Method for preparing low-temperature-resistant palm oil with high iodine value

A palm oil and anti-low temperature technology, applied in the direction of fat oil/fat separation, fat production, etc., can solve the problems of destroying palm oil high temperature resistance, anti-oxidation, increasing palm oil production cost, reducing oil fractionation time, etc., to achieve improved separation Efficiency and separation effect, shortening process operation time, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: (one tooth at a time)

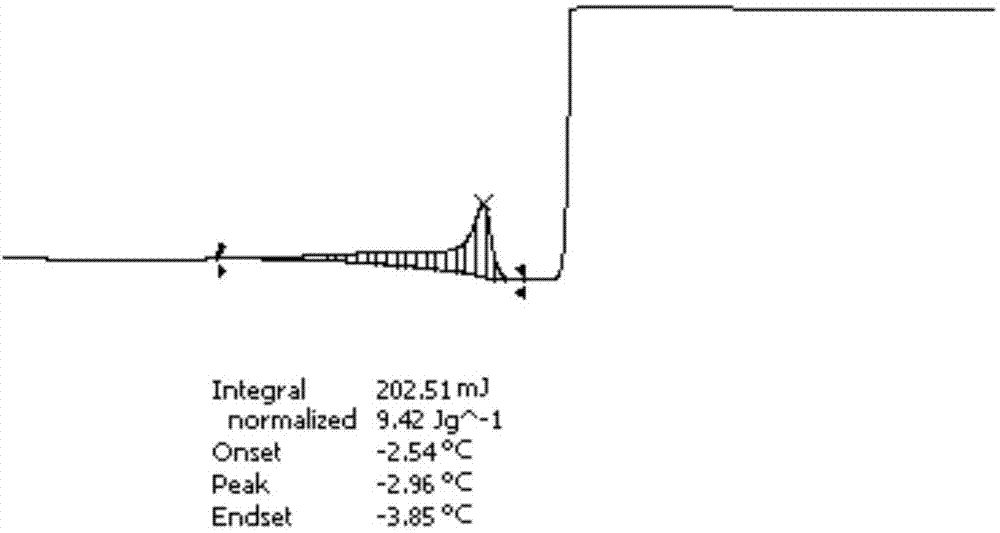

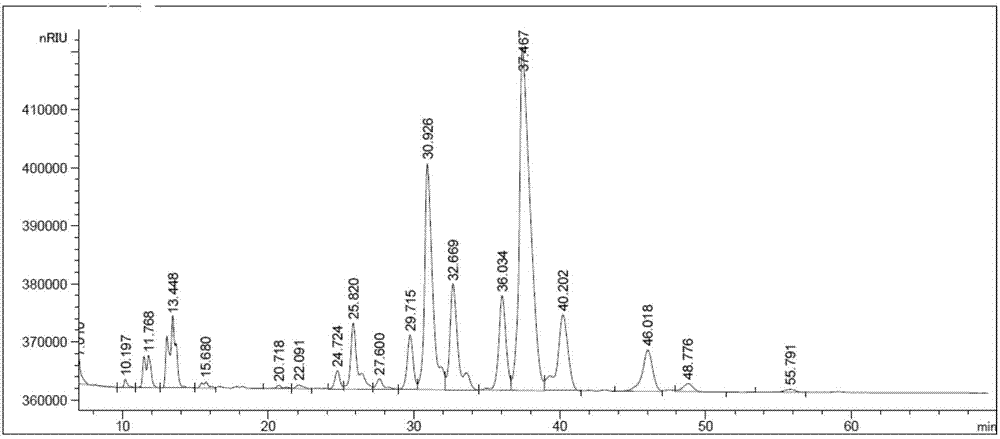

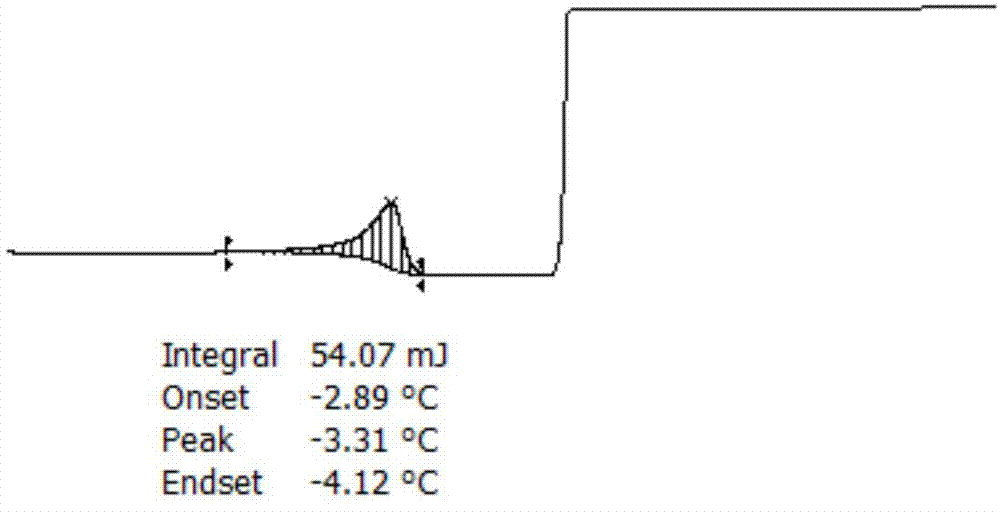

[0033] At a temperature of 80°C, heat palm oil with an iodine value of 64 under stirring to dissolve it completely, then cool down to -3°C at a cooling rate of 1°C / min, and grow crystals at a constant temperature for 60 minutes; then at a rate of 0.2°C / min Raise the temperature to 0°C and keep the temperature constant for 60 minutes; cool down to -4°C at a rate of 0.2°C / min and keep the temperature constant for 60 minutes. The obtained oil was transferred to a separator and centrifuged at -5°C for 20 minutes. The oil was divided into solid and liquid phases, and the solid oil was removed by liquid separation to obtain palm olein with an iodine value of 67.05. The yield is 80.6%, and the product DSC picture is as image 3 shown. From the DSC figure, it can be seen that with figure 1 Compared with the DSC chart of raw oil, the crystallization peak temperature decreased from -2.96°C to -3.31°C, and the melting point decreased by 0.35°C...

Embodiment 2

[0034] Example 2: (two teeth once)

[0035]At a temperature of 60°C, heat palm oil with an iodine value of 64 under stirring to dissolve it completely, then cool down to -10°C at a cooling rate of 0.8°C / min, and grow crystals for 20 minutes; then increase the temperature at a rate of 0.5°C / min Raise the temperature to -4°C, keep it for 20 minutes, then cool it down to -12°C at a cooling rate of 0.5°C / min, and keep it for 20 minutes; The cooling rate is to cool down to -14°C and keep warm for 20min. The obtained oil was transferred to a separator and centrifuged at -15°C for 10 minutes. The oil was divided into solid and liquid phases, and the solid oil was removed by liquid separation to obtain palm olein with an iodine value of 67.7. The yield was 83.2%. Product DSC pictures such as Figure 4 As shown, the crystallization peak temperature was -3.91°C.

Embodiment 3

[0036] Example 3: (primary two-tooth + secondary two-tooth)

[0037] At a temperature of 80°C, heat palm oil with an iodine value of 63 under stirring to dissolve it completely, then cool down to 0°C at a cooling rate of 0.7°C / min, and grow crystals for 30 minutes; then raise the temperature at a heating rate of 0.5°C / min To 4°C, keep warm for 30min; cool down to -2°C at a cooling rate of 0.5°C / min, keep warm for 30min. Then, the temperature was raised to 2°C at a heating rate of 0.3°C / min, and kept for 30 minutes; the temperature was lowered to -4°C at a cooling rate of 0.3°C / min, and kept for 30 minutes. The obtained oil was transferred to a separator and centrifuged at -5°C for 15 minutes. The oil was divided into solid and liquid phases, and the solid oil was removed by liquid separation to obtain palm olein with an iodine value of 67.1. The yield was 82.4%.

[0038] Take the palm oil obtained by one fractionation, heat it at 80°C, dissolve it completely, then cool it do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com