Water-resistant antibacterial marine coating and preparation method thereof

A technology for coatings and ships, applied in the field of water-resistant and antibacterial marine coatings and their preparation, can solve the problems of poor water resistance and antibacterial properties of coatings, wear and damage of hull surface coatings, and achieve improved water resistance and antibacterial properties, long service life, Resistant to wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

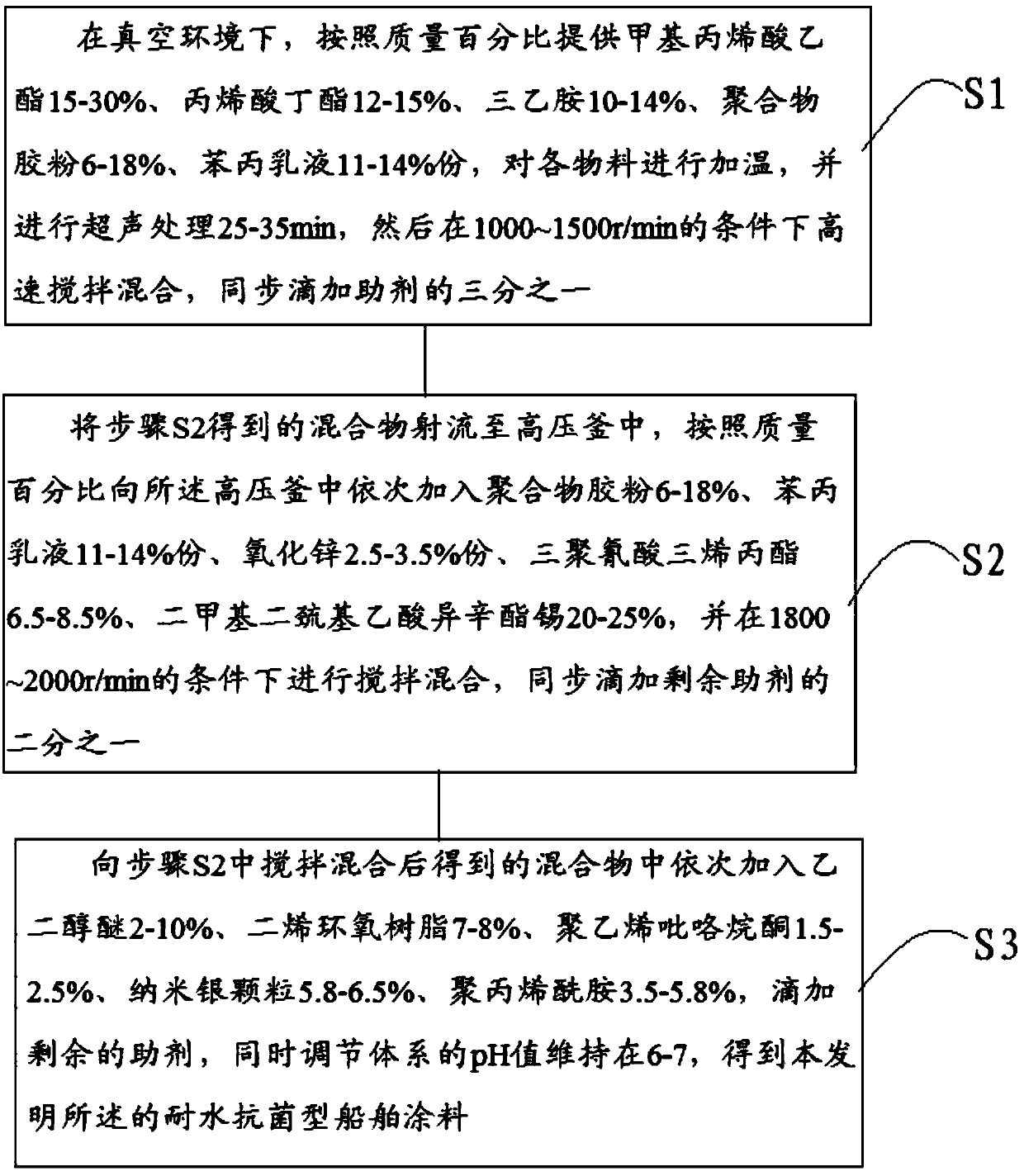

Method used

Image

Examples

Embodiment 1

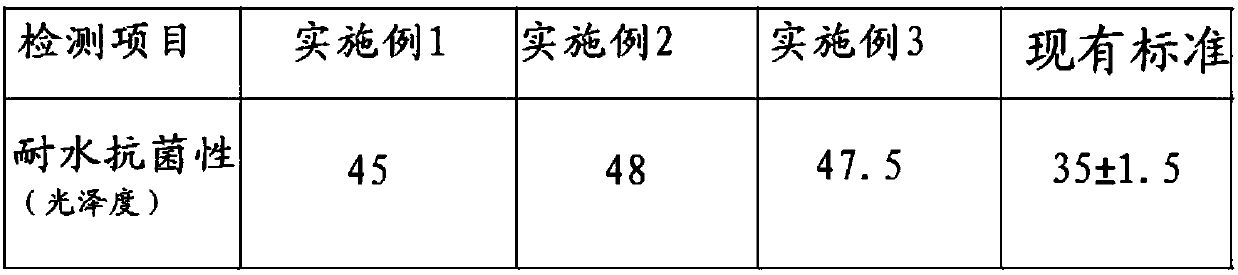

[0034] Under the vacuum degree of -0.05MPa, 30% of ethyl methacrylate, 15% of butyl acrylate, 14% of triethylamine, 18% of polymer rubber powder and 11% of styrene-acrylic emulsion are provided according to the mass percentage, and each material is carried out. Warm up and perform ultrasonic treatment for 25-35 minutes, then stir and mix at a high speed under the condition of 1000r / min, and add one-third of the additives synchronously. The obtained mixture was jet-flowed into the autoclave, and 6% of polymer rubber powder, 11% of styrene-acrylic emulsion, 2.5% of zinc oxide, 6.5% of triallyl cyanurate, 6.5% of triallyl cyanurate, 20% isooctyltin dimethyl dimercaptoacetate, and stir and mix under the condition of 1800-2000r / min, and drop half of the remaining additives synchronously. Add 10% of glycol ether, 8% of diene epoxy resin, 2.5% of polyvinylpyrrolidone, 5.5% of nano-silver particles, and 5.8% of polyacrylamide to the mixture obtained after stirring and mixing, and add ...

Embodiment 2

[0036] Under the vacuum degree of -0.08MPa, 30% ethyl methacrylate, 15% butyl acrylate, 3.8% nano-titanium dioxide, 14% triethylamine, 2.5% carboxymethyl cellulose, polymer rubber powder are provided according to mass percentage 18%, styrene-acrylic emulsion 11%, heat each material, and conduct ultrasonic treatment for 25-35min, then stir and mix at a high speed under the condition of 1000r / min, and drop one-third of the additive simultaneously. The obtained mixture was jet-flowed into the autoclave, and 6% of polymer rubber powder, 11% of styrene-acrylic emulsion, 2.5% of zinc oxide, 6.5% of triallyl cyanurate, 6.5% of triallyl cyanurate, 20% isooctyltin dimethyl dimercaptoacetate, and stir and mix under the condition of 1800-2000r / min, and drop half of the remaining additives synchronously. Add 10% of glycol ether, 8% of diene epoxy resin, 2.5% of polyvinylpyrrolidone, 5.5% of nano-silver particles, and 5.8% of polyacrylamide to the mixture obtained after stirring and mixing...

Embodiment 3

[0038] Under the vacuum degree of -0.05MPa, 30% ethyl methacrylate, 15% butyl acrylate, 3.8% nano-titanium dioxide, 14% triethylamine, 2.5% carboxymethyl cellulose, polymer rubber powder are provided according to mass percentage 18%, styrene-acrylic emulsion 11%, heat each material, and conduct ultrasonic treatment for 25-35min, then stir and mix at a high speed under the condition of 1000r / min, and drop one-third of the additive simultaneously. Jet the obtained mixture into the autoclave, and add 6% of polymer rubber powder, 11% of styrene-acrylic emulsion, 2.5% of zinc oxide, 12% of antibacterial auxiliary agent, and tricyanuric acid three 6.5% allyl ester, 20% isooctyl tin dimethyl dimercaptoacetate, and stir and mix under the condition of 1800-2000r / min, and drop half of the remaining additives synchronously. Add 10% of glycol ether, 8% of diene epoxy resin, 2.5% of polyvinylpyrrolidone, 5.5% of nano-silver particles, and 5.8% of polyacrylamide to the mixture obtained afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com