Nuclear fuel cladding and preparation method thereof and nuclear fuel assembly

A nuclear fuel assembly, nuclear fuel technology, applied in the field of nuclear reactors, can solve problems such as rise, nuclear fuel cladding tube rupture, nuclear leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

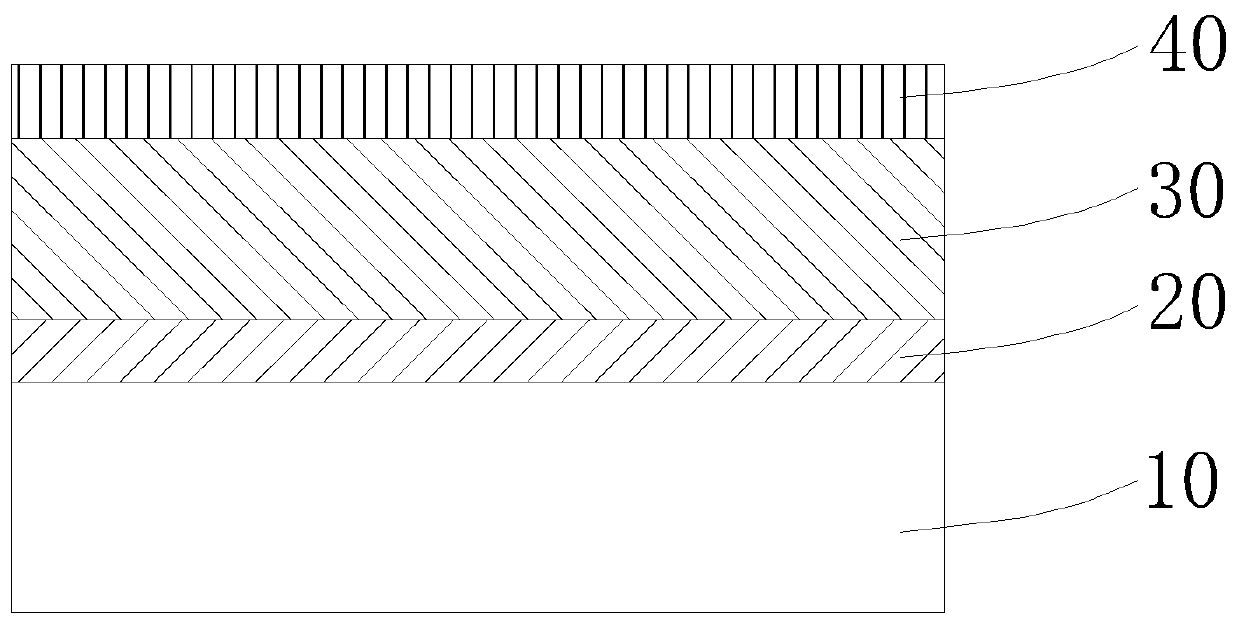

[0042] The present invention also provides a preparation method of nuclear fuel cladding, comprising the following steps:

[0043] S1, provide zirconium alloy base;

[0044] S2, forming a transition layer on the surface of the zirconium alloy substrate;

[0045] S3, forming a MAX phase layer on the surface of the transition layer;

[0046] S4, forming a sealing layer on the surface of the MAX phase layer to obtain a nuclear fuel cladding, wherein the sealing layer is a hard coating.

[0047] In step S1, it also includes removing oxides on the surface of the zirconium alloy substrate. For example, the zirconium alloy substrate is placed on the base frame in the vacuum coating chamber after ultrasonic cleaning in alcohol, and etched with Ar ion beam to remove oxides on the surface of the zirconium alloy substrate.

[0048] Specifically, the flow rate of the incoming argon gas is 25 standard ml / min to 40 standard ml / min, the linear anode ion source current is set to 0.1A to 0....

Embodiment 1

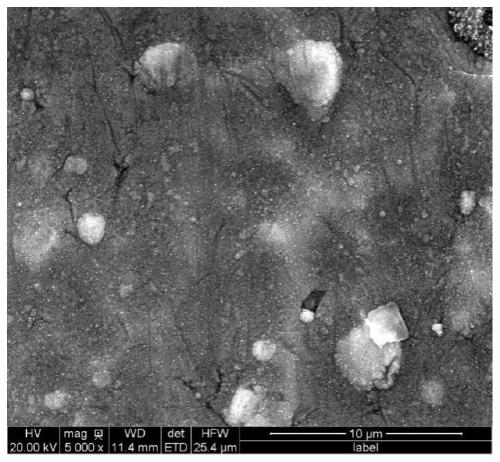

[0063] The zirconium alloy substrate was placed on the base frame in the vacuum coating chamber after ultrasonic cleaning in alcohol, and etched with Ar ion beam to remove oxides on the surface of the zirconium alloy substrate. Among them, the flow rate of the argon gas introduced is 35 standard ml / min, the linear anode ion source current is set to 0.2A, the bias voltage applied on the zirconium alloy substrate is -300V, and the etching time is 40min.

[0064] A TiC layer is deposited on the surface of a zirconium alloy substrate by arc ion plating, wherein the arc target is a titanium target, and the reactive gas is methane. During the deposition process, the base frame rotates at a position facing the arc target. The current of the arc target is 60A, the bias voltage applied on the zirconium alloy substrate is -100V, the flow rate of argon gas is 200 standard ml / min, the flow rate of methane is 50 standard ml / min, and the pressure of the control chamber is 30mtorr. The deposi...

Embodiment 2

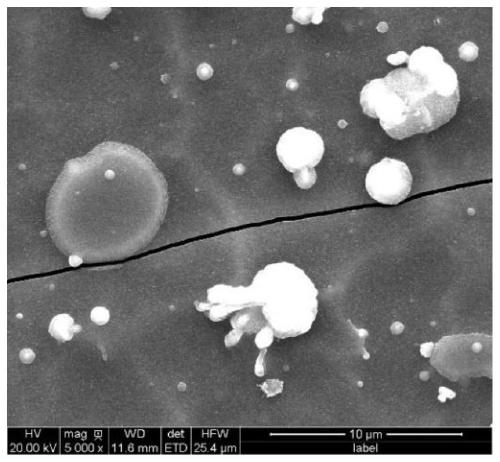

[0076] The zirconium alloy substrate was placed on the base frame in the vacuum coating chamber after ultrasonic cleaning in alcohol, and etched with Ar ion beam to remove oxides on the surface of the zirconium alloy substrate. Among them, the flow rate of argon gas introduced was 25 standard ml / min, the linear anode ion source current was set to 0.1A, the bias voltage applied on the zirconium alloy substrate was -350V, and the etching time was 60min.

[0077] A TiC layer is deposited on the surface of a zirconium alloy substrate by arc ion plating, wherein the arc target is a titanium target, and the reactive gas is methane. During the deposition process, the base frame rotates at a position facing the arc target. The current of the arc target is 55A, the flow rate of argon gas is 200 standard ml / min, the bias voltage applied on the zirconium alloy substrate is -150V, the flow rate of methane is 50 standard ml / min, the pressure of the control chamber is 30mtorr, and the deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com