Machine for testing abrasion property of marine coating

A testing machine and coating technology, which is applied in the direction of analyzing materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve the problems of poor equipment operation stability, cumbersome operation, complex structure, etc., to achieve increased stability, simple operation, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

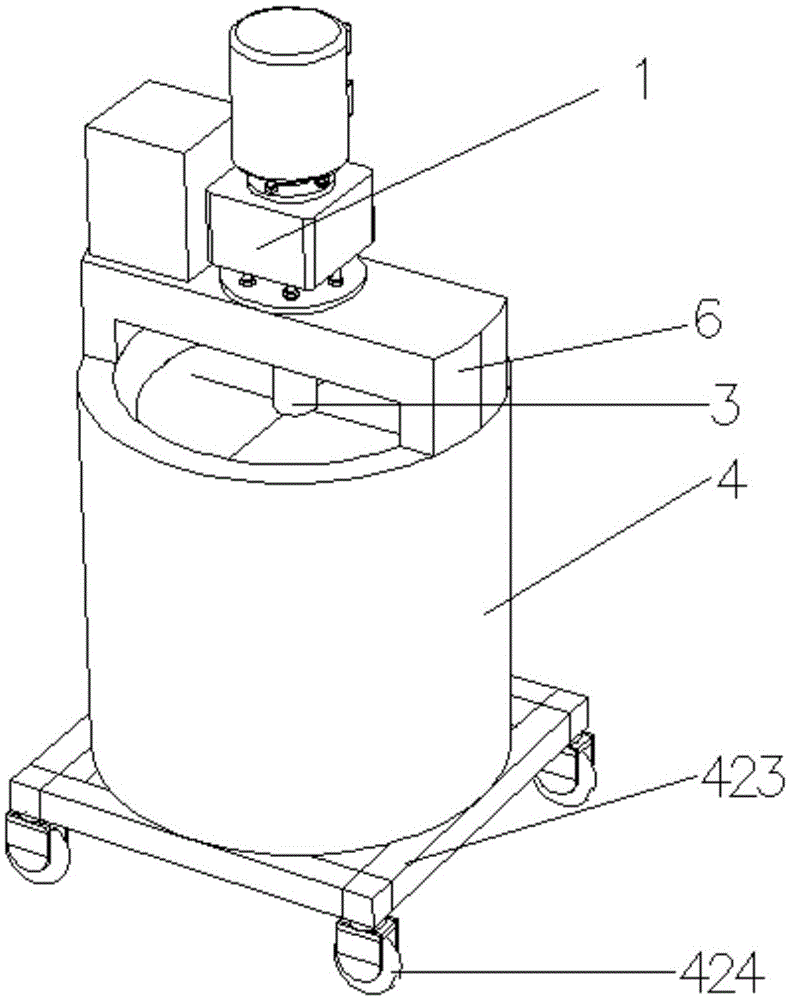

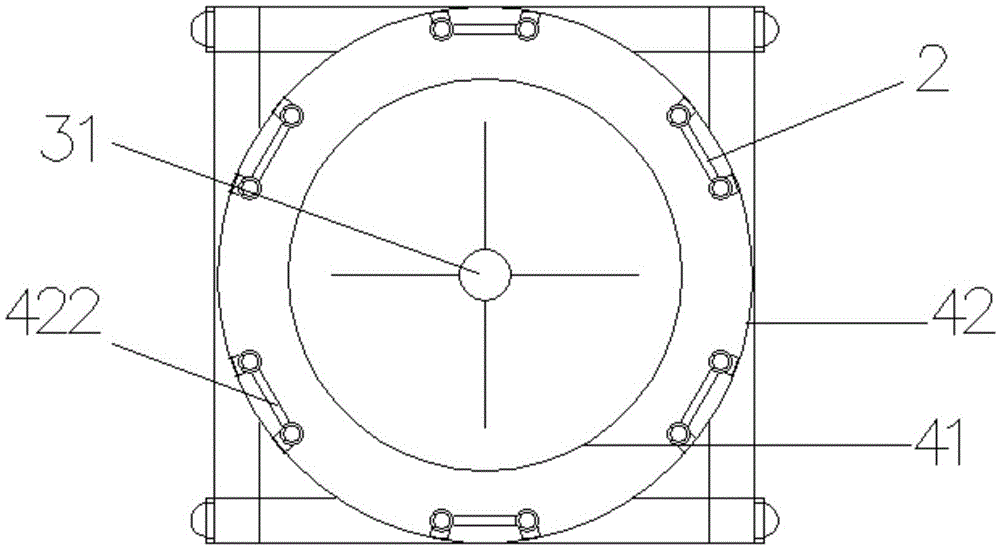

[0027] Such as figure 1 and 3 As shown, a marine paint abrasion performance testing machine includes a power system 1, a sample fixing mechanism 2, a transmission mechanism 3 and a stirring mechanism 4, and the power system 1 is connected to the transmission mechanism 3 and is arranged on the stirring mechanism 4 through a bracket 6, The power system 1 drives the sample fixing mechanism 2 suspended on the stirring mechanism 4 through the transmission mechanism 3 to carry out the test:

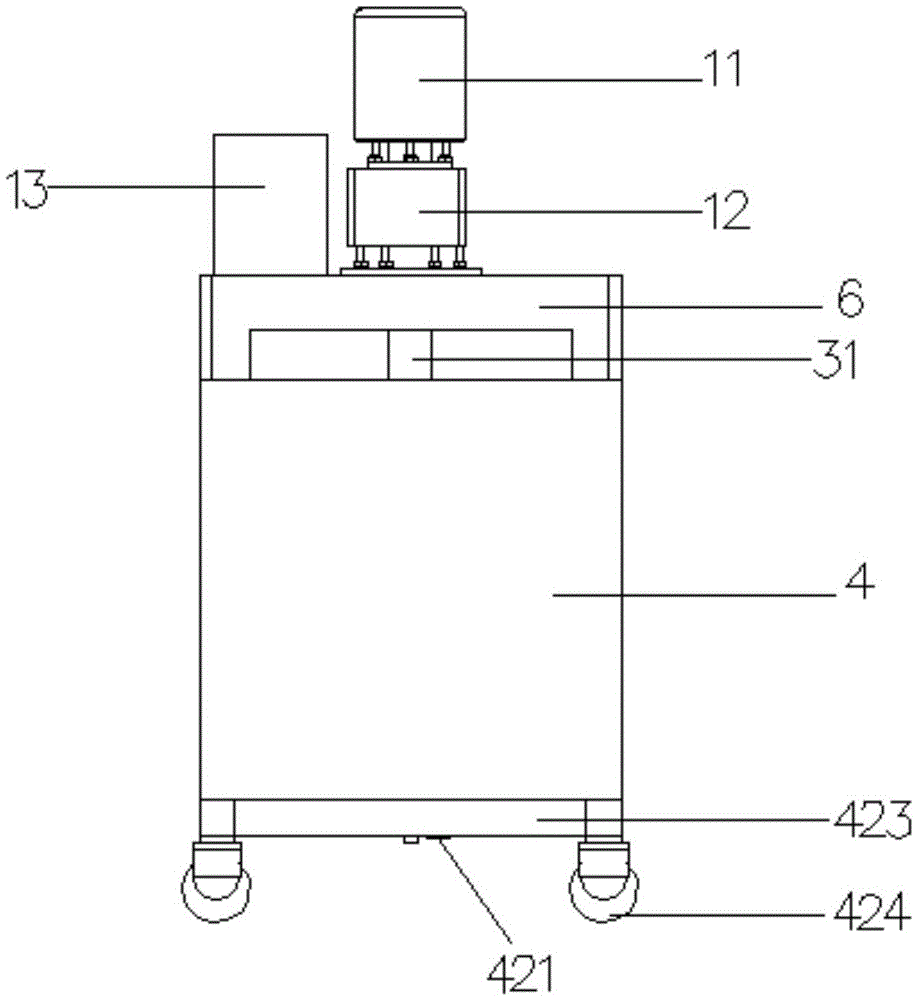

[0028] Such as figure 2 As shown, the power system 1 is composed of a motor 11 with a voltage of AC 380V and a power of 1.1KW, a reducer 12 with a rotation ratio of 4.27 and a power of 1.1KW, and a console 13. The console 13 is composed of an air power switch , MITSUBISH Mitsubishi brand FR-E740-1.5K-CHT type inverter with input current 6.9A, output current 4.9A, input voltage AC380V, frequency 50 / 60Hz, C-Lin Xinling brand HHZ1 type voltage AC220V, frequency 50 / 60Hz intelligent Type tachome...

Embodiment 2

[0034]A kind of marine paint abrasion performance testing machine as shown in Figure 5, differs from embodiment 1 in that: the stirring mechanism 4 is provided with a cooling water circulation system 5, and the cooling water circulation system 5 is connected to the stirring mechanism 4, and the The cooling water circulation system 5 includes a steel cooling drum 51, a water pump 52 with adjustable power and a pipeline group 53. The steel cooling drum 51 and the water pump 52 are connected to the stirring mechanism through the pipeline group 53. The mixing tank The water overflow pipe with a ball valve on the upper part of the body 4 is connected to the upper part of the steel cooling drum 51 through the pipeline group 53, and water is sprayed into the steel cooling drum through the sprinkler nozzle 54. The water inlet pipe with a ball valve at the bottom of the mixing cylinder 42 421 links to each other with water pump 52, steel cooling cylinder 51 bottoms through pipeline grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com