Regeneration method of waste high-cobalt coarse-grain hard alloy

A cemented carbide and high-cobalt technology, which is applied in the regeneration field of waste high-cobalt coarse-grained cemented carbide, can solve the problems of easy introduction of impurities, high crushing difficulty, and high crushing energy consumption, so as to reduce the crushing difficulty and reduce the crushing energy consumption. , the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

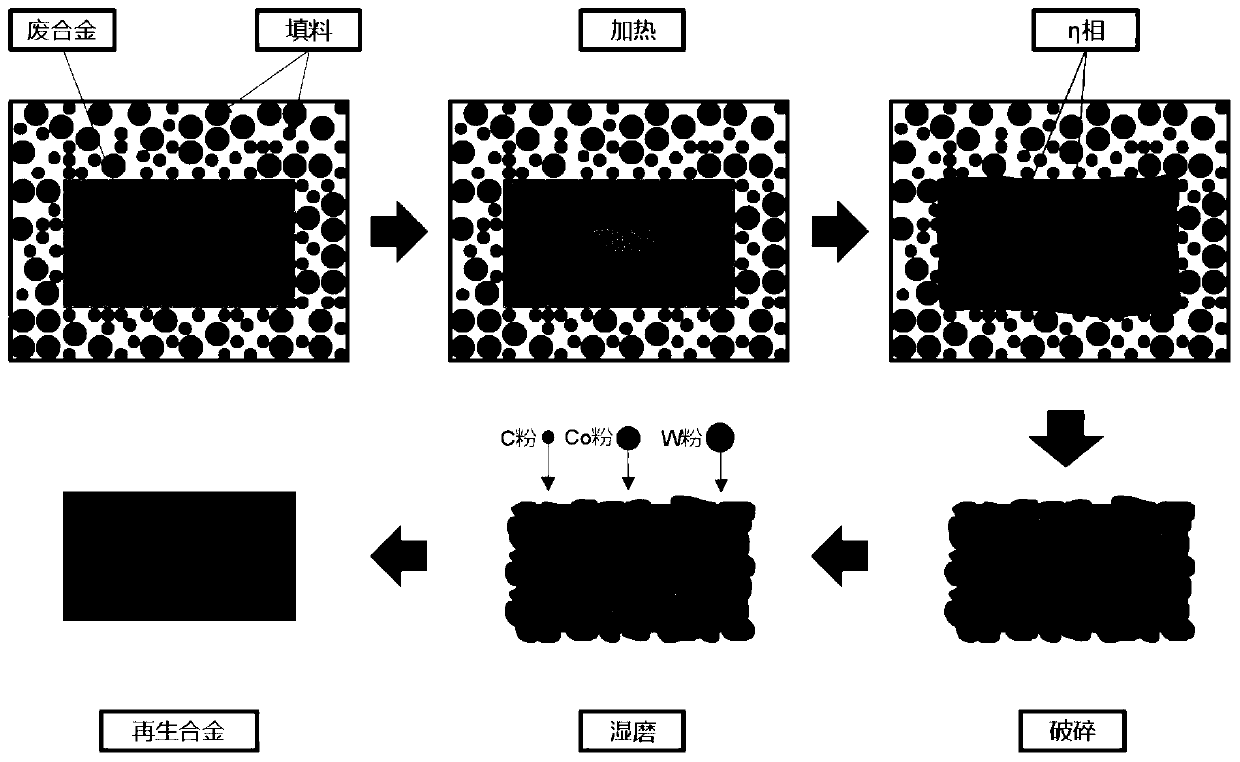

[0038] A kind of regeneration method of waste high-cobalt coarse-grained cemented carbide of the present invention, schematic flow sheet is as figure 1 As shown, the specific process is as follows:

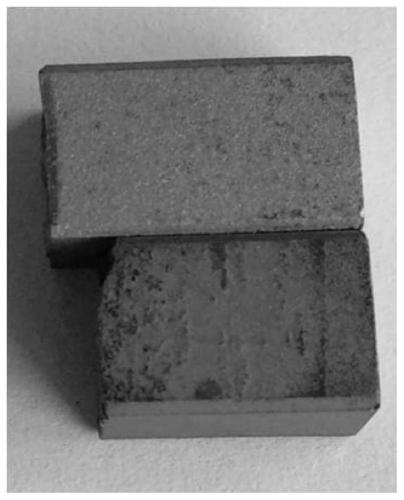

[0039] (1) In the sintering furnace, the waste high-cobalt coarse-grained hard alloy block (photo as figure 2 As shown, the Co content in the cemented carbide is 20wt%, the balance is WC, and the grain size of WC is 1.6 μm) embedded in the alumina powder with a grain size of 0.1 mm, and the sintering furnace is evacuated and heated to 1550 ° C, and kept 1h, obtain the waste high-cobalt coarse-grained hard alloy of calcining treatment, the photo is as image 3 As shown, the microstructure of scrap alloy after sintering is loose;

[0040] (2) Cleaning the surface of the waste high-cobalt coarse-grained cemented carbide after the calcining treatment in step (1), crushing it with a jaw crusher for 20 minutes, and passing through a 100-mesh sieve to obtain waste alloy powder with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com