A polymer water reducer for reducing the viscosity of clay slurry and its preparation and application

A water-reducing agent and polymer technology, which is applied in the field of ceramic water-reducing agent preparation, can solve the problems that organic polymer water-reducing agents have not been industrialized, and inorganic water-reducing agents cannot achieve low dosage and high water-reducing rate. , to achieve the effect of good water reduction, small dosage and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

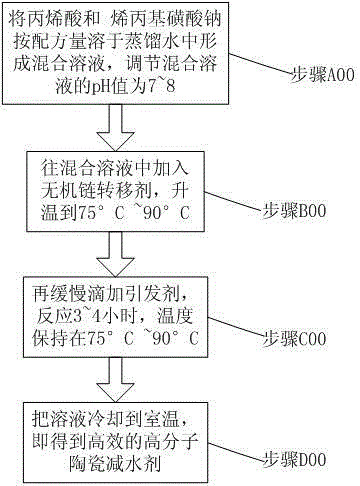

[0027] like figure 1 Shown is a flow chart of the steps of the preparation method of the polymer water reducer for reducing the viscosity of clay slurry in the present invention. A method for preparing a polymer water reducer for reducing the viscosity of clay slurry as described above, specifically comprising the following steps:

[0028] Step A00: dissolving acrylic acid and sodium allyl sulfonate in distilled water according to the formula to form a mixed solution, and adjusting the pH value of the mixed solution to 7-8;

[0029] Step B00: Add an inorganic chain transfer agent to the mixed solution, and heat up to 75°C~90°C;

[0030] Step C00: Slowly add the initiator dropwise, react for 3-4 hours, and keep the temperature at 75°C-90°C;

[0031] Step D00: Cool the solution to room temperature to obtain a high-efficiency polymer ceramic water reducer.

[0032] In this embodiment, in the step A00, adjusting the pH value of the mixed solution to 7-8 is realized by adding so...

Embodiment 1

[0036] Step A00: Add 120 g of acrylic acid, 40 g of sodium allyl sulfonate and 200 g of distilled water into a three-necked flask with a stirrer, stir to form a mixed solution, and dropwise add a 60% mass fraction of sodium hydroxide solution to adjust the mixed solution The pH value is 8; step B00: add inorganic chain transfer agent sodium bisulfite 8g in mixed solution, be warming up to 80 DEG C; Step C00: slowly add initiator ammonium persulfate 9.6g again, react 4 hours, temperature Keep it at 80°C; Step D00: Cool the solution to room temperature to obtain a high-efficiency polymer ceramic water reducer.

[0037] The performance test of the polymer ceramic water reducer prepared above was carried out: the test results showed that when the polymer ceramic water reducer prepared above accounted for 0.25% of the mass fraction of clay, the viscosity of the slurry system was 771mPa·s , the initial flow time is 50s, the fluidity is good, there is no sedimentation phenomenon afte...

Embodiment 2

[0039] Step A00: Add 100 g of acrylic acid, 25 g of sodium allyl sulfonate and 100 g of distilled water into a three-necked flask with a stirrer, stir to form a mixed solution, and dropwise add a 60% mass fraction of sodium hydroxide solution to adjust the mixed solution The pH value is 8; Step B00: add inorganic chain transfer agent sodium bisulfite 8.8gg in mixed solution, be warming up to 85 DEG C; Step C00: slowly add initiator ammonium persulfate 5g again, react 5 hours, temperature Keep it at 85°C; Step D00: Cool the solution to room temperature to obtain a high-efficiency polymer ceramic water reducer.

[0040] The polymer ceramic water reducer prepared above was tested for performance: the test results showed that when the polymer ceramic water reducer prepared above accounted for 0.25% of the mass fraction of clay, the viscosity of the slurry system was 826mPa·s , the initial flow time is 60s, the fluidity is good, there is no sedimentation phenomenon after being left...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com