Polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of chemical building materials, can solve the problems of chain transfer agent not being environmentally friendly, poor production environment, and hidden safety hazards, and achieve the elimination of pollution and safety hazards, and the adaptability of high-slump cement , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

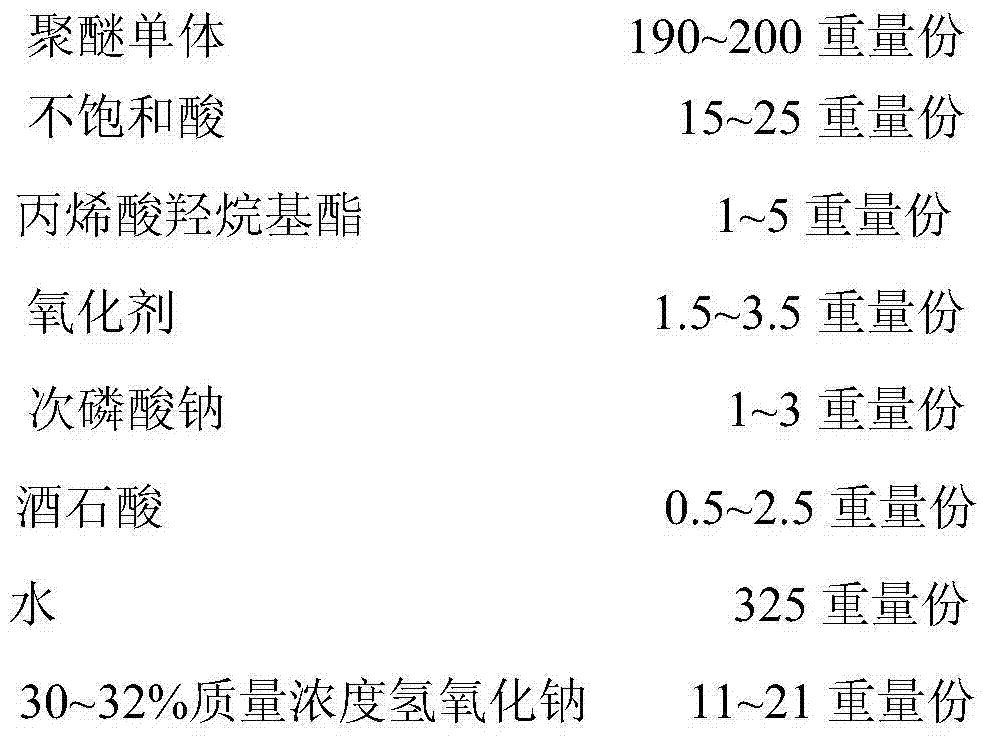

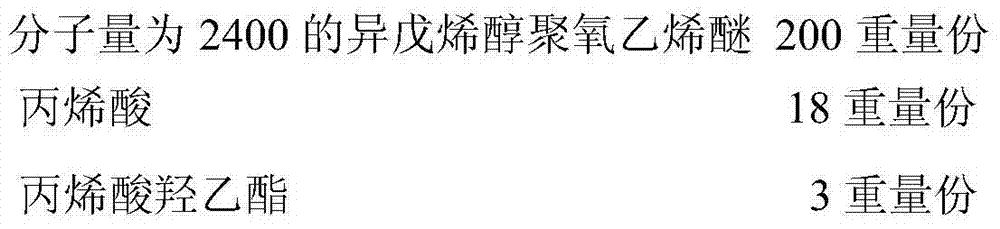

[0027] (1) Take each raw material component by weight as follows:

[0028]

[0029]

[0030] (2) dissolving acrylic acid and hydroxyethyl acrylate in 30 parts by weight of water to obtain the first solution, dissolving the sodium hypophosphite in 30 parts by weight of water to obtain the second solution, dissolving the tartaric acid in 30 parts by weight of water to obtain the second solution Three solutions, isopentenol polyoxyethylene ether is dissolved in 135 parts by weight of water to obtain the fourth solution;

[0031] (3) Add sodium persulfate and 100 parts by weight of water into the reaction kettle, stir and dissolve at 5-40°C, add the first solution, the second solution, the third solution and the fourth solution dropwise, and add dropwise The time is 1.5 to 3 hours, and the temperature is kept for 1 to 2 hours after the dropwise addition, and the copolymerization reaction is carried out;

[0032] (4) After the end of the copolymerization reaction, adjust the...

Embodiment 2

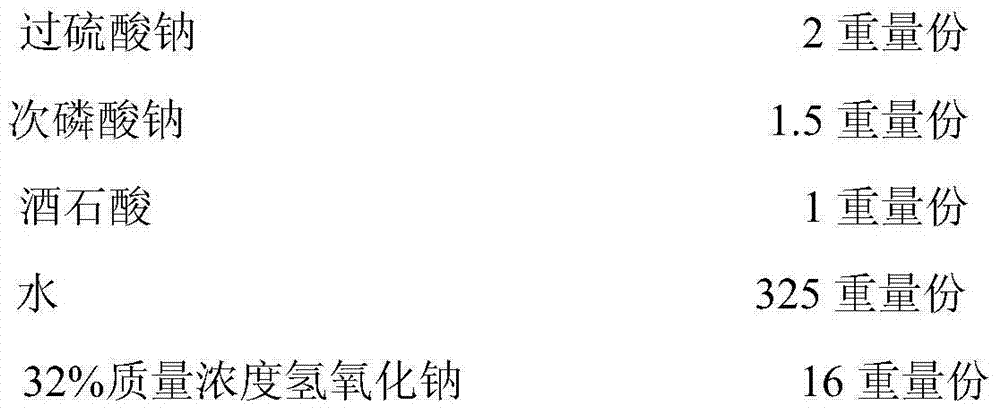

[0034] (1) Take each raw material component by weight as follows:

[0035]

[0036] (2) Acrylic acid and hydroxyethyl methacrylate are dissolved in 30 parts by weight of water to obtain the first solution, the sodium hypophosphite is dissolved in 30 parts by weight of water to obtain the second solution, and the tartaric acid is dissolved in 30 parts by weight of water To obtain the third solution, prenol polyoxyethylene ether was dissolved in 135 parts by weight of water to obtain the fourth solution;

[0037] (3) Add ammonium persulfate and hydrogen peroxide into the reaction kettle together with 100 parts by weight of water, stir and dissolve at 5-40°C, then add dropwise the first solution, the second solution, the third solution and the fourth solution respectively. solution, the dropping time is 1.5 to 3 hours, and the temperature is kept constant for 1 to 2 hours after the dropping, and the copolymerization reaction is carried out;

[0038] (4) After the end of the c...

Embodiment 3

[0040] (1) Take each raw material component by weight as follows:

[0041]

[0042] The block number range of EO and PO in the above-mentioned methallyl polyoxyethylene polyoxypropylene ether is EO:PO=100:0.5~2;

[0043] (2) dissolving acrylic acid and hydroxyethyl acrylate in 30 parts by weight of water to obtain the first solution, dissolving the sodium hypophosphite in 30 parts by weight of water to obtain the second solution, dissolving the tartaric acid in 30 parts by weight of water to obtain the second solution Three solutions, methallyl polyoxyethylene polyoxypropylene ether is dissolved in 135 parts by weight of water to obtain the fourth solution;

[0044] (3) Add sodium persulfate and 100 parts by weight of water into the reaction kettle, stir and dissolve at 5-40°C, add the first solution, the second solution, the third solution and the fourth solution dropwise, and add dropwise The time is 1.5 to 3 hours, and the temperature is kept for 1 to 2 hours after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com