Preparation method of antibacterial preservative for polycarboxylate-type water reducing agent

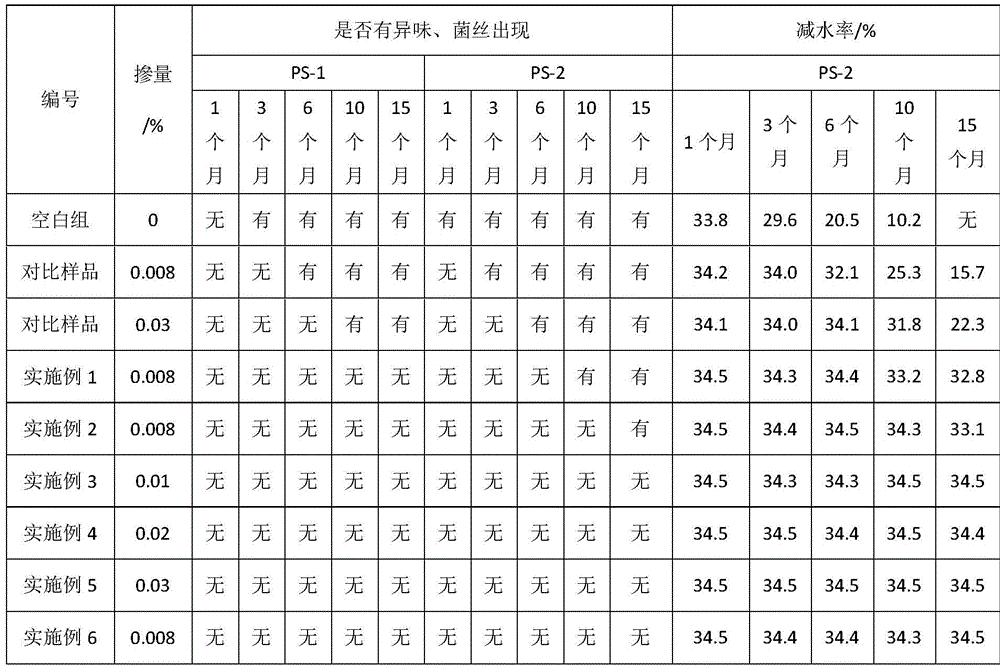

An antibacterial preservative, polycarboxylic acid-based technology, applied in the field of preparation of antibacterial preservatives, can solve the problems of affecting antiseptic performance, easy precipitation, acid generation, mold and the like, and achieves the effects of easy promotion, low dosage and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put 100g prenol polyoxyethylene ether (weight average molecular weight 1400) macromonomer, 16g cetyl dimethyl betaine and 464g water in the kettle, add 1g hydrogen peroxide when the temperature rises to 40°C, and then start dripping Add 12g of dimethyl fumarate and 48g of aqueous solution, and simultaneously dropwise add a mixed solution of 0.2g of vitamin C, 1.6g of 2-mercaptoacetic acid and 28.2g of water; the time for the addition is 2 hours, and after the addition, 3g of fluconazole is added, and then Keep warm for 4 hours. That is, an antibacterial preservative for polycarboxylic acid-based water reducers is obtained.

Embodiment 2

[0020] 200g isopentenol polyoxyethylene ether (weight-average molecular weight 3500) macromonomer, 30g octadecyl dimethyl betaine and 690g water are placed in the kettle, and 2.4g ammonium persulfate is added when the temperature is raised to 35°C. Then start to drop 28g of dimethyl fumarate and 84g of aqueous solution, and dropwise add a mixed solution of 0.5g of sodium bisulfite, 2.8g of 3-mercaptoacetic acid and 62.7g of water at the same time; fluconazole, and then keep warm for 3h. That is, an antibacterial preservative for polycarboxylic acid-based water reducers is obtained.

Embodiment 3

[0022] 100g isopentenol polyoxyethylene ether (weight average molecular weight 2400) macromonomer, 14g dodecyl dimethyl betaine and 266g water are placed in the kettle, when the temperature is raised to 30°C, 1.4g sodium persulfate is added, Then start to drop 16g of dimethyl fumarate and 37g of aqueous solution, and at the same time dropwise add a mixed solution of 0.3g of ferrous sulfate, 1.2g of 2-mercaptopropionic acid and 36g of water; the dropping time is 4h, and after the dropping, add 1.5g fluconazole, and then keep warm for 3h. That is, an antibacterial preservative for polycarboxylic acid-based water reducers is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com