Marine coating for preventing adhesion of marine organisms and processing technology

A technology for marine organisms and ships, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of inconvenient quantitative filling of coatings, unfavorable long-term use of ships, and unsatisfactory adhesion of marine organisms , to achieve the effect of convenient plugging and quantitative filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, the ship coating for preventing the adhesion of marine organisms, the raw materials of the marine coating for preventing the adhesion of marine organisms include: 9 parts of nano silicon dioxide, 7.5 parts of castor oil modified waterborne polyurethane, vinyl polydimethylsiloxane 2.3 parts of alkane, 12 parts of hollow glass microspheres, 18 parts of epoxy resin, 8.3 parts of polychlorotrifluoroethylene, 1.8 parts of titanate coupling agent, 4.5 parts of polyacrylamide and 12 parts of defoamer.

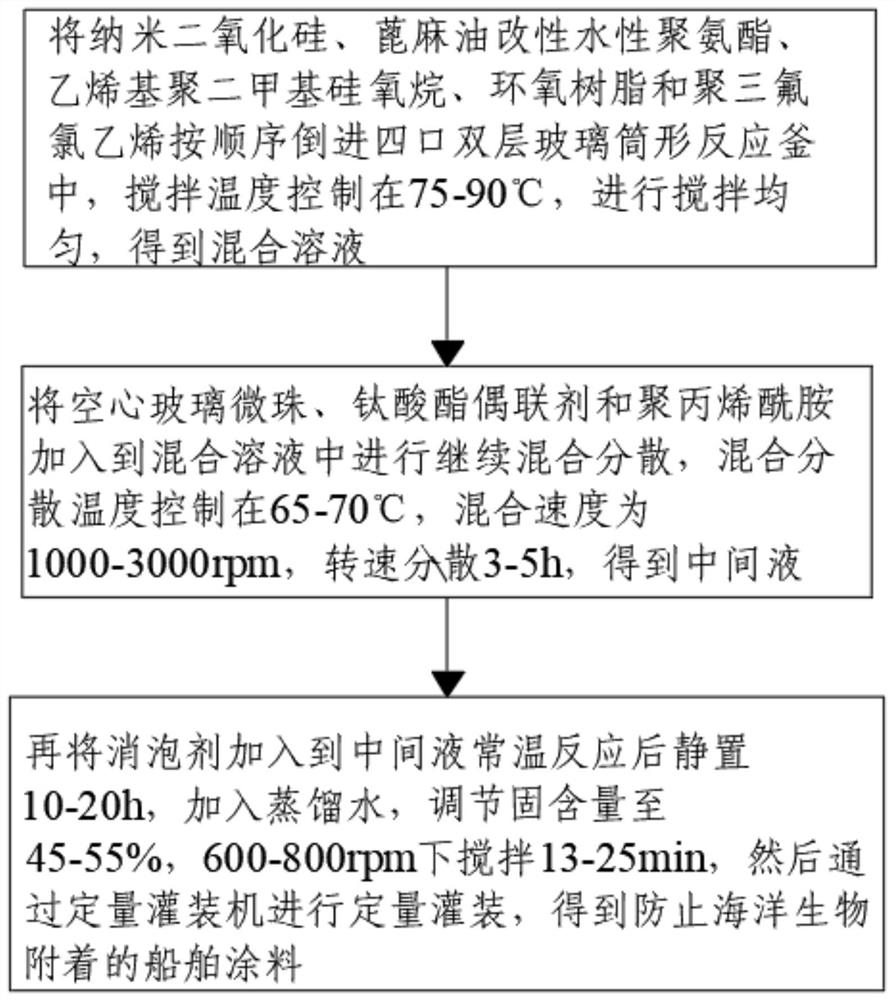

[0046] A processing technology for marine coatings to prevent marine organisms from adhering, the specific steps are as follows:

[0047] S1. Pour nano-silica, castor oil modified water-based polyurethane, vinyl polydimethylsiloxane, epoxy resin and polychlorotrifluoroethylene into four-hole double-layer glass cylindrical reaction kettle in sequence, and stir The temperature is controlled at 90°C, and the mixture is evenly stirred to obtain a mixed s...

Embodiment 2

[0051] Such as figure 1 Shown, embodiment 2 is the further improvement to embodiment 1, the marine coating that prevents marine organisms from adhering, the raw material of this kind of marine organisms adhering to prevent marine coatings comprises in parts: 12 parts of nano silicon dioxide, castor oil modification 4.5 parts of water-based polyurethane, 4.5 parts of vinyl polydimethylsiloxane, 10 parts of hollow glass microspheres, 13 parts of epoxy resin, 11.8 parts of polychlorotrifluoroethylene, 1.5 parts of titanate coupling agent, polyacrylamide 5.8 parts and 24 parts of defoamer.

[0052] A processing technology for marine coatings to prevent marine organisms from adhering, the specific steps are as follows:

[0053] S1. Pour nano-silica, castor oil modified water-based polyurethane, vinyl polydimethylsiloxane, epoxy resin and polychlorotrifluoroethylene into four-hole double-layer glass cylindrical reaction kettle in sequence, and stir The temperature is controlled at...

Embodiment 3

[0058] Embodiment 3 is a further improvement to Embodiment 1.

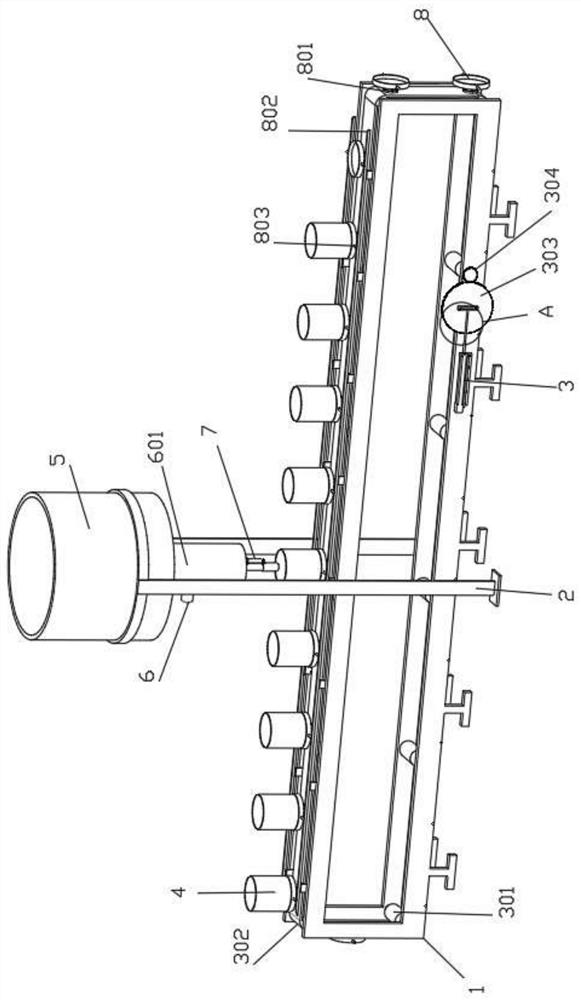

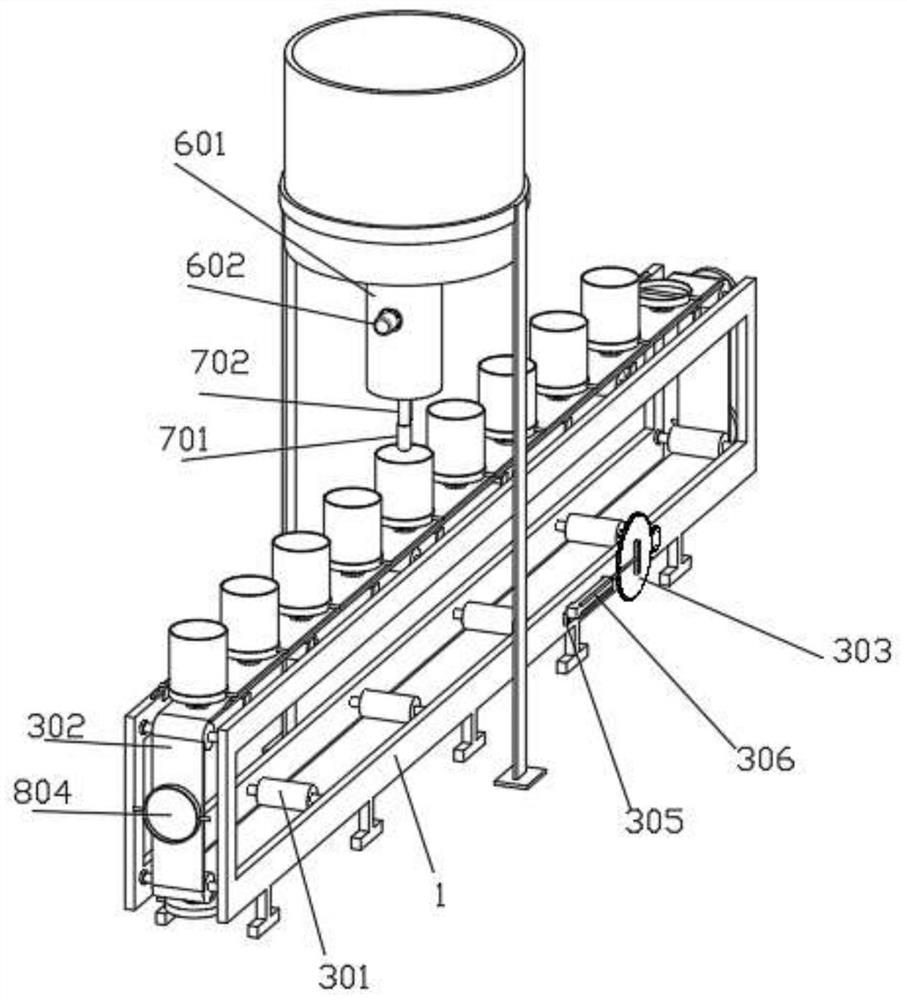

[0059] Such as figure 2 , 3 , 4, 5, 6, 7, 8, 9, 10, and 11, a device for preventing marine organisms from adhering to marine coatings, the preparation device is a quantitative filling machine with step intermittent drive structure 3, including the first support frame 1. The second support frame 2 and the barrel 4, the first support frame 1 is connected with an intermittent drive structure 3 for the intermittent movement of the barrel 4, the intermittent drive structure 3 includes a drive roller 301, a conveyor belt 302, a first ring gear 303, a second Two ring gears 304, support plate 305, cylinder 306, square frame 307, second rotating shaft 308, first rotating shaft 309, push rod 310 and cross bar 311, the top of supporting plate 305 is fixedly equipped with cylinder 306, and the top of cylinder 306 The output end is fixedly connected with a crossbar 311, the end of the crossbar 311 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com