Antibacterial antifouling agent and antibacterial antifouling coating

An antifouling coating and antifouling agent technology, applied in the field of coatings, can solve the safety and durability hazards of marine concrete structures, economic losses, fouling of marine concrete structures, etc., to achieve effective anti-biological adhesion and prolong service life , Improve the effect of safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

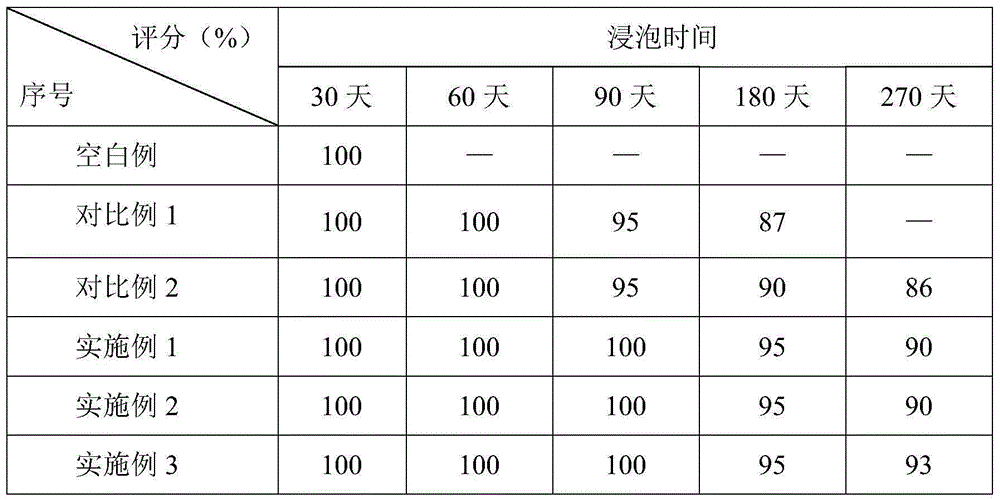

Examples

Embodiment 1

[0028] Step S1: Preparation of polyaspartic acid ester, code name PAE-a

[0029] The amino-terminated polyether JeffamineD-2000 and diethyl maleate are in the ratio n(—NH 2 ): n(—C=C—)=1:1 metering. Add JeffamineD-2000 into the reaction kettle equipped with agitator and heating temperature control device, pass nitrogen gas and raise the temperature to 40°C, add diethyl maleate dropwise at a rate of one drop every two seconds, after the addition is completed, nitrogen protection Stir and heat to 80°C, keep warm for 24 hours, cool down and discharge to obtain polyaspartic acid ester.

[0030] Step S2: Prepare coating A component

[0031] The dosage of 2,4'-diphenylmethane diisocyanate MDI-50 polyoxypropylene diol PPG2000 is measured according to NCO%=15% in the generated prepolymer. Add 2,4'-diphenylmethane diisocyanate MDI-50 into a reaction kettle equipped with a stirrer and a heating temperature control device, blow nitrogen gas and raise the temperature to 40°C, and add p...

Embodiment 2

[0040] Step S1: Preparation of polyaspartic acid ester, code PAE-b

[0041] Jeffamine T-5000 and diethyl maleate by substance ratio n(—NH 2 ): n(—C=C—)=1:1 metering. Add Jeffamine T-5000 into a reaction kettle equipped with a stirrer and a heating temperature control device, pass nitrogen gas and raise the temperature to 40°C, add diethyl maleate dropwise at a rate of one drop every two seconds, after the addition is complete, nitrogen Stir and heat to 80°C under protection, keep warm for 24 hours, cool down and discharge to obtain polyaspartic acid ester.

[0042] Step S2: Prepare coating A component

[0043] The amount of 2,4'-diphenylmethane diisocyanate MDI-50 and polyoxypropylene diol PPG2000 is measured according to NCO%=15% in the prepolymer produced. Add 2,4'-diphenylmethane diisocyanate MDI-50 into a reaction kettle equipped with a stirrer and a heating temperature control device, blow nitrogen and raise the temperature to 40°C, add polyoxypropylene glycol PPG2000 ...

Embodiment 3

[0053] Step S1: Preparation of polyaspartic acid ester, code PAE-c:

[0054] Jeffamine D-230 and diethyl maleate by substance ratio n(—NH 2 ): n(—C=C—)=1:1 metering. Add Jeffamine D-230 into a reaction kettle equipped with a stirrer and a heating temperature control device, blow nitrogen and raise the temperature to 40°C, add diethyl maleate dropwise at a rate of one drop every two seconds, after the addition is complete, nitrogen Stir and heat to 80°C under protection, keep warm for 24 hours, cool down and discharge to obtain polyaspartic acid ester.

[0055] Step S2: Prepare coating A component

[0056] The amount of 2,4'-diphenylmethane diisocyanate MDI-50 and polyoxypropylene diol PPG2000 is measured according to NCO%=15% in the prepolymer produced. Add 2,4'-diphenylmethane diisocyanate MDI-50 into a reaction kettle equipped with a stirrer and a heating temperature control device, blow nitrogen and raise the temperature to 40°C, add polyoxypropylene glycol PPG2000 dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com