Preparation method and application of molasses retarding and water-reducing agent

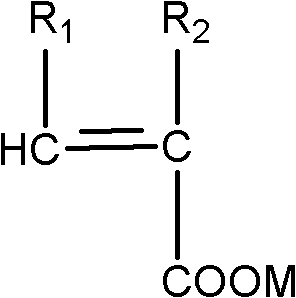

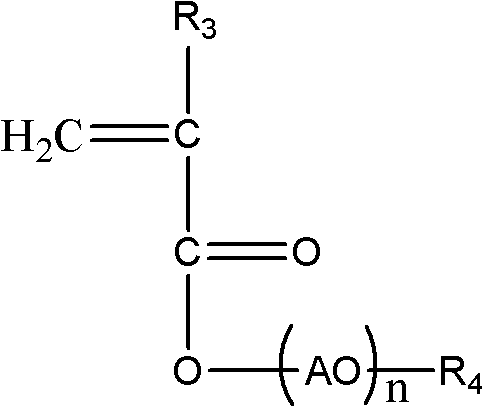

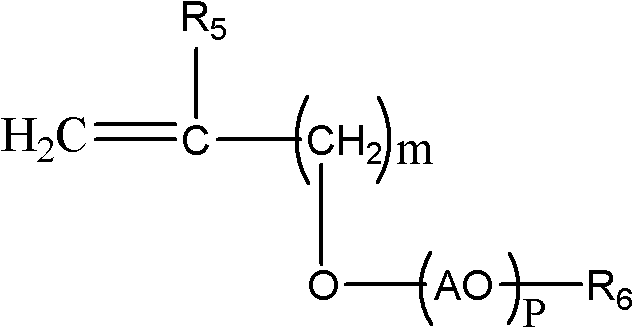

A technology of retarded water reducer and molasses, which is applied in the field of preparation of molasses retarded water reducer, which can solve the problems of low water reduction rate and fast loss of molasses, and achieve improved dispersion performance, short reaction time, and improved water reduction low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Place a flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen inlet tube in a water bath, add molasses 200g, water 50g, B 2 -830g, stir 0.2g of ferrous sulfate heptahydrate evenly, heat up to 30°C, and simultaneously add A-14g monomer solution dissolved in 30g water dropwise, hydrogen peroxide 0.07g (concentration 30%) oxidant solution dissolved in 30g water, mercapto Propionic acid 0.37g is dissolved in 20g water chain transfer agent solution, add dropwise for 1h, continue to keep warm for 2h, add 25.4g 30% NaOH solution to neutralize the polymer to pH=8.0, and obtain the polymer solution, the weight average of the polymer The molecular weight is 21000, which is recorded as P-1.

Embodiment 2

[0050] Place a flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen inlet tube in a water bath, add molasses 200g, water 50g, B 2 -712.2g Stir evenly, heat up to 45°C, add 0.29g of hydrogen peroxide (concentration 30%) in the reaction bottle before starting to drop the solution, and drop A-22.5g monomer solution dissolved in 20g of water at the same time, 0.25g of ascorbic acid A reducing agent solution dissolved in 25g of water, 0.15g of thioglycolic acid dissolved in 20g of water as a chain transfer agent was added dropwise for 3 hours, continued to keep warm for 4 hours, and 5.0g of 30% NaOH solution was added to neutralize the polymer pH=6.0 to obtain a polymer solution , the weight average molecular weight of the polymer is 31200, denoted as P-2.

Embodiment 3

[0052] Place the flask equipped with a thermometer, stirrer, dropping funnel and nitrogen inlet tube in a water bath, add 300g of molasses, 75g of water, B 1 -427.5g, 0.25g ammonium persulfate, stir evenly, heat up to 55°C, and dropwise add reducing agent solution of 0.09g sodium bisulfite dissolved in 40g water, 11.5g B 1 -1 and 3.7gA-3 dissolved in 60g water monomer solution, dodecanethiol 0.01g dissolved in 40g water chain transfer agent solution, add dropwise for 1.5h, keep warm for 5h, add 13.7g 30% NaOH solution to neutralize The pH of the polymer is 7.5, and the weight average molecular weight of the polymer is 35100, denoted as P-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com