Polycarboxylate-type water reducing agent

A weak acid and catalyst technology, applied in the field of building materials, to achieve the effect of ensuring dispersion retention, increasing steric hindrance effect, and enhancing slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

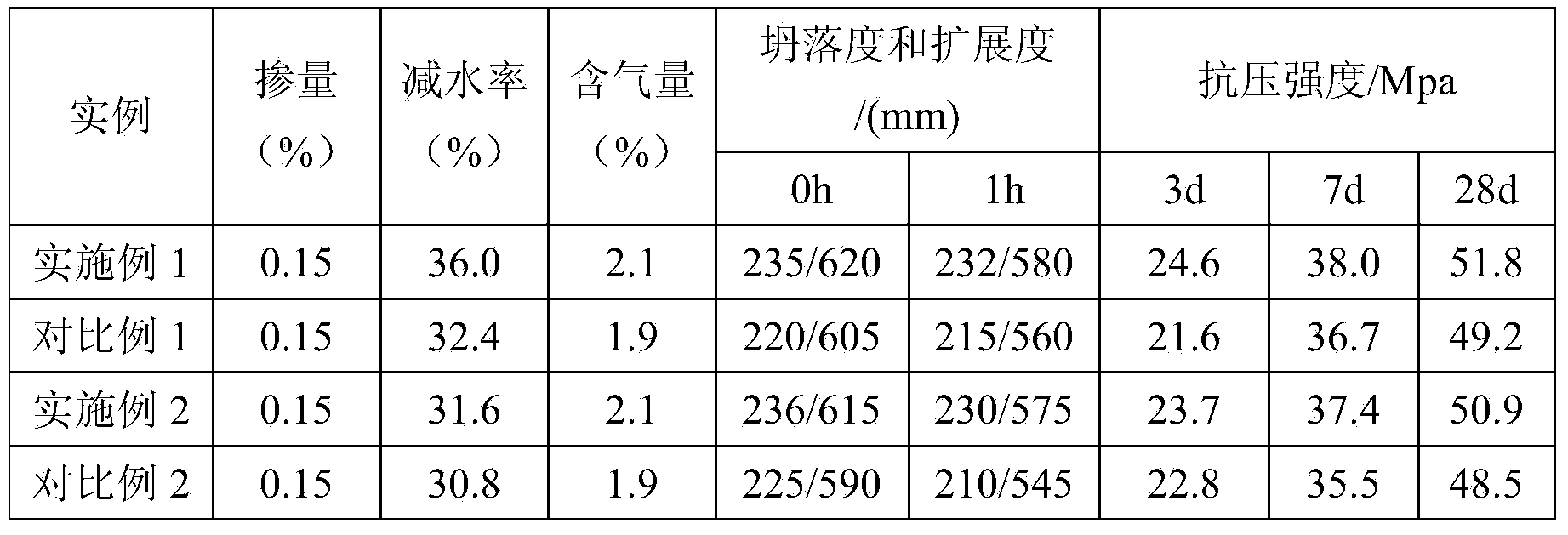

Examples

Embodiment 1

[0033] Embodiment 1: The 30L autoclave was first rinsed with distilled water. After drying the reactor, it is cooled to room temperature, and in the reactor, add 6000 g of prenol polyoxyethylene ether with a molecular weight of 1000 and 50 g of powdered sodium methylate, and use an inert gas N 2 Replace the air in the reactor. Raise the temperature in the reactor to 90°C to carry out the dealcoholization reaction. Observe the vacuum degree in the reactor, and start to add 6000g of ethylene oxide when the reactor is in vacuum. This process keeps the temperature in the reactor at 130°C, and the flow control is completed within 2 hours. Keep the temperature in the reactor constant, continue to add 3600g propylene oxide in the reactor, and the flow control is completed in 1 hour. Raise the temperature of the reactor to 145° C., add the remaining 14500 g of ethylene oxide into the reactor, and control the flow rate in 3.5 hours to complete. Heat preservation and aging until the ...

Embodiment 2

[0037] Embodiment 2: First, the 30L autoclave was rinsed with distilled water. After drying the reactor, it is cooled to room temperature, and in the reactor, add 6000 g of prenol polyoxyethylene ether with a molecular weight of 1000 and 50 g of powdered sodium methylate, and use an inert gas N 2 Replace the air in the reactor. Raise the temperature in the reactor to 90°C to carry out the dealcoholization reaction. Observe the vacuum degree in the reactor, and start to add 3120g of ethylene oxide when the reactor is in vacuum. This process keeps the temperature in the reactor at 130° C., and the flow control is completed in 1.5 hours. Keep the temperature in the reactor constant, continue to add 1875g propylene oxide in the reactor, and the flow control is completed in 1 hour. Raise the temperature of the reactor to 145° C., add the remaining 7540 g of ethylene oxide into the reactor, and control the flow rate in 2.5 hours to complete. Heat preservation and aging until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com