Preparation method and products of water phase thioether compound

A compound and phase sulfide technology, which is applied in the field of preparation of sulfide compounds, can solve the problems of solvent pollution, climate change, flammability and explosion, etc., and achieves the effects of mild conditions, simple operation and a wide range of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]

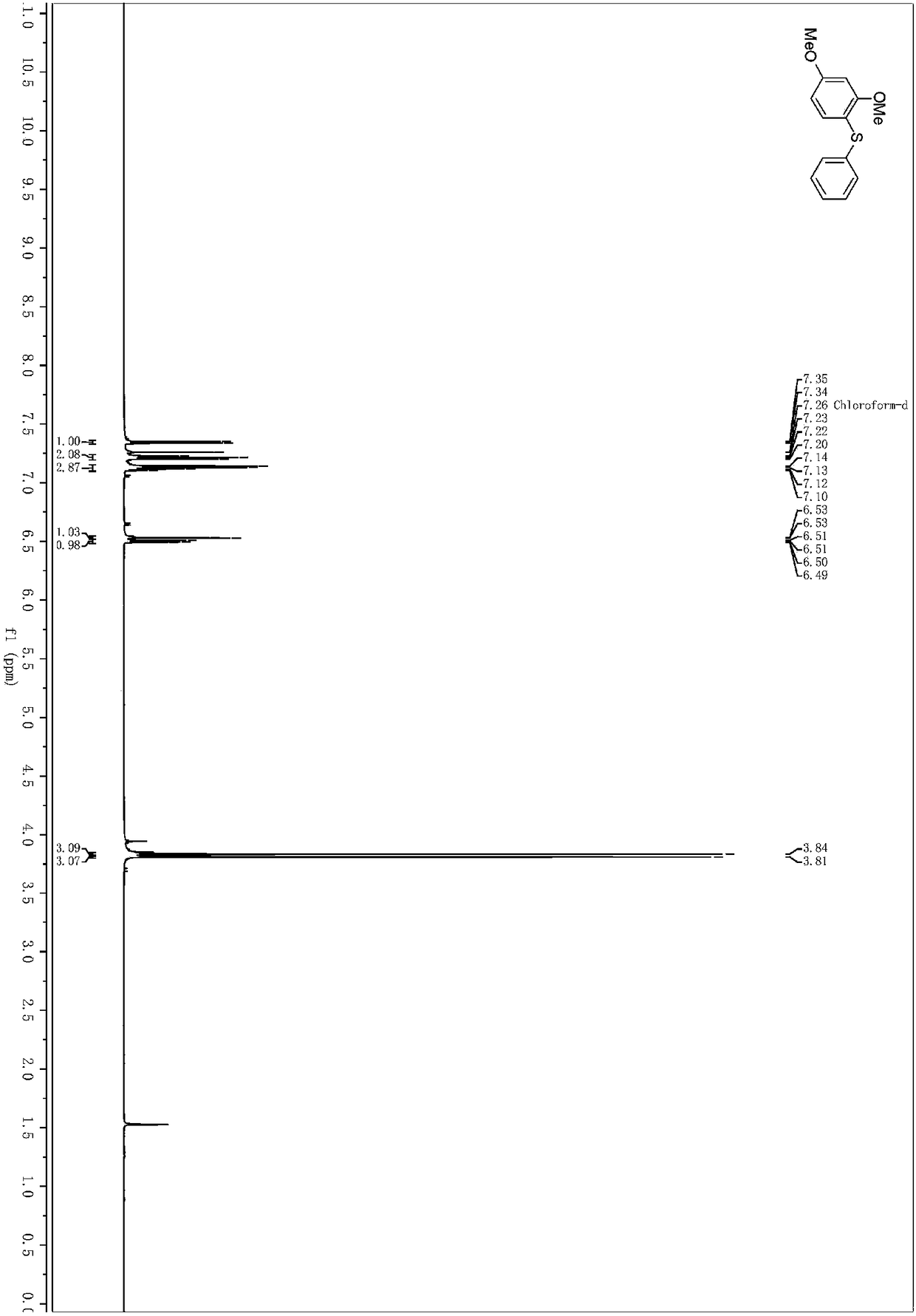

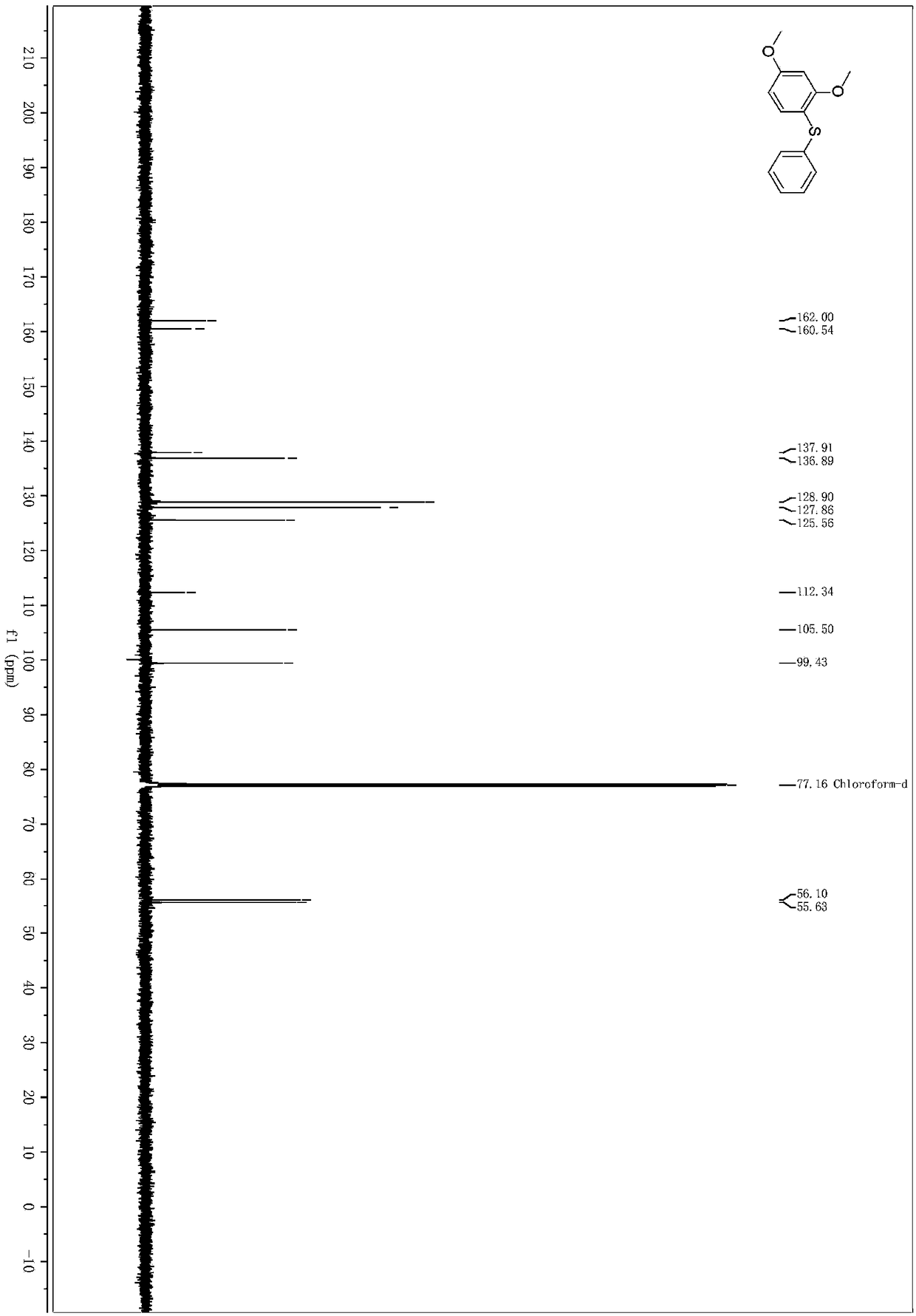

[0044] In a pre-dried 4mL reaction bottle, at room temperature, sequentially add zinc dichloride (3.28mg, 0.024mmol), 1,3-dimethoxybenzene (32.0μL, 0.24mmol), surfactant TPGS-750- M aqueous phase system (0.4mL), stir the mixture evenly, add allyl phenyl sulfide (35.2μL, 0.24mmol), slowly add periodiodine compound PIFA (105.2mg, 0.24mmol) and stir at 500rpm while heating to 60°C 24h.

[0045] After the reaction solution was stirred, it was extracted three times with ethyl acetate, and the organic phases extracted several times were combined into a 25mL eggplant-shaped flask, and the Heidolph rotary evaporator was used at a speed of 80-100rpm, a temperature of 38°C, and a vacuum of 0.1Mpa. , treated for 3 min, and then subjected to column chromatography using 200-mesh column chromatography silica gel, and the developer was petroleum ether: ethyl acetate = 49:1, and the target compound 1 was isolated. (41.3 mg, yield rate is 70%, and the purity through HPLC analysis ...

Embodiment 2

[0049]

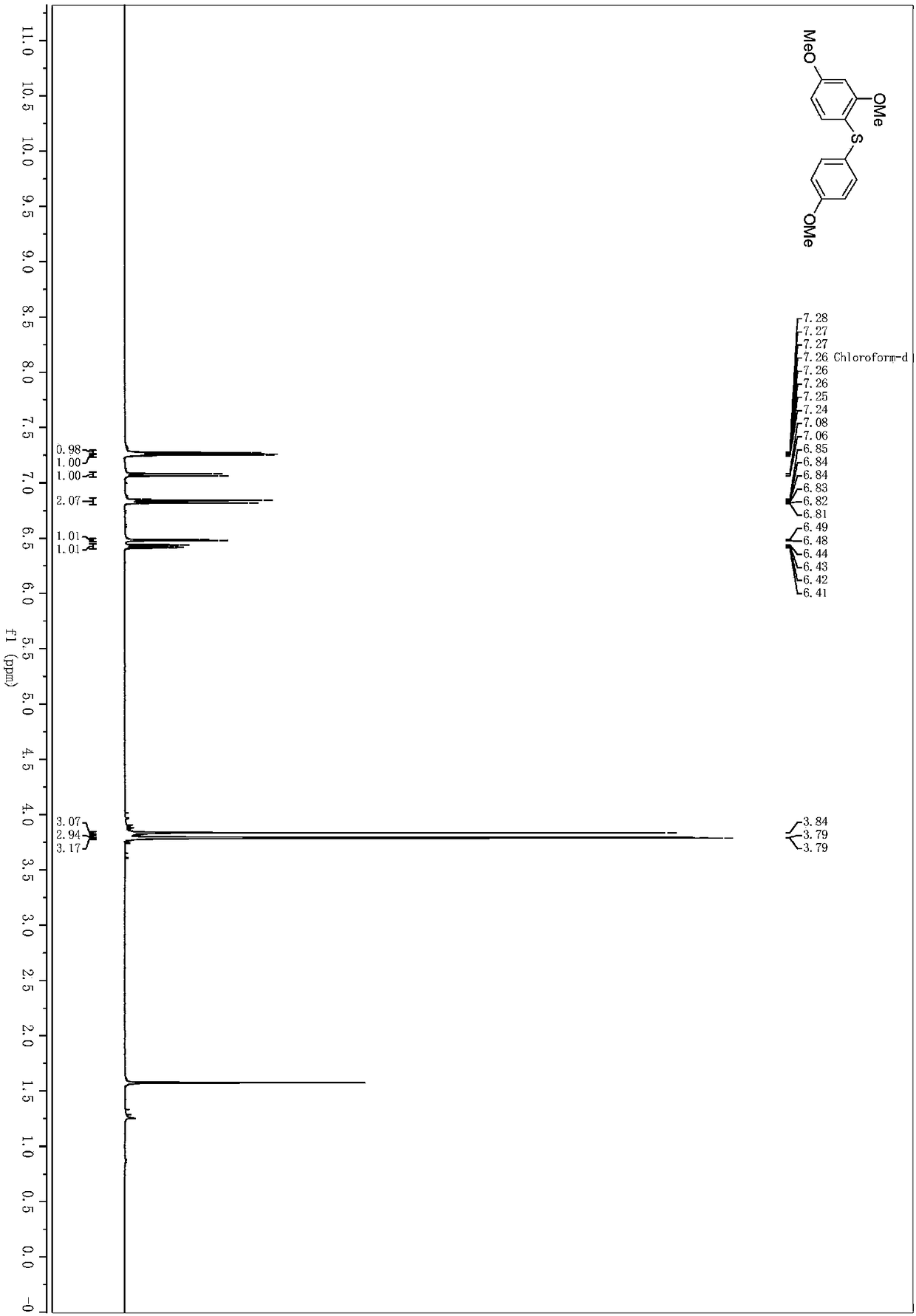

[0050] In a pre-dried 4mL reaction bottle, at room temperature, sequentially add zinc dichloride (3.28mg, 0.024mmol), 1,3-dimethoxybenzene (32.0μL, 0.24mmol), surfactant TPGS-750- M aqueous phase system (0.4mL), stir the mixture evenly, add 4-methoxyallyl phenyl sulfide (43.2mg, 0.24mmol), slowly add periodiodine compound PIFA (105.2mg, 0.24mmol) and heat to 60°C Stir at 500 rpm for 24 h at temperature.

[0051] After the reaction solution was stirred, it was extracted three times with ethyl acetate, and the organic phases extracted several times were combined into a 25mL eggplant-shaped flask, and the Heidolph rotary evaporator was used at a speed of 80-100rpm, a temperature of 38°C, and a vacuum of 0.1Mpa. , treated for 3 min, and then subjected to column chromatography using 200-mesh column chromatography silica gel, and the developer was petroleum ether: ethyl acetate = 49:1, and the target compound 2 was isolated. (34.5mg, productive rate is 52%, and the puri...

Embodiment 3

[0054]

[0055] In a pre-dried 4mL reaction bottle, at room temperature, sequentially add zinc dichloride (3.28mg, 0.024mmol), 1,3,5-trimethoxybenzene (41.2mg, 0.24mmol), surfactant TPGS-750 -M water phase system (0.4mL), the mixture was stirred evenly and added 4-methoxyallyl phenyl sulfide (43.2mg, 0.24mmol), slowly added periodiodine compound PIFA (105.2mg, 0.24mmol) and heated to 60 Stir at 500 rpm for 24 h at °C.

[0056] After the reaction solution was stirred, it was extracted three times with ethyl acetate, and the organic phases extracted several times were combined into a 25mL eggplant-shaped flask, and the Heidolph rotary evaporator was used at a speed of 80-100rpm, a temperature of 38°C, and a vacuum of 0.1Mpa. , treated for 3 min, and then subjected to column chromatography using 200-mesh column chromatography silica gel, and the developer was petroleum ether: ethyl acetate = 19:1, and the target compound 3 was isolated. (51.4 mg, the yield is 70%, and the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com