Ultralow-mercury catalyst and production process thereof

A mercury catalyst and catalyst technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of unseen, extremely serious harm to human health and the environment, and cannot continue to survive and other problems, to achieve the effect of high activity, high catalytic activity and long service life

Inactive Publication Date: 2014-02-05

SHIJIAZHUANG KECHUANG ADDITIVES CO LTD

View PDF4 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Mercury is also a global pollutant, which can be transmitted through air, water and other media. It is very mobile. After it settles, it is further transformed into methylmercury, which is extremely harmful to human health and the environment. Therefore, the international community has given Attach great importance to: the annual mercury emissions of the United States should be controlled within the range of 10-15 tons by legislation; Almost all countries participated in this meeting and signed a global treaty to mitigate mercury pollution; at the end of 2009, the China Petroleum and Chemical Industry Association, China Chlor-Alkali Industry Association, and China Chemical Industry Environmental Protection Guidance Opinions" to set the work target "In 2015, my country's PVC industry will all use low-mercury catalysts, and the recovery rate of waste mercury catalysts will reach 100%". If the above goals cannot be a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

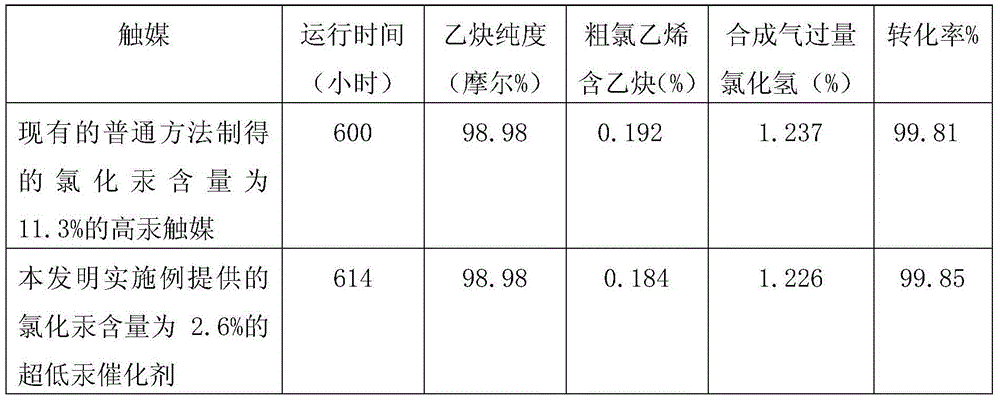

The invention discloses an ultralow-mercury catalyst. The ultralow-mercury catalyst is prepared by taking the wooden activated carbon with carbon tetrachloride adsorption rate of being greater than or equal to 70 percent, an iodine value of being greater than or equal to 1,000 mg/g, moisture of being less than or equal to 5 percent, ash content of being less than or equal to 7 percent, mechanical strength of being greater than or equal to 95 percent, stacking density of being 360-420 g/l, particle size of being 2.5-4.0 mm and specific surface area of being 1,000-1,800 m<2>/g as a carrier and adsorbing mercury chloride and collaborative promoters of zinc chloride, barium chloride, potassium chloride and bismuth chloride at a central position, wherein the content of the mercury chloride is only 0.5-4.0 percent; but since the mercury chloride occupies the central position with stronger activated carbon adsorption capacity and reaction activity and the added active ingredient bismuth chloride and the adopted activated carbon are the wooden activated carbon with ultrahigh voidage, and meanwhile the collaborative promoters are also added to realize great collaborative effect of the activated carbon and the mercury chloride, the catalyst has longer service life and higher activity.

Description

technical field [0001] The invention relates to a mercury catalyst for the addition reaction of acetylene gas and hydrogen chloride gas to synthesize vinyl chloride and its production process, in particular to an ultra-low mercury catalyst and its production process. Background technique [0002] Polyvinyl chloride (PVC) is a synthetic resin with superior performance and wide application. In 2012, the total production capacity of PVC in my country was 23 million tons. The raw material - vinyl chloride is still mainly produced by the calcium carbide acetylene method. At present, the calcium carbide method PVC accounts for more than 80% of my country's total PVC production capacity. Calcium carbide method PVC production has less investment and relatively mature technology, so we believe that it will still be the mainstream technology for the development of my country's polyvinyl chloride industry for a long period of time in the future. However, there are many shortcomings in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/18B01J32/00B01J35/10C07C21/06C07C17/08

Inventor 那风换薛之化李法曾张国杰曹锦贤高淑芝孙鸿雁

Owner SHIJIAZHUANG KECHUANG ADDITIVES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com