Patents

Literature

34results about How to "No cracking problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

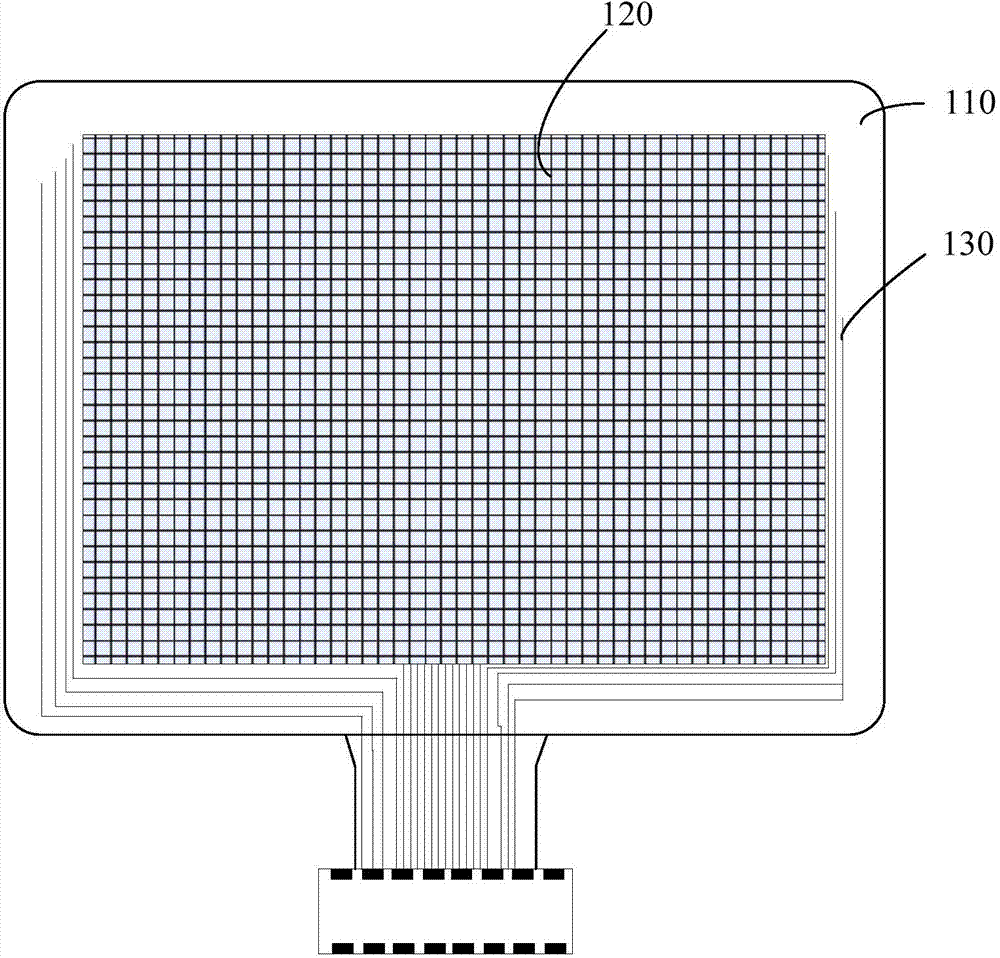

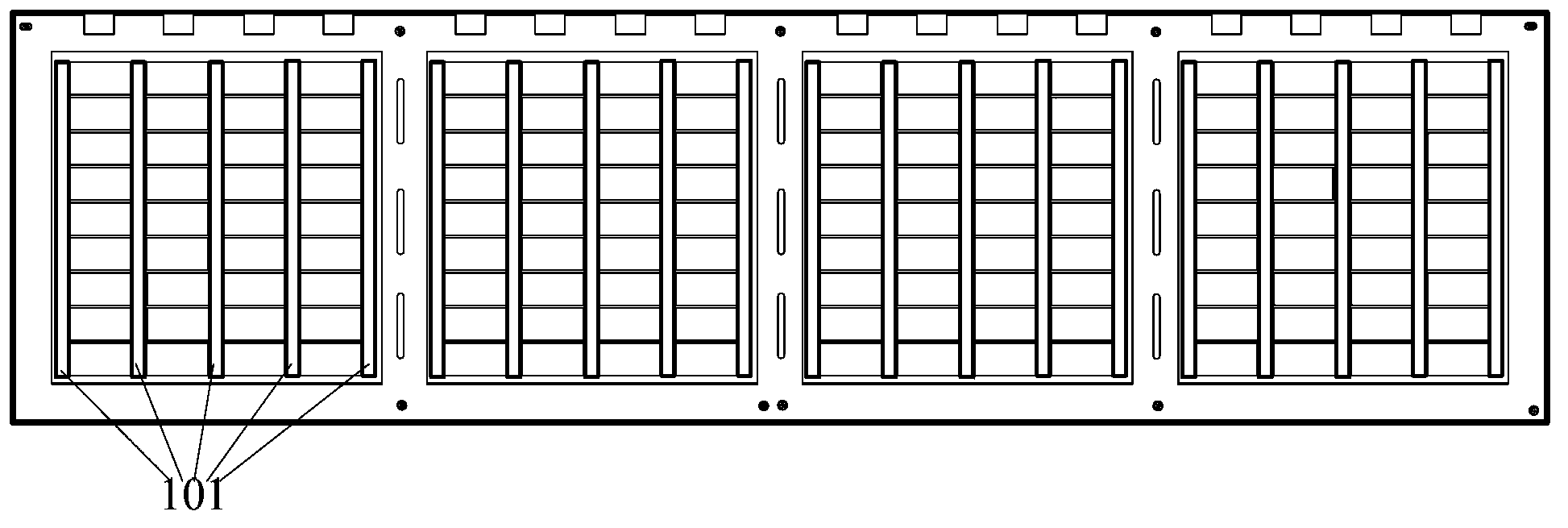

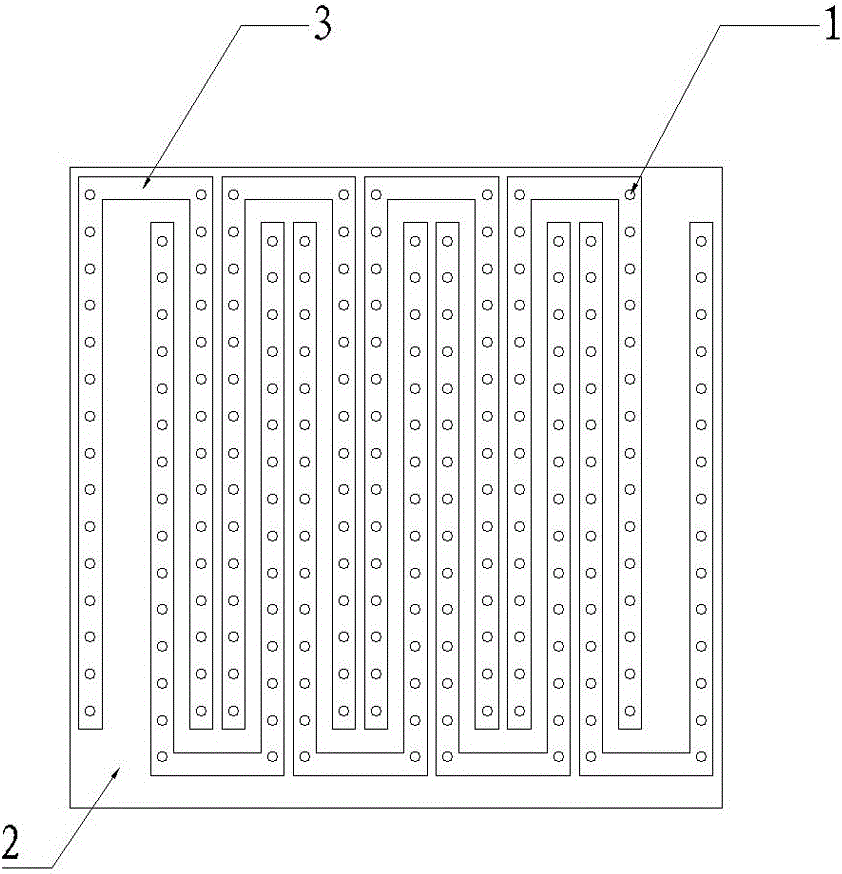

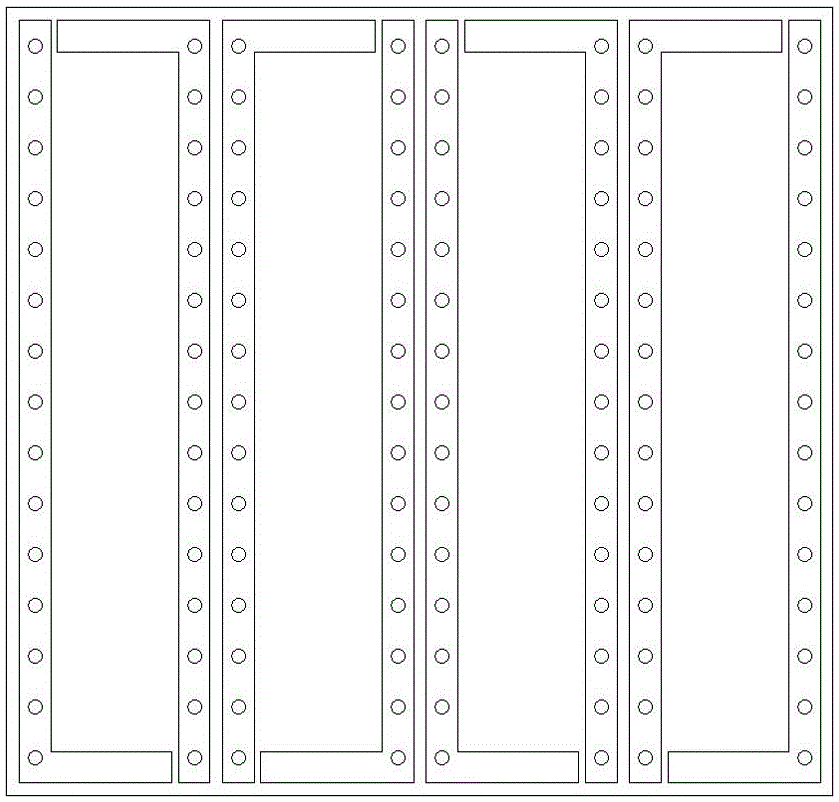

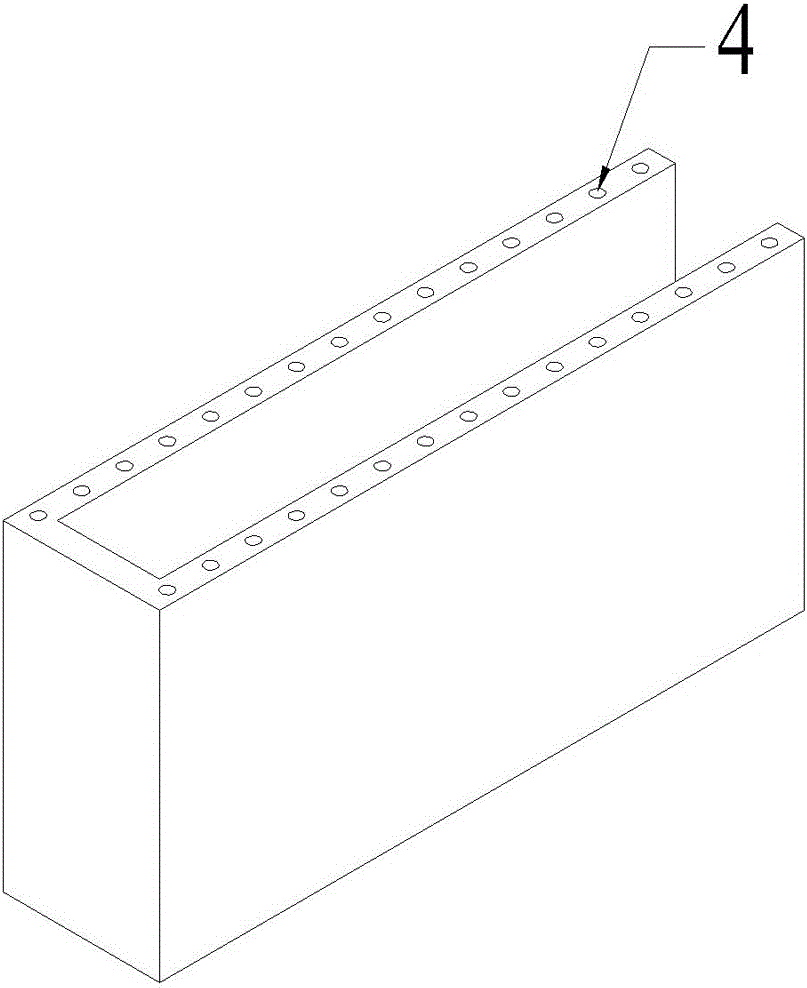

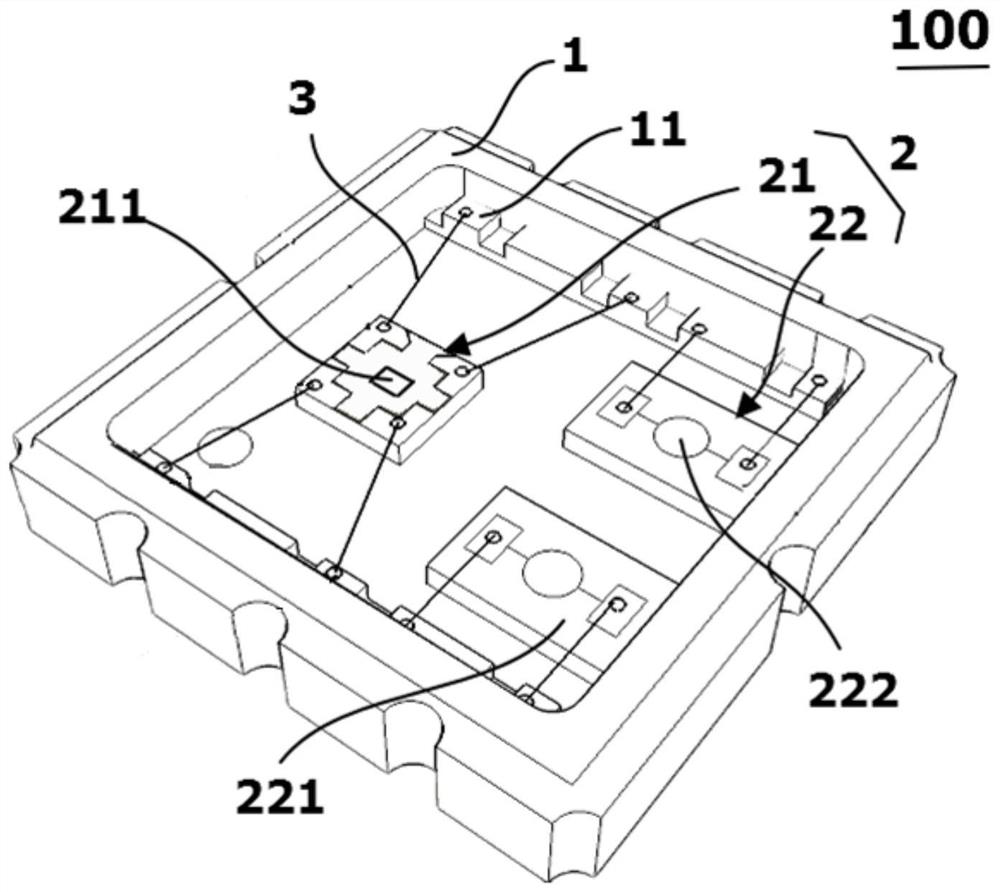

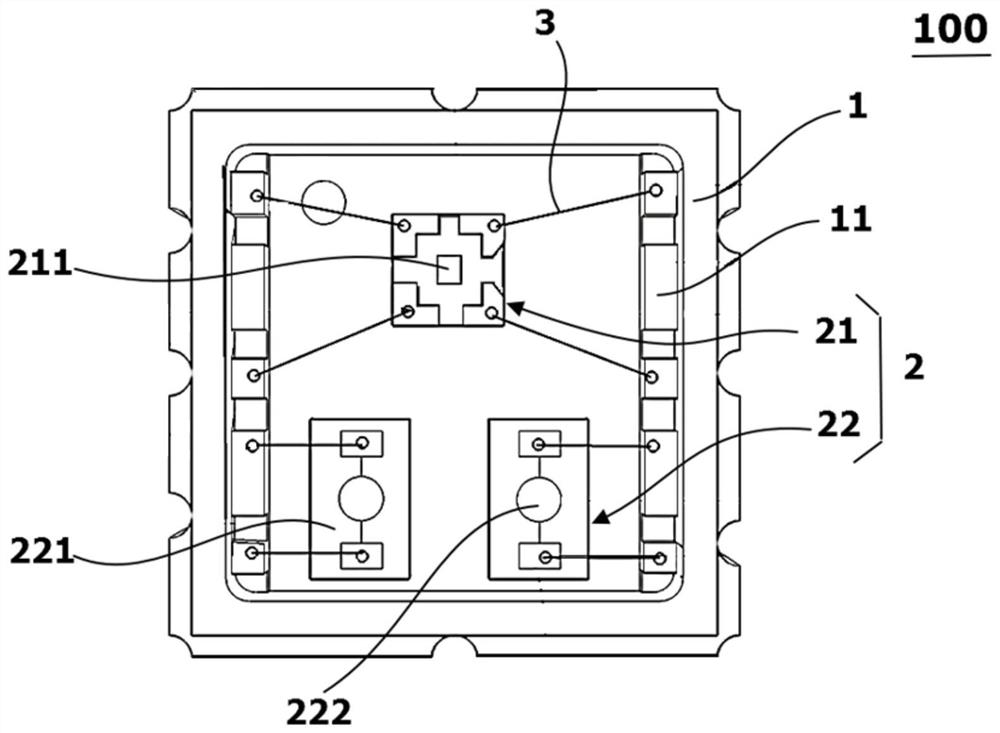

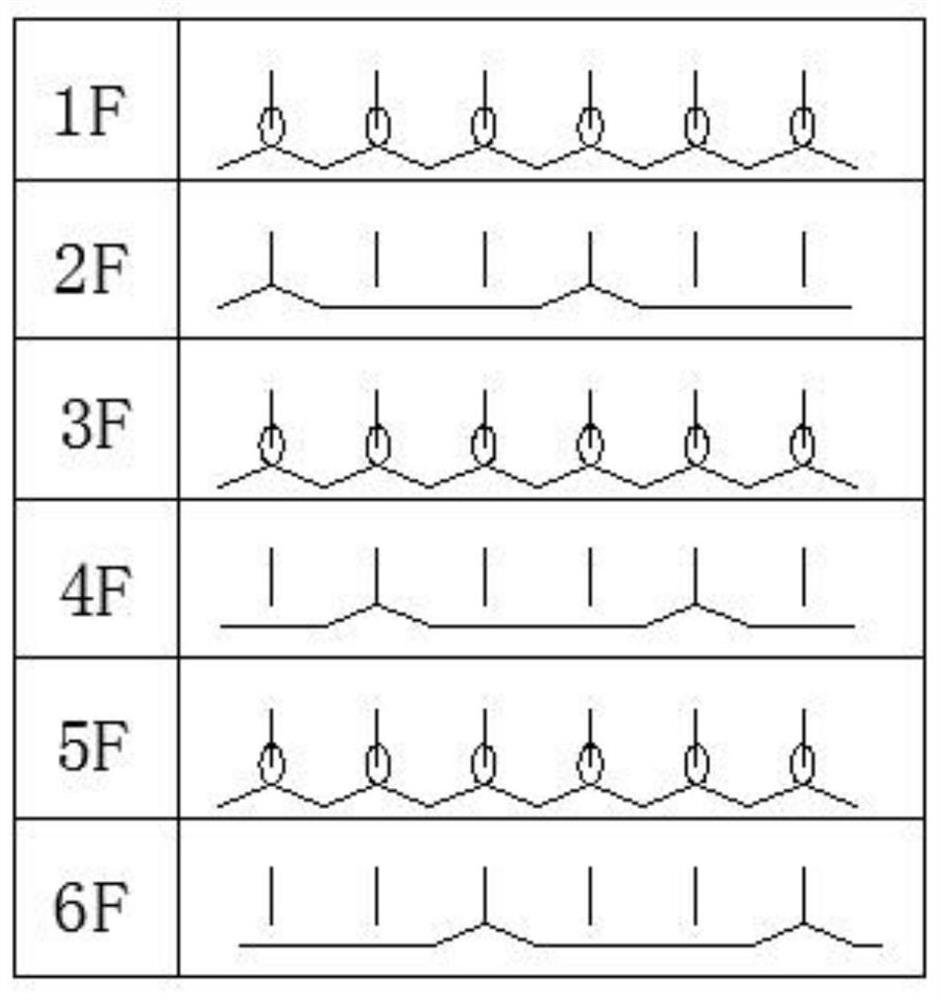

Capacitive biometric feature recognition sensor

The invention relates to a capacitive biometric feature recognition sensor which comprises a first conductive layer, a second conductive layer and an insulating layer, wherein the first conductive layer includes a plurality of first electrode wires distributed in a mutually-isolated mode, the second conductive layer includes a plurality of second electrode wires distributed in a mutually-isolated mode, the projections of the second electrode wires on the plane where the first electrode wires are arranged intersect with the first electrode wires, and the insulating layer is arranged between the first conductive layer and the second conductive layer. According to the capacitive biometric feature recognition sensor, mutual-induction conductance is formed through the mutually-isolated first electrode wires and the mutually-isolated second electrode wires, whether a subcutaneous layer is in contact with mutual-induction conductance can be detected according to the change of capacitance, the CMOS semiconductor technology does not need to be adopted to form a fingerprint recognition sensor on a substrate, the problem of breakage due to pressing with great force does not occur, and the cost is reduced.

Owner:NANCHANG VIRTUAL REALITY RES INST CO LTD

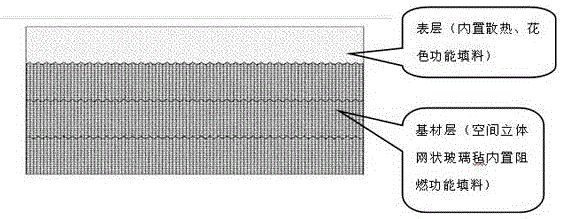

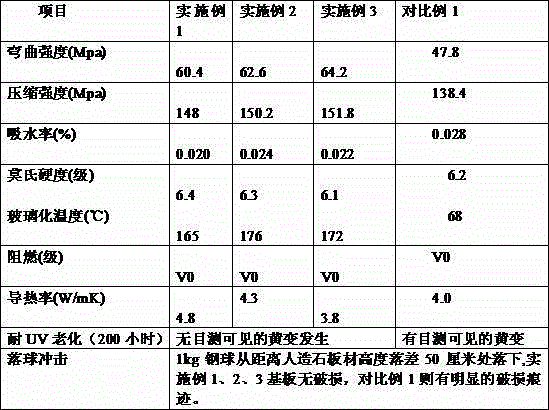

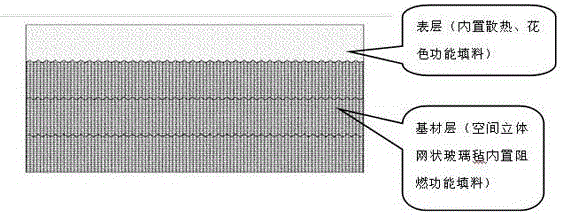

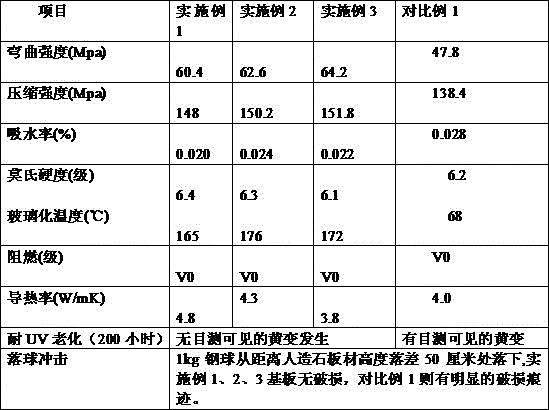

Composite artificial stone table board and preparation method thereof

ActiveCN105060776ANo cracking problemImprove the decorative effectLayered productsEpoxySurface layer

The invention discloses a composite artificial stone table board and a preparation method thereof. The composite artificial stone table board comprises a surface layer and a base material layer, wherein the surface layer is prepared from raw materials, namely, quartz sand, quartz powder, a curing agent, an accelerant, a solvent, multifunctional epoxy resin, a coupling agent, a pigment and heat-conducting powder; the base material layer is prepared from raw materials, namely, aluminum hydroxide powder, quartz powder, a curing agent, an accelerant, a solvent, multifunctional epoxy resin, a coupling agent and a glass mat. The composite artificial stone table board has the advantages that the table board is high in strength, high in torsion and bending deformation resistance, high in heat conductivity coefficient, quick in heat dissipation, good in heat resistance and flame-retardant, does not age and yellow easily and the like, and the table board is suitable for popularization and application.

Owner:来宾环球经典新型建材有限公司

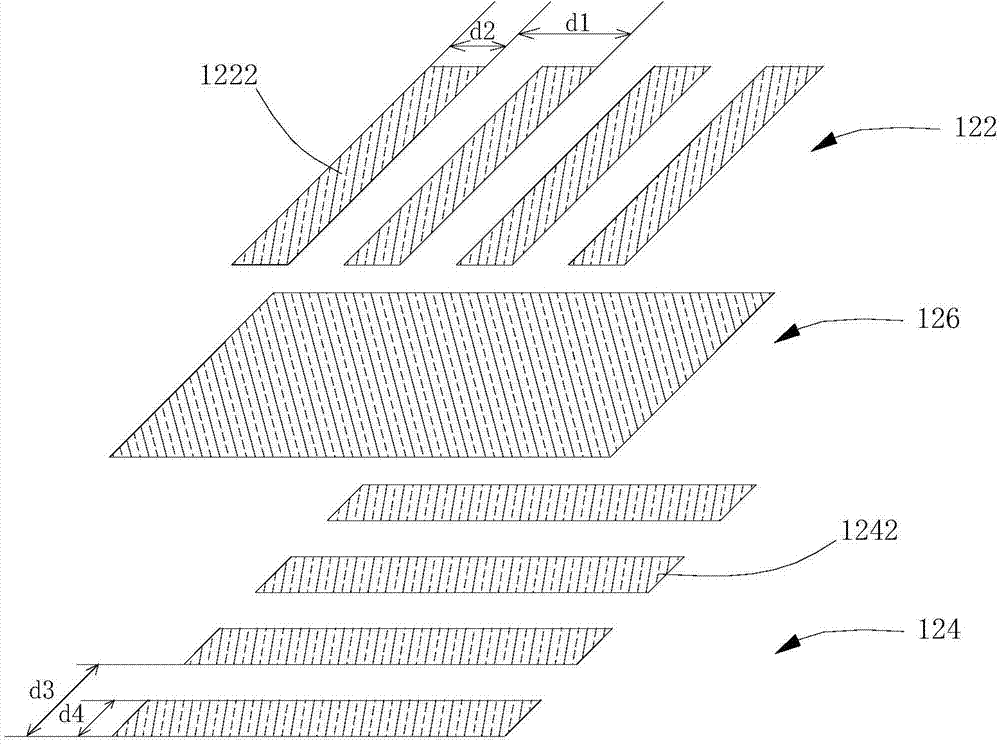

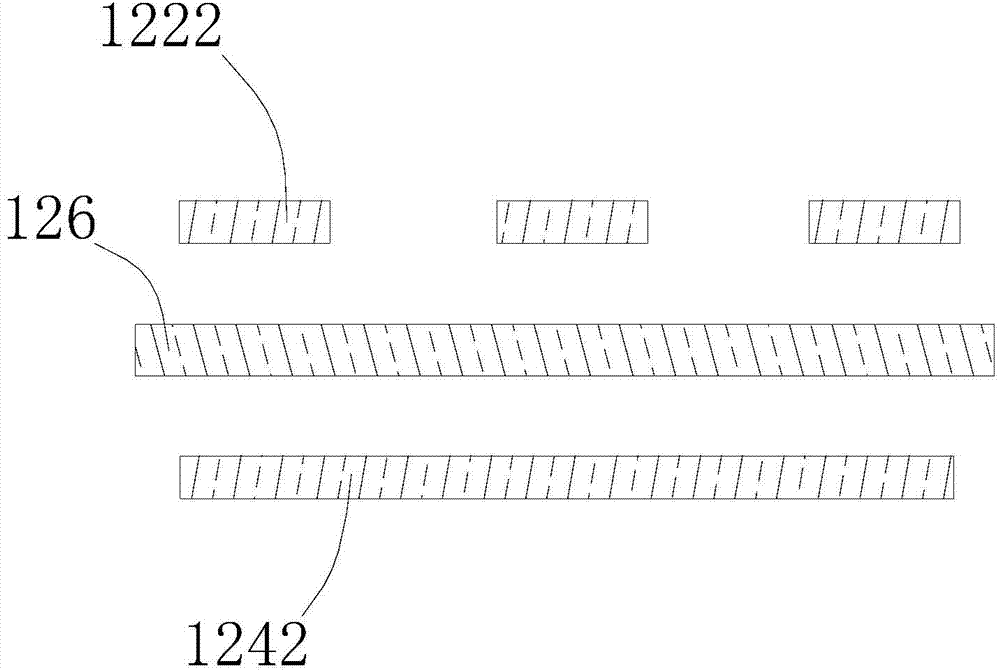

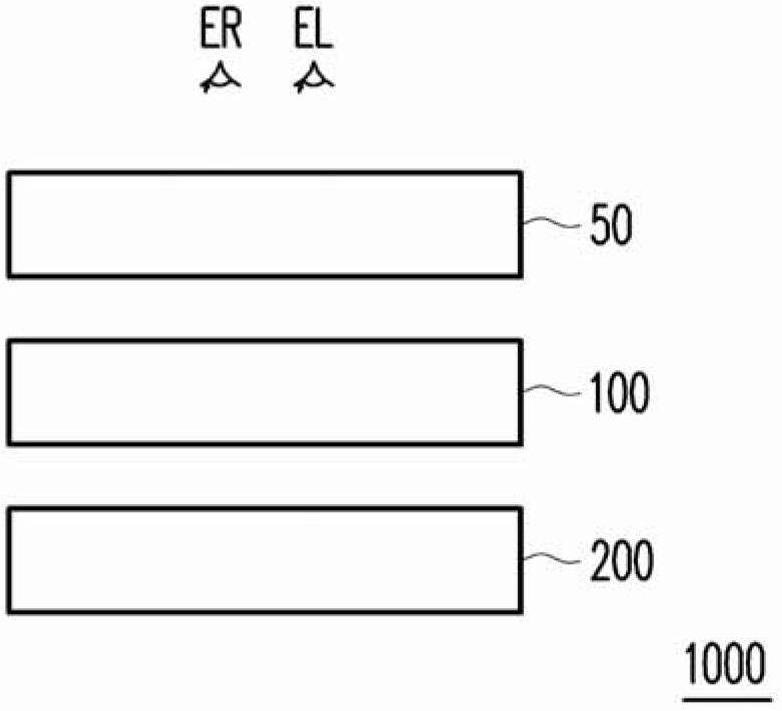

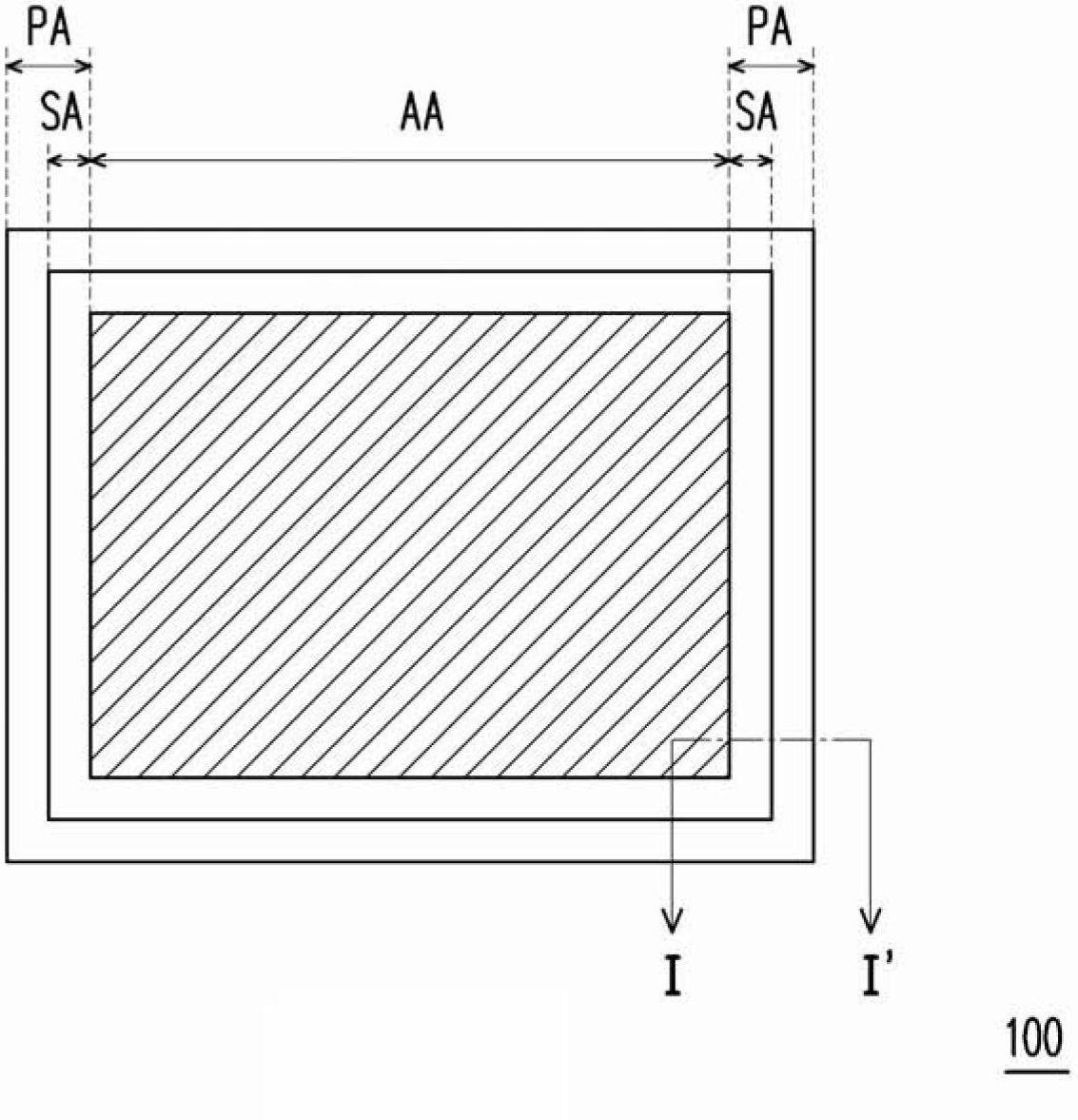

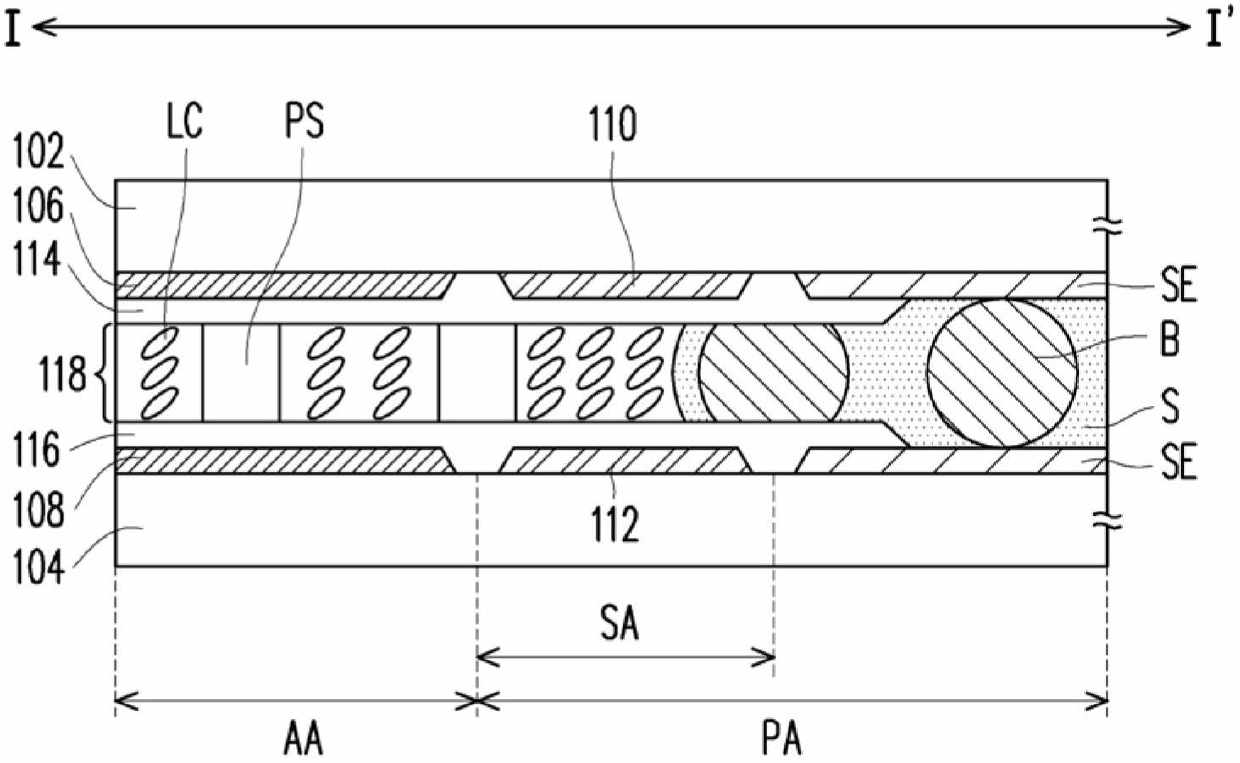

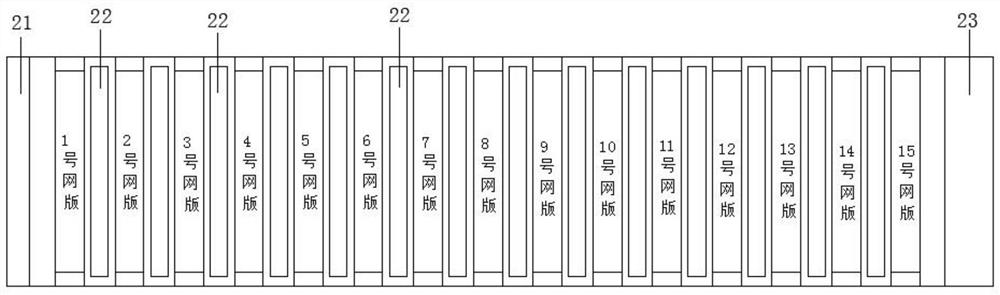

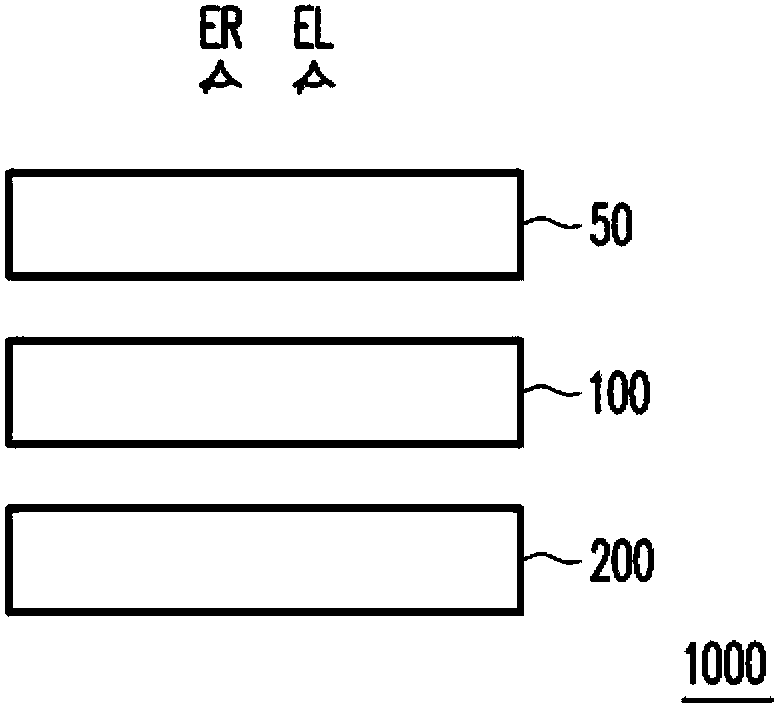

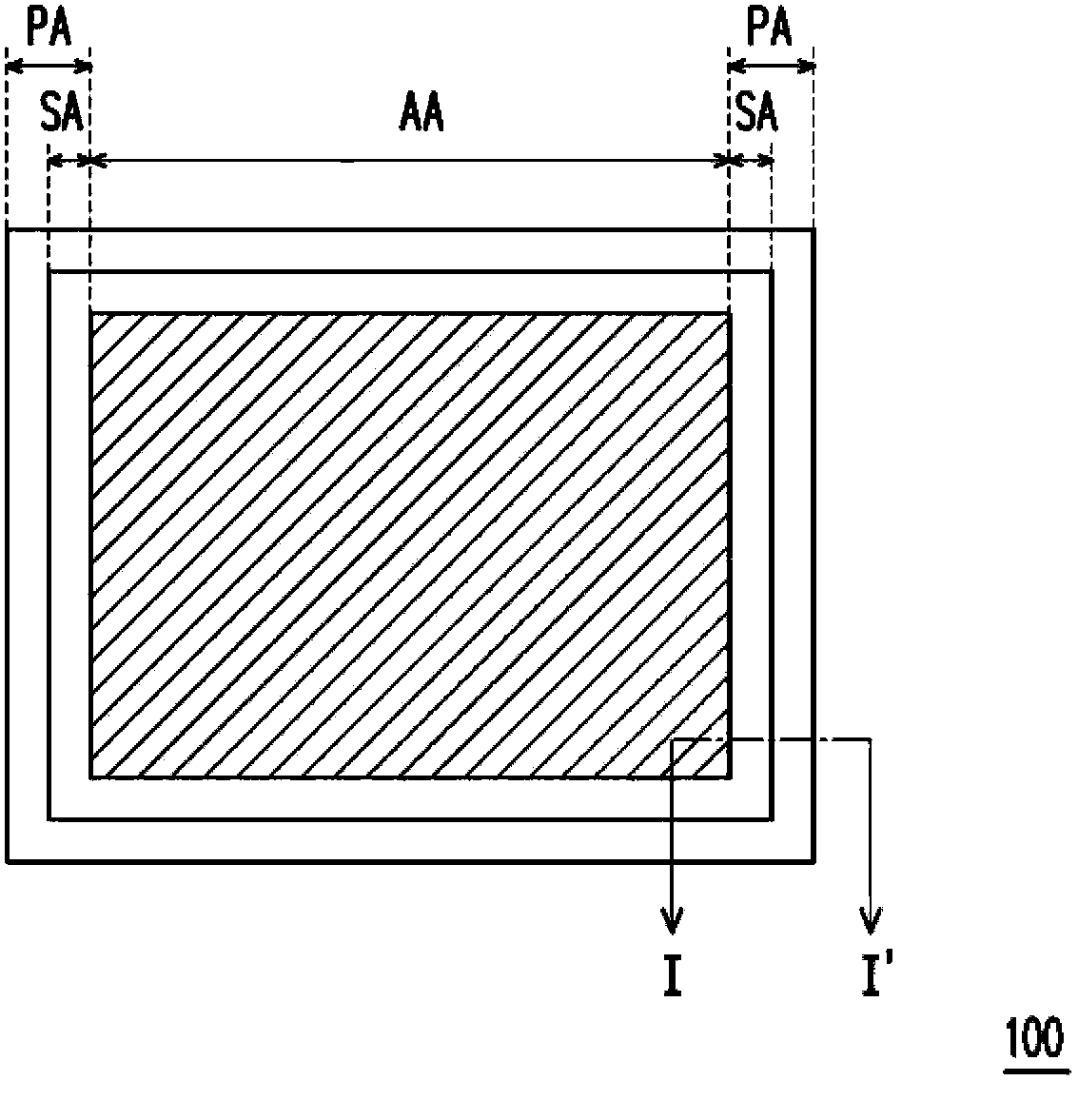

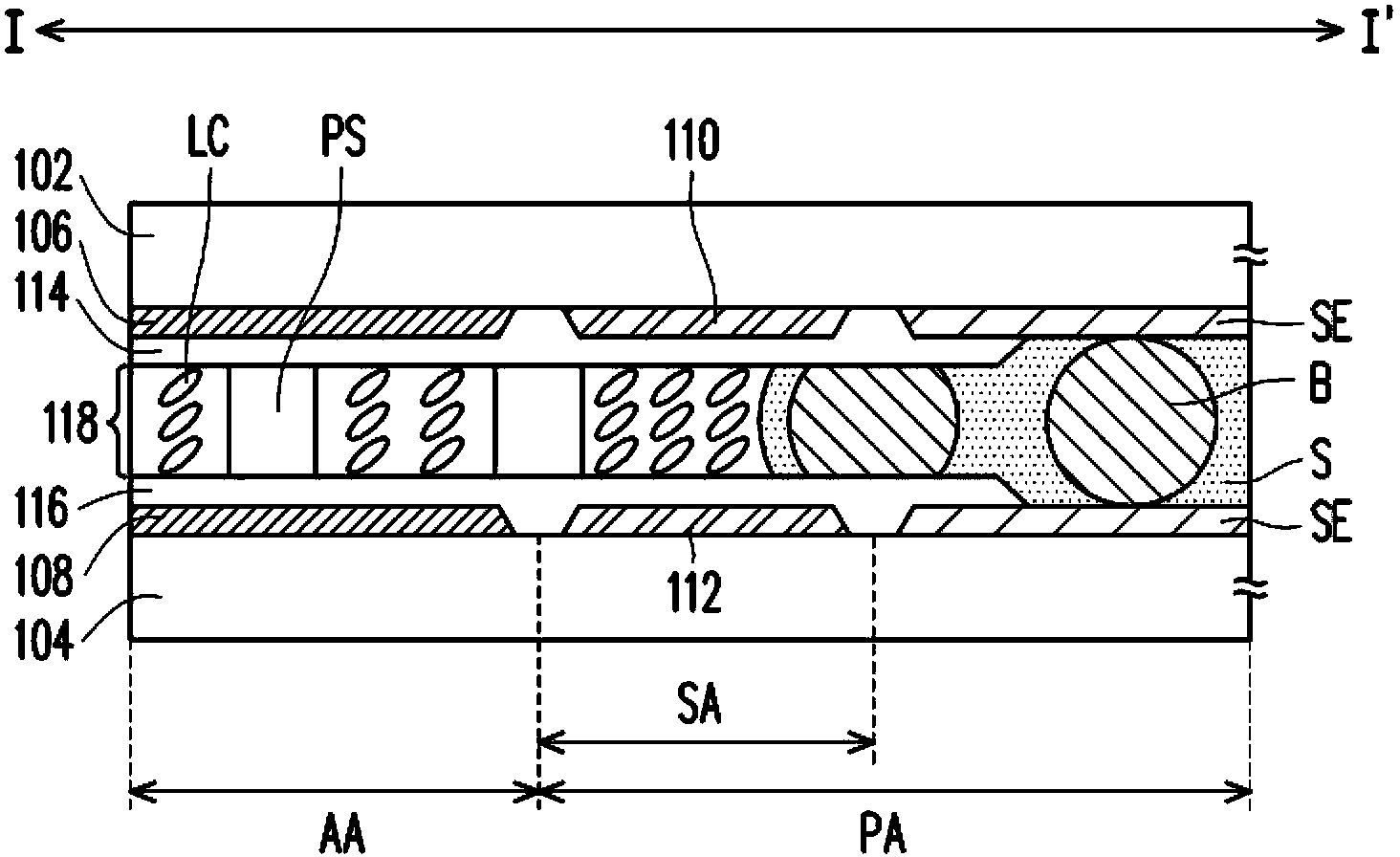

Stereo display panel and screen panel

InactiveCN102654648AImprove performanceNo cracking problemSteroscopic systemsNon-linear opticsCyclo olefin polymerComputer science

The invention provides a stereo display panel, which is provided with an active zone and a circumferential zone, the stereo display panel comprises a display panel and a screen panel disposed at one side of the display panel, wherein the screenpanel comprises: a first substrate and a second substrate oppositely disposed, wherein the first substrate and the second substrate comprise a cycloolefin copolymer or a cycio olefins polymer; a first electrode layer and a second electrod layer respectively disposed at the first substrate and the second substrate and in the active zone; a first bonding layer and a second bonding layer respectively disposed on the first substrate and the second substrate and in the circumferential zone; a first alignment layer covering the first electrode layer and the first adherence layer; a second alignment layer covering the second electrode layer and the second adherence layer; and a liquid crystal layer disposed between the first alignment layer and the second alignment layer.

Owner:AU OPTRONICS CORP

Film coating agent for extract medicament solid preparation and preparation method thereof

ActiveCN101829334ANon-irritatingSmall molecular weightOil/fats/waxes non-active ingredientsPlasticizerMethyl cellulose

The invention relates to a film coating agent for an extract medicament solid preparation, which comprises the following components in parts by weight: 30-60 parts of hydroxypropyl methyl cellulose, 5-30 parts of plasticizer and 2-30 parts of stearic acid. The invention also relates to a preparation method of the film coating agent, which comprises the following steps of: (1) weighing the hydroxypropyl methyl cellulose, the plasticizer and the stearic acid in parts by weight; and (2) adding the hydroxypropyl methyl cellulose, the plasticizer and the stearic acid into a high-speed shearing machine and uniformly mixing the materials at the speed of 350-600 rpm to prepare a coating agent finished product. The coating agent is safe and non-toxic, and can form a hydrophobic molecular layer on the surface of a medicament for inhibiting the adsorption and osmosis of steam on the surface of a coating film, thereby reducing the moisture absorbing rate of a medicament coating tablet and preventing the damping and hardening of the medicament and medicament efficiency loss; meanwhile, the coating film has strong flexibility, and the coating quality is stable; and the preparation method has the outstanding advantages of high production efficiency, low energy consumption, favorable application performance of coating agent finished products, and the like.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

Preparation method of filled baked wheaten cake

The invention relates to a preparation method of a filled baked wheaten cake and belongs to the technical field of food. The technical scheme is as follows: step one, 2 g of yeast is dissolved in water, the obtained solution is uniformly mixed with 400 g of flour, 10-30 g of vegetable oil and 60-70 g of eggs, the obtained mixture is mixed with water, and then kneading is carried out to form uniform and soft dough, and the dough is covered with a preservative film and fermented to be 2 times the size of the dough in a warm place; step two, filling is prepared; step 3, dough pieces in proper size are prepared from the fermented dough according to the preference, and wrappers which are thin on the periphery and thick in the middle are prepared with a rolling pin; step four, the wrappers are filled with the filling with closing openings facing downwards and then flattened by pressing; step 5, after a pot of cakes are prepared, the cakes can be properly rested for 10 min according to the degree of dough, oil is placed in an electric baking pan, the cakes are put and coated with oil, the electric baking pan is covered for baking, and turning can be conducted several times during baking;and step 6, the baked cakes are placed in a charcoal fire grill to be baked over charcoal fire until no oil layers exist on the surfaces. The purpose is achieved with the technical scheme.

Owner:WEIHAI GUANBIAO INFORMATION TECH

Film coating agent for extract medicament solid preparation and preparation method thereof

ActiveCN101829334BNon-irritatingSmall molecular weightOil/fats/waxes non-active ingredientsPlasticizerMethyl cellulose

The invention relates to a film coating agent for an extract medicament solid preparation, which comprises the following components in parts by weight: 30-60 parts of hydroxypropyl methyl cellulose, 5-30 parts of plasticizer and 2-30 parts of stearic acid. The invention also relates to a preparation method of the film coating agent, which comprises the following steps of: (1) weighing the hydroxypropyl methyl cellulose, the plasticizer and the stearic acid in parts by weight; and (2) adding the hydroxypropyl methyl cellulose, the plasticizer and the stearic acid into a high-speed shearing machine and uniformly mixing the materials at the speed of 350-600 rpm to prepare a coating agent finished product. The coating agent is safe and non-toxic, and can form a hydrophobic molecular layer onthe surface of a medicament for inhibiting the adsorption and osmosis of steam on the surface of a coating film, thereby reducing the moisture absorbing rate of a medicament coating tablet and preventing the damping and hardening of the medicament and medicament efficiency loss; meanwhile, the coating film has strong flexibility, and the coating quality is stable; and the preparation method has the outstanding advantages of high production efficiency, low energy consumption, favorable application performance of coating agent finished products, and the like.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

Manufacturing method for vanes of vane pump

The invention discloses a manufacturing method for vanes of a vane pump. The manufacturing method comprises the following steps: step I, using a band sewing machine to cut out basic vane blank, and unloading the basic vane blank; step II, milling double side surfaces of the vane blank through a milling machine; step III, flatly grinding the vane blank milled by the milling machine; step IV, thermally treating the flatly grinded vane blank; step V, grinding the thickness and the height of the vane blank subjected to thermal treatment, and performing rough polishing on the vane blank; step VI, grinding one side, which is in contact with a pressurizing cavity, of the vane blank; step VII, grinding height and width of vane semi-finished products, and performing rough polishing on the vane semi-finished products; and step VIII, cleaning the sorted vane finished products. According to the manufacturing method for the vanes of the vane pump disclosed by the invention, the steps I to VIII areset, so that vanes can be effectively produced; and moreover, in the production process, multiple parts of the vanes are grinded by many times, so that smoothness of the vanes is effectively improved.

Owner:缙云县耐而特机械制造有限公司

Method for manufacturing packaging product with metalized side wall

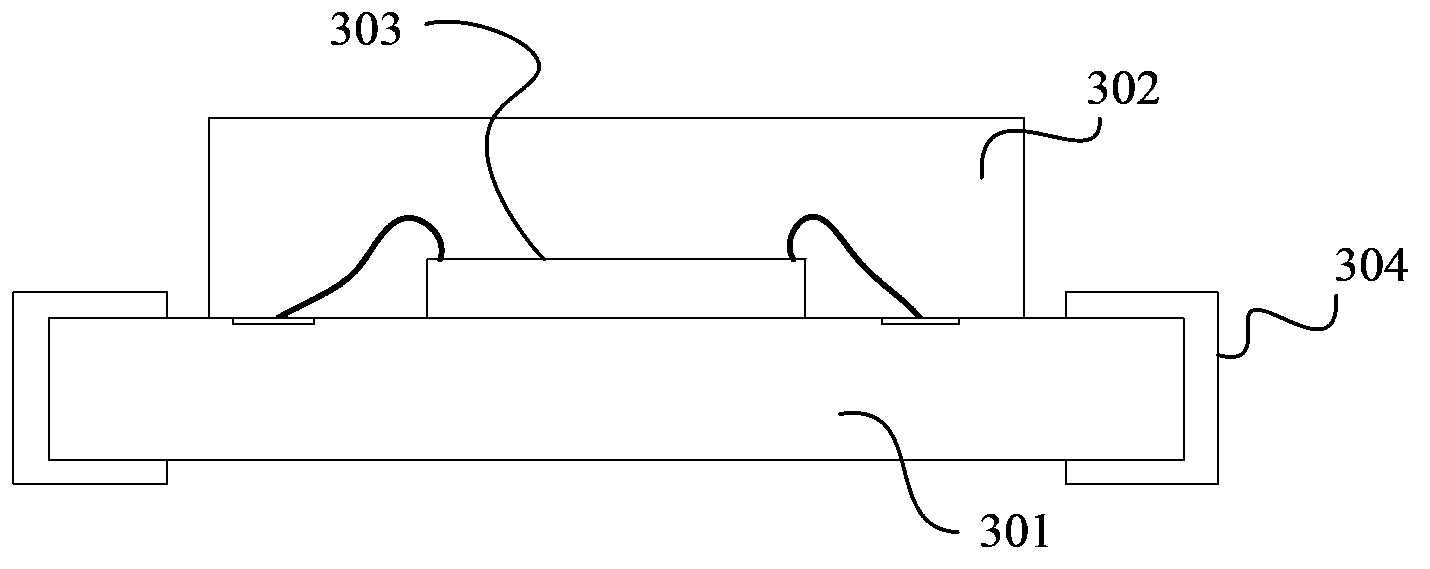

ActiveCN103579010AGuaranteed StrengthNo cracking problemSolid-state devicesSemiconductor/solid-state device manufacturingBiochemical engineeringExertion

The embodiment of the invention discloses a method for manufacturing a packaging product with the metalized side wall. Metallization is conducted on the side wall after packaging is conducted, metallization can be conducted on the side wall without forming a groove in the process of manufacturing a substrate, and therefore manufacturing of the substrate is simplified. When the packaging process is conducted, due to the fact that the groove has not been formed in the substrate for metallization of the side wall, no special jig is needed when processing is conducted through the vacuum absorption technology, and therefore positioning is very easy to conduct, the packaging process is simplified, the process complexity of the packaging product with the metalized side wall is lowered, production cost is reduced, and work efficiency is improved. When the packaging process is conducted, the groove has not been formed in the substrate, the strength of the substrate is ensured, the problem of substrate cracking caused by improper force exertion can not occur, and therefore the product quality is ensured. In addition, due to the fact that the accuracy of groove forming in the packaging process is higher than the accuracy of groove forming in the substrate manufacturing process, the number of packaging substrate units which can be arranged on a strip is increased. In addition, machining of multi-electrode packaging products with the metalized side walls can be achieved through the method.

Owner:SKY CHIP INTERCONNECTION TECH CO LTD

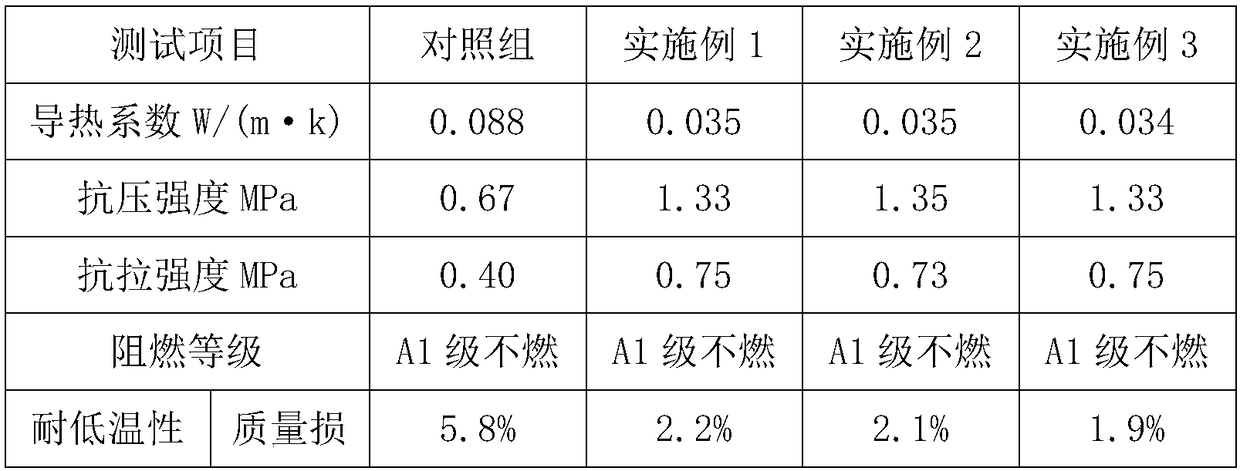

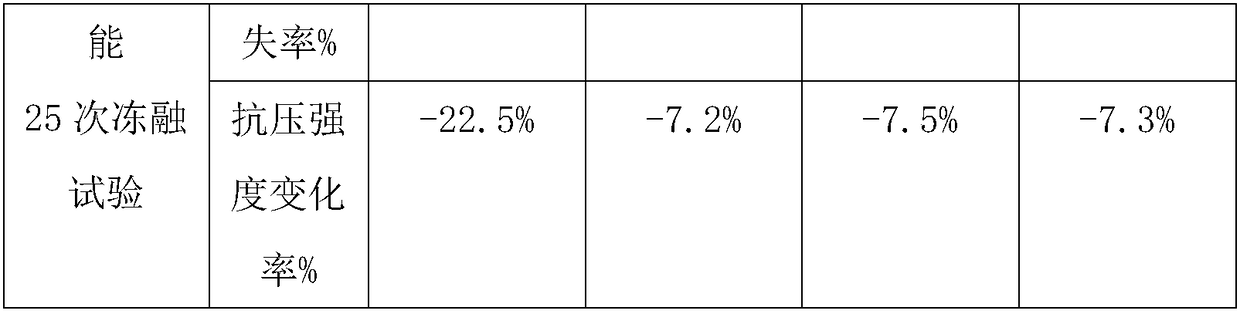

Anti-freezing anti-cracking cement foaming heat preservation board

The invention relates to the technical field of heat preservation construction materials, in particular to an anti-freezing anti-cracking cement foaming heat preservation board. The heat preservationboard is prepared from cement, coal dust, water glass, a cold-resistant flexibilizer, aluminum oxide fibers, a foaming agent, a foam stabilizer, a water reducer, an anti-freezing agent and water, wherein the cold-resistant flexibilizer is a novel material compound by various elastic materials, high-hardness fillers and the like. Cement is a mixture made by blending Portland cement with magnesium oxychloride cement according to a mass ratio of 8:1; the water reducer is a lignin water reducer or a poly-carboxyl water reducer or a melamine water reducer; the foaming agent is hydrogen peroxide; the foam stabilizer is calcium stearate; the anti-freezing agent contains propylene glycol butyl ether, glycol butyl ether acetate and diethylene glycol. The thermal conductivity of the heat preservation board is low, and the heat preservation performance is great. The cold-resistant anti-freezing performance of the materials is great, the tenacity is high, and the heat preservation board is not easily fractured at low temperature.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

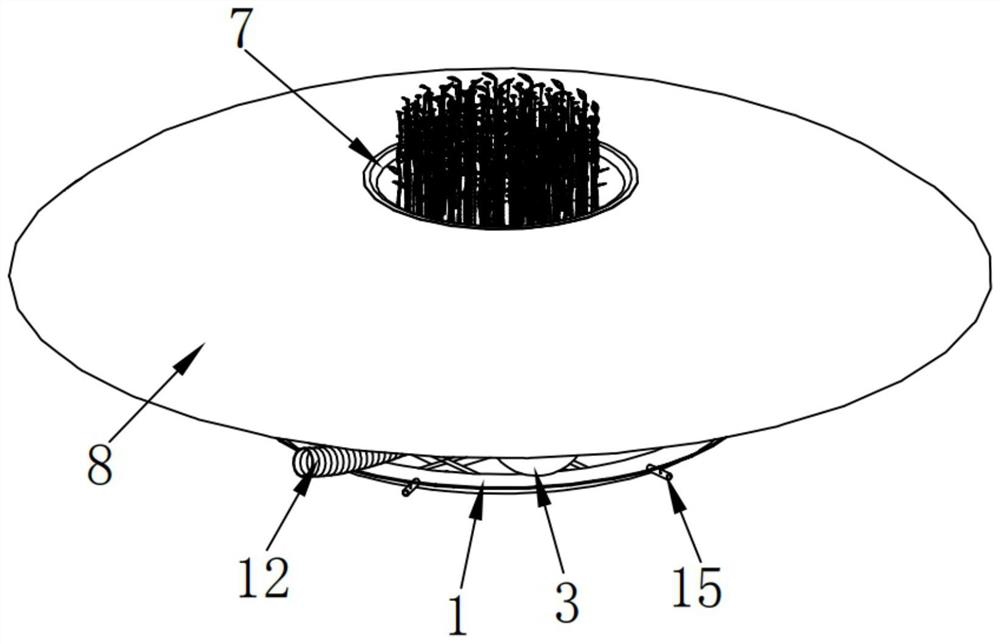

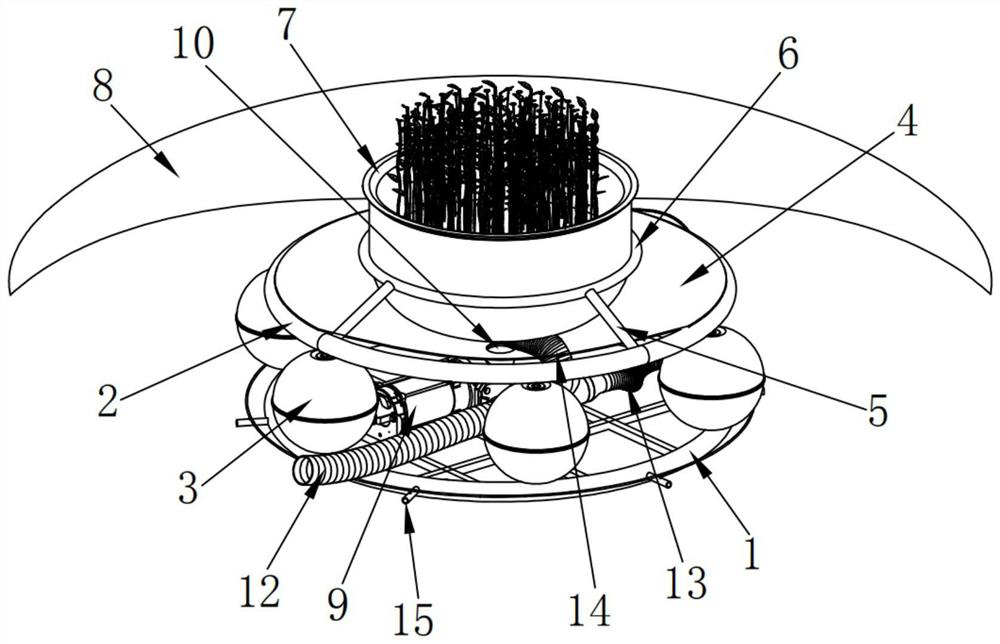

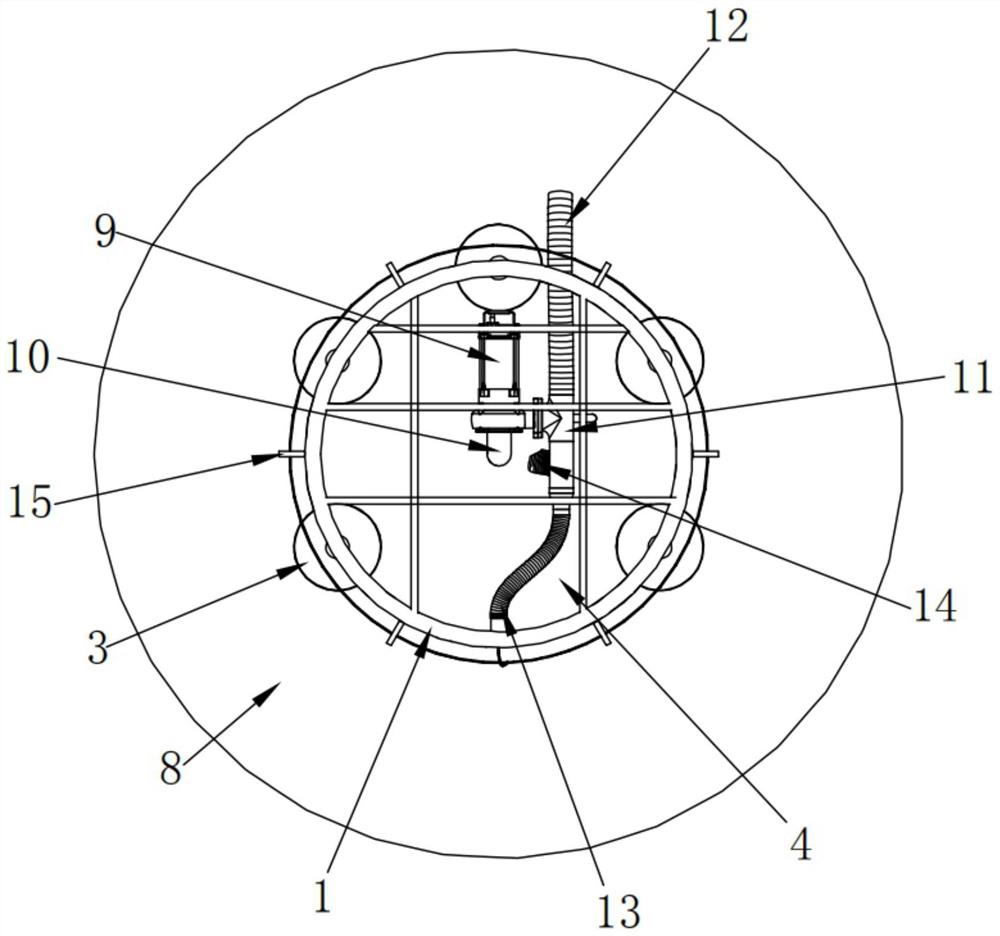

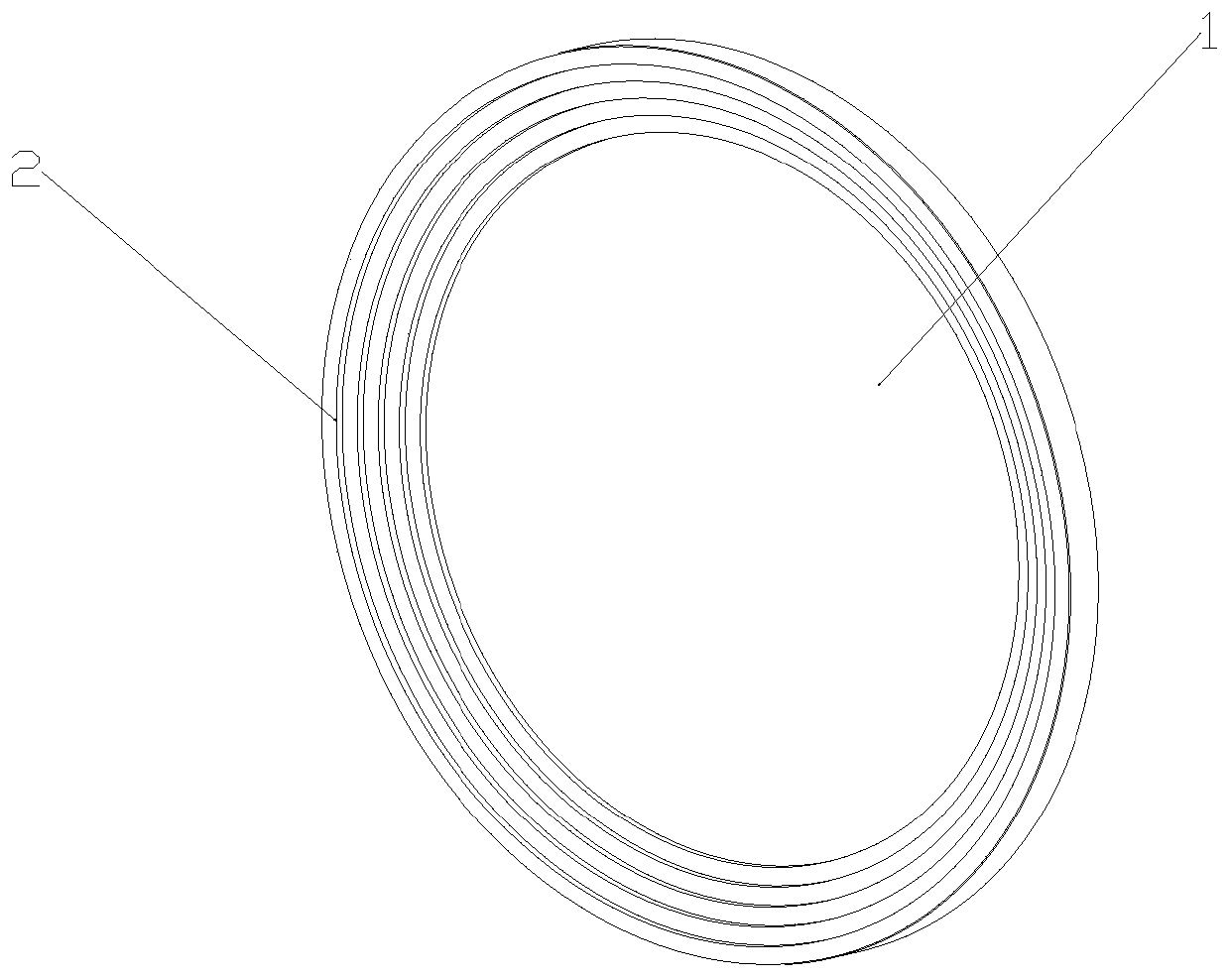

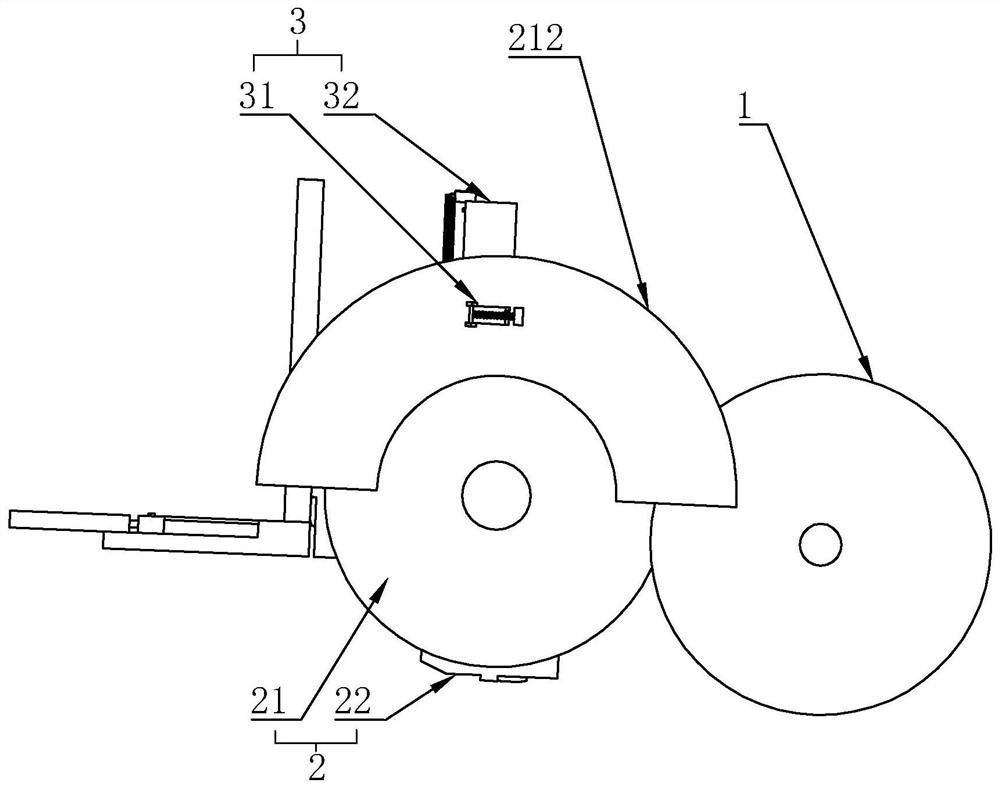

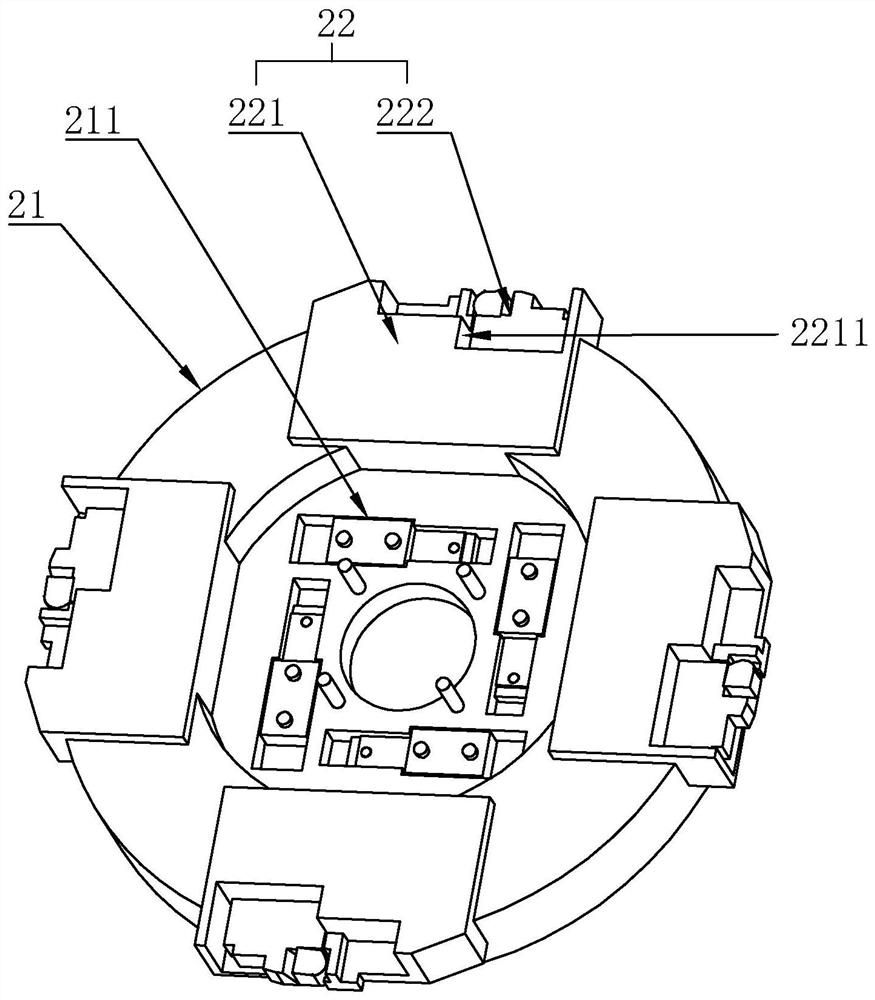

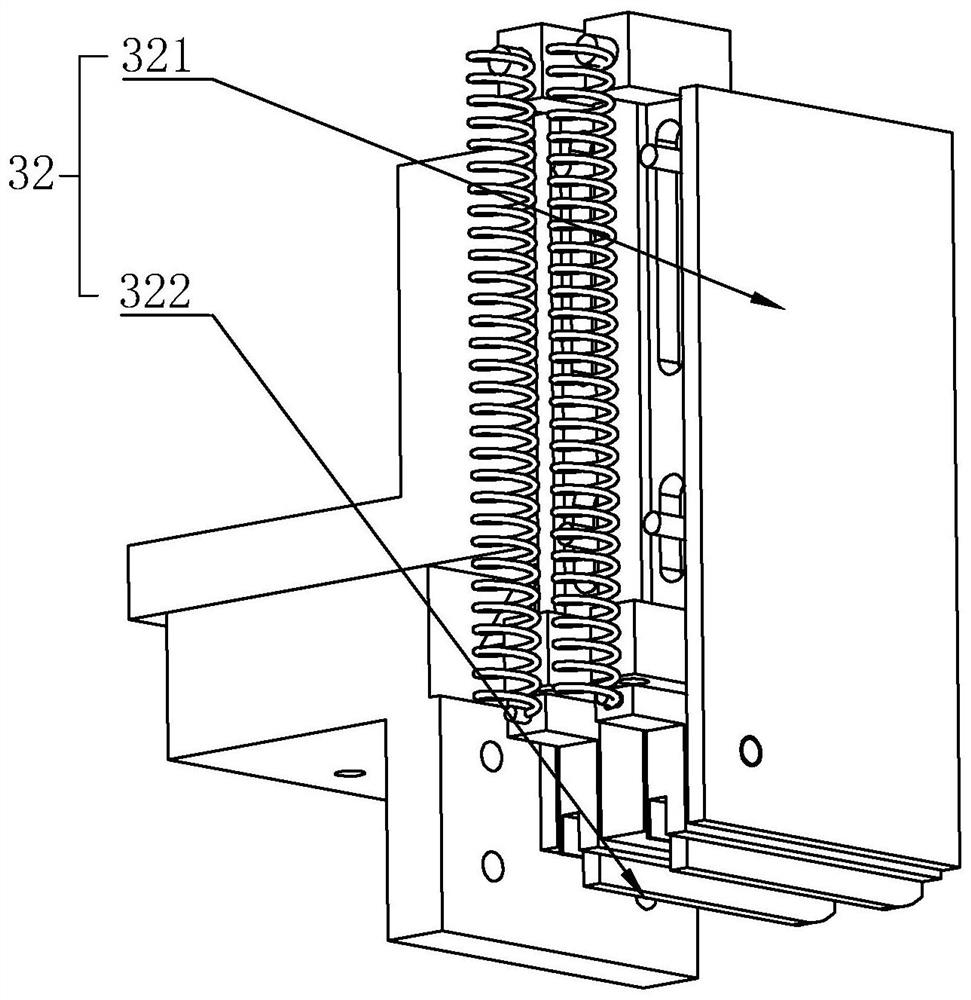

Integrated landscape algae sucking and controlling device

InactiveCN112982275ANo cracking problemReduce lossesWater cleaningWaterborne vesselsEnvironmental engineeringMechanical engineering

The invention provides an integrated landscape algae sucking and controlling device. The integrated landscape algae sucking and controlling device comprises a ring pipe, a first frame ring, five floating balls, a flow guide basin, four fixing rods, a second frame ring and a landscape green plant basin, wherein the first frame ring is arranged above the ring pipe; the five floating balls are arranged between the ring pipe and the first frame ring; the flow guide basin is arranged in the first frame ring; the four fixing rods are fixedly mounted on the first frame ring and are uniformly distributed in a circular array; the second frame ring is fixedly mounted at the top ends of the four fixing rods; and the landscape green plant basin is arranged in the second frame ring. The integrated landscape algae sucking and controlling device provided by the invention has the advantages of high integration, relatively good aesthetic property, simplicity and easiness in mounting, relatively low operation and maintenance cost and capability of effectively aiming at blue-green algae.

Owner:江苏中鲁环境工程有限公司

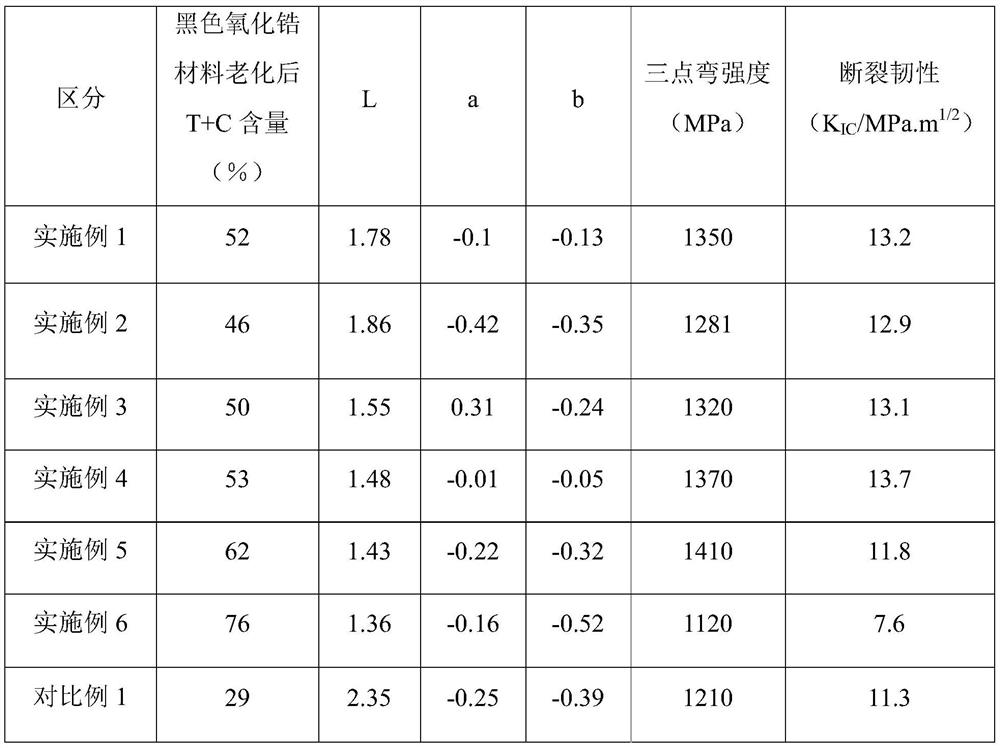

Preparation method of high-toughness and high-strength black zirconia ceramic material

The invention relates to a preparation method of a high-toughness and high-strength black zirconia ceramic material, and belongs to the technical field of zirconia ceramics. According to the preparation method, a hydrolytic polymerization method and a microwave crystallization process are adopted to regulate and control the uniformity of powder components, the black zirconium oxide ceramic powderwith high sintering activity and uniform dispersion is provided, and then the black zirconium oxide ceramic powder is preformed; and high-temperature sintering is performed on the preformed ceramic blank to obtain the high-toughness high-strength black zirconia ceramic material. The product prepared by the invention does not contain toxic chromium element, has uniform chemical components, stable black chromaticity, high blackness, high toughness, high strength, good aging resistance and good product consistency and stability, and is suitable for being applied to various fields.

Owner:长裕控股集团股份有限公司

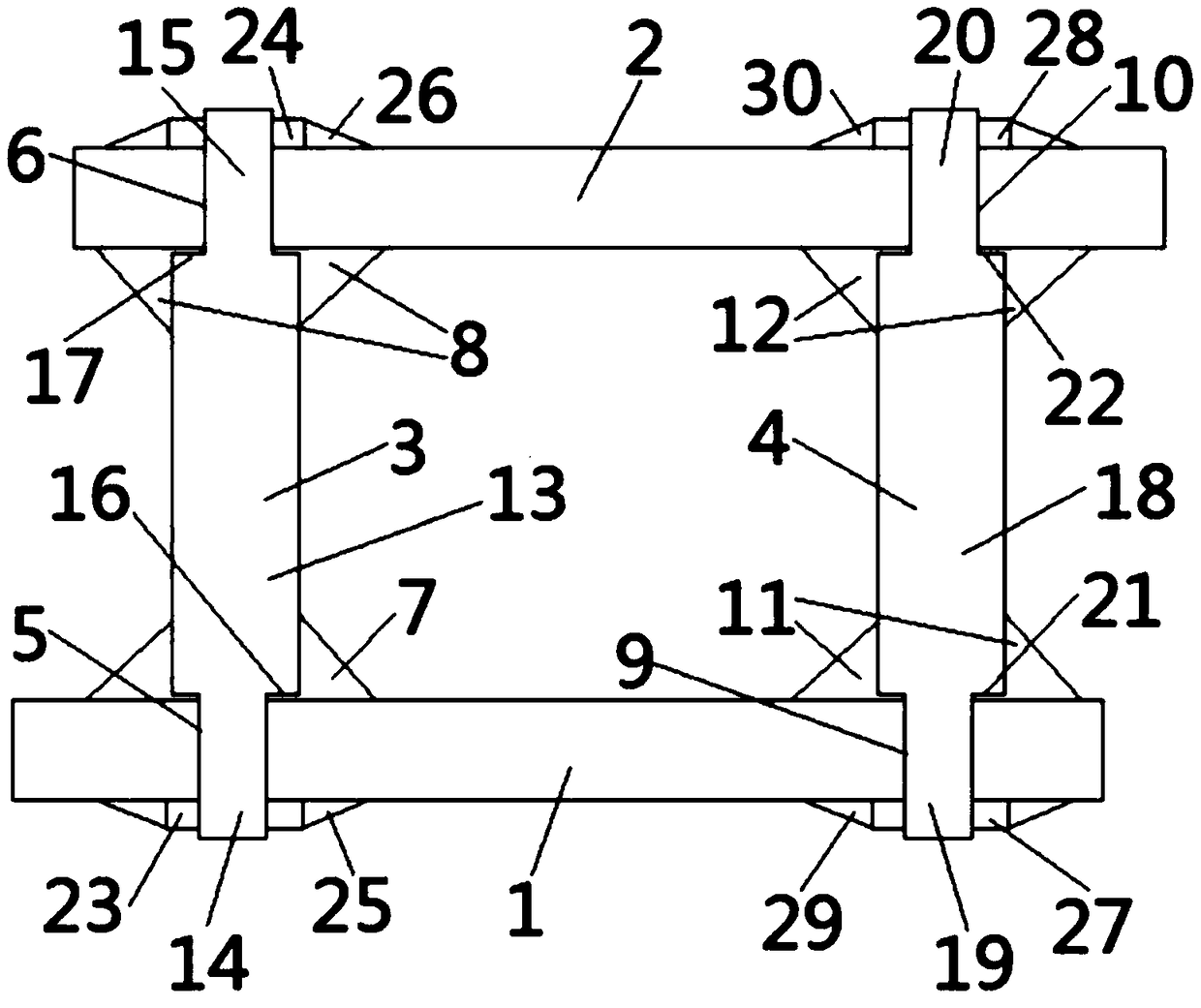

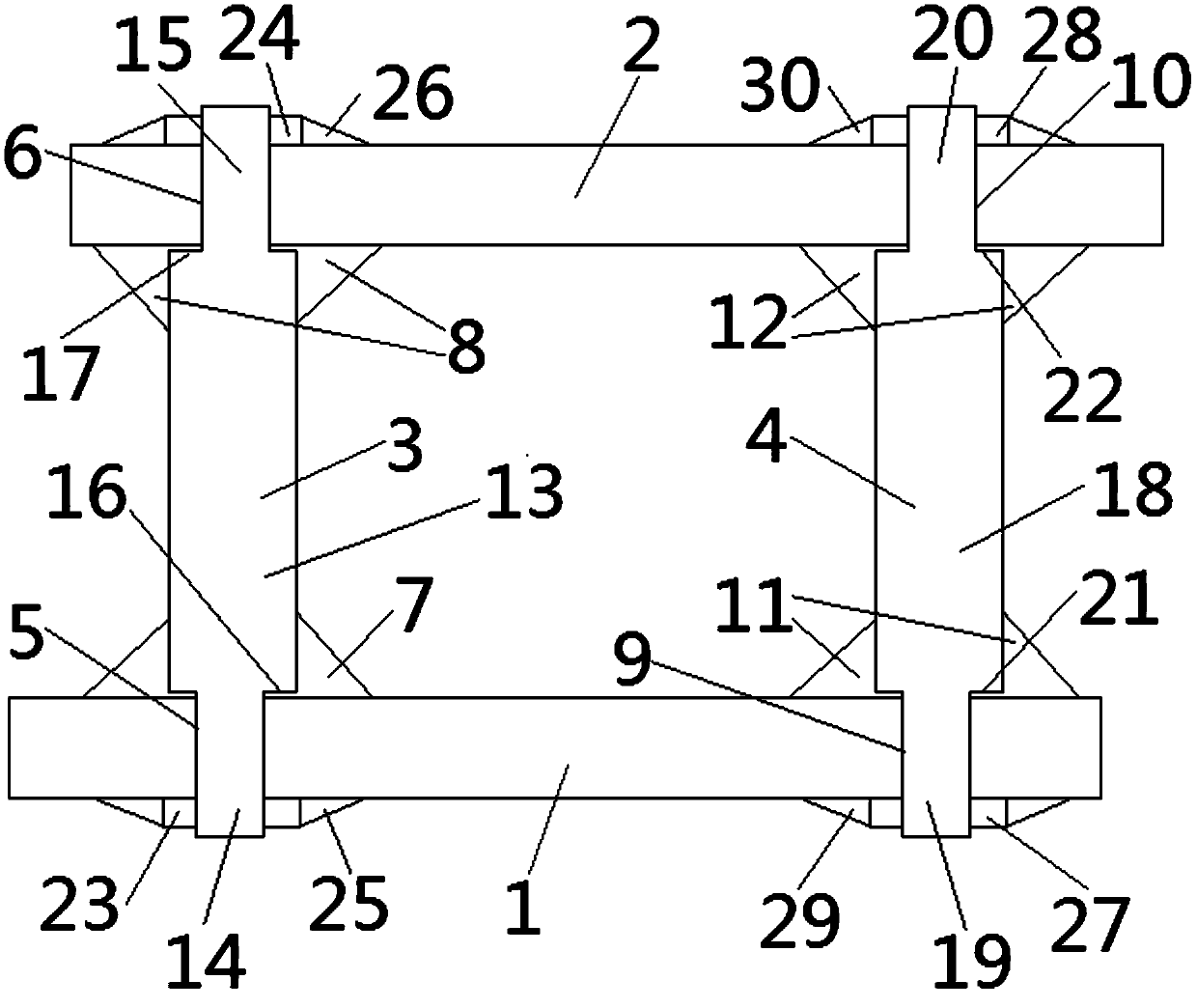

Edge beam type automobile frame

InactiveCN108438054ACombined with reliableImprove deformation resistanceUnderstructuresVehicle frameWelding joint

The invention provides an edge beam type automobile frame applied to the field of automobile chassis parts. A left front reinforcing block (23) welded to the outer side face of a left longitudinal beam (1) is simultaneously welded to the end of a left front connecting rod (14) penetrating through the left front reinforcing block (23). A right front reinforcing block (24) welded to the outer side face of a right longitudinal beam (2) is simultaneously welded to the end of a right front connecting rod (15) penetrating through the right front reinforcing block (24). The edge beam type automobileframe is simple in structure, connection between the longitudinal beams and crossbeams can be stably and reliably achieved, the overall rigidity of the automobile frame is effectively improved, the automobile frame cannot deform when bearing a large load or large impact in the traveling process, the problem that the portions of welding joints crack can be solved, and the bearing force is increased.

Owner:梁延津

Method for completing grain cutting of thin wafer by applying plasma grain cutting and laser equipment

PendingCN111446155AYellow light reduction processEfficient execution of the cutting processSemiconductor/solid-state device manufacturingLaser technologyLaser processing

The invention discloses a method for completing grain cutting of a thin wafer by applying plasma grain cutting and laser equipment. The method comprises the steps of adhering the front surface of an ultrathin wafer to a grain cutting frame; coating the upper end of the ultrathin wafer with a water-soluble or organic-soluble transparent polymer; using a laser technology to carry out laser processing on the transparent polymer , and cutting the polymer and the titanium / aluminum copper metal layer through to form a cutting channel pattern; carrying out a plasma process on the ultrathin wafer to cut crystal grains; using DI water / solvent for cleaning and removing polymers and metal impurities left in the laser process; and cutting the crystal grains on a UV type film frame. According to the invention, the coating water-soluble or organic-soluble transparent polymer is used, and a laser and path editing program process is applied, so that a sequence of yellow light processes is reduced; thetransparent polymer is aligned with the cutting channel, so that the cutting process is effectively implemented; and after the metal layer on the cutting channel is cut through by laser to form a polymer cutting channel pattern, the comprehensive plasma process is carried out to cut the crystal grains, and the wafer is not polluted.

Owner:绍兴同芯成集成电路有限公司

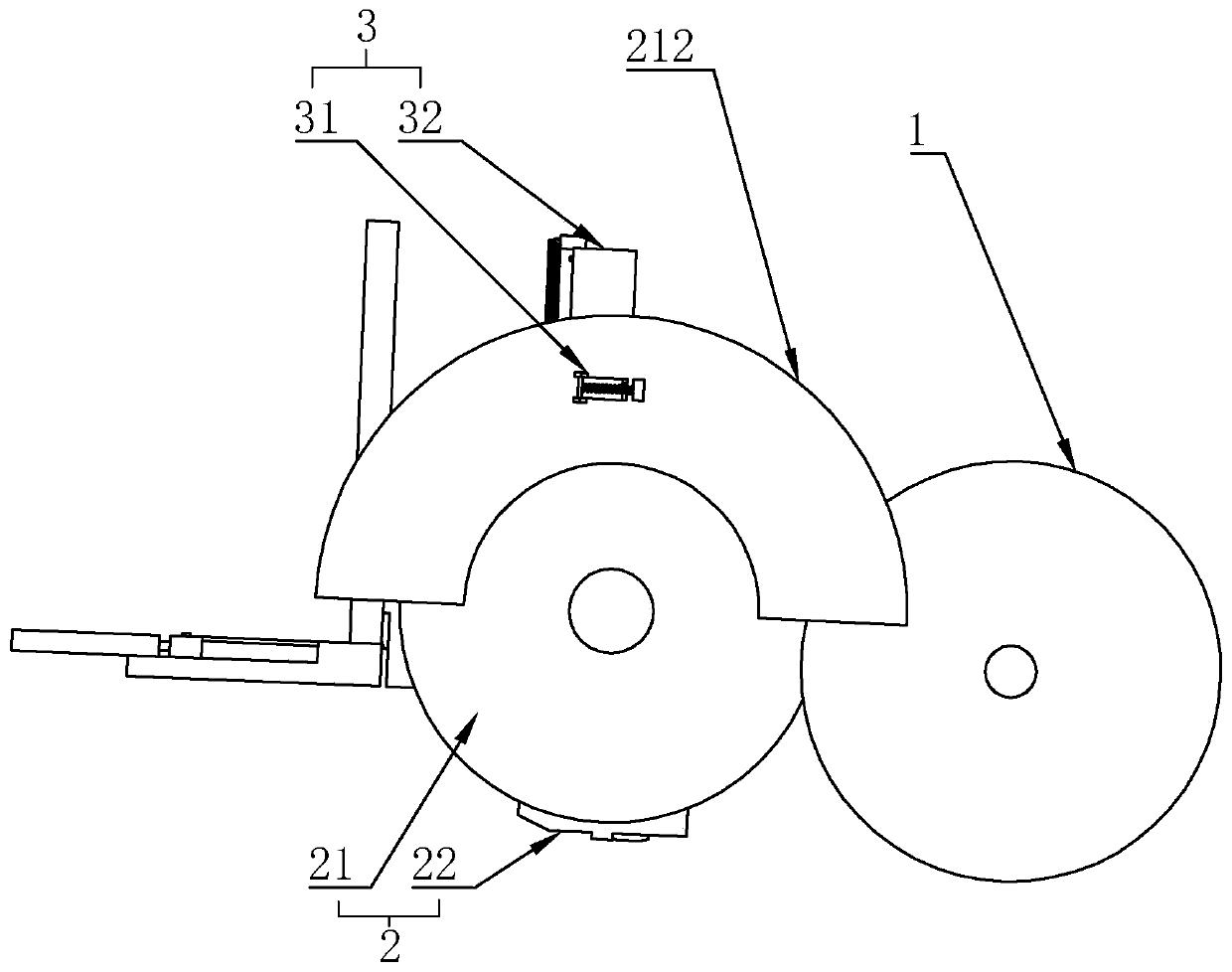

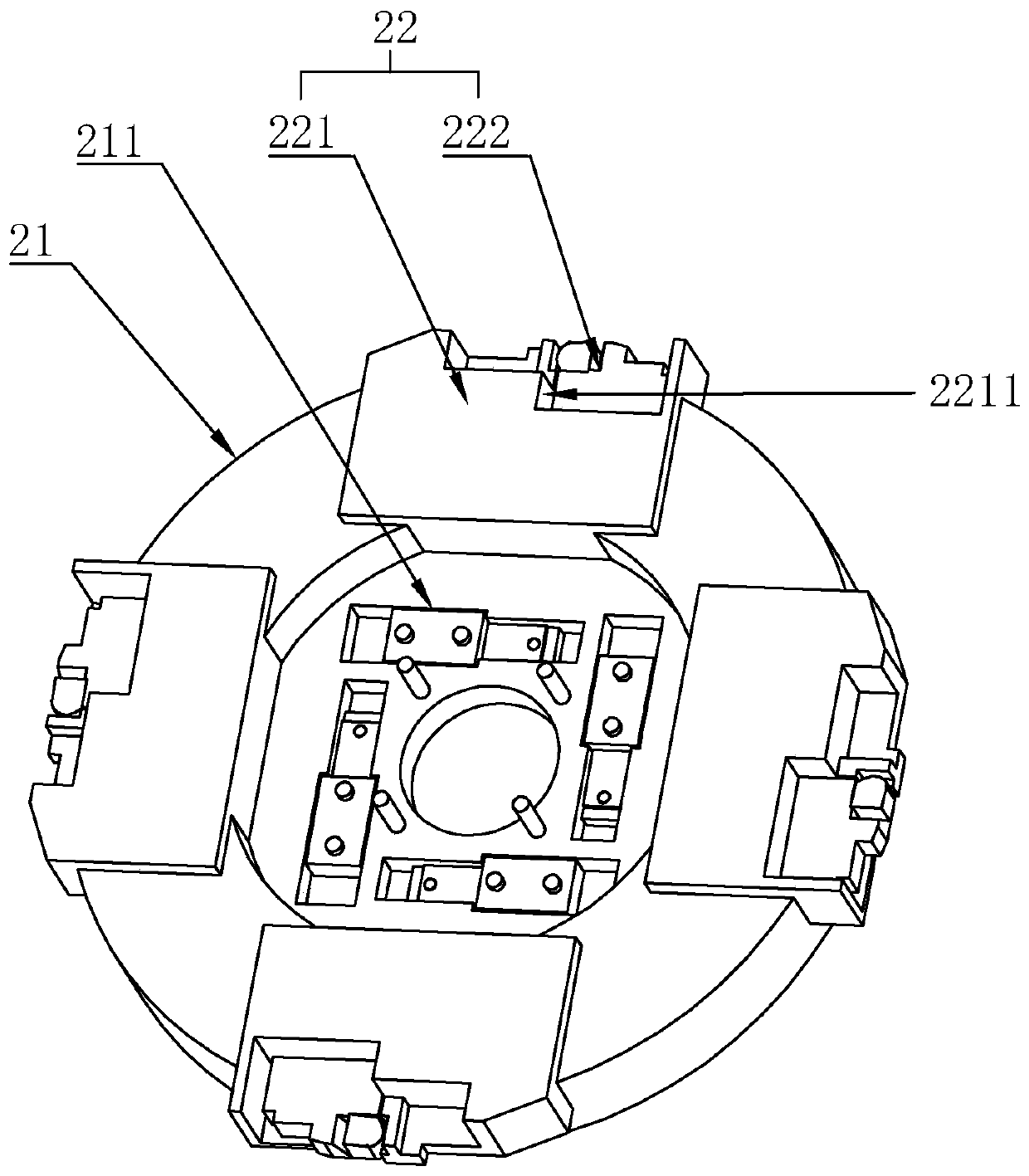

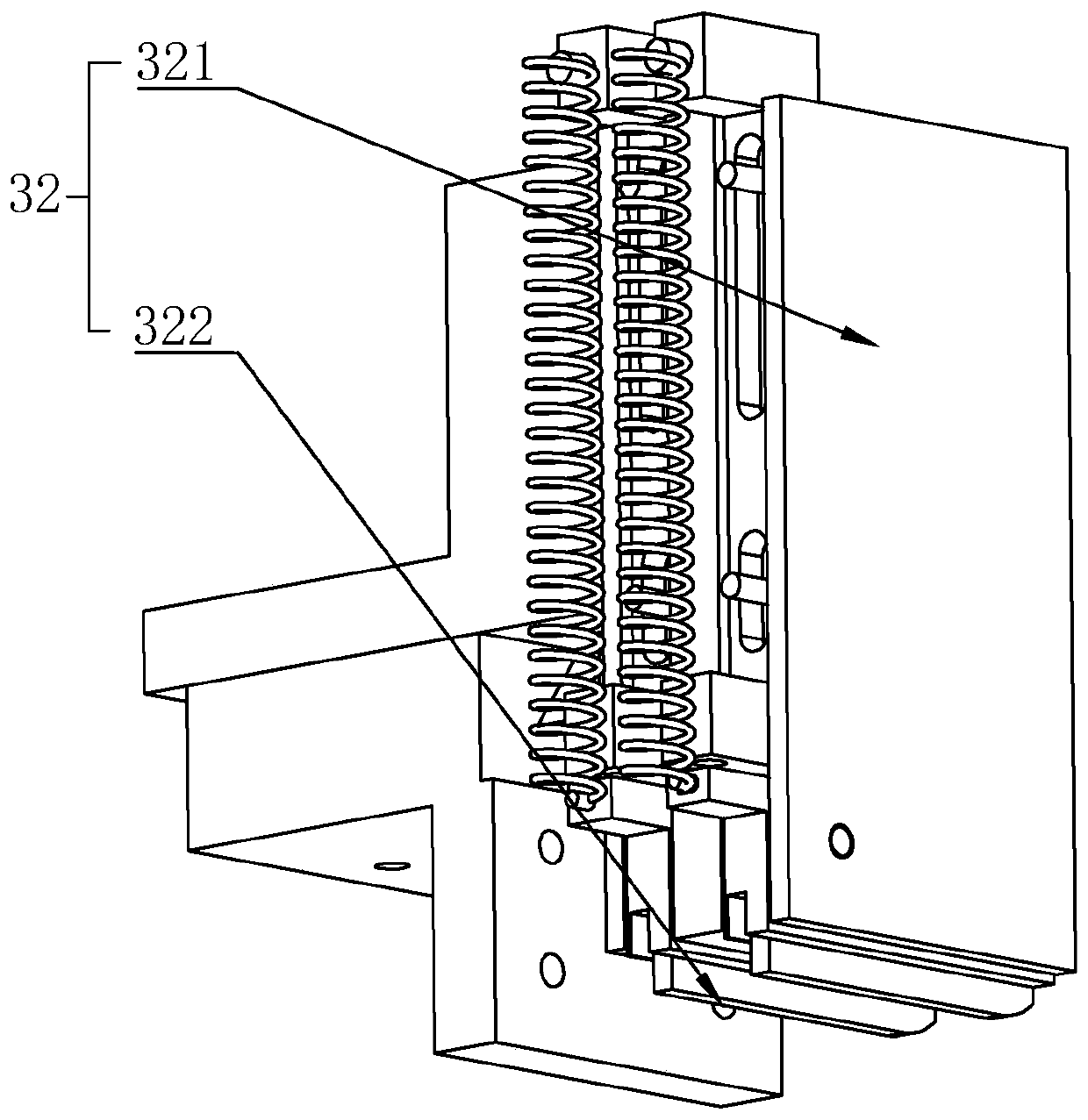

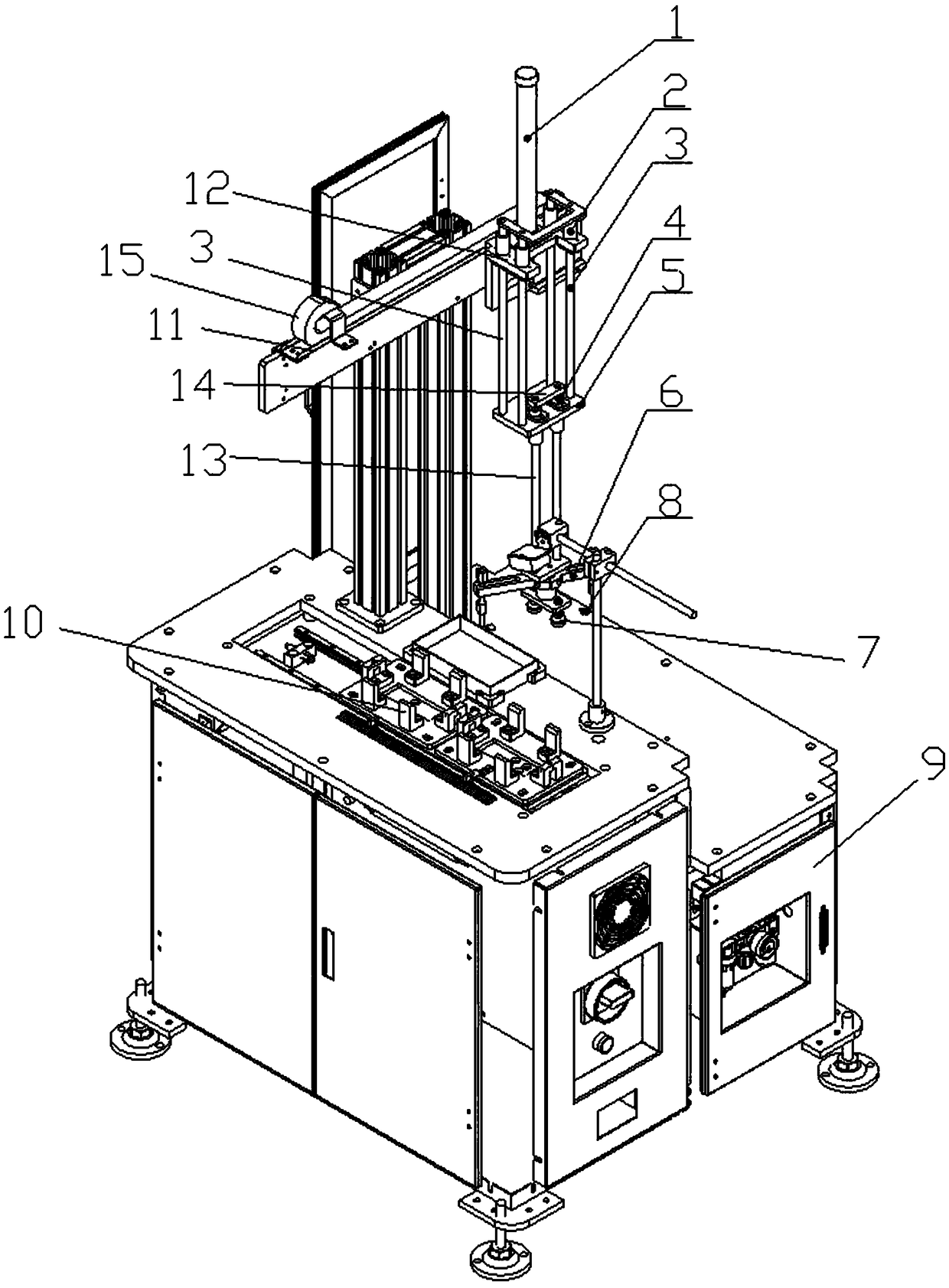

Glass sheet feeding mechanism

PendingCN109132545AIngenious structureAdsorption immobilizationCharge manipulationConveyor partsEngineeringGlass sheet

The invention discloses a glass sheet feeding mechanism which comprises a bed frame. A glass sheet containing and placement table, a horizontal guide rail, a sliding seat, an air cylinder, sliding rods and suction cups are arranged on the bed frame. The glass sheet locating and containing table is used for containing to-be-grabbed glass sheets. The horizontal guide rail is horizontally fixed abovethe glass sheet locating and placement table. The sliding seat is in sliding connection to the Y-direction guide rail. The air cylinder is fixed to the sliding seat and provided with an air cylindershaft stretching out vertically downwards. The lifting seat is connected with the air cylinder shaft of the air cylinder so as to be driven by the air cylinder to move up and down. The sliding rods vertically penetrate through the sliding seat and can slide up and down relative to the lifting seat. Limiting parts used for preventing the sliding rods from sliding out of the lifting seat downwards are arranged at the top ends of the sliding rods. The suction cups are connected to the lower ends of the sliding rods, and suction nozzles of the suction cups are vertically downward. The glass sheetfeeding mechanism solves the problem that the glass surface is scratched or broken when an existing feeding mechanism picks up glass.

Owner:ANHUI SHENGLI PRECISION MFG TECH CO LTD

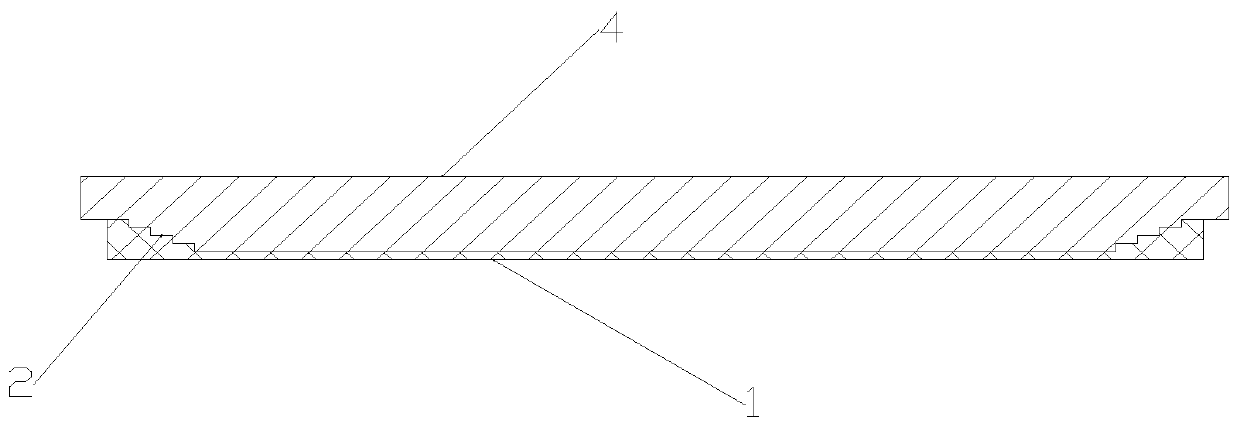

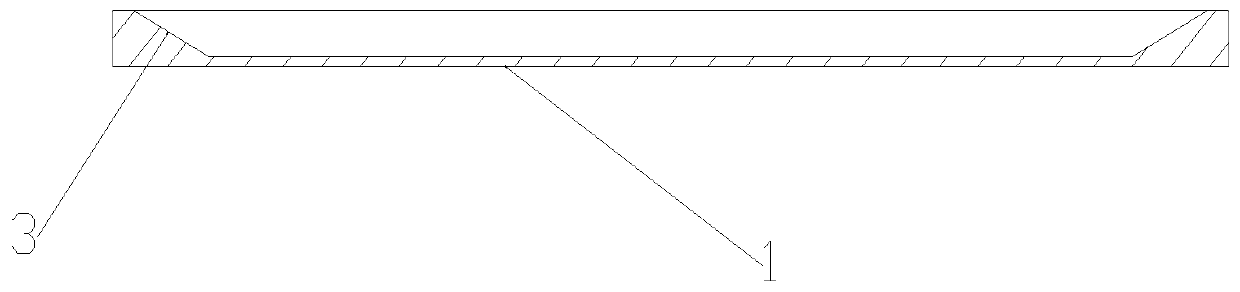

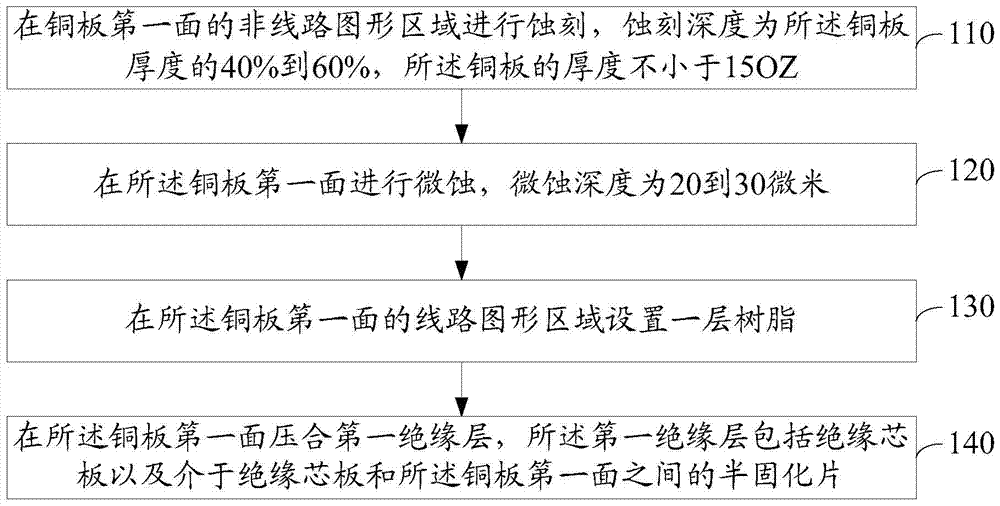

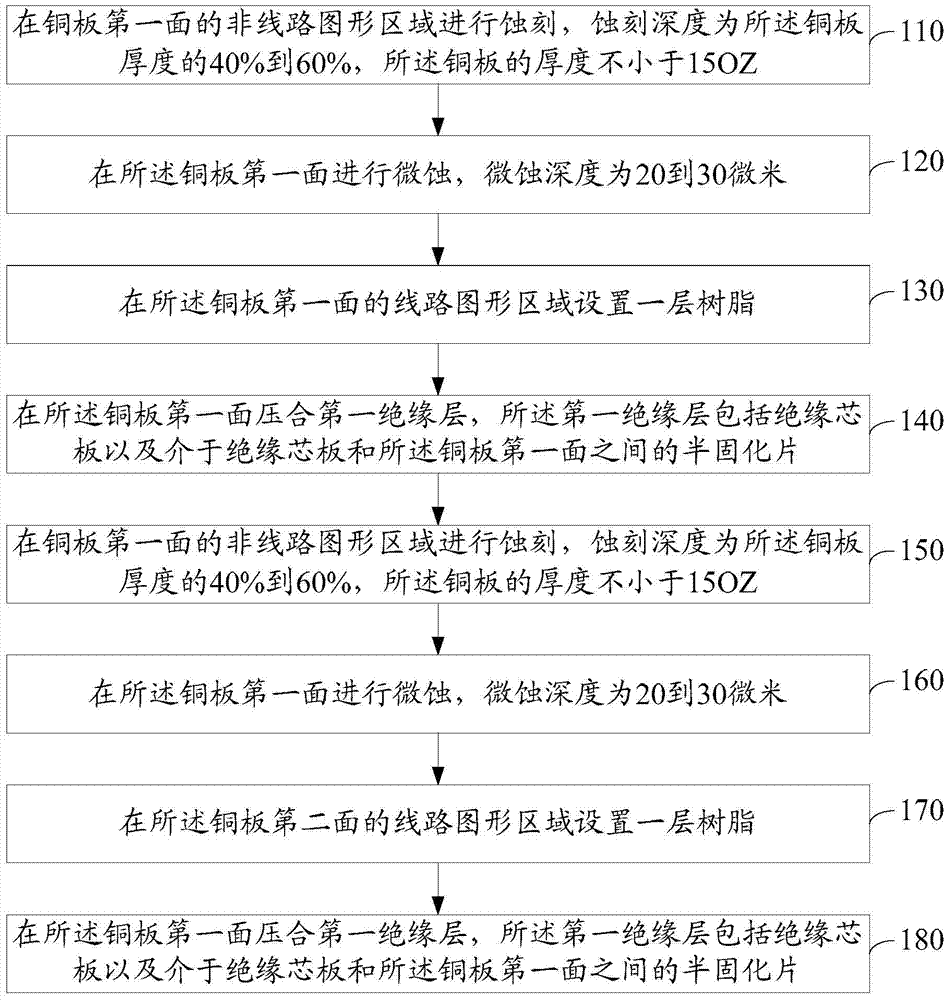

A kind of thick copper circuit board processing method

ActiveCN104684257BEliminate peakingNo cracking problemPrinted circuit aspectsConductive material chemical/electrolytical removalGlass fiberCopper

The invention discloses a processing method of a thick copper circuit board. The processing method comprises the steps of etching a non-line graph area of the first surface of a copper plate, wherein the etching depth is 40% to 60% of the thickness of the copper plate, and the thickness of the copper plate is not less than 15 OZ; microetching the first surface of the copper plate, wherein the microetching depth is 20 to 30 micrometers; applying a layer of resin in a line graph area of the first surface of the copper plate; pressing a first insulating layer on the first surface of the copper plate, wherein the first insulating layer comprises an insulating core plate and a prepreg which is arranged between the insulating core plate and the first surface of the copper plate. According to the technical scheme of the processing method, burrs on a shoulder of a line after etching can be eliminated, so that the problem of cracks caused by mechanical squeezing of the burrs on glass fiber is avoided; a large quantity of bubbles remained in the resin can be avoided, so as to avoid layering or delamination caused the bubbles during subsequent pressing; the subsequent drilling difficulty can be reduced, and the breaking risk is reduced; the thickness uniformity of the obtained thick copper circuit board can be increased.

Owner:SHENNAN CIRCUITS

A kind of composite artificial stone table top and preparation method thereof

ActiveCN105060776BNo cracking problemImprove the decorative effectLayered productsEpoxySurface layer

The invention discloses a composite artificial stone table board and a preparation method thereof. The composite artificial stone table board comprises a surface layer and a base material layer, wherein the surface layer is prepared from raw materials, namely, quartz sand, quartz powder, a curing agent, an accelerant, a solvent, multifunctional epoxy resin, a coupling agent, a pigment and heat-conducting powder; the base material layer is prepared from raw materials, namely, aluminum hydroxide powder, quartz powder, a curing agent, an accelerant, a solvent, multifunctional epoxy resin, a coupling agent and a glass mat. The composite artificial stone table board has the advantages that the table board is high in strength, high in torsion and bending deformation resistance, high in heat conductivity coefficient, quick in heat dissipation, good in heat resistance and flame-retardant, does not age and yellow easily and the like, and the table board is suitable for popularization and application.

Owner:来宾环球经典新型建材有限公司

Thermal insulation formwork shell for steel cage, construction method and forming mold thereof

ActiveCN104786351BWith ventilation and heat dissipation effectNo cracking problemWallsMouldsDie castingBreathing

The invention relates to a heat preservation formwork for a reinforcement cage and a construction method and a forming die of the heat preservation formwork and belongs to the technical field of decoration projects of buildings. The heat preservation formwork is formed through a specially-manufactured die in a die casting mode and is used for heat preservation construction of a shear wall. The side wall of the heat preservation formwork for the reinforcement cage is provided with an outrigger, and the side wall of the heat preservation formwork for the reinforcement cage is provided with vertical tubular ventilation holes. Under the action of the heat preservation formwork, the built shear wall has the advantages that the built shear wall is not likely to be cracked, automatic heat dissipation is achieved, and the service life is prolonged.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

How to make vane pump vane

The invention discloses a method for manufacturing blades of a vane pump, which comprises the following steps: step 1, using a band saw to cut out basic blade blanks, and then blanking; step 2, milling both sides of the blade blanks by a milling machine; Step 3, flat grinding the blade blanks milled by the milling machine; Step 4, heat-treating the flat-ground blade blanks; Step 5, grinding the thickness and height of the heat-treated blade blanks, and then performing rough polishing Step 6: Grinding the side of the blade blank that is in contact with the pressurized cavity; Step 7: Grinding the height and width of the semi-finished blade, and then roughly throwing it; Step 8: Cleaning the finished blade after classification . The manufacturing method of the vane pump vane of the present invention can effectively realize the production of the vane through the setting of steps 1 to 8, and multiple parts of the vane are polished during the production process, which effectively improves the smoothness of the vane .

Owner:缙云县耐而特机械制造有限公司

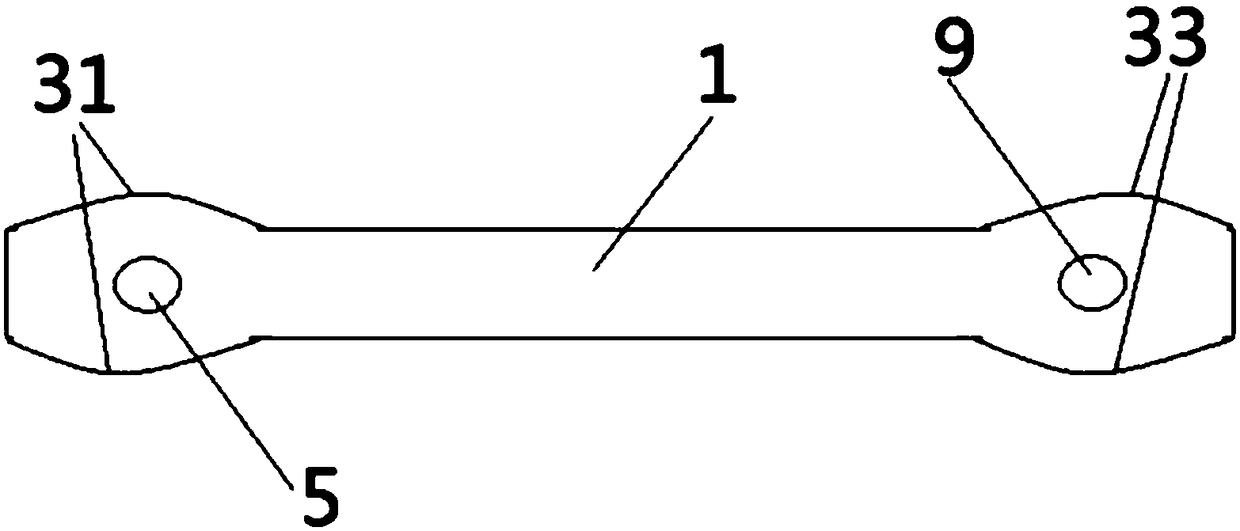

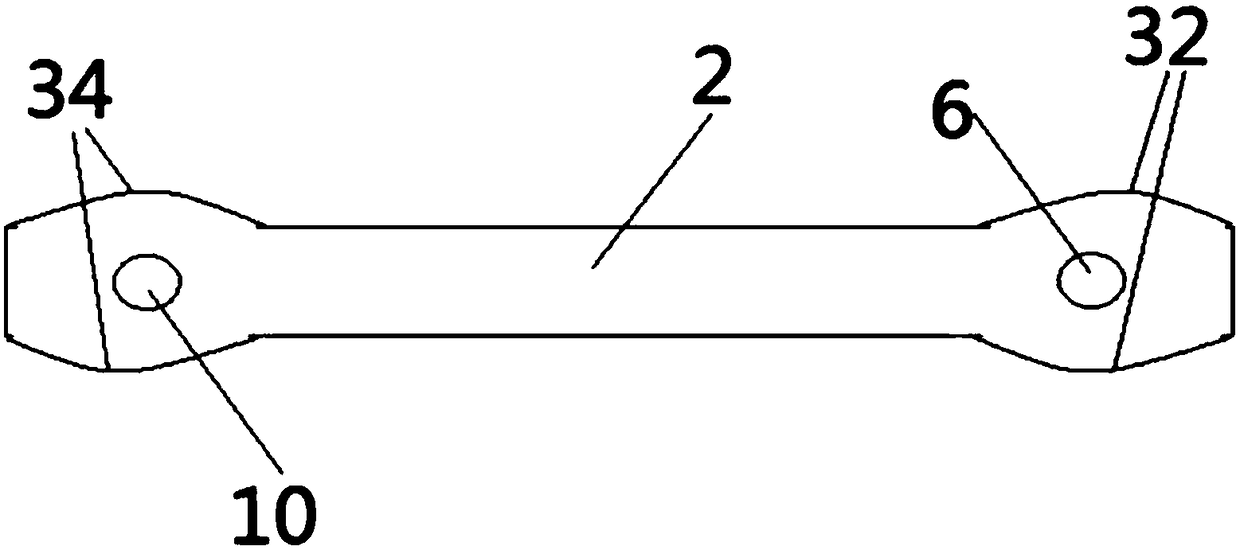

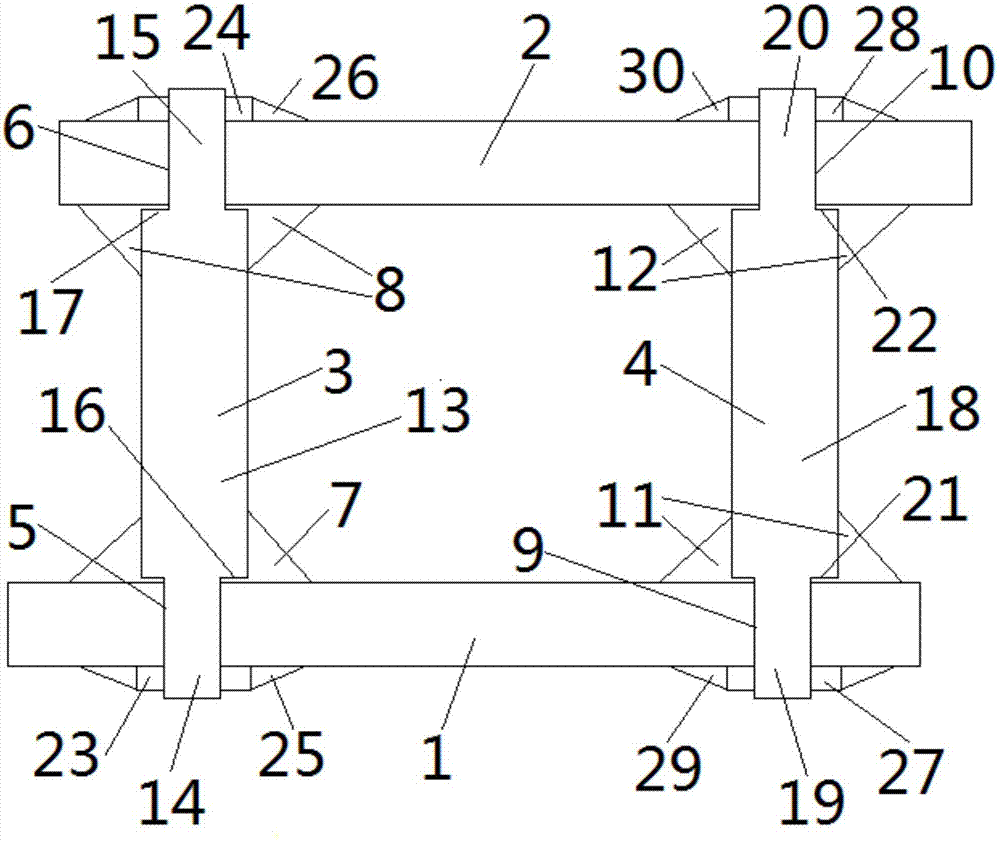

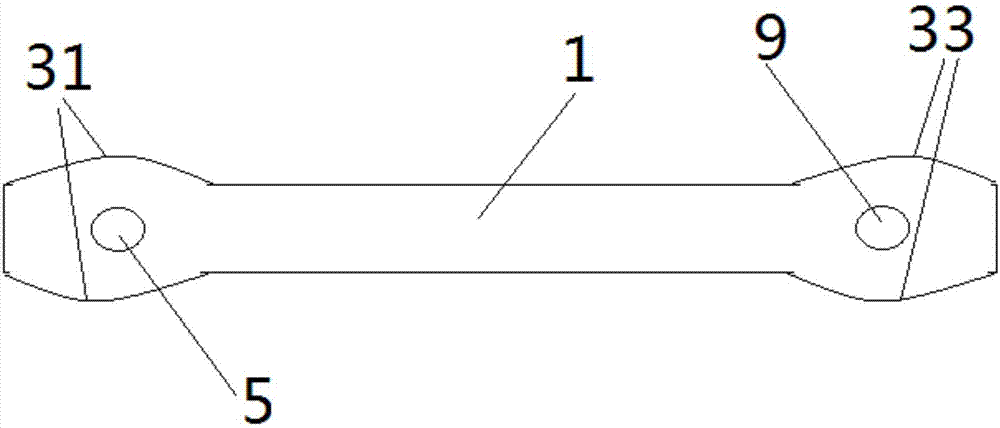

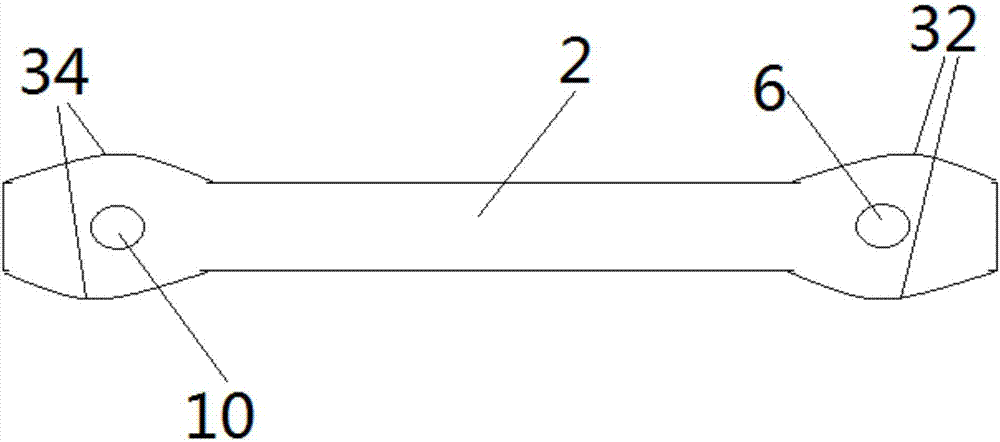

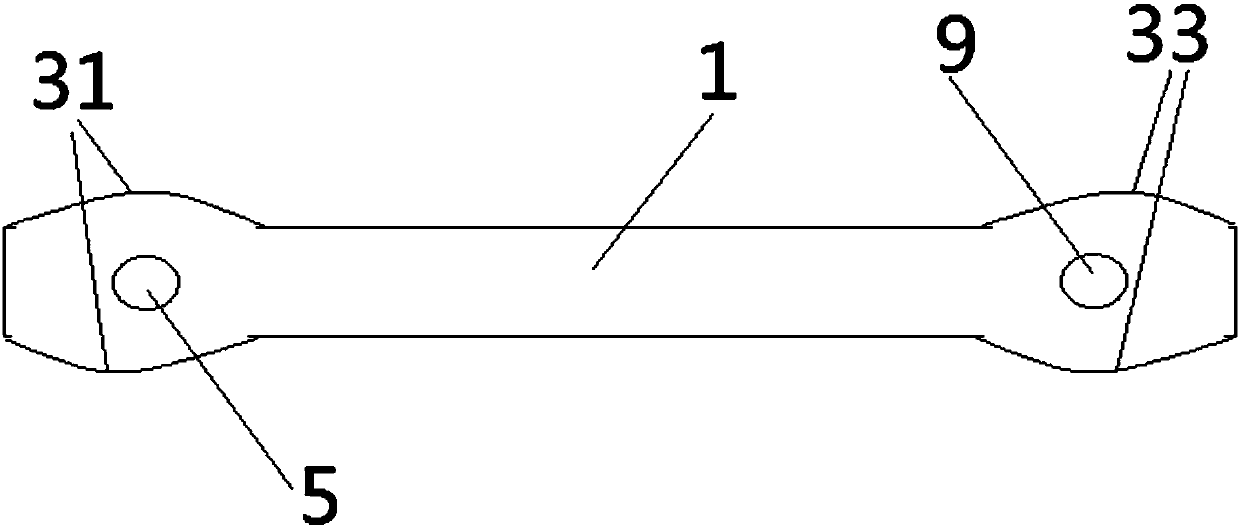

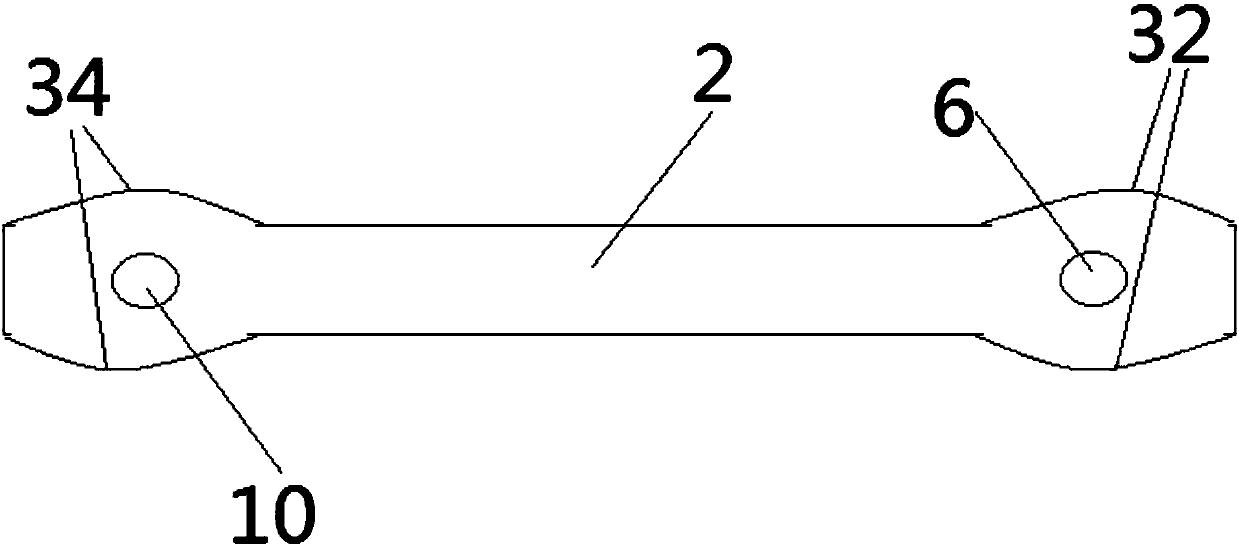

Motor vehicle frame structure

The invention provides a motor vehicle frame structure which is applied to the field of vehicle chassis parts. A front left hole (5) is formed in the front portion of a left longitudinal beam (1) of the motor vehicle frame structure, and a front right hole (6) is formed in the front portion of a right longitudinal beam (2); one end of a front cross beam (3) penetrates through the front left hole (5), and the other end of the front cross beam (3) penetrates through the front right hole (6); and a front left protruded block (31) arranged on the upper surface of the front portion of the left longitudinal beam (1) is arranged on the position, located above the front left hole (5), of the left longitudinal beam (1), and a front right protruded block (32) arranged on the upper surface of the front portion of the right longitudinal beam (2) is arranged on the position, located above the front right hole (6), of the right longitudinal beam (2). According to the motor vehicle frame structure, the structure is simple, the integral rigidity of a vehicle frame can be effectively improved, when large loads or impact are borne by the vehicle frame in the travelling process, the problems that thevehicle frame deforms, and welding joints crack can be avoided, the bearing capacity is effectively improved, and the safety accident is avoided.

Owner:WUHU XUEYING IND CO LTD

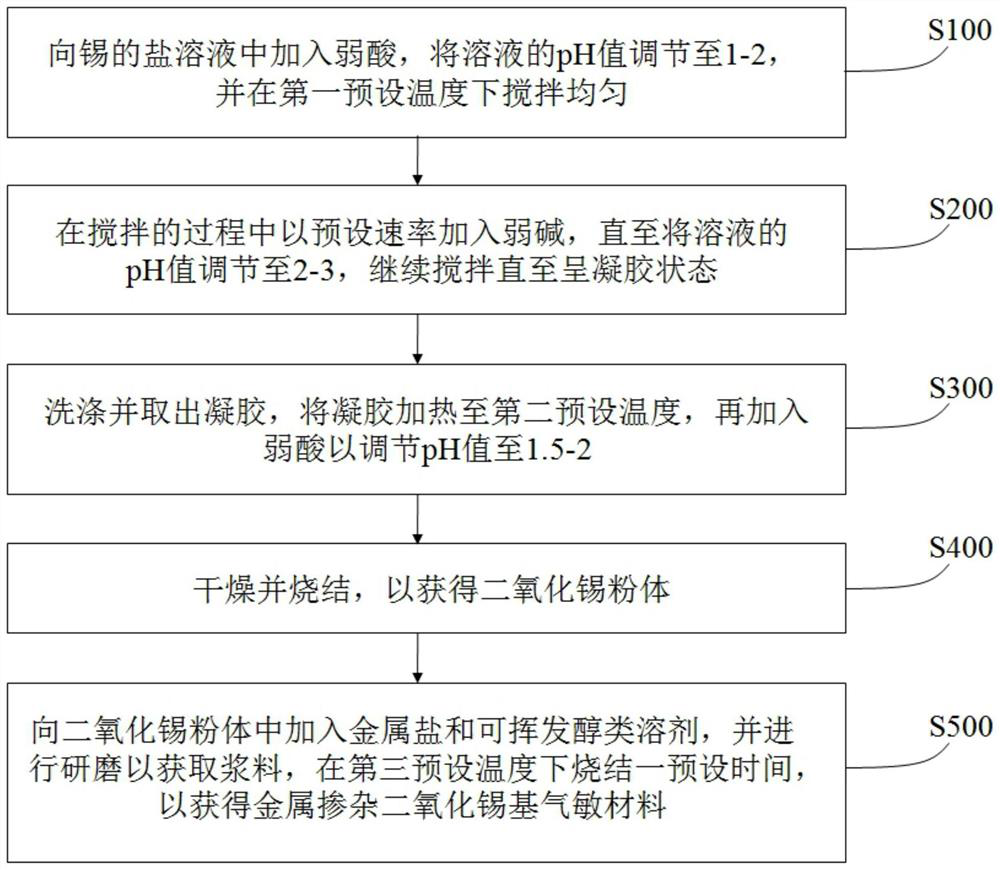

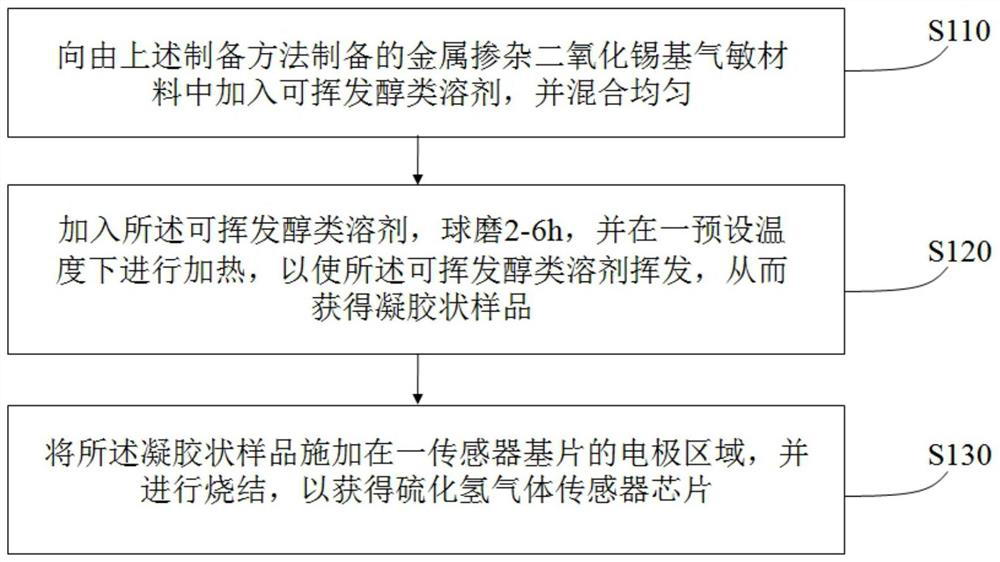

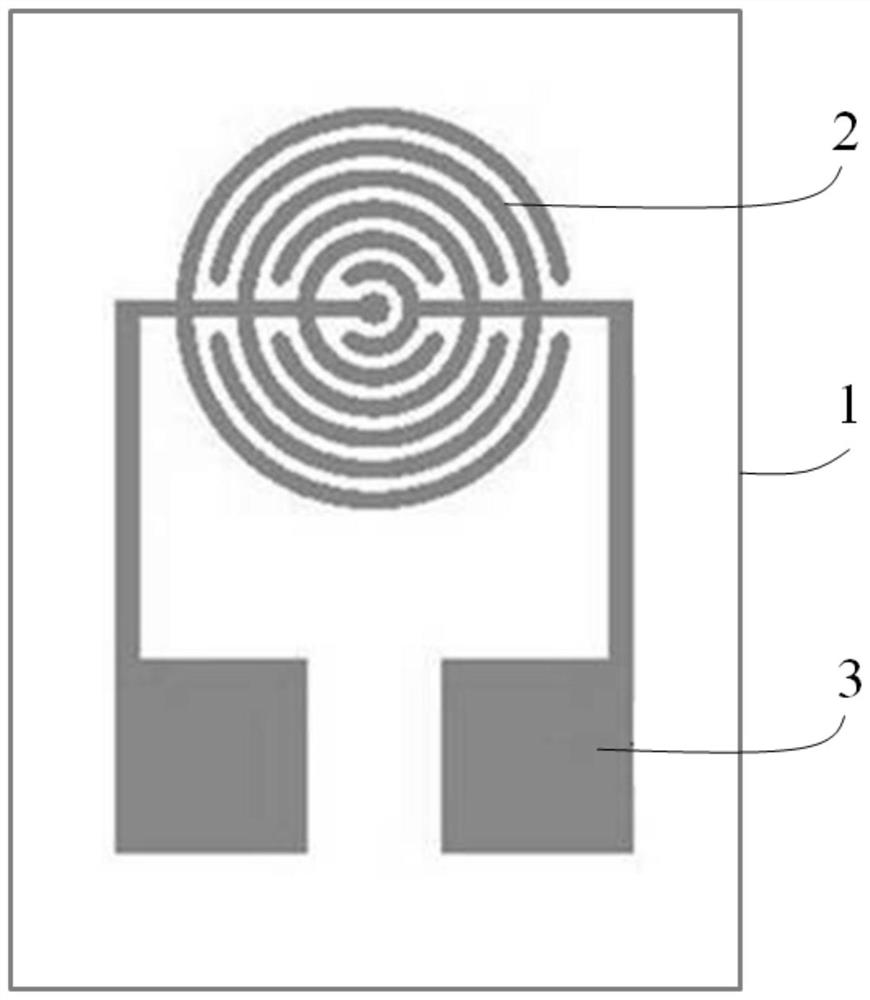

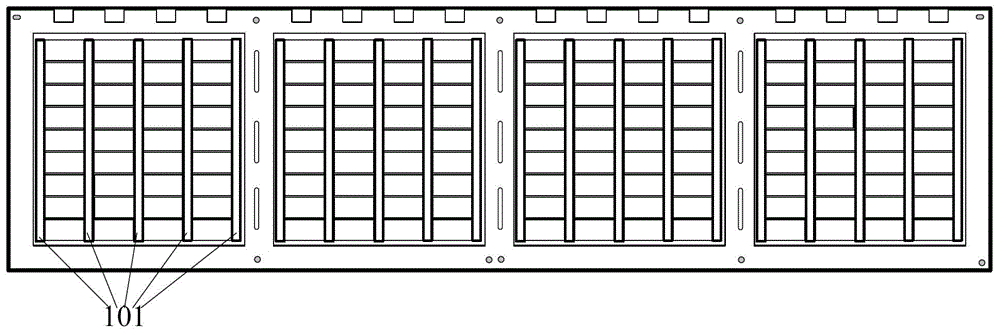

Preparation method of tin dioxide-based gas sensitive material and hydrogen sulfide gas sensor chip, hydrogen sulfide gas sensor

ActiveCN108318542BChange the way of film formationQuick responseMaterial resistanceTin dioxidePolyethylene glycol

Owner:苏州慧闻纳米科技有限公司

A kind of manufacturing method of sidewall metallization encapsulation product

ActiveCN103579010BGuaranteed StrengthNo cracking problemSolid-state devicesSemiconductor/solid-state device manufacturingProcess complexityMechanical engineering

The embodiment of the present invention discloses a sidewall metallization method, which performs sidewall metallization treatment after packaging, and does not require slotting for sidewall metallization during substrate fabrication, which simplifies substrate fabrication. During the packaging process, due to The substrate has not been slotted for sidewall metallization, so that no special fixture is needed for vacuum adsorption technology, and the positioning is very simple, which simplifies the packaging process, thereby reducing the process complexity and production cost of sidewall metallization packaging products, and improving Improve work efficiency; when performing the above packaging process, because the substrate has not been slotted, the strength of the substrate is guaranteed, and the problem of cracking of the substrate will not be caused by improper force during packaging, thereby ensuring product quality. The accuracy is higher than the slotting accuracy during substrate fabrication, and the number of packaged substrate units that can be laid out on the strip increases. In addition, the processing method of the present invention can realize the processing of multi-electrode side wall metallization products.

Owner:SKY CHIP INTERCONNECTION TECH CO LTD

Carburization and QPQ treatment complex technique and application thereof

PendingCN110359008AImprove wear resistanceImprove corrosion resistanceSolid state diffusion coatingAcid fracturingHardness

The invention discloses a carburization and QPQ treatment complex technique and application thereof, and belongs to the technical field of valve body heat treatment. The technique comprises the stepsthat a. a workpiece made of low-carbon alloy steel is selected; b. the workpiece in the step a is put into a carburizing furnace to be subjected to deep carburization treatment, the temperature is 920-940 DEG C, and 4-7% of BaCO<3> is adopted as an energizer; c. quenching is conducted, the core hardness of the quenched workpiece is guaranteed to be HRC 34-40, the surface hardness is HRC 59-62, andthe carburization depth is 2.2-2.5 mm; d. tempering is conducted twice at the temperature of 180 DEG C; and e. QPQ salt bath complex technological treatment is conducted. The complex technique is applied to valve bodies and valve seats adopted by petroleum drilling and natural gas drilling. The technical problems that the strength of an existing valve body is not enough in the using process, an carburization layer is uneven, and the valve body is prone to shattering and cannot be used for acid fracturing are solved.

Owner:安徽聚力石油钻采设备科技有限公司

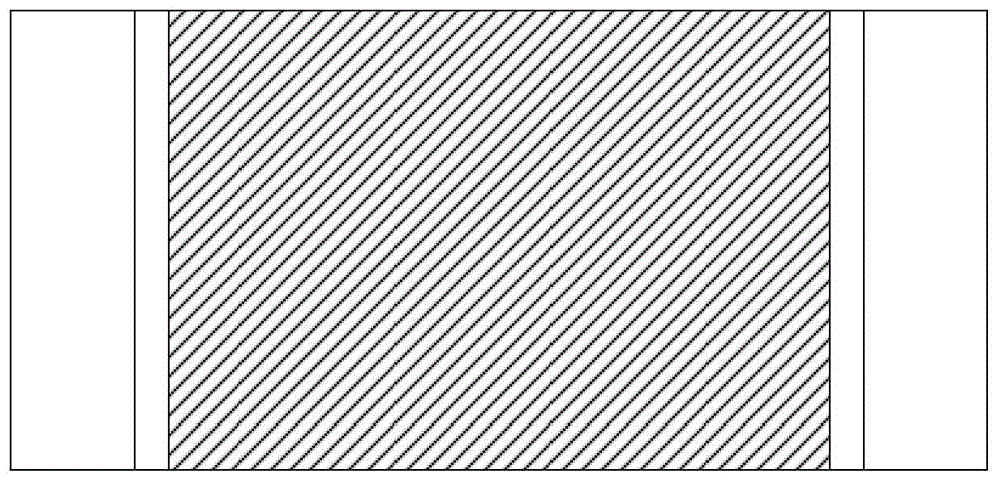

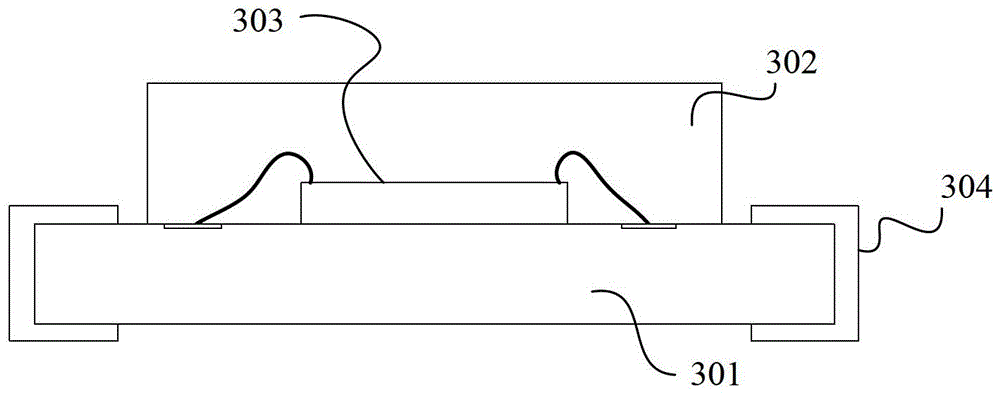

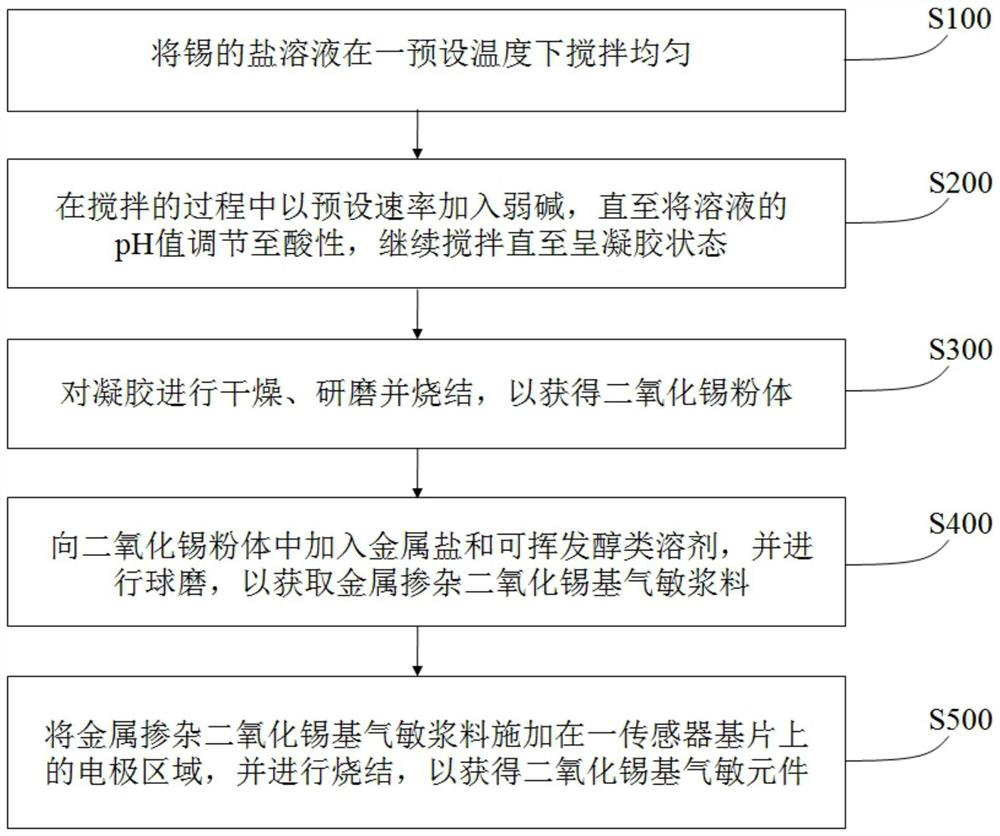

Preparation method of tin dioxide-based gas sensor and carbon monoxide gas sensor system

ActiveCN108120747BSolve the technical problem of high working temperatureReduce film thicknessMaterial resistanceTin dioxideSlurry

The invention provides a preparation method of a stannic oxide-based gas sensitive element and a carbon monoxide gas sensor system. The preparation method comprises the following steps in sequence: uniformly stirring a saline solution of tin at a preset temperature; adding weak base according to a preset speed in the stirring process until the pH value of the solution is adjusted to be acid, continuously stirring until a gel state is achieved; drying gel, grinding and sintering to obtain stannic oxide powder; adding metal salt and volatilizable alcohol solvent into the stannic oxide powder, and carrying ball milling to obtain metal-doped stannic oxide-based gas sensitive slurry; and applying the metal-doped stannic oxide-based gas sensitive slurry to the electrode area of a sensor substrate, and sintering to obtain the stannic oxide gas sensitive element. According to the preparation method, the technical problem of high work temperature of a SnO2 gas sensitive element can be fundamentally solved by changing the preparation process of the stannic oxide-based gas sensitive element.

Owner:江苏智闻智能传感科技有限公司

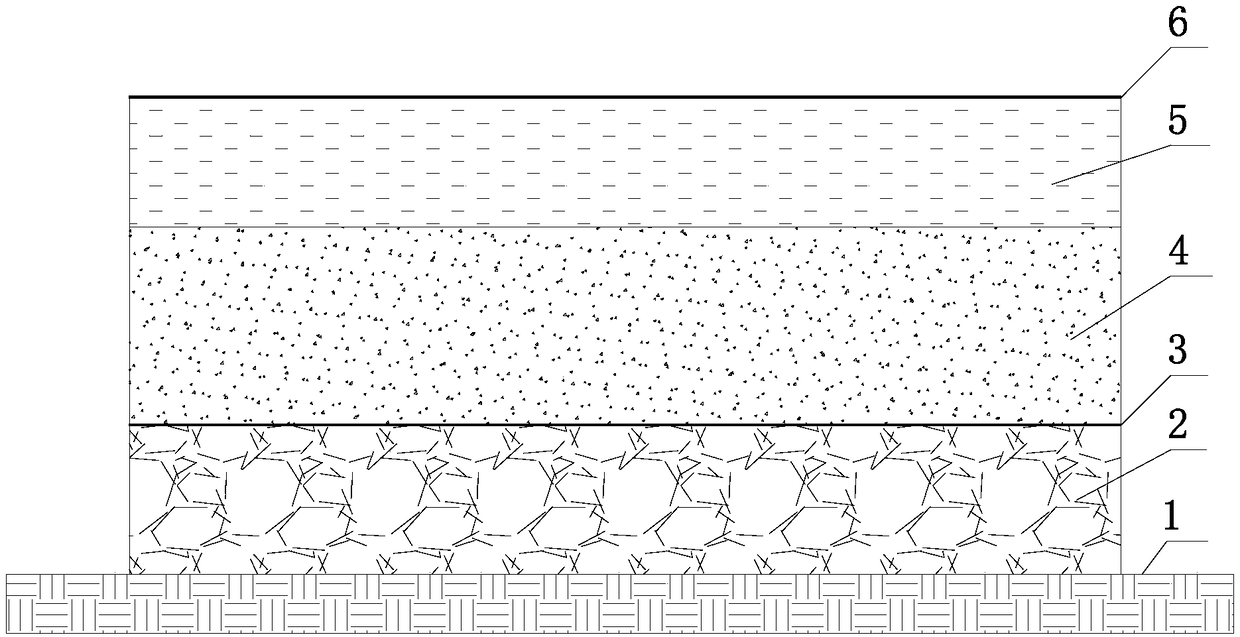

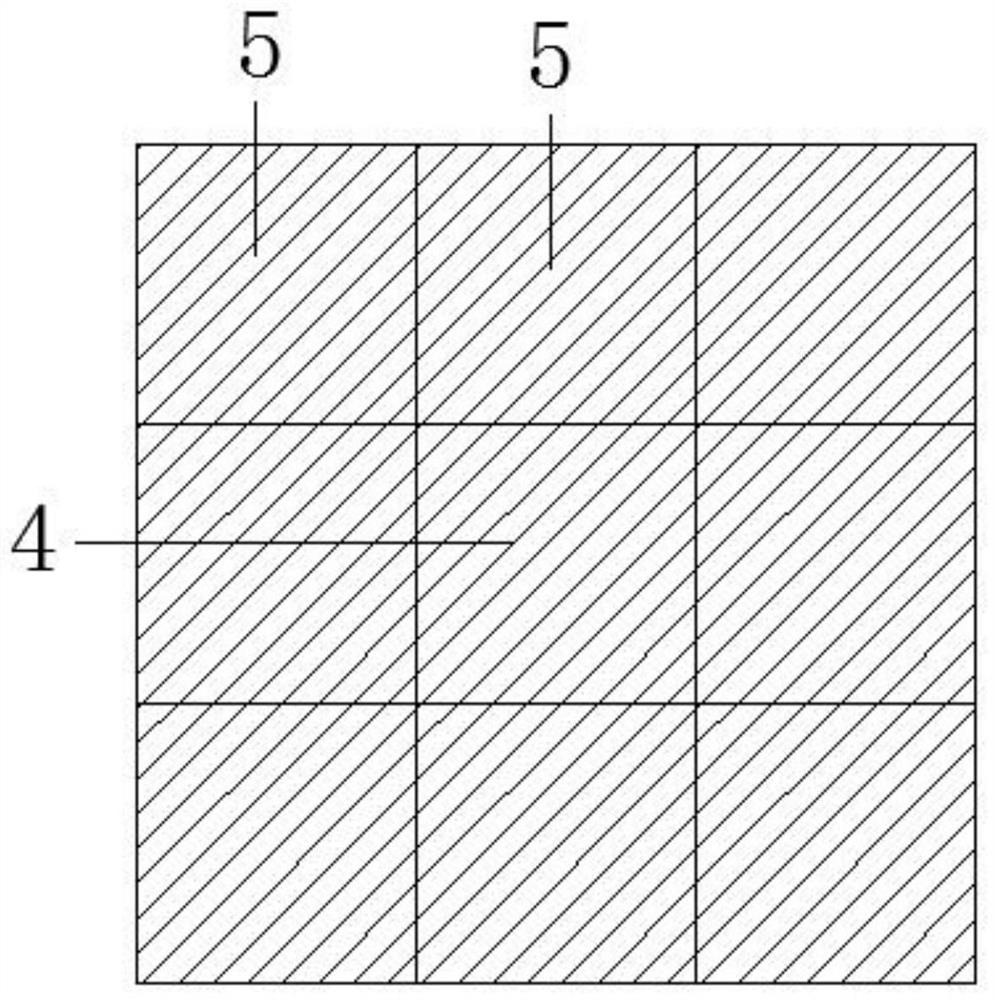

Covering layer structure for restoring contaminated soil through thermal desorption

PendingCN109304357APrevent escapeSolve crackingContaminated soil reclamationThermal desorptionMaterials science

The invention discloses a covering layer structure for restoring contaminated soil through thermal desorption. The covering layer structure is paved on the ground (1) of a contaminated soil area and comprises a pebble layer (2), a lower-layer steel plate (3) and a concrete layer (4), wherein the pebble layer (2) is paved on the ground (1); the lower-layer steel plate (3) is paved on the pebble layer (2); and the concrete layer (4) is arranged on the lower-layer steel plate (3). According to the covering layer structure, the pebble layer is paved on the ground of the contaminated soil area, thelower-layer steel plate is paved on the pebble layer, and the concrete layer is poured on the lower-layer steel plate, so that dissipation of contaminated steam can be prevented; the lower-layer steel plate can play an excellent sealing effect and also can solve the technical problems about crack and steam leakage caused by the traditional concrete as a covering structure to realize an excellentin-situ restoration effect through thermal desorption.

Owner:CENT INT GROUP

A manufacturing process of dreamy color-changing fabric

ActiveCN108642774BFeel plump and thickThe cloth is firm and thickSucessive textile treatmentsTwo or more solvent application treatmentTextile printerEngineering

Owner:SHAOXING DAFABRIC CLOTH TRADE

Stereo display panel and screen panel

InactiveCN102654648BImprove performanceNo cracking problemSteroscopic systemsNon-linear opticsLiquid-crystal displayCyclo olefin polymer

The invention provides a stereo display panel, which is provided with an active zone and a circumferential zone, the stereo display panel comprises a display panel and a screen panel disposed at one side of the display panel, wherein the screenpanel comprises: a first substrate and a second substrate oppositely disposed, wherein the first substrate and the second substrate comprise a cycloolefin copolymer or a cycio olefins polymer; a first electrode layer and a second electrod layer respectively disposed at the first substrate and the second substrate and in the active zone; a first bonding layer and a second bonding layer respectively disposed on the first substrate and the second substrate and in the circumferential zone; a first alignment layer covering the first electrode layer and the first adherence layer; a second alignment layer covering the second electrode layer and the second adherence layer; and a liquid crystal layer disposed between the first alignment layer and the second alignment layer.

Owner:AU OPTRONICS CORP

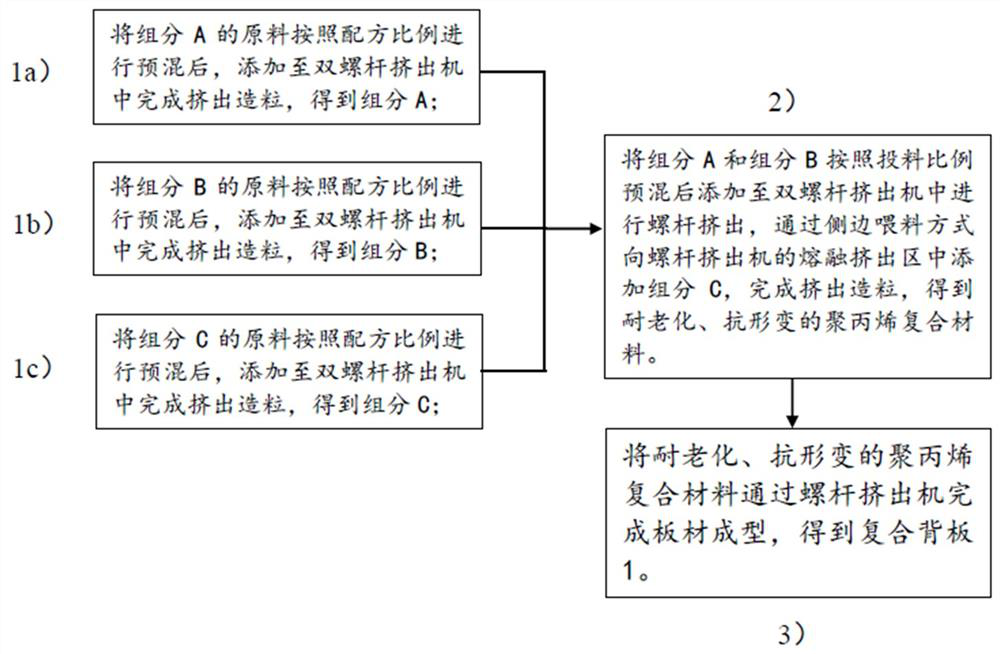

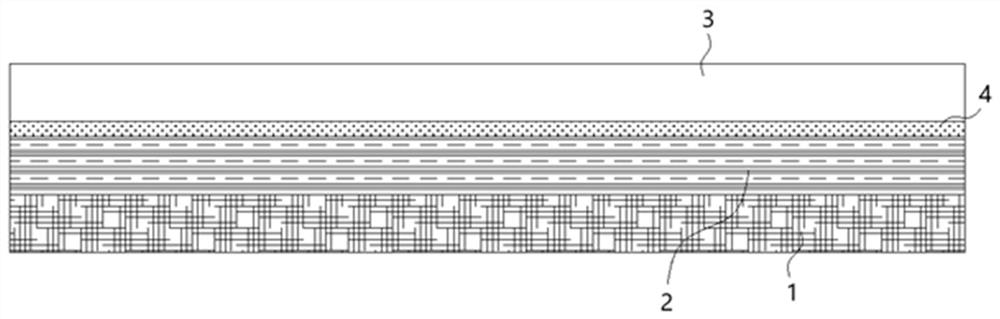

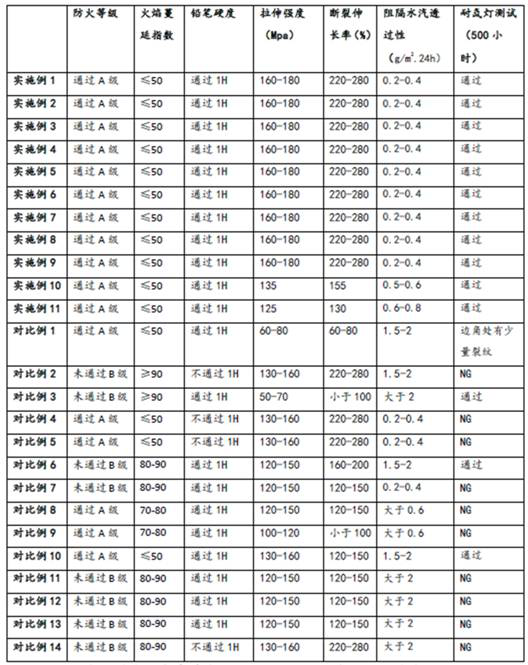

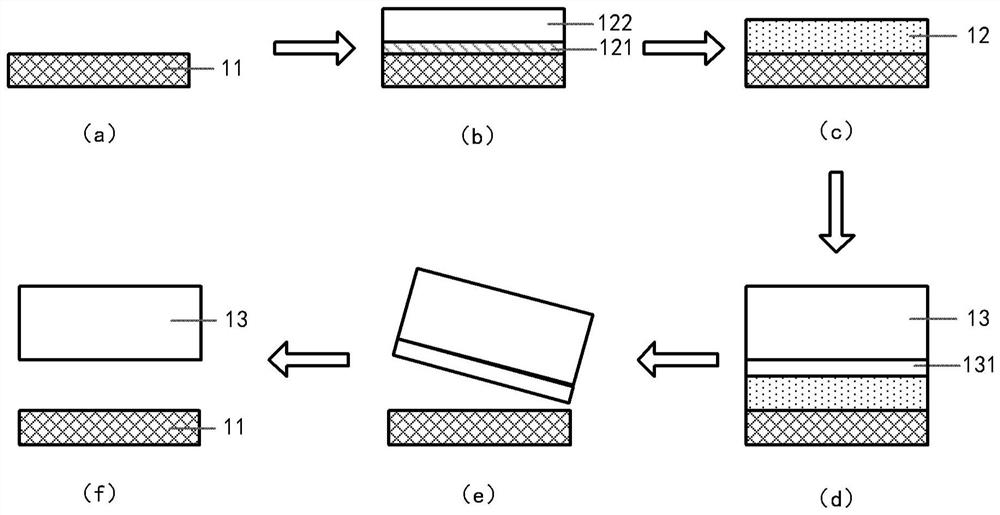

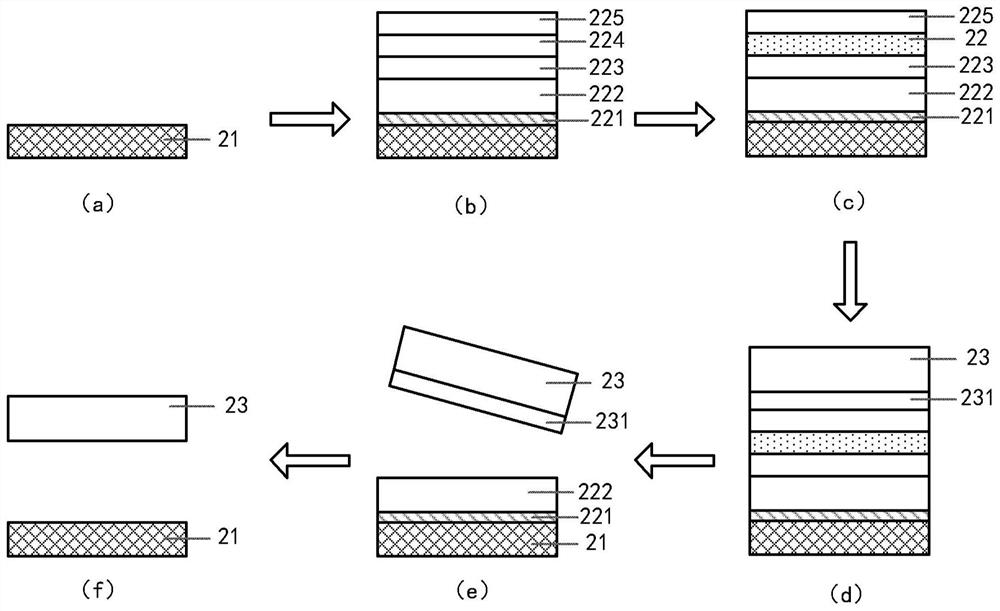

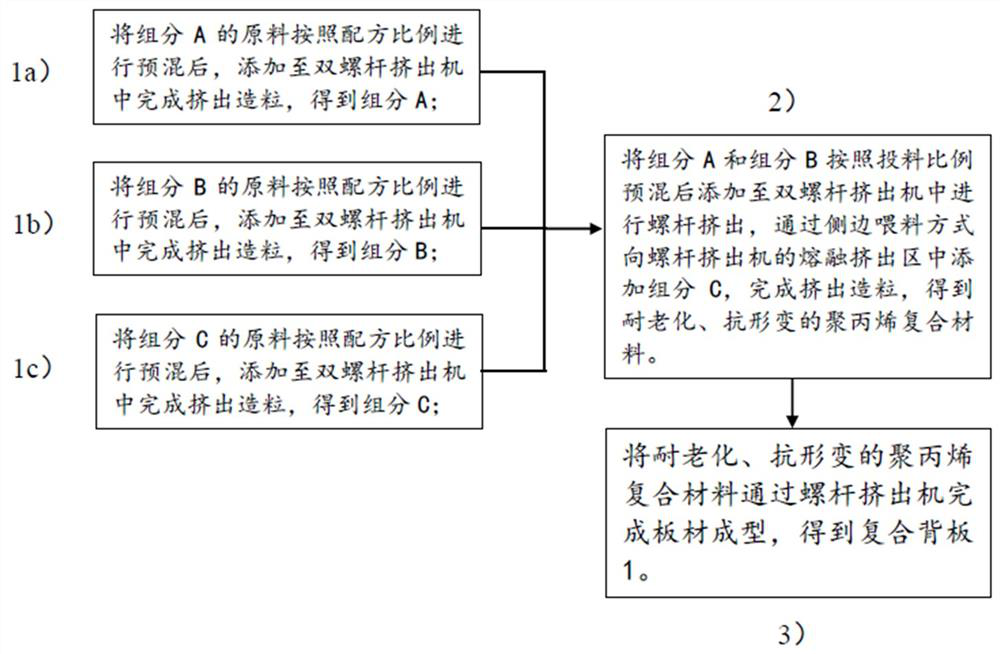

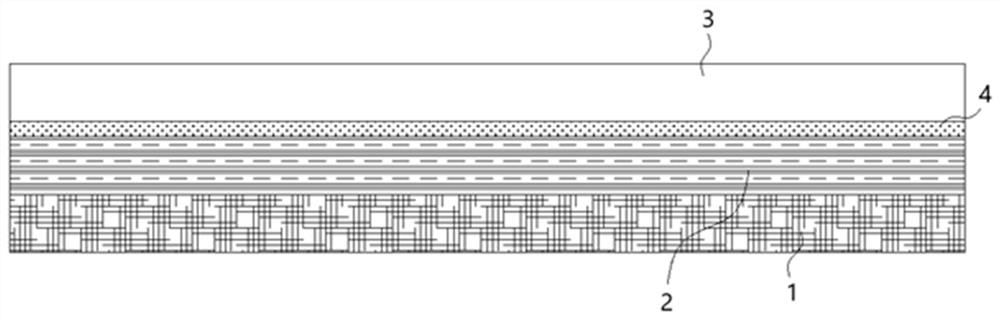

Composite backboard of photovoltaic module

ActiveCN113563830AGood melt compoundingStrong complementarityNon-macromolecular adhesive additivesMacromolecular adhesive additivesGlass fiberPolymer science

The invention discloses a composite backboard of a photovoltaic module, the composite backboard is in direct contact with a battery string layer, the composite backboard and the battery string layer are packaged into a whole through a lamination process, the composite backboard adopts a single-layer structure, and the raw material of the single-layer structure comprises a component A, a component B and a component C, wherein the component A comprises the following raw materials: polypropylene resin, a first polyester resin curing agent and chopped glass fibers; the component B comprises the following raw materials: polyester resin, a second polyester resin curing agent and chopped glass fibers; the raw material of the component C comprises EVA resin; the curing temperature of the polyester resin is higher than the melting point of the polypropylene resin; the temperature of the lamination process is higher than the curing temperature of the polyester resin; the composite backboard prepared by the invention has good water vapor barrier permeability, insulativity, flame retardance, weather resistance and deformation resistance, keeps good plastic processing performance and adhesion performance, does not need to be independently provided with an adhesive layer, and can be directly contacted and laminated with the battery string layer.

Owner:苏州通优新材料科技有限公司

Automobile frame structure

InactiveCN107651018AImprove deformation resistanceIncreased torsional stiffnessUnderstructuresVehicle frameEngineering

The invention provides an automobile frame structure applied to the field of automobile chassis parts. One end of a front cross beam (3) of the automobile frame structure penetrates through a front left hole (5), and the other end of the front cross beam (3) penetrates through a front right hole (6); front left triangular blocks (7) are welded to the positions of the inner side face of a left longitudinal beam (1) and one end of the front cross beam (3), and front right triangular blocks (8) are welded to the inner side face of a right longitudinal beam (2) and the other end of the front crossbeam (3); one end of a rear cross beam (4) penetrates through a rear left hole (9), and the other end of the rear cross beam (4) penetrates through a rear right hole (10); and rear left triangular blocks (11) are welded to the positions of the inner side face of the left longitudinal beam (1) and one end of the rear cross beam (4), and rear right triangular blocks (12) are welded to the inner side face of the right longitudinal beam (2) and the other end of the rear cross beam (4). The automobile frame structure is simple in structure and cannot deform when an automobile frame bears large load or impact during travelling, the problem of cracking of welding joint parts does not occur, and bearing capability is effectively improved.

Owner:WUHU XUEYING IND CO LTD

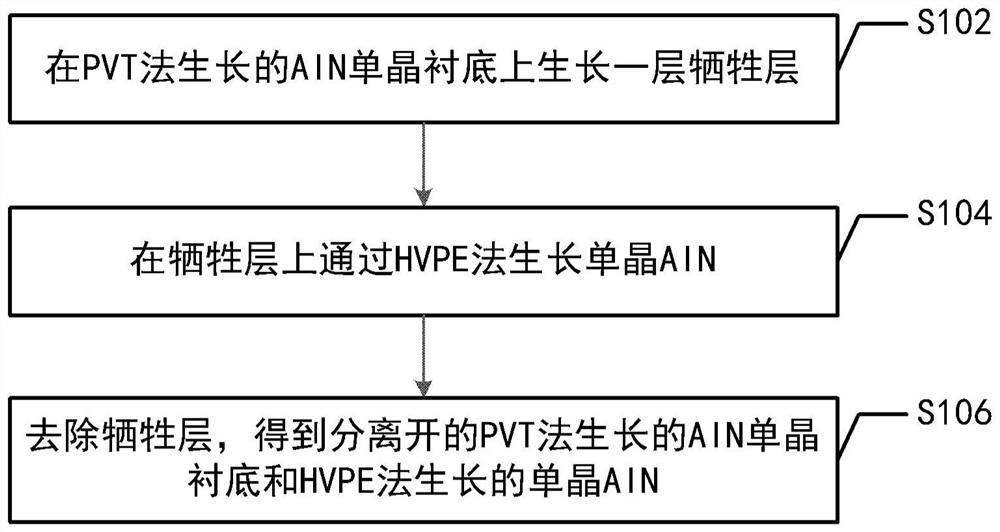

Preparation method and substrate of transparent single crystal Aln, ultraviolet light-emitting device

ActiveCN109461644BSolve Oxidation ProblemsAchieve recyclingSemiconductor/solid-state device manufacturingSemiconductor devicesUltraviolet lightsSingle crystal substrate

The invention discloses a method for preparing a transparent single crystal AlN, a substrate, and an ultraviolet light-emitting device, wherein the method for preparing a transparent single crystal AlN comprises: growing a sacrificial layer on an AlN single crystal substrate grown by a PVT method, the The sacrificial layer is: a conductive porous structure, a porous structure self-decomposed by thermal stress, or a polycrystalline buffer layer grown at low temperature; a single crystal AlN is grown on the sacrificial layer by HVPE; and the sacrificial layer is removed by electrochemical etching or laser lift-off , or directly use thermal stress to realize self-separation of the sacrificial layer, and obtain separated AlN single crystal substrate grown by PVT method and single crystal AlN grown by HVPE method. Only the thinner sacrificial layer needs to be simply removed, which is fast and effective, and at the same time avoids the oxidation problem caused by CMP, and the AlN single crystal substrate grown by the PVT method can be retained to realize recycling and effectively reduce the cost of transparent single crystal AlN substrate. The production cost of the bottom material. However, the single crystal AlN grown by HVPE method has high transmittance in the ultraviolet band, which is more suitable for the preparation of ultraviolet light-emitting devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A composite backplane for photovoltaic modules

ActiveCN113563830BGood melt compoundingStrong complementarityNon-macromolecular adhesive additivesMacromolecular adhesive additivesGlass fiberPolymer science

Owner:苏州通优新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com