Early strength type ether polycarboxylate superplasticizer and preparation method thereof

A technology of ether polycarboxylic acid and water reducer, which is applied in the field of building materials, can solve the problems of difficult control of the reaction process, unfavorable environmental protection, and long time consumption, and achieve high free radical polymerization conversion rate, small slump loss, and early The effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of early-strength ether polycarboxylate water reducer is characterized in that it comprises the following steps:

[0057] (1) By parts by weight, the prenyl alcohol polyethylene glycol monomethyl ether macromonomer with a polymerization degree of 27, the prenyl alcohol polyethylene glycol monomethyl ether macromonomer with a polymerization degree of 113, 2- Add acrylamido-2-methyl-1-propanesulfonic acid and deionized water into the three-necked flask, heat and start the stirrer to dissolve;

[0058] (2) Chain transfer agent and initiator are dissolved in 40 parts of deionized water in parts by weight;

[0059] (3) Acrylic acid is added into 35 parts of deionized water to dissolve in parts by weight;

[0060] (4) After the temperature of the reactor rises to 38-42°C and the isopentenol polyethylene glycol monomethyl ether macromonomer is dissolved, a constant flow pump is used to drop the mixed solution of chain transfer agent and initiator 2-3 H...

Embodiment 1

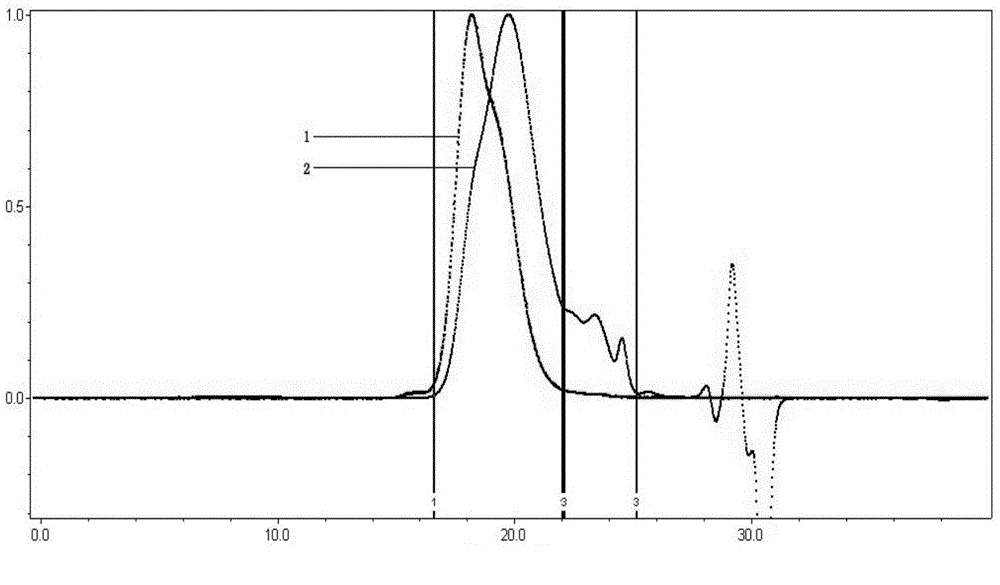

[0073] Such as figure 1 As shown, the polycarboxylate superplasticizer with early strength function can be preferably made of the following raw materials in parts by weight:

[0074] 24 parts of prenyl alcohol polyethylene glycol monomethyl ether macromonomer with a degree of polymerization of 27, 50 parts of prenyl alcohol polyethylene glycol monomethyl ether macromonomer with a degree of polymerization of 113, 6.5 parts of acrylic acid, chain transfer 0.3 parts of agent, 0.58 parts of initiator, 2.8 parts of 2-acrylamido-2-methyl-1-propanesulfonic acid, and 125 parts of deionized water. Wherein, the chain transfer agent is mercaptopropionic acid; the initiator is a combination of hydrogen peroxide and vitamin C, and in 0.49 parts of the initiator, hydrogen peroxide accounts for 0.4 part, and vitamin C accounts for 0.09 part.

[0075] The deionized water includes deionized water X, deionized water Y and deionized water Z. The parts by weight of deionized water X used to dis...

Embodiment 2

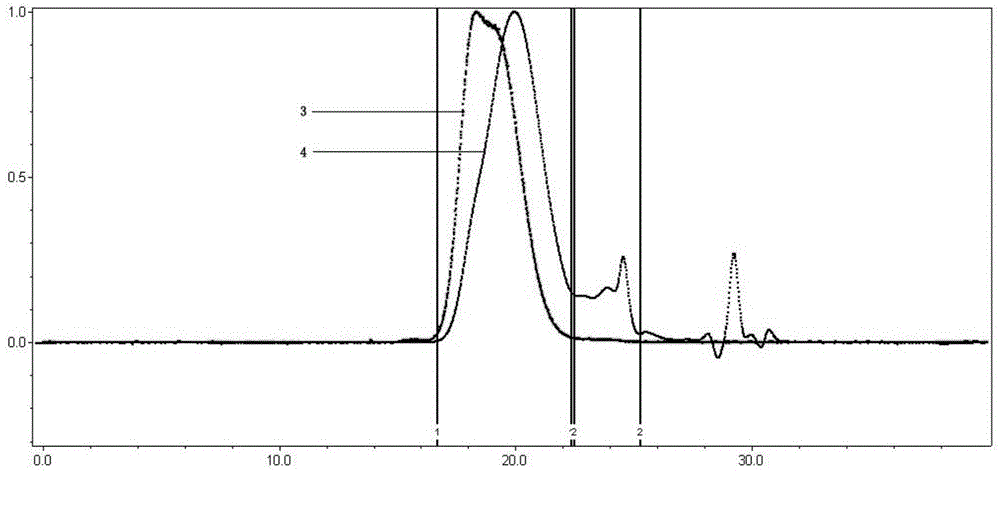

[0079] Such as figure 2 As shown, the polycarboxylate water reducer with early strength function can also be preferably made of the following raw materials in parts by weight:

[0080] 20 parts of prenyl alcohol polyethylene glycol monomethyl ether macromonomer with a degree of polymerization of 27, 60 parts of prenyl alcohol polyethylene glycol monomethyl ether macromonomer with a degree of polymerization of 113, 7.6 parts of acrylic acid, chain transfer 1.2 parts of agent, 0.48 parts of initiator, 2.5 parts of 2-acrylamido-2-methyl-1-propanesulfonic acid, and 135 parts of deionized water. Wherein, the chain transfer agent is sodium methallylsulfonate; the initiator is ammonium persulfate.

[0081] The deionized water includes deionized water X, deionized water Y and deionized water Z. The parts by weight of deionized water X used to dissolve polyoxyethylene ether macromonomers and 2-acrylamido-2-methyl-1-propanesulfonic acid are 60 parts for dissolving initiators and chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com