Phase change energy storage microcapsule and preparation method thereof

A technology of phase change energy storage and microcapsules, which is applied in the field of phase change energy storage, can solve problems such as high resistance to low temperature, poor mechanical strength, and easy breakage, and achieve good sealing, high heat storage capacity, and good compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the phase change energy storage microcapsules described in the above technical solution, comprising the following steps:

[0034] mixing the emulsifier with water to obtain an aqueous phase;

[0035] Mix polyimide resin, n-alkane phase change material and volatile solvent to obtain oil phase;

[0036] The water phase and the oil phase are mixed and dispersed to obtain an oil-in-water emulsion;

[0037] The oil-in-water emulsion and the stabilizer are mixed and heated to obtain the phase-change energy storage microcapsules.

[0038] In the present invention, the emulsifier is mixed with water to obtain a water phase. In the present invention, the HLB value of the emulsifier is preferably 8 to 15; the emulsifier is further preferably styrene maleic anhydride copolymer sodium salt (SMA-Na), nonylphenol polyoxyethylene ether ammonium salt, Polyoxyethylene (20) sorbitan dioleate, sodium abietate, cocamidopropyl b...

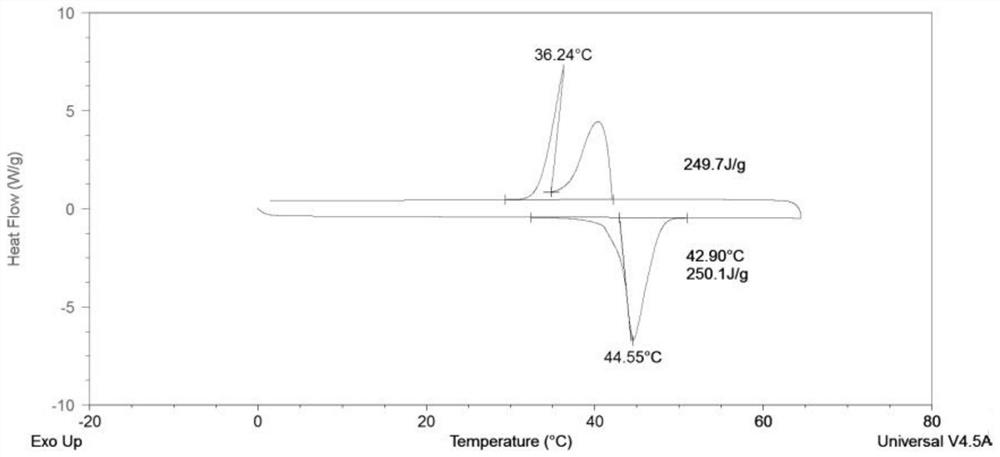

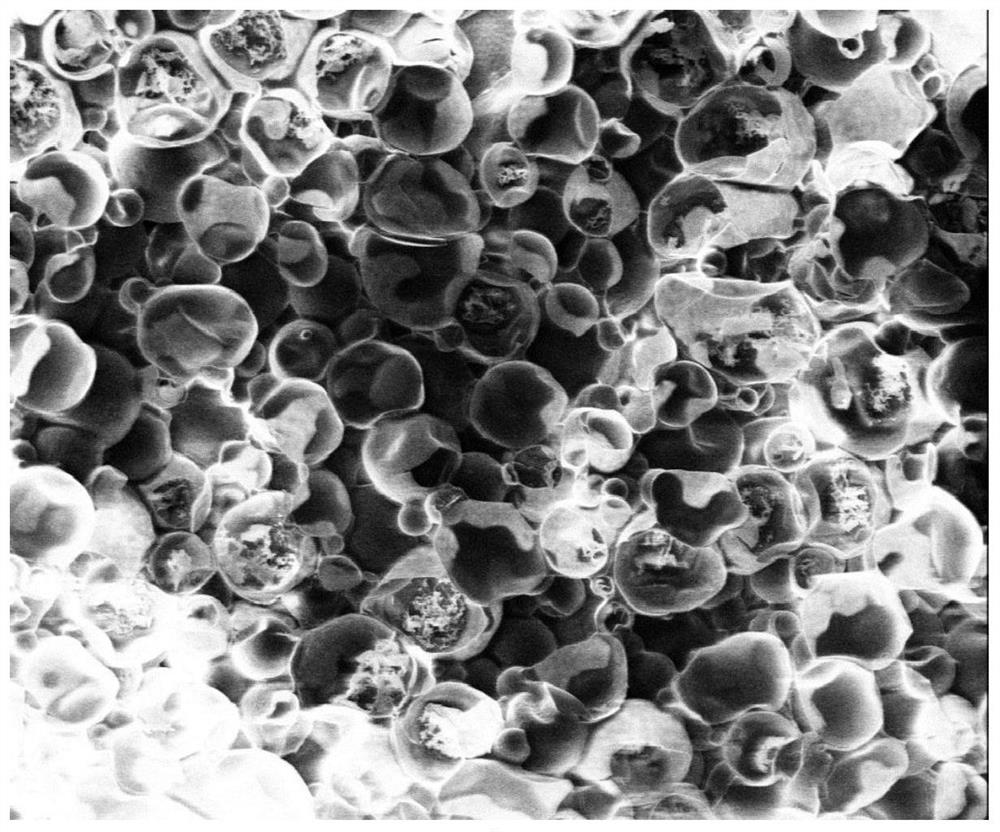

Embodiment 1

[0048] Take 50 grams of mass concentration as 10% styrene-maleic anhydride copolymer sodium salt (SMA-Na) aqueous solution in a beaker, add deionized water to 100 grams, stir to make the emulsifier dissolve completely, and adjust the pH value with glacial acetic acid 4.0 to 5.0, to obtain an emulsifier aqueous solution with a mass concentration of 5% as the water phase;

[0049] At room temperature, add 15 grams of soluble polyimide powder (produced by DuPont, USA) and 100 grams of chloroform to a beaker and mix them until they are completely miscible, then add 60 grams of n-octadecane, stir, dissolve and mix well to obtain an oil phase ;

[0050] After the water phase was kept at 60°C for 15 minutes, the oil phase was added to the water phase and dispersed at a high speed of 5000rpm for 15 minutes to form a stable oil-in-water emulsion;

[0051] After the emulsification is over, reduce the rotation speed, add 20 grams of polyvinyl alcohol 1788 aqueous solution with a mass co...

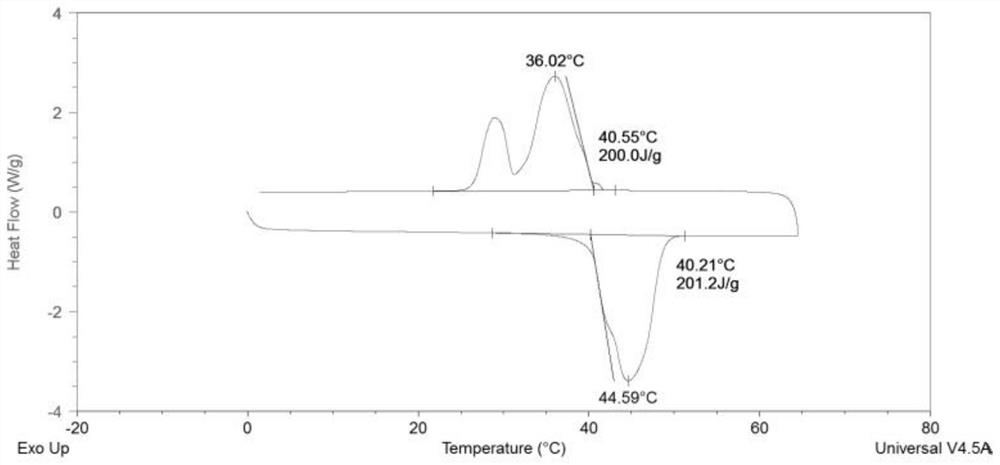

Embodiment 2

[0054] Weigh 5 grams of sodium dodecylbenzenesulfonate in a beaker, add deionized water to 100 grams, stir to make the emulsifier completely dissolve, and prepare an emulsifier aqueous solution with a mass concentration of 5% as the water phase;

[0055] Add 20 grams of soluble polyimide (the soluble polyimide is shown in formula (1)) and 100 grams of chloroform in a beaker and mix, stir until completely miscible, add 80 grams of n-docosane, stir and dissolve Mix well to obtain the oil phase;

[0056]

[0057] After the water phase was kept at 60°C for 15 minutes, the oil phase was added to the water phase and dispersed at a high speed of 2500 rpm for 15 minutes to form a stable oil-in-water emulsion;

[0058] After the emulsification is over, reduce the rotation speed, add 40 grams of polyvinyl alcohol 2488 aqueous solution with a mass concentration of 5% to the above emulsion, transfer the emulsion to a device with distillation and recovery of organic solvents, stir, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com