High-performance polycarboxylic acid water reducing agent and preparation method therefor

A technology of polycarboxylate and water reducer, which is applied in the field of high performance polycarboxylate water reducer and its preparation, can solve the problems of large resource consumption, high gas content of water reducer, unfavorable environmental protection and energy saving, etc. Gas content, increase effective molecular weight, and enhance the effect of slump retention function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

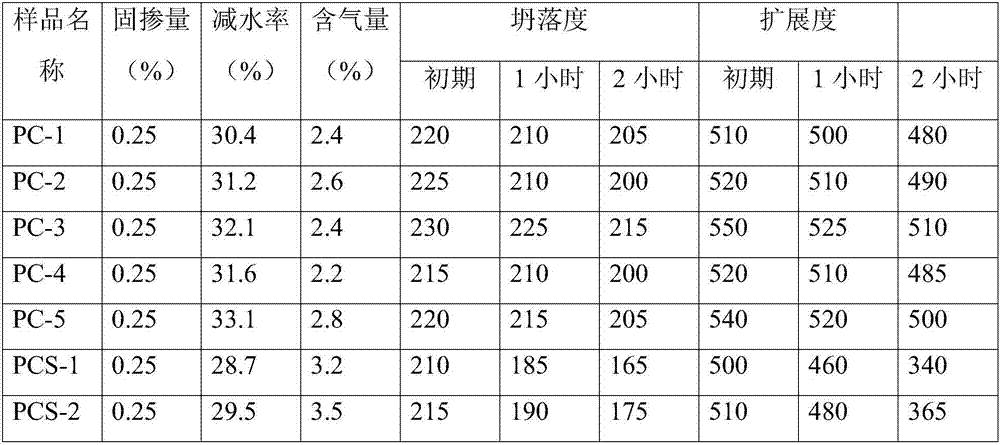

Examples

Embodiment 1

[0025] Add 320g of methallyl alcohol polyoxyethylene ether and 300g of deionized water into a four-necked flask with a capacity of 1L, stir and dissolve, add 2.5g of azobisisobutyronitrile after the dissolution is complete, and add liquid A, B liquid and C liquid (the A liquid is made up of 30g acrylic acid, 16gN-vinylpyrrolidone and 62g deionized water; The B liquid is made up of 0.8g hanging white block, 0.6g glucose, 3.6g thioglycolic acid and 80g deionized water Composition; described C liquid is made up of 2.5g ammonium persulfate and 84g deionized water). Add liquid A dropwise for 3.0 hours, and add liquid B and C dropwise for 3.5 hours. If the system temperature exceeds 45°C during the dropwise addition, you need to turn on the cooling system to keep the temperature in the reactor at 42-45°C. After the dropwise addition, mature for 2 hours, then add 15g of sodium hydroxide for neutralization, supplement 112g of deionized water to adjust the resulting product to 40% soli...

Embodiment 2

[0027] Add 320g of methallyl alcohol polyoxyethylene ether and 300g of deionized water into a four-neck flask with a capacity of 1L, stir to dissolve, add 2.2g of ammonium persulfate after the dissolution is complete, and add A, B and C dropwise at the same time ten minutes later Liquid (the A liquid is made up of 33g acrylic acid, 5g vinyl acetate, 4g2-acrylamide-2-methylpropanesulfonic acid and 62g deionized water; the B liquid is made up of 1.8g vitamin C, 3.6g thioglycolic acid and 80g Composition of deionized water; the C liquid is composed of 3.5g concentration of 27.5% hydrogen peroxide and 84g deionized water). Add liquid A dropwise for 4 hours, and add liquid B and C dropwise for 4.5 hours. If the system temperature exceeds 45°C during the dropwise addition, you need to turn on the cooling system to keep the temperature in the reactor at 42-45°C. After the dropwise addition, mature for 2 hours, then add 15g of sodium hydroxide for neutralization, and add 36g of deioni...

Embodiment 3

[0029] Add 320g of methallyl alcohol polyoxyethylene ether and 300g of deionized water into a four-necked flask with a capacity of 1L, stir and dissolve, add 2.2g of ammonium persulfate after the dissolution is complete, and add liquid A, liquid B and C solution (the A solution is composed of 30.2g acrylic acid, 4g2-acrylamide-2-methylpropanesulfonic acid, 12g4-vinylpyridine and 62g deionized water; the B solution is composed of 1.8g vitamin C, 3.2g mercapto Acetic acid and 80g deionized water; the C solution is composed of 3.5g concentration of 27.5% hydrogen peroxide and 84g deionized water). A solution was added dropwise for 4 hours, B solution and C solution were added dropwise for 4.5 hours, after the dropwise addition was completed, it was aged for 2 hours, then 15g of sodium hydroxide was added for neutralization, and 33g of deionized water was added to adjust the obtained product to 40% solid content. That is, the finished product PC-3 of the polycarboxylic acid high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com