Preparation method of high-thixotropy early-strength type polycarboxylate superplasticizer

A thixotropic and early-strength technology, applied in the field of building materials, can solve the problems of insufficient research on thixotropic properties, and achieve the effects of simple operation, accelerated construction progress, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

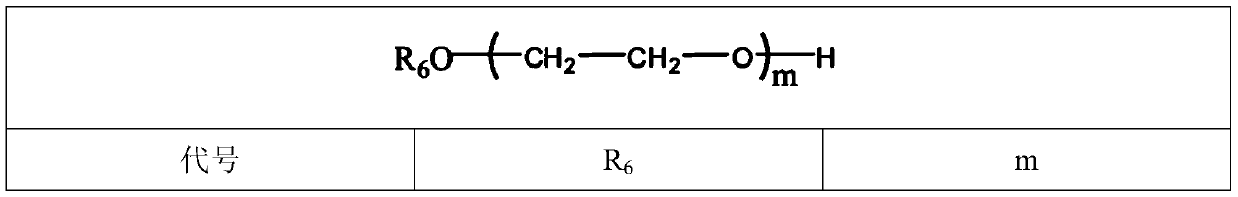

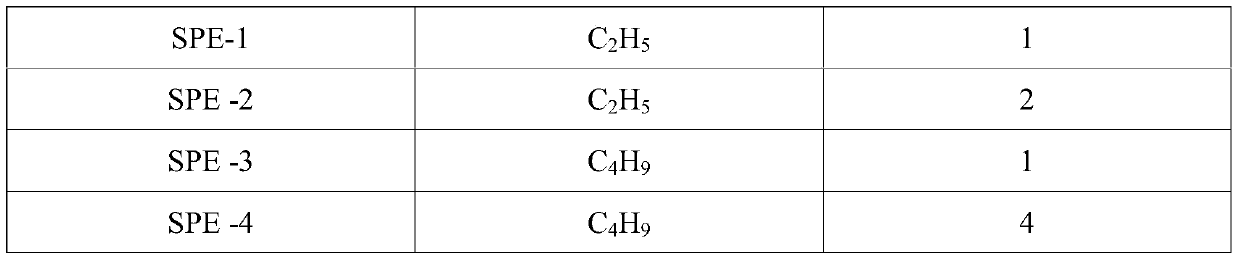

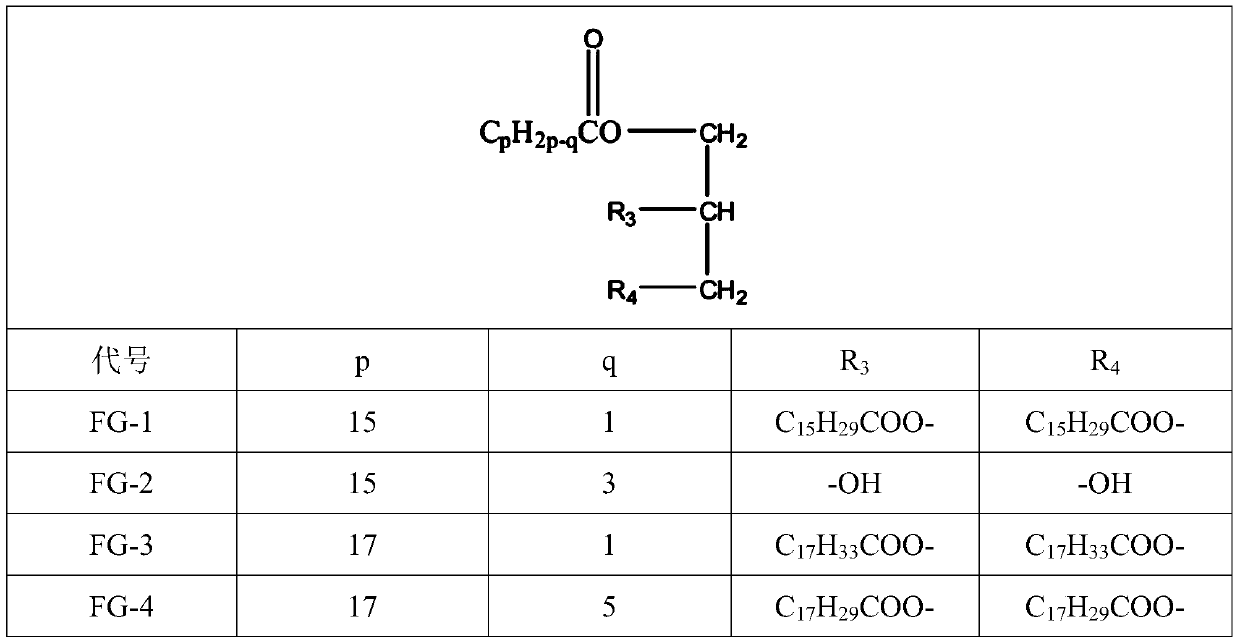

[0033] (1) Add 200 parts by weight of isobutylene alcohol polyoxyethylene ether macromonomer (molecular weight Mw is 3000), 1.5 parts by weight of methacryloyloxyethyl trimethyl in a four-necked flask equipped with a thermometer, a stirrer and a peristaltic pump ammonium chloride, 10 parts by weight of small molecule polyether SPE-1, 3 parts by weight of unsaturated fatty acid glyceride FG-1, 1.5 parts by weight of ammonium persulfate and 156 parts by weight of water, stirred and dissolved at 20°C;

[0034] (2) The first solution that 0.15 parts by weight 2-hydroxyl-2-sulfinic acid group acetic acid and the water of 25 parts by weight are made into, the second solution that the water of 0.8 parts by weight mercaptoacetic acid and 25 parts by weight are made into and 16 The third solution that the acrylic acid of weight part and 4 weight parts hydroxyethyl acrylate and the water of 15 weight parts are made into;

[0035] (3) Add the above-mentioned first solution, second soluti...

Embodiment 2

[0038] (1) Add 200 parts by weight of isobutylene alcohol polyoxyethylene ether macromonomer (molecular weight Mw is 4000), 2 parts by weight of acryloyloxyethyl trimethyl chloride in a four-necked flask equipped with a thermometer, a stirrer and a peristaltic pump Ammonium chloride, 12 parts by weight of small molecule polyether SPE-2, 5 parts by weight of unsaturated fatty acid glyceride FG-2, 1.6 parts by weight of sodium persulfate and 158 parts by weight of water were stirred and dissolved at 25°C;

[0039] (2) 0.25 parts by weight of 2-hydroxyl-2-sulfinic acid disodium salt and 25 parts by weight of water are made into the first solution, 0.9 parts by weight of 3-mercaptopropionic acid and 25 parts by weight of water are made into The methacrylic acid of the second solution and 13 parts by weight and the third solution that the water of 5 parts by weight hydroxyethyl methacrylate and 15 parts by weight is made into;

[0040] (3) Add the above-mentioned first solution, se...

Embodiment 3

[0043](1) Add 200 parts by weight of isobutylene alcohol polyoxyethylene ether macromer (molecular weight Mw is 5000), 3 parts by weight of diallyl dimethyl chloride in a four-necked flask equipped with a thermometer, a stirrer and a peristaltic pump Ammonium, 15 parts by weight of small molecule polyether SPE-3, 8 parts by weight of unsaturated fatty acid glyceride FG-3, 1.9 parts by weight of potassium persulfate and 158 parts by weight of water were stirred and dissolved at 30°C;

[0044] (2) The first solution made of 0.18 parts by weight of 2-hydroxy-2-sulfonic acid and 25 parts by weight of water, the second solution made of water of 0.8 parts by weight of thioglycerol and 25 parts by weight of water, and 15 parts by weight The methacrylic acid of part and the 3rd solution that the water of 6 parts by weight hydroxypropyl methacrylate and 15 parts by weight is made into;

[0045] (3) Add the above-mentioned first solution, second solution and third solution dropwise to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com