A kind of ultra-sustained release polycarboxylic acid slump retaining agent and preparation method thereof

An ultra-slow-release polycarboxylic acid technology, which is applied in the field of ultra-slow-release polycarboxylic acid slump-retaining agent and its preparation, can solve the problems of high numerical value and complicated production process, and achieve simple feeding procedures, simple process and high performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

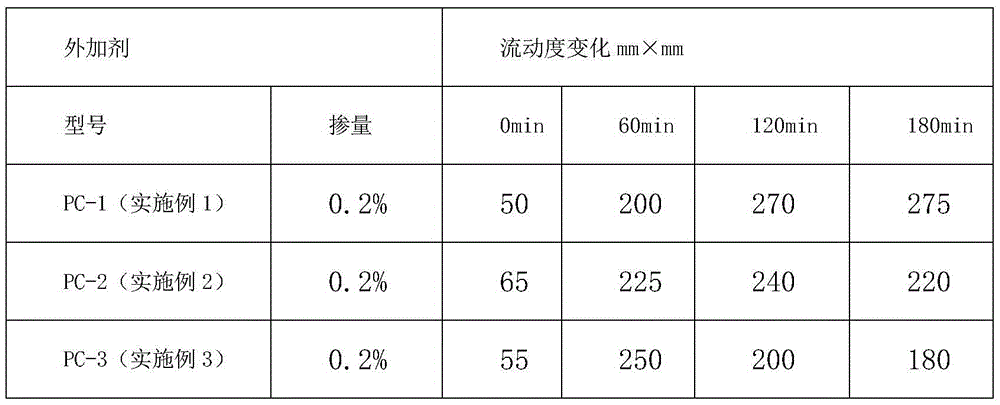

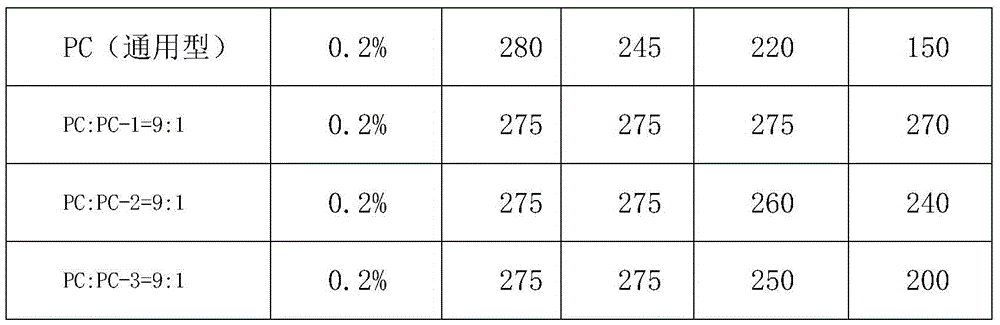

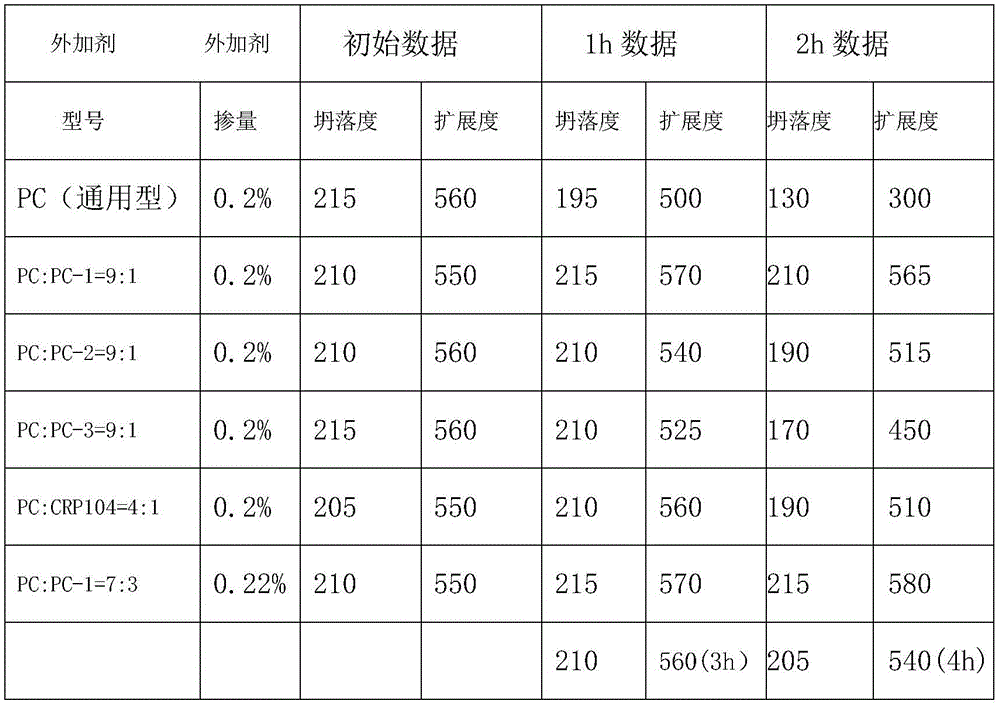

Examples

Embodiment 1

[0023] Put 120.00 parts of isopentenyl polyoxyethylene ether with a molecular weight of 2400 and 75 parts of water into a reaction container, raise the temperature, stir at a temperature of 50±5°C to completely dissolve the reactants, and then add polyethylene glycol into the container. Diol maleic acid monoester 12g, add dropwise the aqueous solution of 7.2 parts of acrylic acid + 1.09 parts of sodium methacrylate + 22.75 parts of hydroxypropyl acrylate + 31.04 parts of water and 45.00 parts of 5% ammonium persulfate solution, and control the dripping Acceleration, drop at 120±10 minutes and 150±10 minutes respectively, keep the temperature at 50±5°C, and continue the reaction for 1 hour. After cooling, add about 5 parts of 30% sodium hydroxide solution to adjust the pH to 6.5±0.5 to obtain the 50% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 2

[0025] Put 120.00 parts of isopentenyl polyoxyethylene ether with a molecular weight of 2400 and 75 parts of water into a reaction container, raise the temperature, and stir at a temperature of 65±5°C to completely dissolve the reactants, and then add polyethylene glycol into the container. 12 parts of diol maleic acid diester, dropwise add 7.2 parts of acrylic acid + 1.09 parts of sodium methacryl sulfonate + 22.75 parts of vinyl acetate + 31.04 parts of water and 45.00 parts of 5% ammonium persulfate solution, dropwise Acceleration, drop at 120±10 minutes and 150±10 minutes respectively, keep the temperature at 50±5°C, and continue the reaction for 1 hour. After cooling, add about 5 parts of 30% sodium hydroxide solution to adjust the pH to 6.5±0.5 to obtain the 50% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 3

[0027]Put 120.00 parts of isopentenyl polyoxyethylene ether with a molecular weight of 2400 and 71 parts of water into a reaction container, raise the temperature, stir at a temperature of 50±5°C to completely dissolve the reactants, and then add polyethylene glycol into the container. A total of 12g of diol maleic acid monoester and polyethylene glycol maleic acid diester is added dropwise with an aqueous solution of 7.2 parts of acrylic acid+1.09 parts of sodium methacrylate sulfonate+22.3 parts of hydroxyethyl acrylate+30.59 parts of water and 45.00 parts of 5% ammonium persulfate solution, control the rate of addition, drop at 120±10 minutes and 150±10 minutes respectively, keep the temperature at 50±5°C, and continue the reaction for 1 hour. After cooling, add about 5 parts of 30% sodium hydroxide solution to adjust the pH=6.5±0.5 to obtain the 50% polycarboxylate high-performance concrete water reducer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com