, clothes dryer and clothes washing and drying integrated machine

The technology of drying clothes and filter screen is applied in the field of clothes drying system, clothes dryer and all-in-one clothes washing and drying machine, which can solve the problems such as affecting the normal performance of the clothes dryer, the airflow cannot be circulated normally, and the clothes dryer is stopped abnormally, etc. Achieve the effect of avoiding blocking performance, ensuring smooth airflow, and maintaining good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Drying system example:

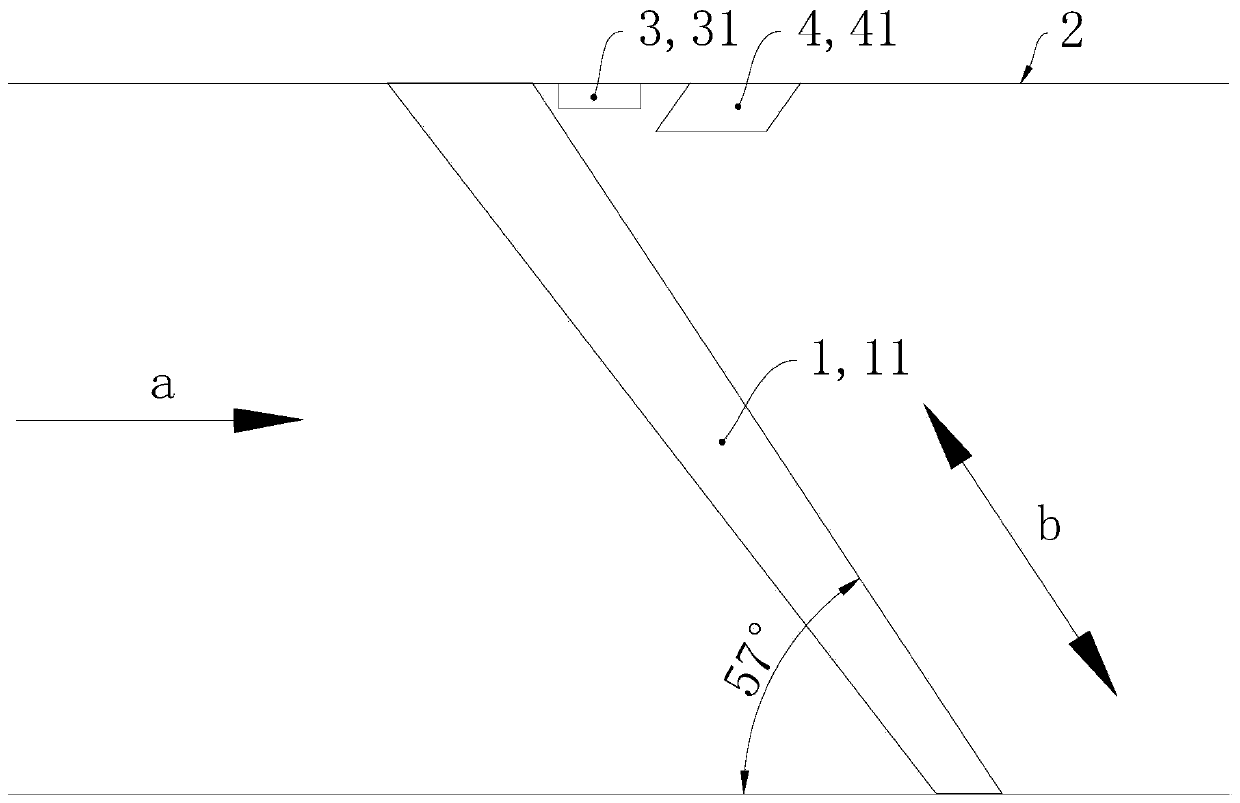

[0030] Please refer to figure 1 The clothes drying system of this embodiment includes a filter screen 1, an air channel 2, a spray device 3 and a blower device 4, the filter screen 1 is installed in the air channel 2, and the air flow of the air channel 2 section where the filter screen 1 is installed is along the first a horizontal direction a.

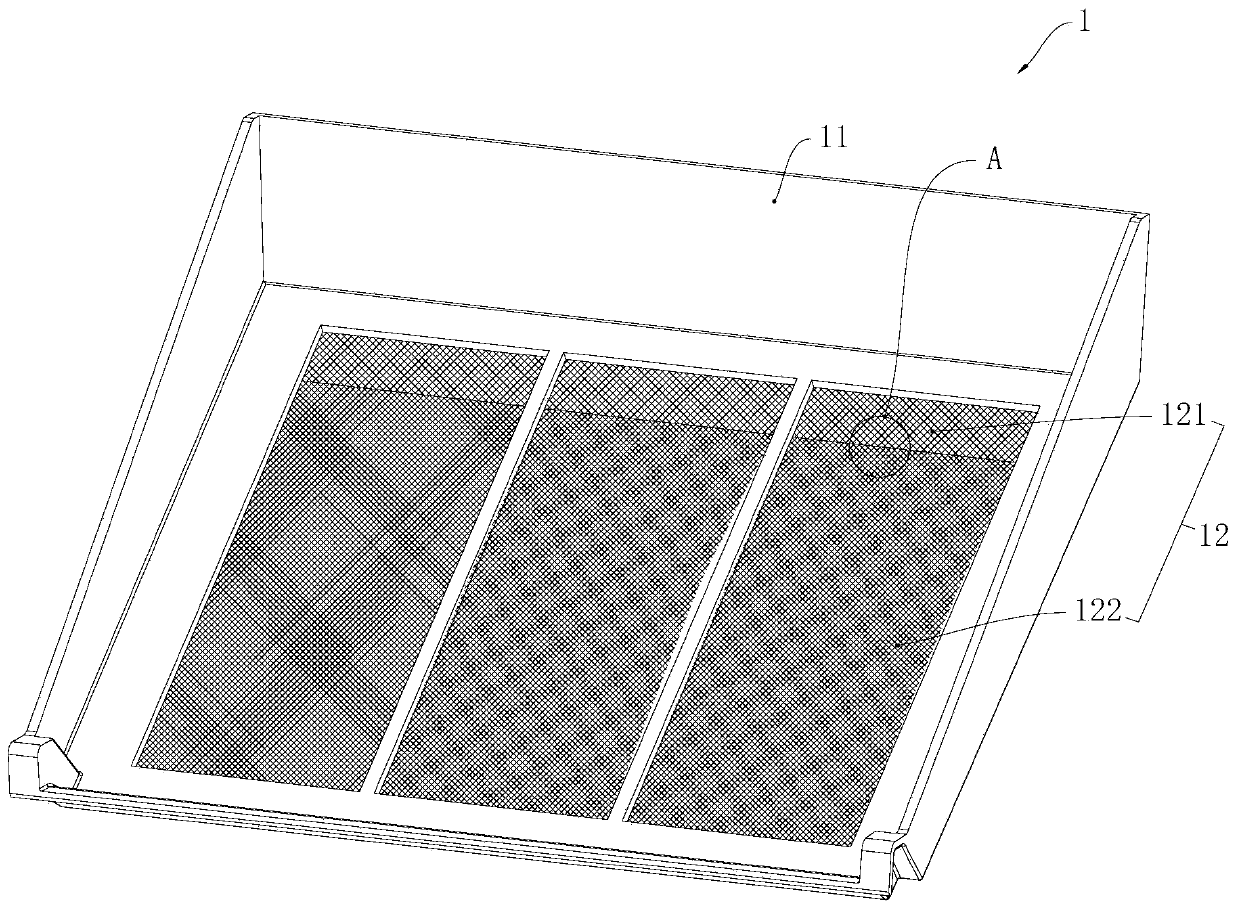

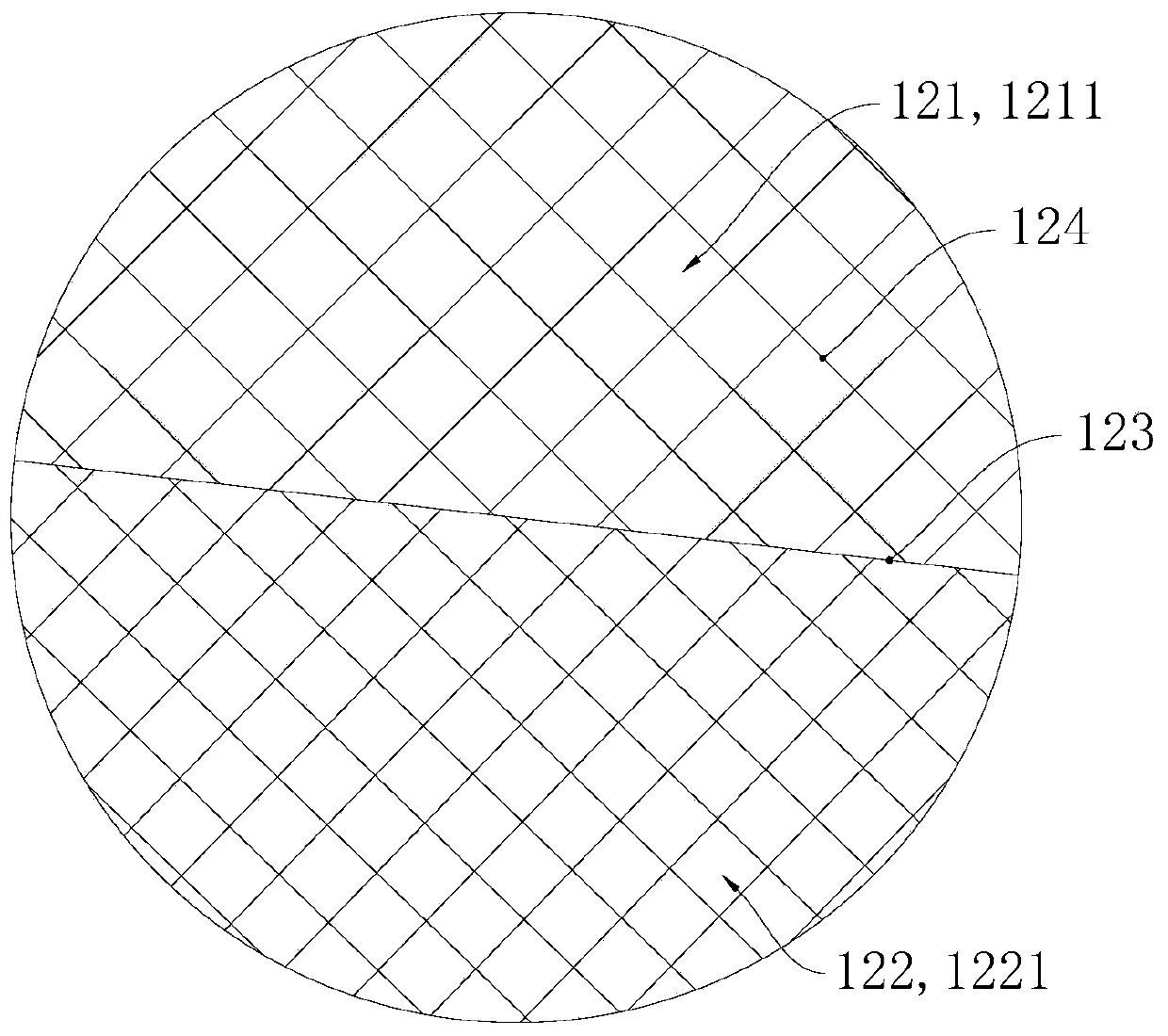

[0031] Please refer to Figure 1 to Figure 3 , the filter screen 1 includes a base frame 11 and a mesh surface 12, the mesh surface 12 is formed by interweaving fiber strands in the base frame 11, the mesh surface 12 has an angle of 57° with the horizontal plane, and the mesh surface 12 includes a first area 121 and a second Area 122 , the area of the first area 121 is one-twentieth of the area of the entire mesh surface 12 , the first area 121 is located on the upper part of the mesh surface 12 , and the second area 122 is located on the lower part of the mesh surface 12 .

[0032] The first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com