High-iodine controlled-release type sanitizer

A bactericide and solvent technology, applied in the field of disinfectants, can solve problems such as the impact of bactericidal performance and limited use range, and achieve strong killing ability, good disinfection effect, and strong resistance to organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

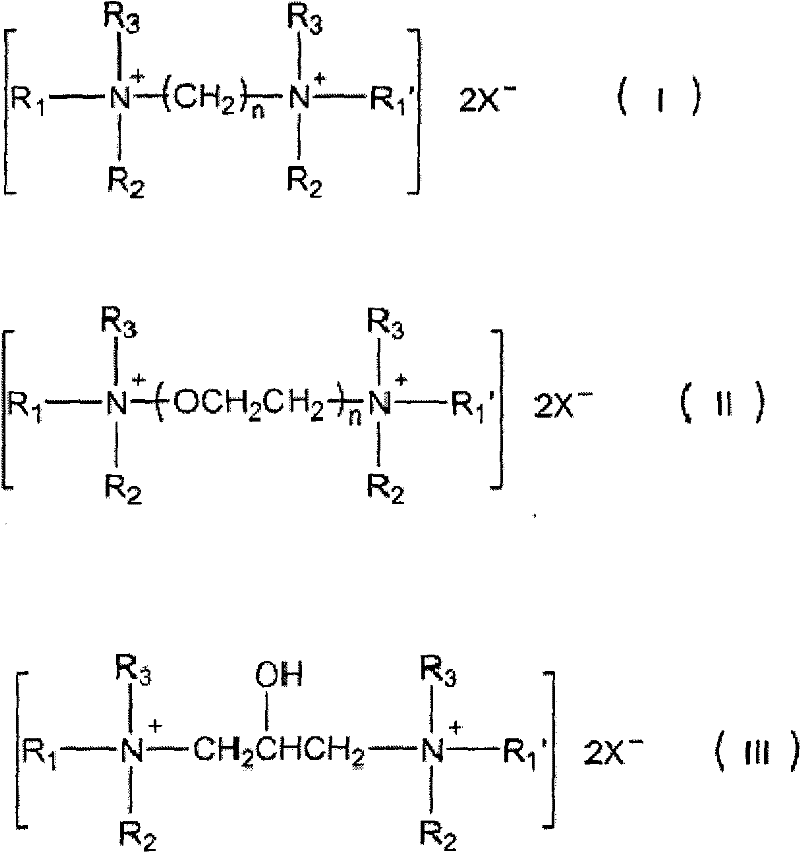

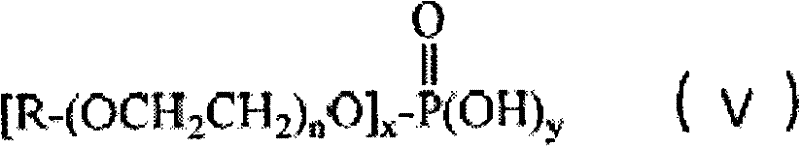

Method used

Image

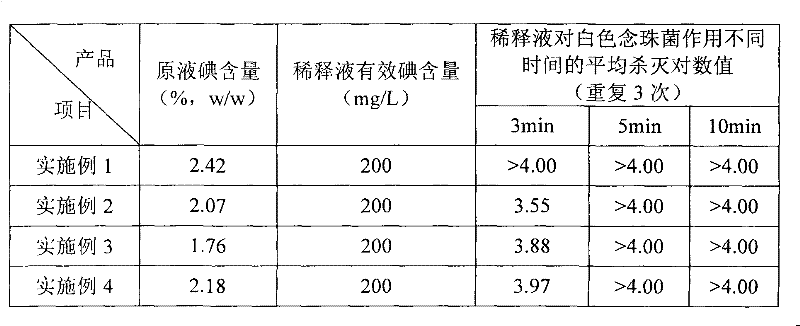

Examples

Embodiment 1

[0029] Add 848g of dodecyl amine oxide (OA-12) into a 2000mL reaction kettle, stir and heat up to 60°C, add 32g of elemental iodine, stir until the iodine is completely dispersed and dissolved, then add 48g of AEO-3 phosphate in sequence , 64g phosphoric acid, 200g gemini quaternary ammonium salt (12-3OH-12), stop heating after the addition is completely dissolved, continue to stir for 2 hours, obtain reddish-brown transparent liquid.

Embodiment 2

[0031] Add 848g of dodecyl amine oxide (OA-12) into a 2000mL reaction kettle, stir and heat up to 60°C, add 32g of elemental iodine, stir until the iodine is completely dissolved, then add 48g of dodecyl phosphate, 64g of phosphoric acid, 200g of Gemini quaternary ammonium salt (12-4-12), stop heating after the addition is completely dissolved, and continue to stir for 2 hours to obtain a reddish-brown transparent liquid.

Embodiment 3

[0033] Add 1000g of lauryl amine oxide (OA-12) into a 2000mL reaction kettle, add 36g of elemental iodine at the same time, stir and heat up to 70°C, after all the iodine is dissolved, add 48g of phosphoric acid and 100g of gemini quaternary ammonium salt in sequence (14-2-14) and 50g ethanol, stop heating after the addition is completely dissolved, and continue to stir for 2 hours to obtain a reddish-brown transparent viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com