Method and system for generating power jointly by nuclear fuel and fossil fuel

A fossil fuel and combined power generation technology, applied in nuclear power generation, nuclear power plants, nuclear engineering, etc., can solve the problems that limit the power generation efficiency and economic benefits of nuclear power plants, low power generation efficiency, and small steam enthalpy drop, etc., to achieve high energy utilization Efficiency and economic benefits, lower power generation costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

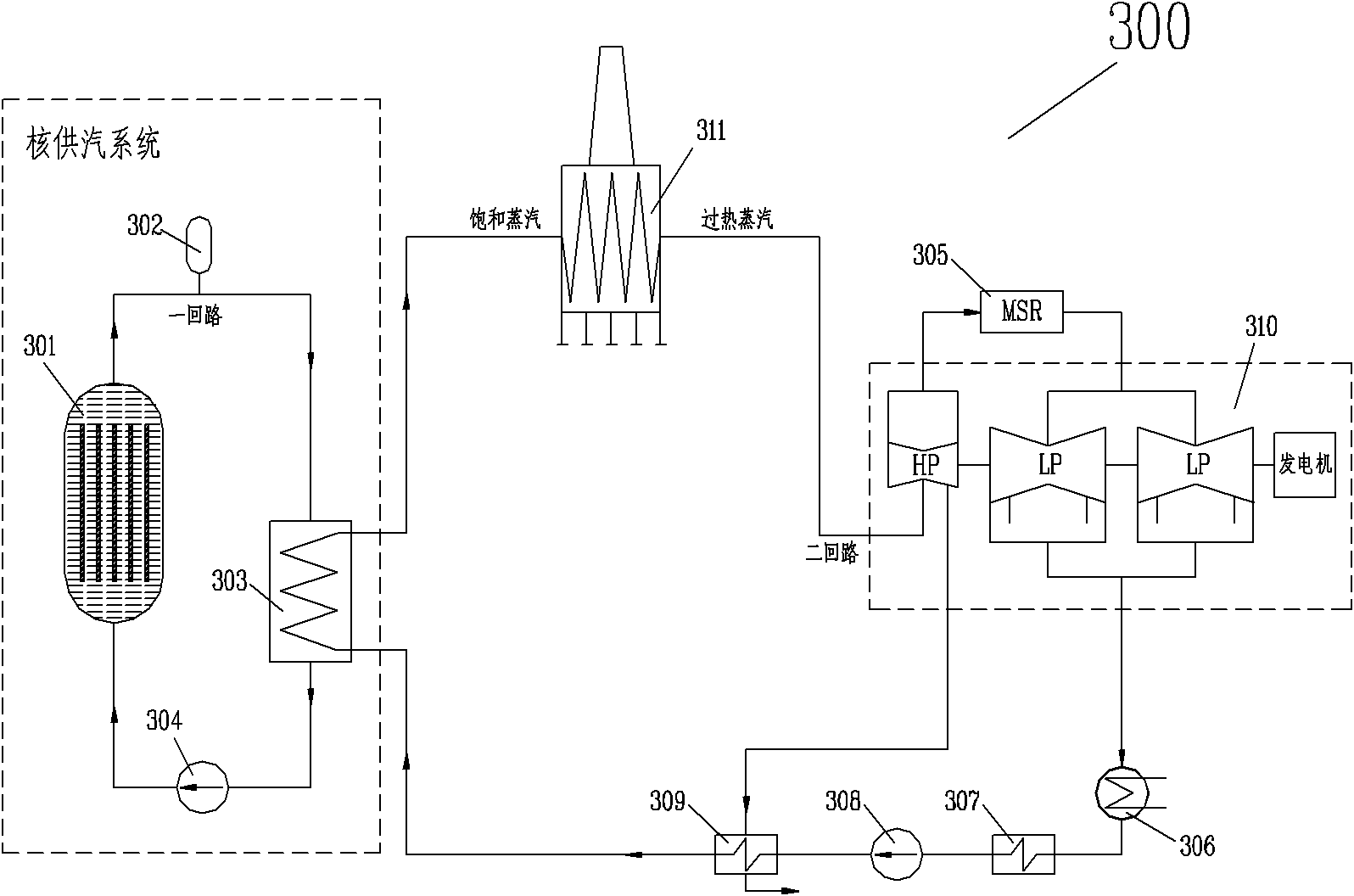

[0051] image 3 Schematically shows the working principle diagram of the combined power generation system 300 including the pressurized water reactor type nuclear steam supply system and the steam superheating furnace burning fossil fuels according to Embodiment 1 of the present invention.

[0052]The combined power generation system 300 includes at least a pressurized water reactor 301, a reactor coolant system, also called a primary loop, and a steam and power conversion system, also called a secondary loop. In the context of the present invention, as known to those skilled in the art, the reactor, reactor coolant system and its auxiliary systems are collectively referred to as a nuclear steam supply system. The reactor coolant in the primary circuit enters the core of the pressurized water reactor 301 under the drive of the reactor coolant pump 304, absorbs the heat energy released by nuclear fission in the pressurized water reactor, enters the steam generator 303, passes t...

Embodiment 2

[0055] Figure 4 It schematically shows the working principle diagram of the PWR nuclear fuel and fossil fuel combined power generation system 400 according to Embodiment 2 of the present invention.

[0056] Figure 4 The China United Power Generation System 400 is different from image 3 The combined power generation system 300 shown is that the steam superheating furnace 411 is designed to heat the water in another feedwater circuit to obtain superheated steam while heating the saturated steam or slightly superheated steam from the nuclear steam supply system to obtain superheated steam. Self-produced saturated steam or superheated steam. Except for the steam superheating device 411 , the working principle of the combined power generation system in this embodiment is the same as that of the combined power generation system shown in Embodiment 1.

Embodiment 3

[0058] Figure 5 A schematic diagram showing the working principle of the PWR nuclear fuel and fossil fuel combined power generation system 500 according to Embodiment 3 of the present invention.

[0059] Figure 5 The combined power generation system 500 shown uses a steam superheating device 511 to heat saturated steam or slightly superheated steam from a nuclear steam supply system to obtain superheated steam. The steam superheating device 511 includes a plurality of steam superheating furnaces arranged in parallel, such as steam superheating furnaces 512 and 514 . Different from Embodiment 1, this embodiment uses a steam superheating device including multiple steam superheating furnaces arranged in parallel to heat saturated steam or slightly superheated steam. Except for the steam superheating device 511 , the working principle of the combined power generation system in this embodiment is the same as that of the combined power generation system shown in Embodiment 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com