Method for preparing active carbon from ramie stalks

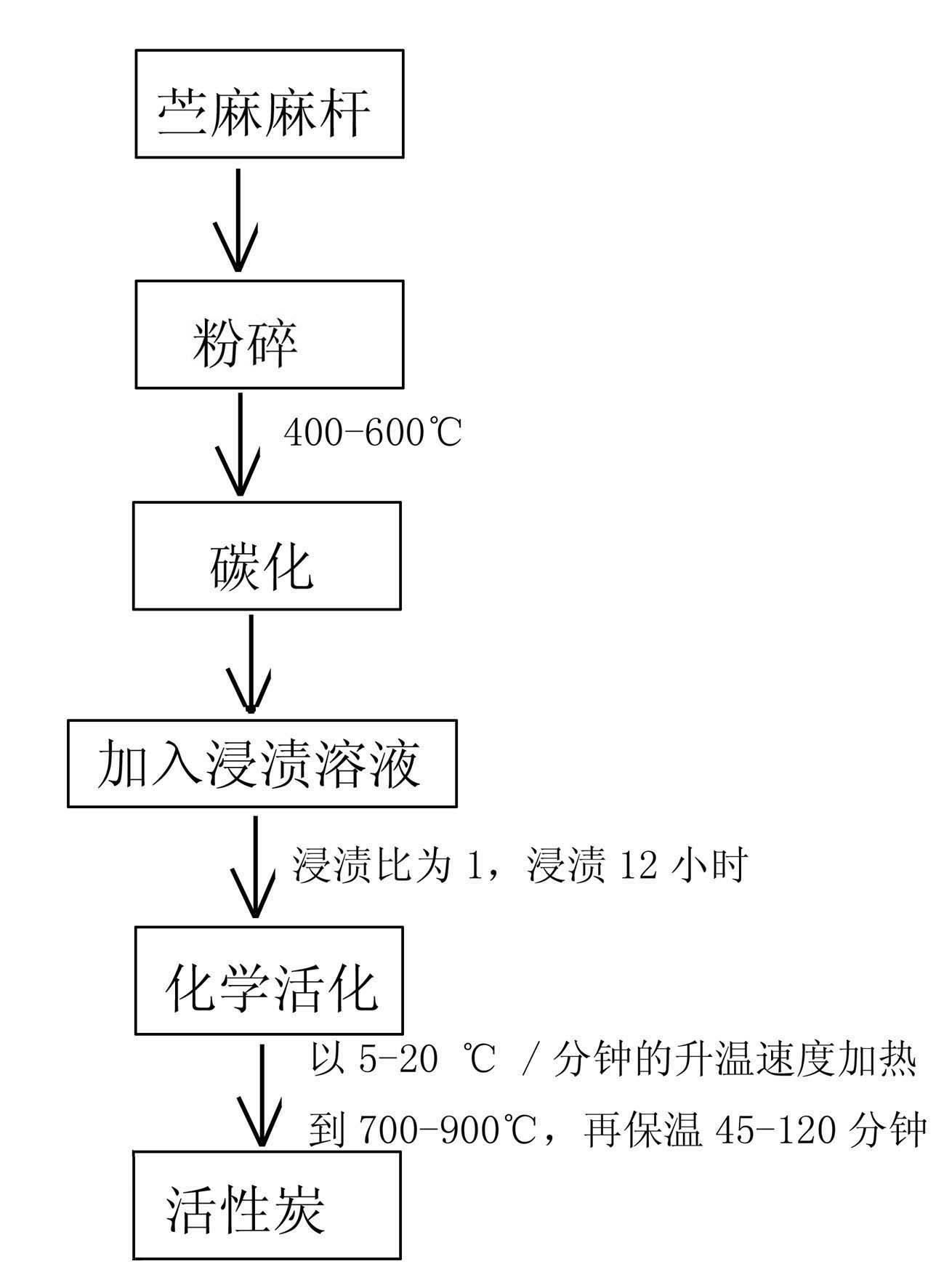

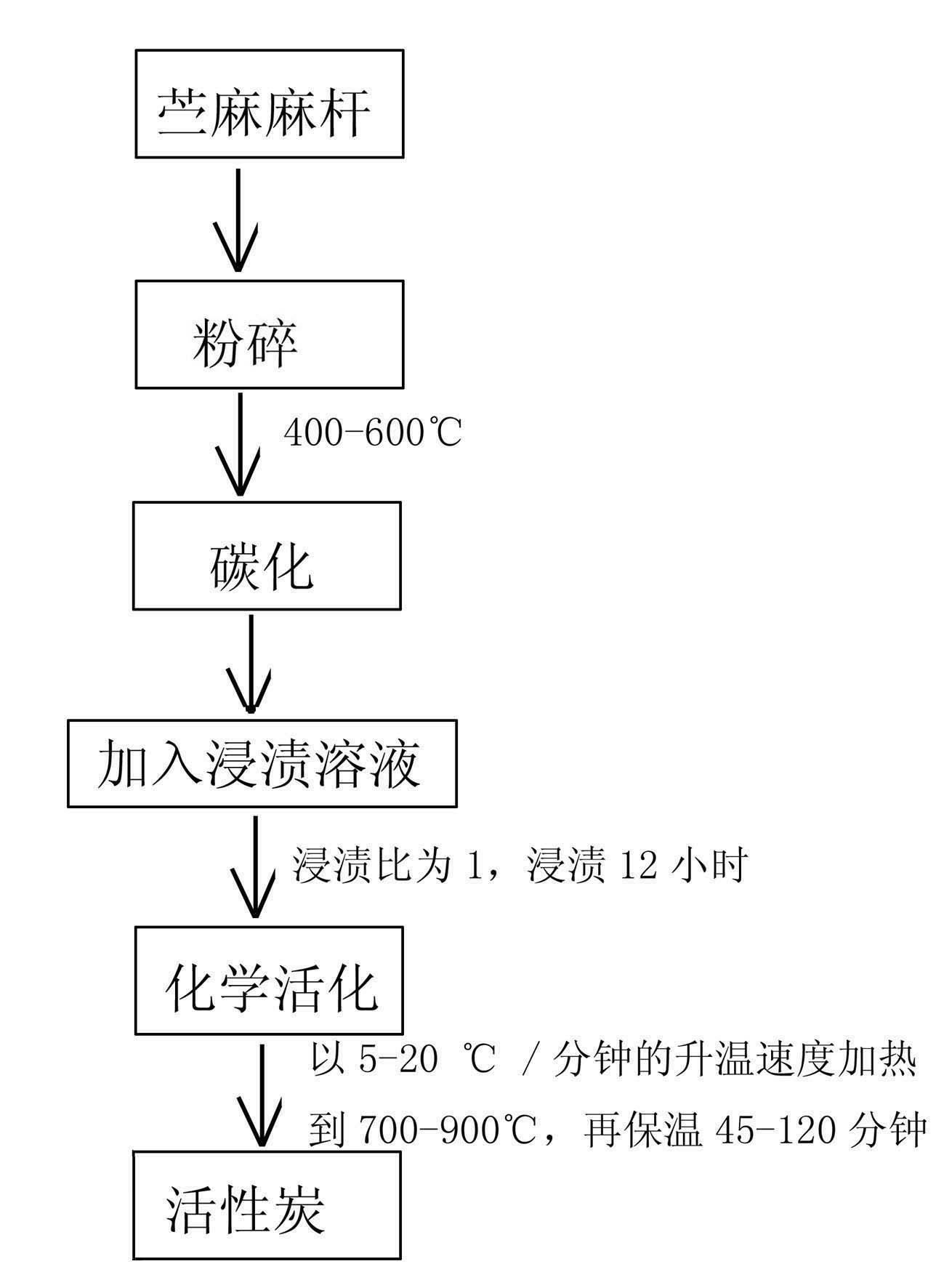

A technology for preparing activated carbon and hemp rods, which can be used in the removal of solid wastes, etc., can solve problems such as hidden dangers of aircraft safety, affecting crop growth, and hindering cultivation, and achieves the effects of low price, developed mesopores, and high adsorption value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Wash the ramie stalks with water for several times to remove the impurities attached to the stalks, dry them at 105±5°C, cut them and crush them in a pulverizer until the stalks have a particle size of 50-200 mesh; and dry the ramie The hemp stalk raw material particles were placed in a concentration of 60% H 3 PO 4 The solution was soaked for 12 hours, the dipping ratio was 1, and the carbonized ramie stalk particles were obtained after dehydration by a centrifuge. These carbonized particles are then placed in a tubular carbonization furnace for high-temperature activation treatment. The heating rate is 10°C / min, and after reaching the set temperature of 700°C, keep it warm for 1 hour, and take it out after cooling to room temperature. Wash with hydrochloric acid and distilled water at 70°C until the pH of the filtrate is 6.5-7, and dry to obtain activated carbon with ramie stalks as raw materials.

Embodiment 2

[0022] Wash the ramie stalks with water for several times to remove the impurities attached to the stalks, dry them at 105±5°C, cut them and crush them in a pulverizer until the stalks have a particle size of 50-200 mesh; and dry the ramie The raw material particles of hemp stalks are placed in 60% ZnCl 2 The solution was soaked for 12 hours, the dipping ratio was 1, and the carbonized ramie stalk particles were obtained after dehydration by a centrifuge. These carbonized particles are then placed in a tubular carbonization furnace for high-temperature activation treatment. The heating rate is 10°C / min, and after reaching the set temperature of 700°C, keep it warm for 1 hour, and take it out after cooling to room temperature. Wash with hydrochloric acid and distilled water at 70°C until the pH of the filtrate is 6.5-7, and dry to obtain activated carbon with ramie stalks as raw materials.

Embodiment 3

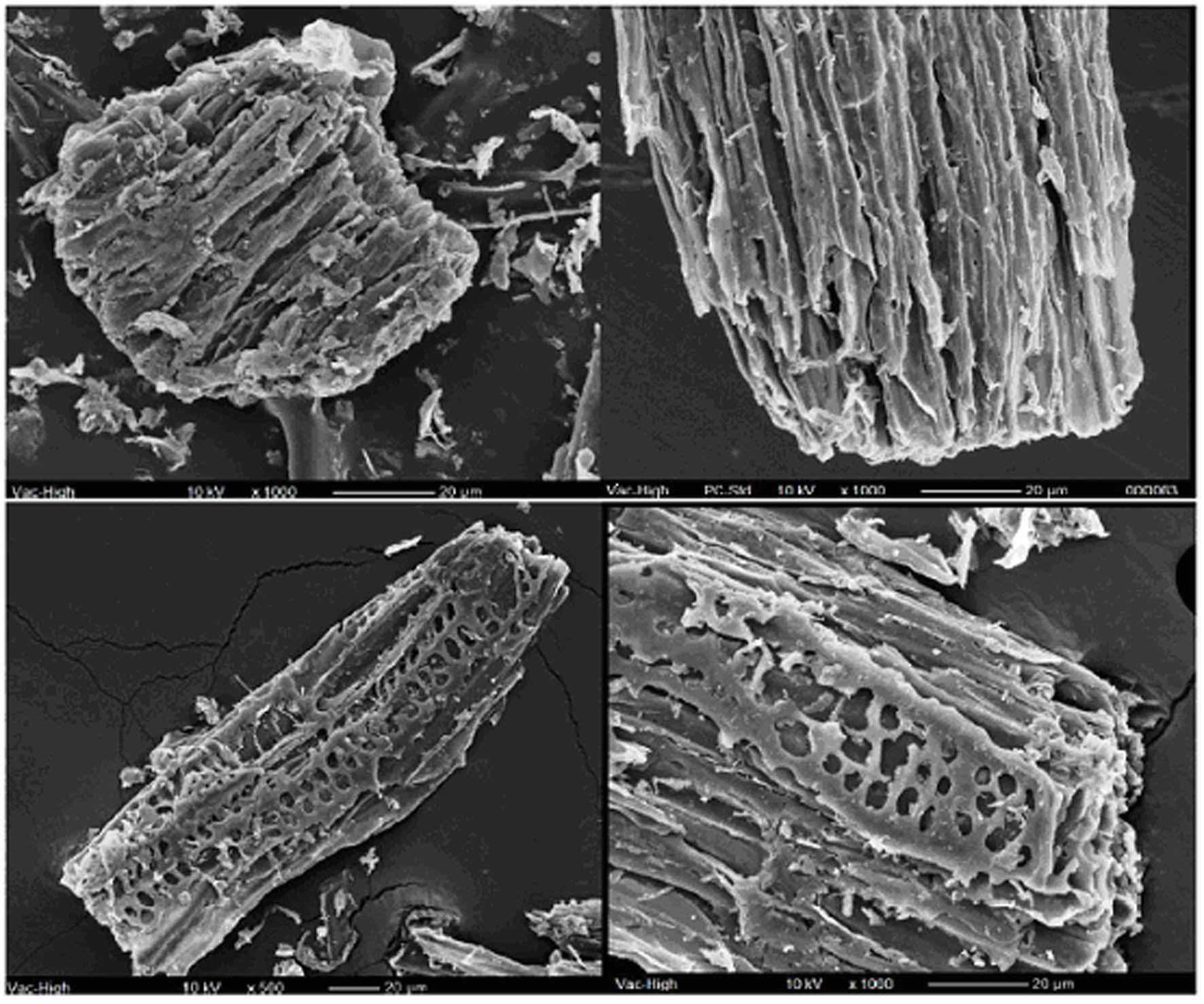

[0024] Wash the ramie stalks with water for several times to remove the impurities attached to the stalks, dry them at 105±5°C, cut them and crush them in a pulverizer until the stalks have a particle size of 50-200 mesh; and dry the ramie Raw material particles of ramie stalks were impregnated in 60% KOH solution for 12 hours with an impregnation ratio of 1, dehydrated by a centrifuge to obtain carbonized ramie stalk particles. These carbonized particles are then placed in a tubular carbonization furnace for high-temperature activation treatment. The heating rate is 10°C / min, and after reaching the set temperature of 750°C, keep it warm for 1 hour, and take it out after cooling to room temperature. Wash with hydrochloric acid and distilled water at 70°C until the pH of the filtrate is 6.5-7, and dry to obtain activated carbon with ramie stalks as raw materials. figure 2 It is a scanning electron microscope image of activated carbon prepared by the method described in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com